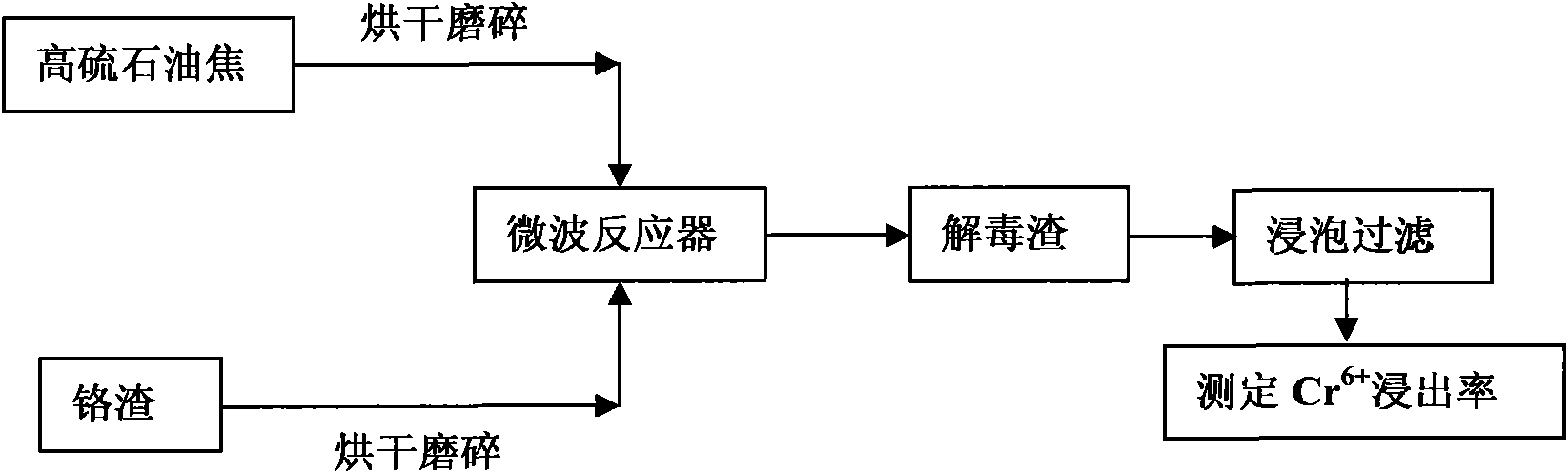

Method for detoxicating chromium residue by utilizing high sulfur petroleum coke through microwave

A technology of high-sulfur petroleum and petroleum coke, which is applied in recycling technology, solid waste removal, electronic waste recycling, etc., can solve the problems of increased production cost, complicated treatment process, and increased production cost, so as to protect the environment and solve a large number of problems. Storing and heating uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

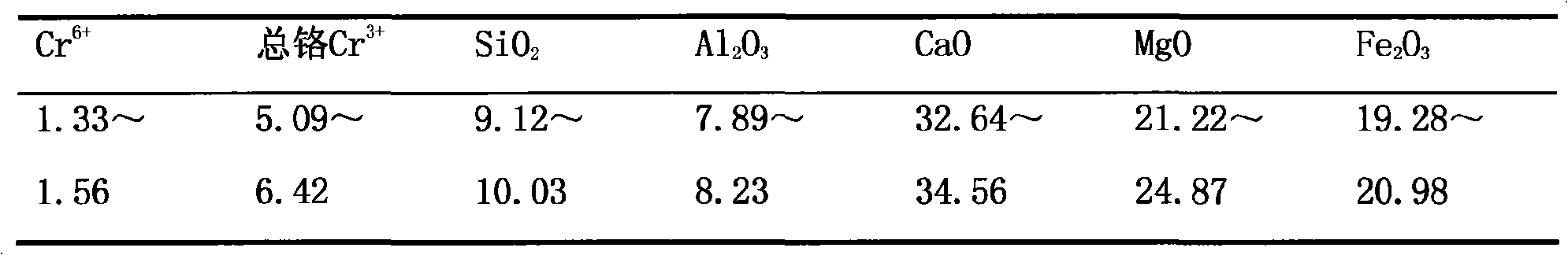

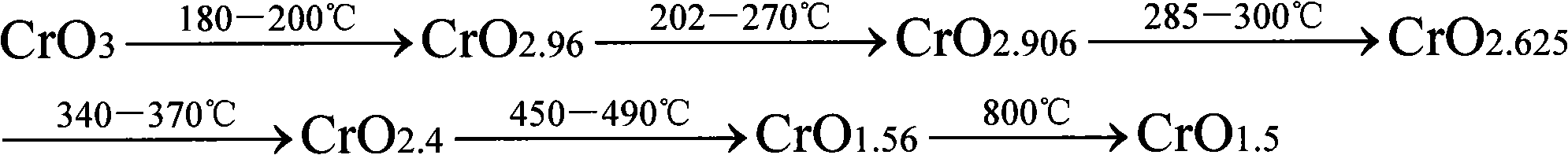

[0036] Embodiment 1: 10g of chromium slag and 1.0g of high-sulfur petroleum coke are loaded into the reactor (ceramic crucible), and mixed evenly, then the reactor is put into a microwave oven, and the slag wool insulation material is used around the reactor to insulate, and a shielding is adopted. The armored thermocouple measures the temperature in the microwave field, raises the temperature to 700°C, turns off the microwave oven after 20 minutes of heat preservation, and opens the furnace door after 8 minutes. After the material is cooled, immerse the material in distilled water, filter after soaking for 24 hours, and set the filtrate to volume To 250ml, use diphenylcarbazide spectrophotometry to measure the Cr in the filtrate 6+ Concentration, calculated as Cr 6+ The detoxification rate is 99.024%.

Embodiment 2

[0037] Embodiment 2: 10g of chromium slag and 2.5g of high-sulfur petroleum coke are loaded into the reactor (ceramic crucible), and mix uniformly, then the reactor is put into a microwave oven, and the surroundings of the reactor are insulated with slag wool insulation materials, and a shielding The armored thermocouple measures the temperature in the microwave field, raises the temperature to 800°C, turns off the microwave oven after 25 minutes of heat preservation, and opens the oven door after 8 minutes. After the material is cooled, immerse the material in distilled water, filter after soaking for 24 hours, and make the filtrate to volume To 250ml, use diphenylcarbazide spectrophotometry to measure the Cr in the filtrate 6+ Concentration, calculated as Cr 6+ The detoxification rate is 99.135%.

Embodiment 3

[0038] Embodiment 3: 10g of chromium slag and 5.0g of high-sulfur petroleum coke are loaded into the reactor (ceramic crucible), and mix uniformly, then the reactor is put into a microwave oven, and the surroundings of the reactor are insulated with slag wool insulation materials, and a shielding The armored thermocouple measures the temperature in the microwave field, raises the temperature to 900°C, turns off the microwave oven after 30 minutes of heat preservation, and opens the furnace door after 8 minutes. After the material is cooled, immerse the material in distilled water, filter after soaking for 24 hours, and constant the filtrate To 250ml, use diphenylcarbazide spectrophotometry to measure the Cr in the filtrate 6+ Concentration, calculated as Cr 6+ The detoxification rate is 99.373%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com