Ultrasonic and hot air combined carrot drying method and ultrasonic and hot air combined drying device

A hot air drying and carrot technology, applied in food processing, food science, fruit/vegetable preservation through dehydration, etc., can solve the problems of low product quality, high energy consumption, increased energy consumption, etc., to improve heat transfer and mass transfer efficiency , enhance heat transfer and mass transfer, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

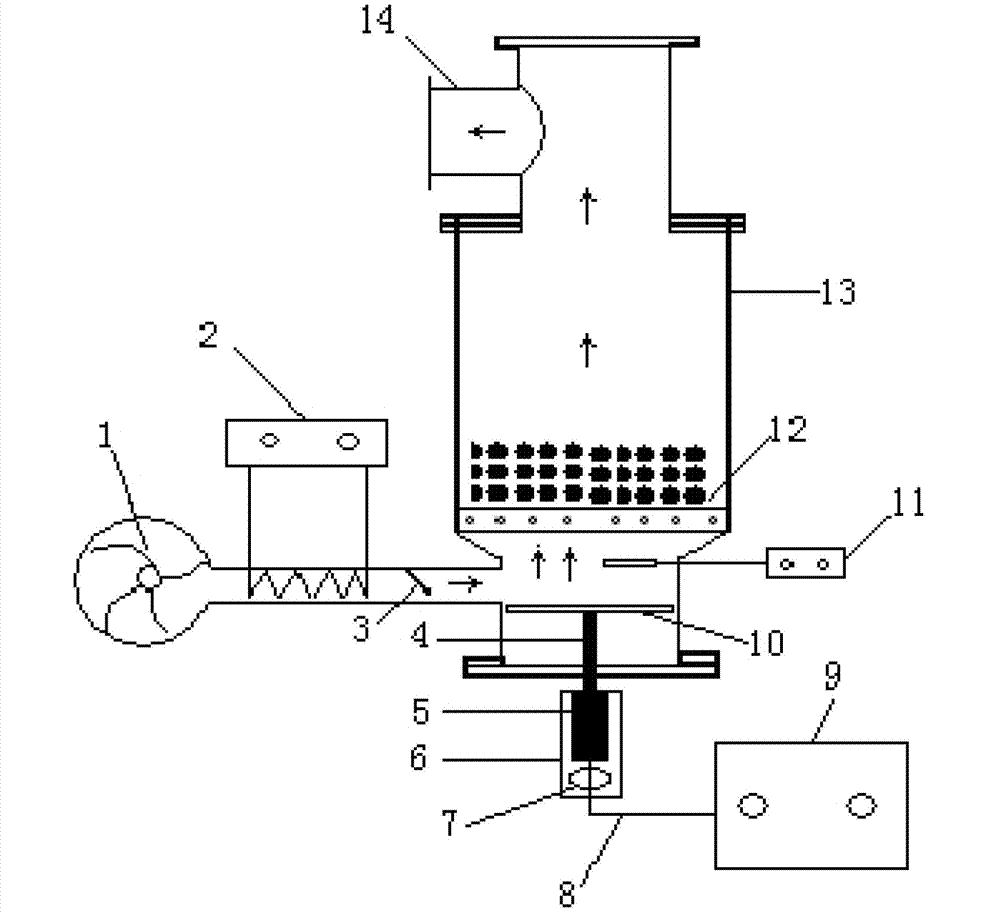

Method used

Image

Examples

Embodiment 1

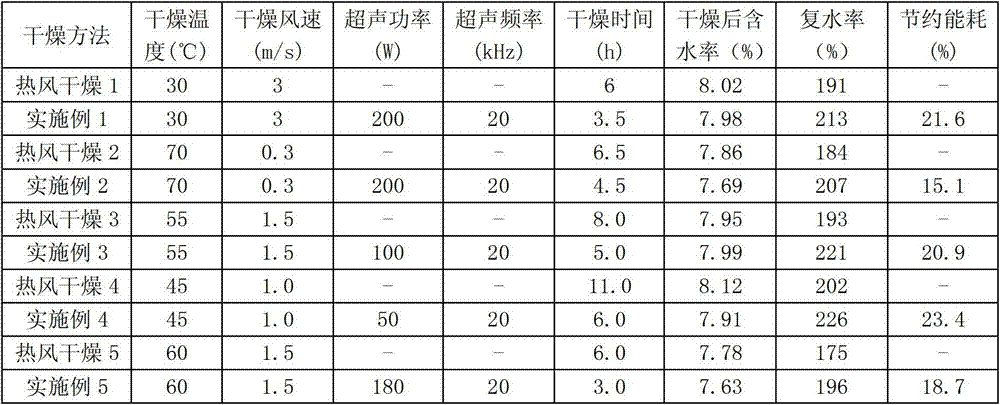

[0026] Embodiment 1 of the method for ultrasonic combined hot air drying carrot of the present invention, comprises the following steps:

[0027] 1) Pre-treatment of carrot raw materials: select fresh carrots with full shape and no pests and diseases, wash and remove the soil and impurities at the root, slice, and the thickness of carrot slices is 2.5mm;

[0028] 2) Ultrasonic combined with hot air drying: Put the carrot slices on the sieve, turn on the heating and blowing device, and the ultrasonic irradiation device in turn, and carry out ultrasonic combined hot air drying on the carrot slices. The drying temperature is 30°C, and the drying wind speed is 3m / s. The ultrasonic power is 200W, the ultrasonic frequency is 20kHz, the distance between the ultrasonic irradiation device and the screen is 5cm, and the drying time is 3.5h.

Embodiment 2

[0029] Embodiment 2 of the method for ultrasonic combined hot air drying of carrots of the present invention comprises the following steps:

[0030] 1) Pre-treatment of carrot raw materials: select fresh carrots with full shape and no pests and diseases, wash and remove the soil and impurities at the root, slice, and the thickness of carrot slices is 3.0mm;

[0031] 2) Ultrasonic combined with hot air drying: Put the carrot slices on the screen, turn on the heating and blowing device, and the ultrasonic irradiation device in turn, and carry out ultrasonic combined hot air drying on the carrot slices at a drying temperature of 70°C and a drying wind speed of 0.3m / s , the ultrasonic power is 200W, the ultrasonic frequency is 20kHz, the distance between the ultrasonic irradiation device and the screen is 25cm, and the drying time is 4.5h.

Embodiment 3

[0032] Embodiment 3 of the method for ultrasonic combined hot air drying of carrots of the present invention comprises the following steps:

[0033] 1) Pre-treatment of carrot raw materials: select fresh carrots with full shape and no pests and diseases, wash and remove the soil and impurities at the root, slice, and the thickness of carrot slices is 3.5mm;

[0034] 2) Ultrasonic combined with hot air drying: put the carrot slices on the sieve, turn on the heating and blowing device, and the ultrasonic irradiation device in turn, and carry out ultrasonic combined hot air drying on the carrot slices at a drying temperature of 55°C and a drying wind speed of 1.5m / s , the ultrasonic power is 100W, the ultrasonic frequency is 20kHz, the distance between the ultrasonic irradiation device and the screen is 10cm, and the drying time is 5.0h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com