Method for freezing and drying mango

A mango, analytical drying technology, applied in the field of agricultural product processing, can solve unseen problems, achieve the effects of less damage, easy preservation and long-distance transportation, and good rehydration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

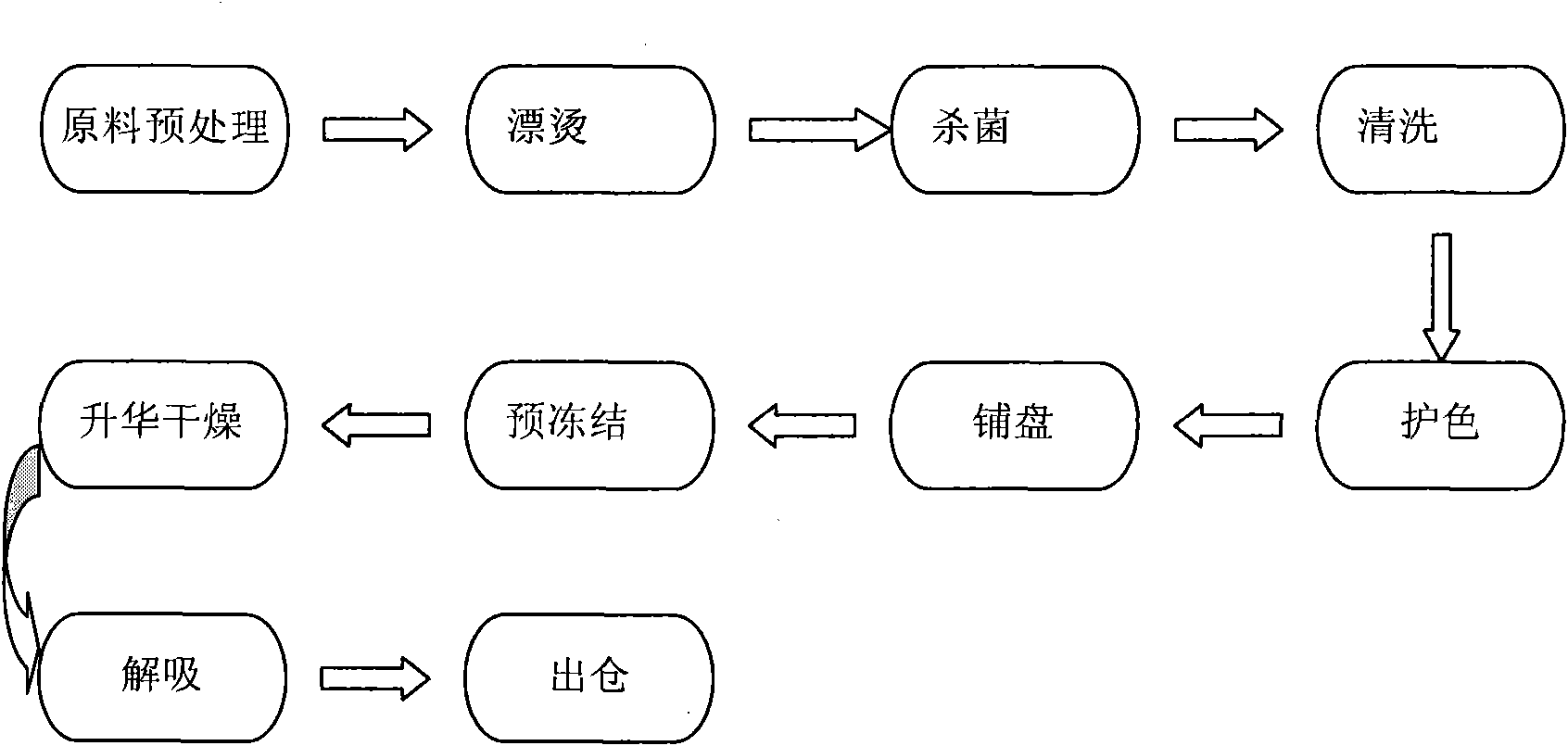

[0028] A kind of mango freeze-drying method of the present invention, concrete steps are:

[0029] 1. Pretreatment

[0030] (1) Grading: Use the visual inspection method to select raw mangoes with basically the same maturity and color and classify them into one category, that is, choose yellow or milk yellow basically intact ones as one category, and distinguish raw materials with mechanical damage and slight pests and diseases. Treat it separately.

[0031] (2) Peeling and pitting: Peel the skin with a paring knife, and then use a pitting knife to cut the pit from the top of the mango.

[0032] (3) Cutting: Cut the material into 3-5mm square diced materials with a dicing machine.

[0033] 2. Blanching: Soak and blanch the pretreated fruit material in hot water at 95°C for 60 seconds. The principle of time control is that the peroxidase in the raw material basically loses its activity; V c , The retention rate of crude protein and total sugar is based on the higher retentio...

Embodiment 2

[0046] A kind of mango freeze-drying method of the present invention, concrete steps are:

[0047] 1, pretreatment: pretreatment condition is identical with embodiment 1.

[0048] 2. Blanching: Soak and blanch the pretreated fruit in hot water at 95°C for 120 seconds. The principle of time control is that the peroxidase in the raw material basically loses its activity; V c , The retention rate of crude protein and total sugar is based on the higher retention rate. The sensory characteristics are based on the fact that the blanched diced mango becomes soft and has a cooked taste, but it is not boiled.

[0049] 3. Sterilization: immerse the blanched fruit in 300ppm sodium hypochlorite solution for 10 minutes to sterilize.

[0050] 4. Cleaning: Wash the diced mango soaked in sodium hypochlorite in flowing water to remove the soaking smell, and wash until the pH of the drinking water is consistent.

[0051] 5. Color protection: use 0.015% ascorbic acid and 0.01% malic acid compoun...

Embodiment 3

[0060] A kind of mango freeze-drying method of the present invention, concrete steps are:

[0061] 1, pretreatment: pretreatment condition is identical with embodiment 1.

[0062] 2. Blanching: Soak the pretreated fruit material in hot water at 95°C and blanching for 180 seconds. The principle of time control is that the peroxidase in the raw material basically loses its activity; V c , The retention rate of crude protein and total sugar is based on the higher retention rate. The sensory characteristics are based on the fact that the blanched diced mango becomes soft and has a cooked taste, but it is not boiled.

[0063] 3. Sterilization: immerse the blanched fruit in 300ppm sodium hypochlorite solution for 10 minutes to sterilize.

[0064] 4. Cleaning: Wash the diced mango soaked in sodium hypochlorite in flowing water to remove the soaking smell, and wash until the pH of the drinking water is consistent.

[0065] 5. Color protection: use 0.015% ascorbic acid and 0.01% mali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com