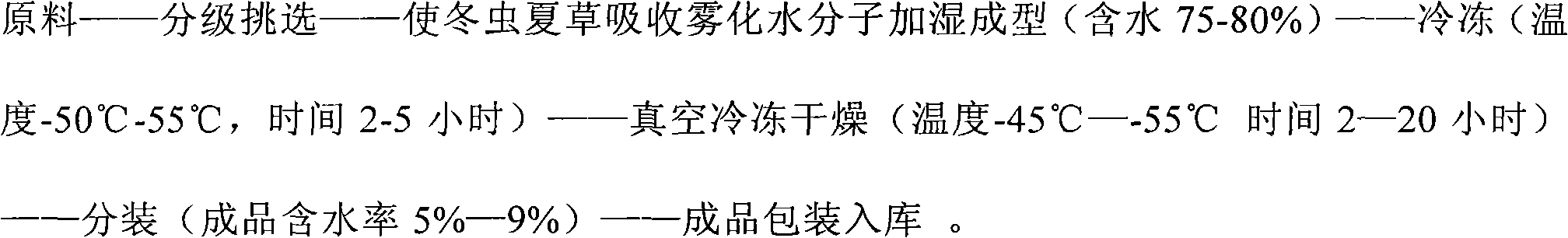

Biological vacuum freezing and drying method for aweto

A vacuum freeze-drying, Cordyceps sinensis technology, applied in the fields of botanical equipment and methods, plant/algae/fungus/moss ingredients, pharmaceutical formulations, etc. Cordyceps sinensis product quality grade decline and other problems, to achieve the effect of high integrity rate, new color and no loss of nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 1.1 Water absorption and reshaping: put the pretreated Cordyceps sinensis on a fence-type drying rack, spread it flat, put it in a closed room, use an ultrasonic humidifier to spray and humidify it, and take a sample after a period of time to test its moisture content. When the moisture content When it reaches 75%, the spray heating can be stopped. The specifications of the ultrasonic heater are selected: the atomized water molecule temperature is 0-3°C, and the particle size is 1-5 microns.

[0020] 1.2 Quick freezing: Put it in a quick freezer for quick freezing, and freeze it at -50°C for 3 hours.

[0021] 1.3 Vacuum freeze-drying: in a vacuum freeze dryer, vacuum freeze-dry at -45°C for 16 hours,

[0022] 1.4 Finished product testing: the moisture content of the finished product reaches 7%.

[0023] 1.5 Packaging and storage.

