Patents

Literature

53results about How to "Improve polymerization conversion rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

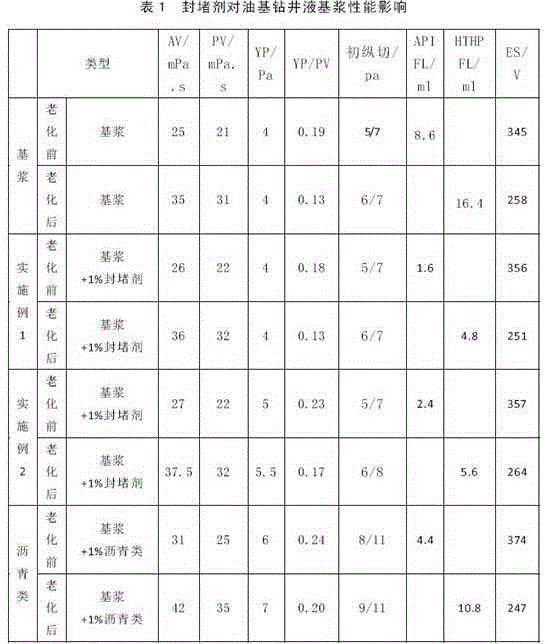

Resin type nanoparticle latex blocking agent for drilling fluids and preparation method of blocking agent

ActiveCN105462568AHigh blocking rateWide particle size distributionDrilling compositionBenzeneNanoparticle

