Multi-solid-waste admixture, preparation method thereof and cement mortar

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The present invention provides a preparation method for the multi-solid waste admixture described in the above technical solution, comprising the following steps:

[0046] Mixing the modified oil shale semi-coke-iron tailings and carbide slag for ball milling to obtain a ball mill;

[0047] The ball mill is mixed with high calcium fly ash, alkaline activator and water reducer to obtain multi-solid waste admixture.

[0048] The invention mixes the modified oil shale semi-coke-iron tailings and calcium carbide slag for ball milling to obtain ball milling material. In the present invention, the ball-to-material ratio of the ball milling is preferably 1:1; the time of the ball milling is preferably 25 to 35 minutes, more preferably 30 minutes, and the effect of the ball milling is not good if the time is short, and the agglomeration effect will be caused if the time is long; The ball milling is preferably carried out in a star ball mill. In the present invention, the prop...

Embodiment 1

[0054] A kind of multi-solid waste admixture, raw material is as follows:

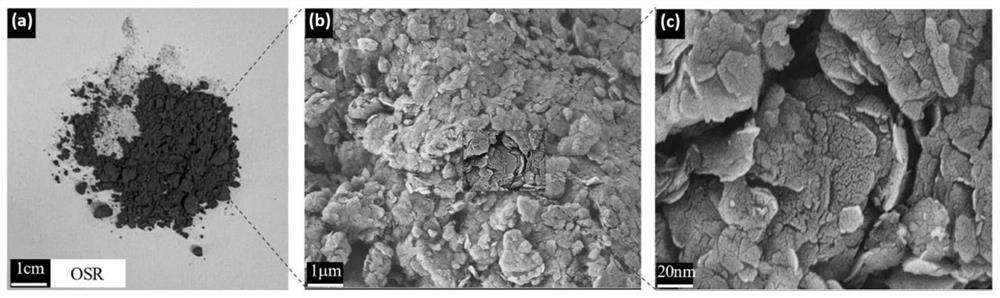

[0055] Oil shale semi-coke: the mass content of silicon dioxide in oil shale semi-coke is 50-60%, the mass content of alumina is 20-30%, and the mass content of iron oxide is 5-10%; crushed and ground to Particles below 1.5mm;

[0056] Iron tailings: the mass content of silicon dioxide in iron tailings is 50-60%, the mass content of aluminum oxide is 8-15%, the mass content of iron oxide is 10-15%, and the mass content of calcium oxide is 8-15%. 15%, the mass content of magnesium oxide is 5-10%; crush and sieve the particles with a particle size below 0.75mm;

[0057] Calcium carbide slag: the mass content of calcium oxide in calcium carbide slag is 90-95%, the mass content of silicon dioxide is 5-10%, the mass content of aluminum oxide is 1-2%, and the mass content of iron oxide is 1-2%. ;Crush and sieve out particles with a particle size below 0.75mm;

[0058] High-calcium fly ash: The mass conten...

Embodiment 2

[0069] A kind of multi-solid waste admixture, raw material is the same as embodiment 1. The preparation method is as follows:

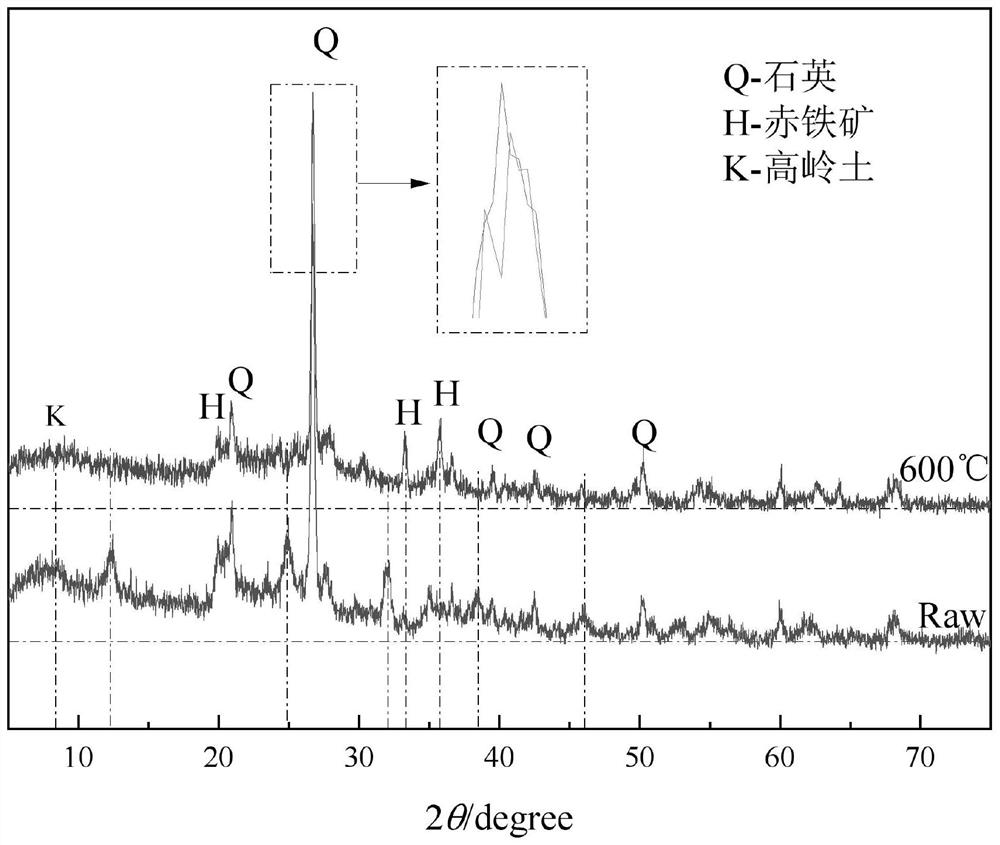

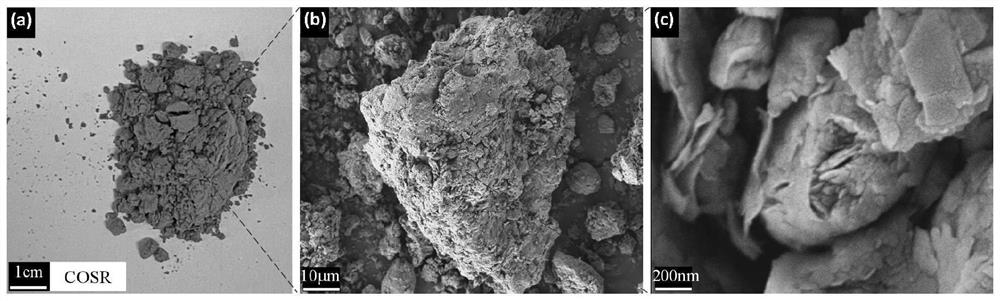

[0070] (1) Mix 85g of oil shale semi-coke particles with 15g of iron tailings and calcinate at 600°C for 2 hours to obtain modified oil shale semi-coke-iron tailings powder; modified oil shale semi-coke- In the iron tailings, particles with a particle size greater than 0 and less than or equal to 0.1mm accounted for 40-60wt%, particles with a particle size greater than 0.1mm and less than or equal to 0.3mm accounted for 20-30wt%, and particles with a particle size greater than 0.3mm and less than or equal to 1.5mm Accounting for 20-30wt%;

[0071] (2) Take 20g of calcium carbide slag particles and 100g of modified oil shale semi-coke-iron tailings powder particles and mix them into a star-shaped ball mill (the ratio of ball to material is 1:1) for ball milling for 30 minutes to obtain ball mill powder; The proportion of particles with a particle siz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com