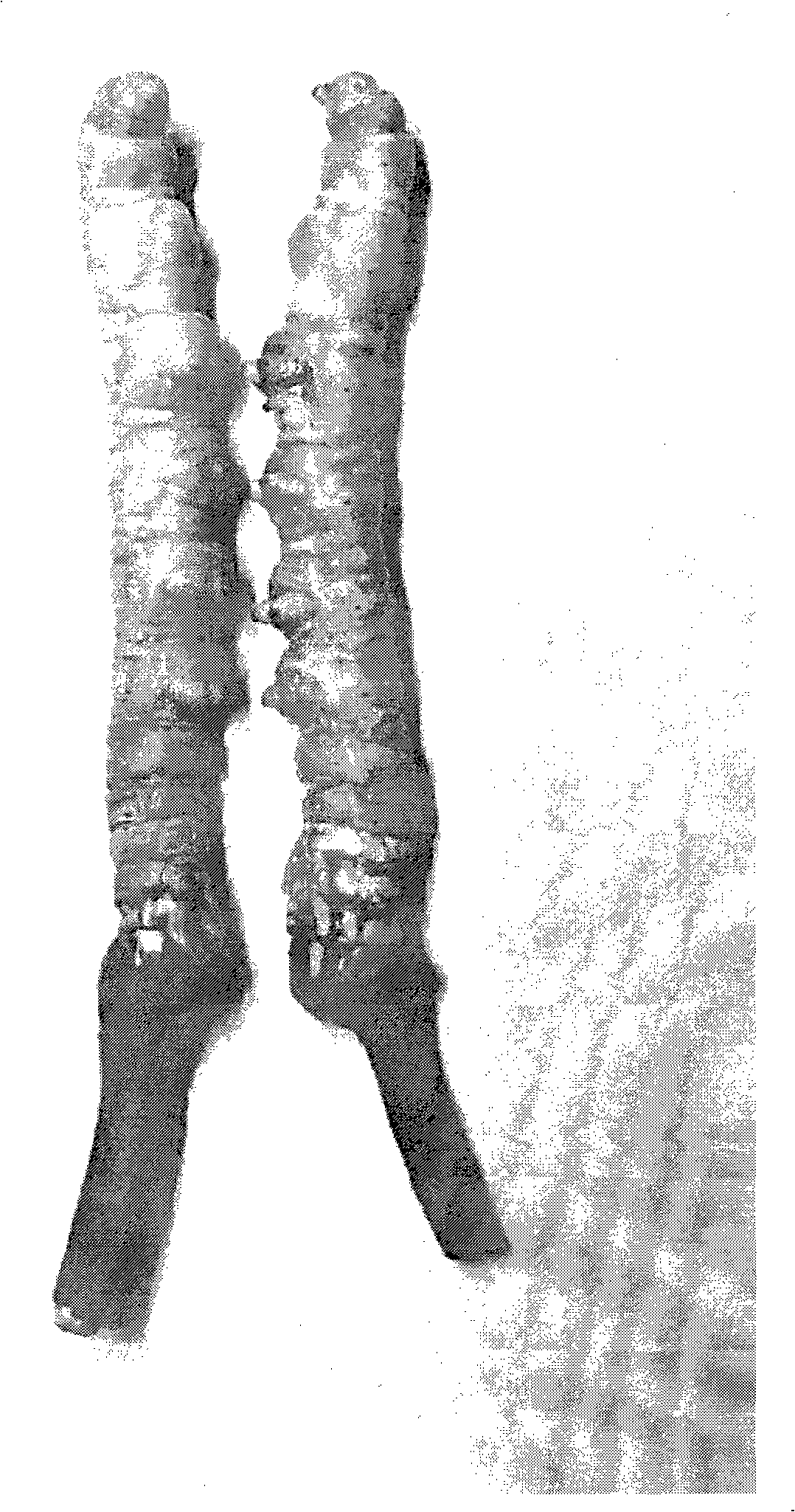

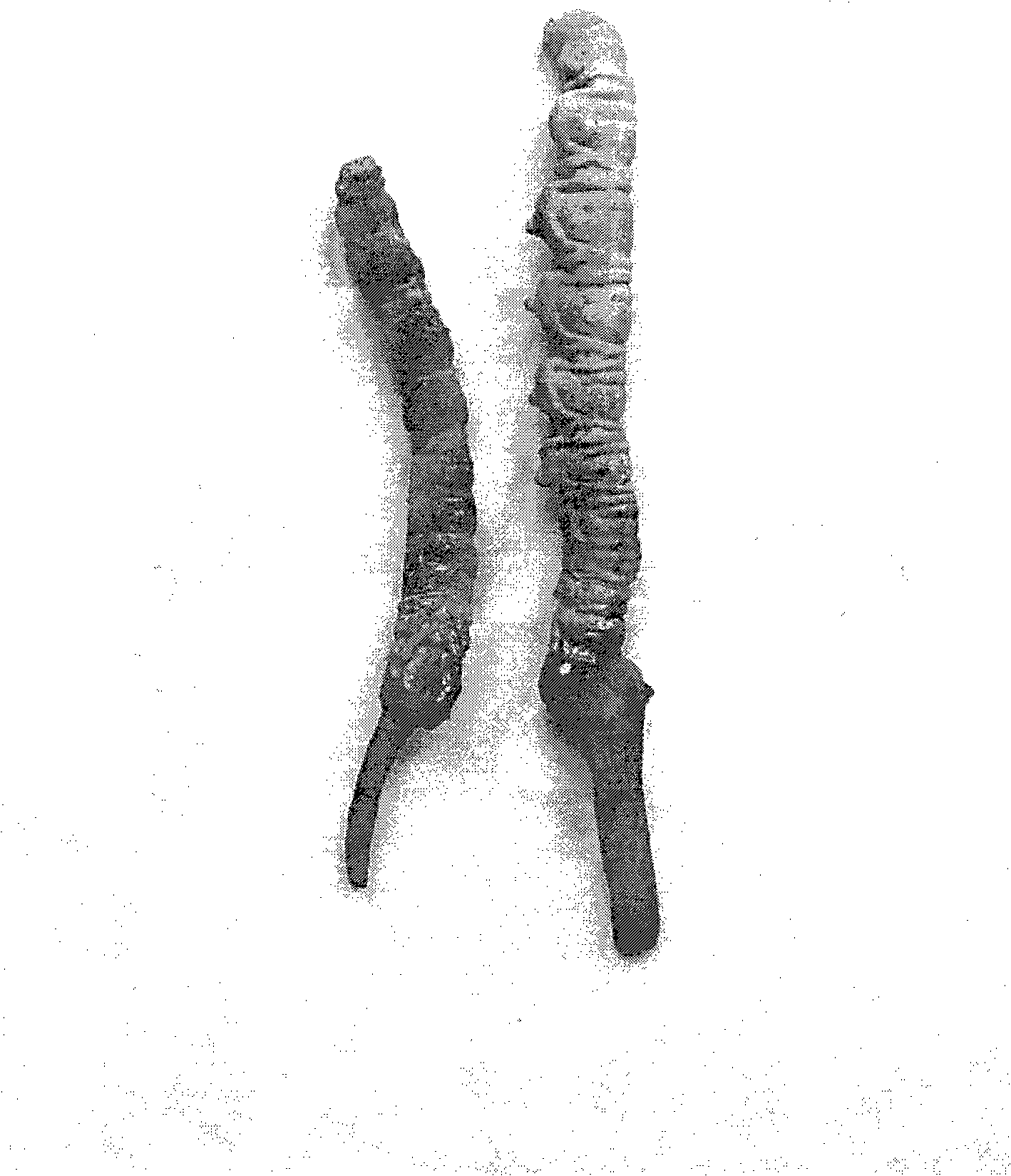

[0024] image 3 It is an unprocessed product of Cordyceps sinensis, figure 2 It is the Cordyceps sinensis product processed by the met...

Embodiment 2

[0026] 2.1 Water absorption and reshaping: put the pretreated Cordyceps sinensis on a fence-type drying rack and spread it flat, put it in a closed room, use an ultrasonic humidifier to spray and humidify it, and take a sample after a period of time to test its moisture content. When the moisture content When it reaches 80%, the spray heating can be stopped. The specifications of the ultrasonic heater are selected: the atomized water molecule temperature is 0-3°C, and the particle size is 1-5 microns.

[0027] 2.2 Quick freezing: Put it in a quick freezer and freeze it at -55°C for 2 hours.

[0028] 2.3 Vacuum freeze-drying: in a vacuum freeze dryer, vacuum freeze-dry at -55°C for 9 hours,

[0029] 2.4 Finished product testing: the moisture content of the finished product reaches 9%.

[0030] 2.5 Packaging and storage.

Embodiment 3

[0032] 3.1 Water absorption and reshaping: put the pretreated Cordyceps sinensis on a fence-type drying board, spread it flat, put it in a closed room, use an ultrasonic humidifier to spray and humidify it, and take a sample after a period of time to test its moisture content. When the moisture content When it reaches 78%, the spray heating can be stopped. The specifications of the ultrasonic heater are selected: the atomized water molecule temperature is 0-3°C, and the particle size is 1-5 microns.

[0033] 3.2 Express freezing: Put it in the quick freezer for quick freezing, and freeze it at -50°C for 5 hours.

[0034] 3.3 Vacuum freeze-drying: in a vacuum freeze dryer, vacuum freeze-dry at -50°C for 20 hours,

[0035] 3.4 Finished product inspection: the moisture content of the finished product reaches 5%.

[0036] 3.5 Packaging and storage.

[0037] The product processed by the above method can meet the hygienic requirements of edible mushrooms for direct consumption. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com