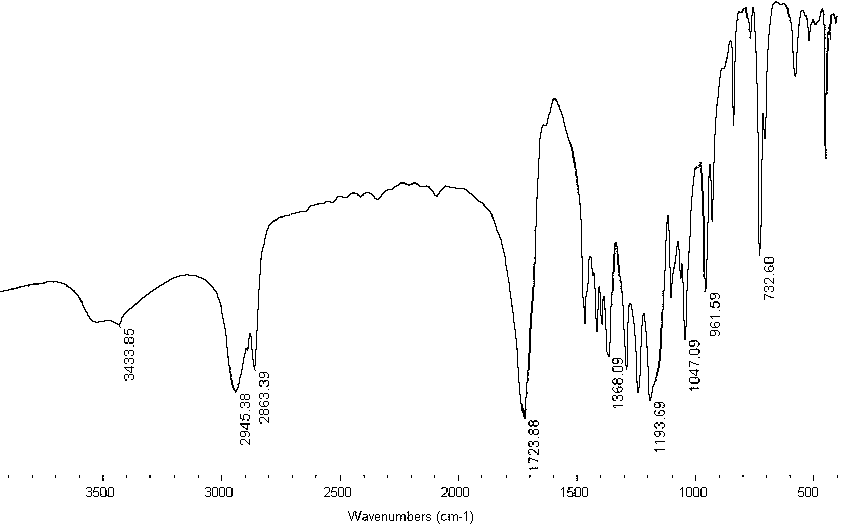

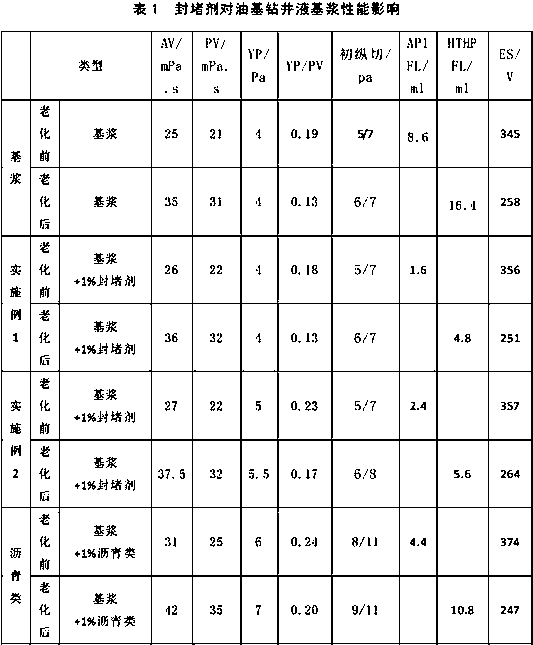

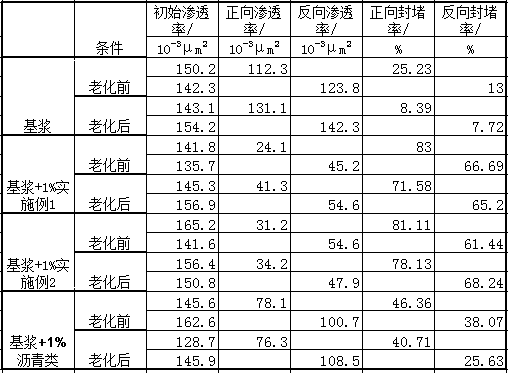

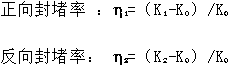

The invention discloses a resin type nanoparticle latex blocking agent for drilling fluids. The blocking agent comprises raw materials in parts by weight as follows: 20 parts of alkenyl benzene, 15 parts of acrylate, 1 part of acrylates and 10 parts of hard inorganic materials, wherein the mass ratio of short-chain monomers to long-chain monomers in acrylate monomers is 3:1. The blocking agent is a composite product of the inorganic materials and organic materials, combines the hard materials with soft materials, has a higher blocking rate and is wide in particle size distribution and wider in application range; the rheological property of the drilling fluids are seldom influenced after the blocking agent is added to the drilling fluids, the blocking capacity of the drilling fluids can be remarkably improved, and the filter loss of the drilling fluids is reduced.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

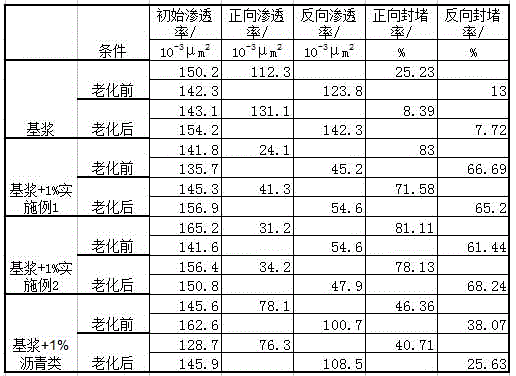

Nylon-6 slice production method capable of improving polymerization conversion rate

The invention discloses a nylon-6 slice production method capable of improving a polymerization conversion rate. The method comprises the following steps: fusing and storing raw materials, preparing an additive, performing pre-polymerization, performing post polymerization, performing casting strip slicing, performing multistage extraction, performing continuous drying, conveying the slices, metering and packaging. The method disclosed by the invention has the beneficial effects that a two-stage polymerization process, namely pressurized pre-polymerization and normal pressure post polymerization, is adopted, a polymerization tower is subjected to sectional heat supply by utilizing different heat transfer media, and different requirements on reaction conditions at different reaction stages are met by using a flash technology, so that the polymerization conversion rate of caprolactam is improved from the conventional 90 percent to over 92 percent. Therefore, the raw material utilization rate is improved, the pressure at the extraction and recovery section is alleviated, the product cost is reduced, and the economic benefits are improved.

Owner:HUNAN JINBO CHEM FIBER

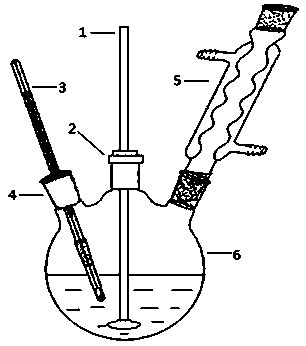

Method for producing high absorptive resin

A process for preparing high-hydroscopicitiy resin includes prepolymerization between monomers to be polymerized, trigger, system and cross-linking agent, and polymerizing to obtain gel-state solid product. Its advantages are high hydroscopicity (500-2000 g / g for deionized water), high water absorbing speed (less than 10 S) and high gel strength after the water is absorbed by it.

