Circulating type jet mill and milling system thereof

A technology of jet mill and pulverization system, which is applied in grain processing and other directions, can solve the problems of low efficiency of ultra-fine powder, easy to be carried by air flow, etc., and achieve the effect of simple structure, high material utilization rate and fast speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

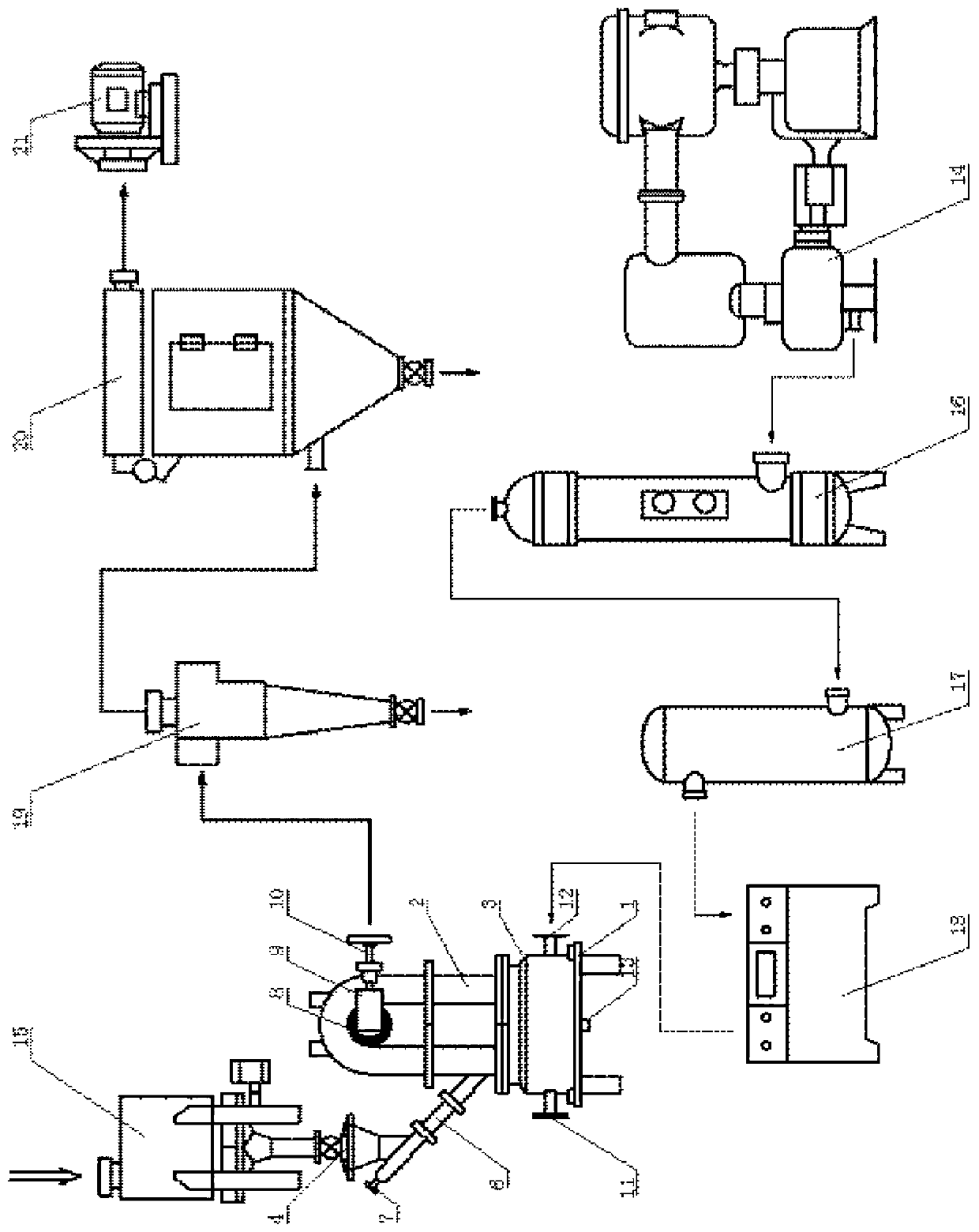

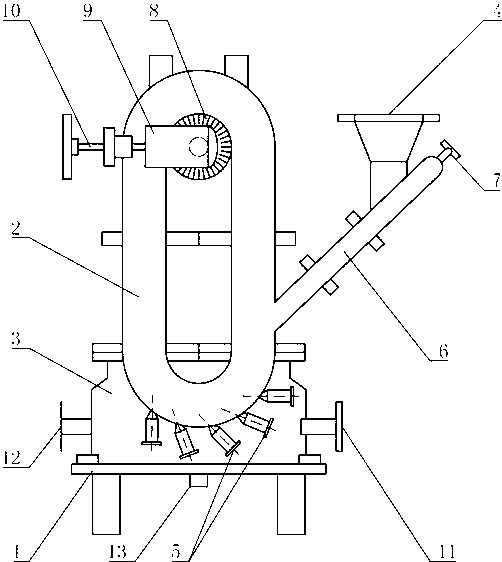

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

[0018] Circulating jet mill of the present invention, as figure 1 As shown, it includes a frame 1, a pulverizing chamber 2 arranged on the frame 1, connected to a compressed air storage chamber 3 arranged at the bottom of the pulverizing chamber 2, wherein the pulverizing chamber 2 is in the form of an annular oblong shape, namely The upper and lower ends are ring-shaped half cylinders, and the middle is connected by cuboids; a classification device is arranged on the upper part of the crushing chamber 2, and a feeding port 4 and several grinding nozzles 5 are arranged on the lower part; the air intake of the grinding nozzles 5 The air end communicates with the compressed air storage chamber 3, and the air outlet end is connected tangentially with the lower ring of the crushing chamber 2 respectively, which can accelerate the materials entering the pulverizer step by s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com