Owner:KEYUAN PRODIVE POWER PROMOTION CENT OF PETROCHEM IND SHANDONG

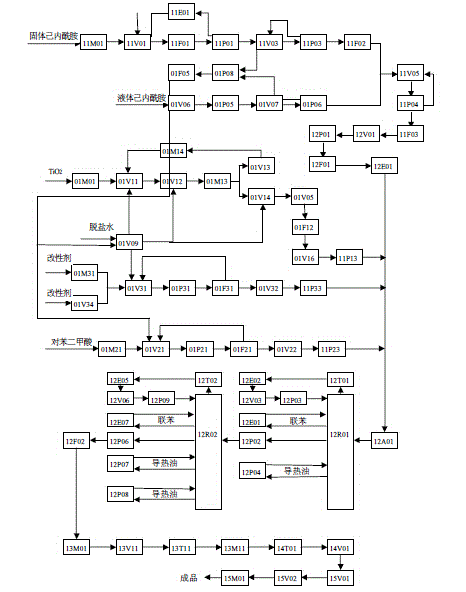

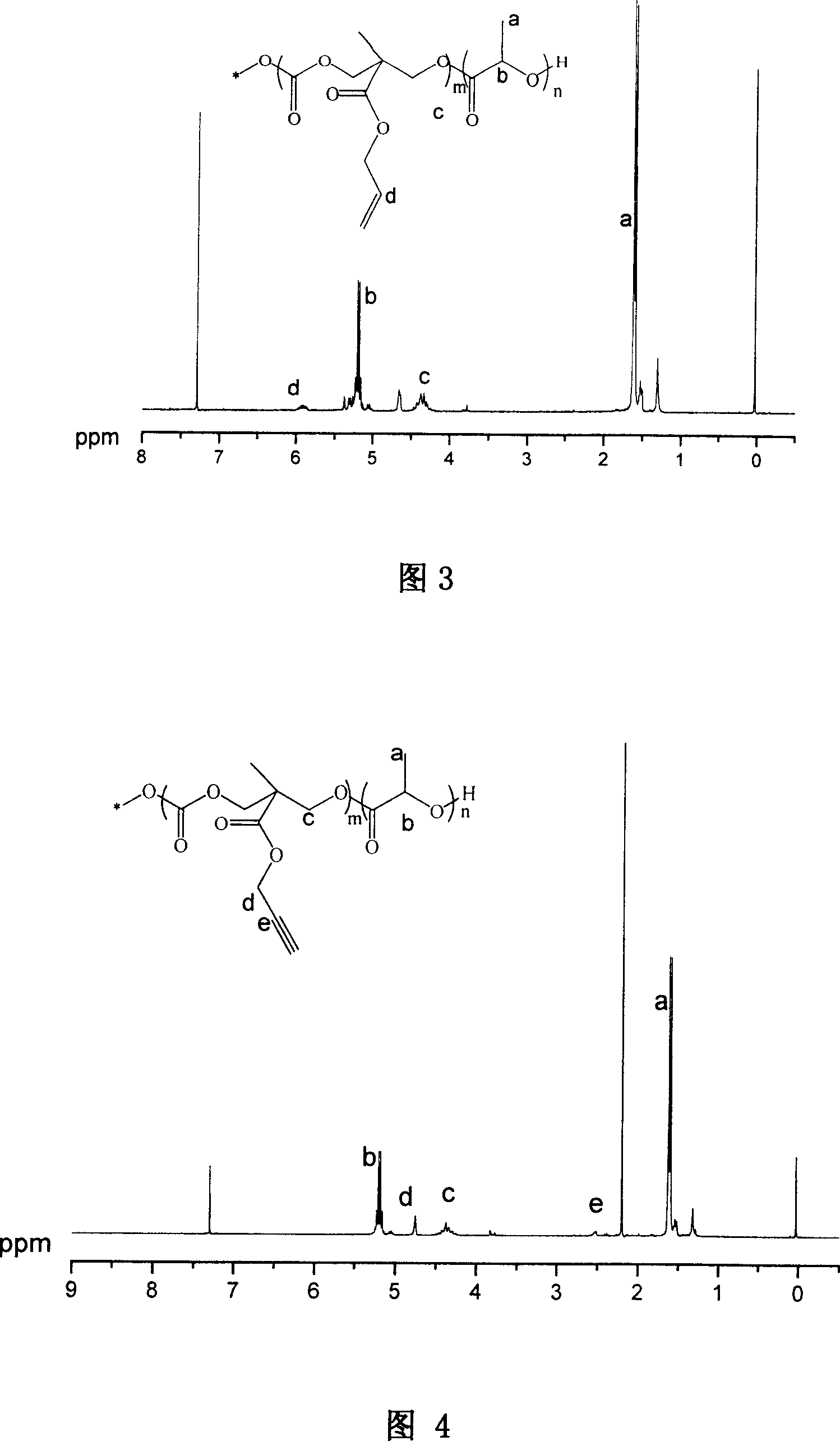

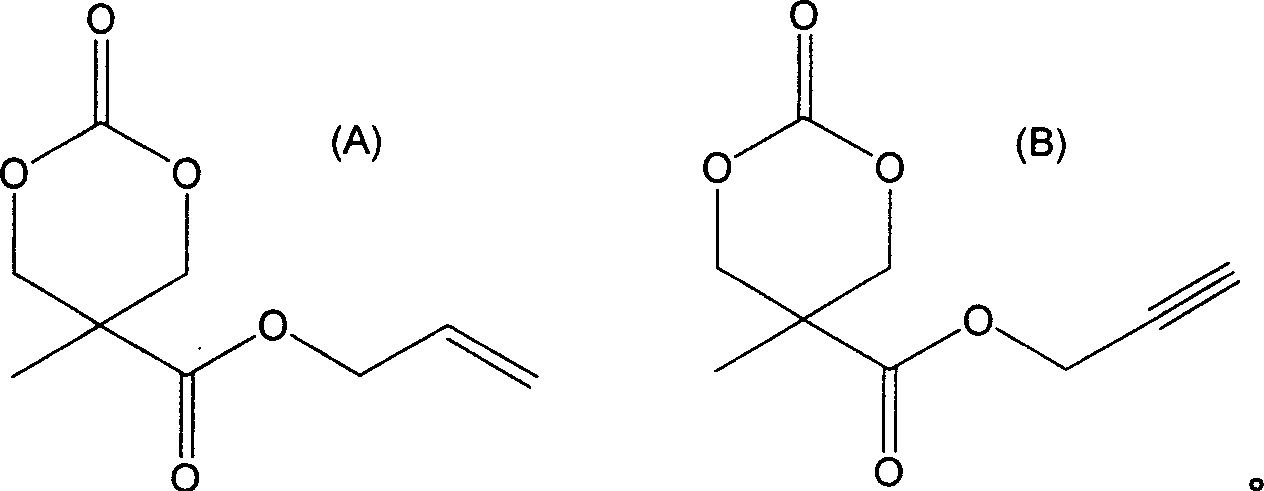

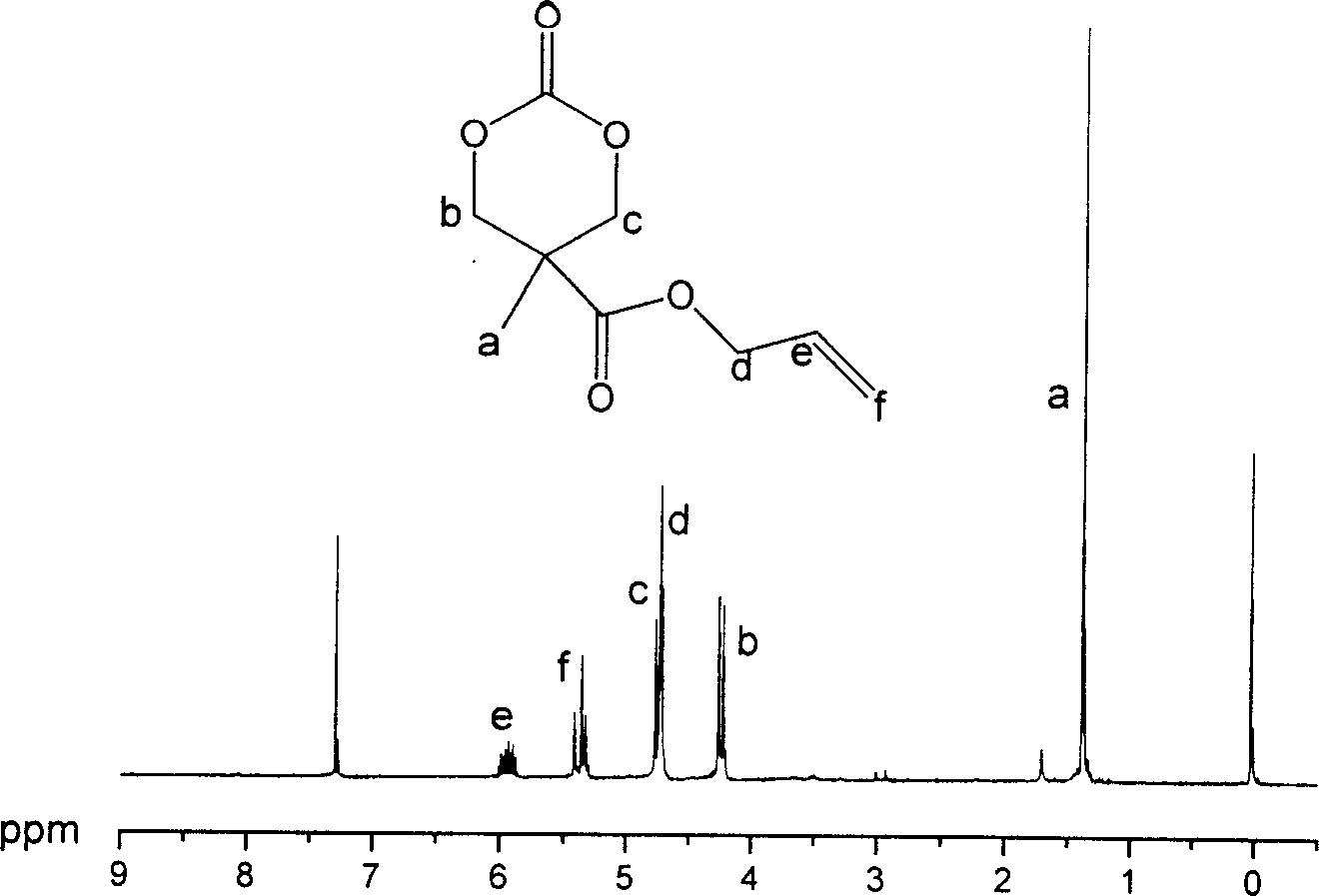

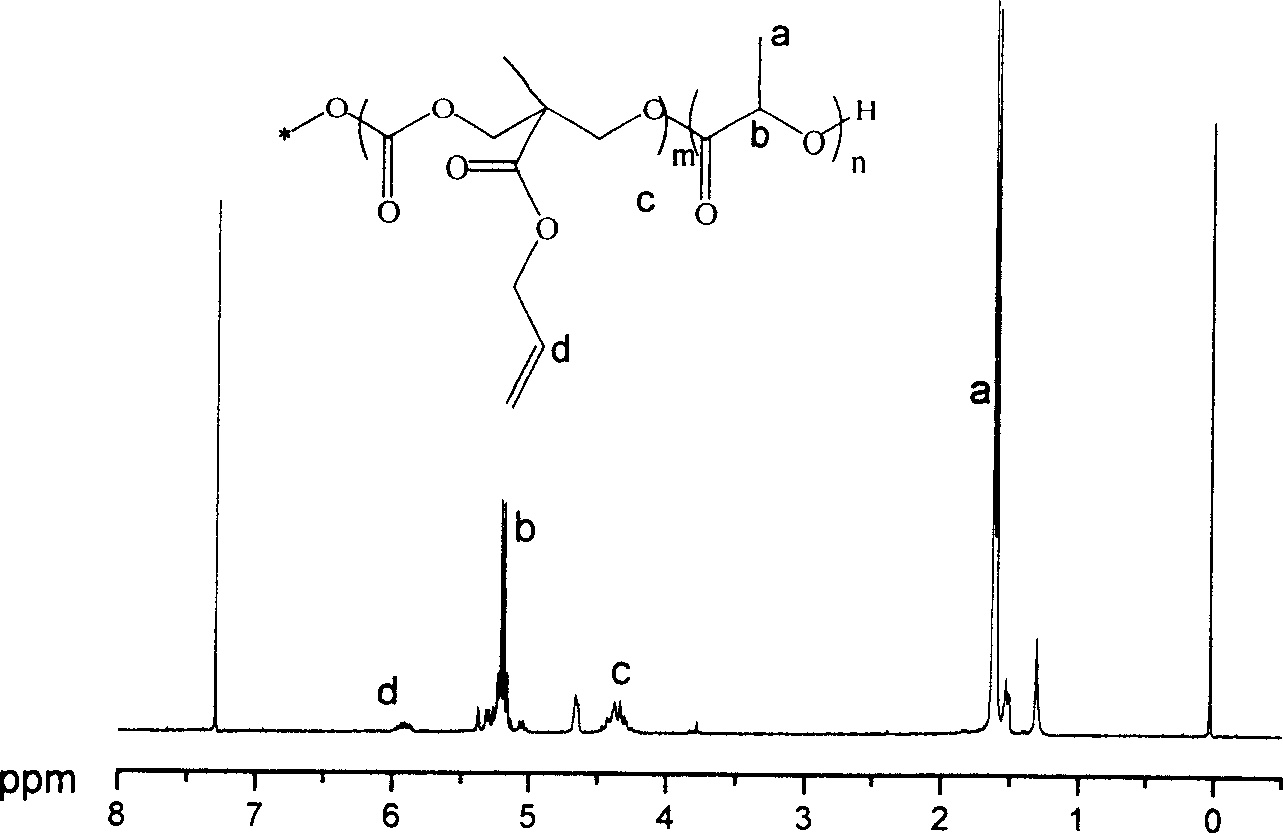

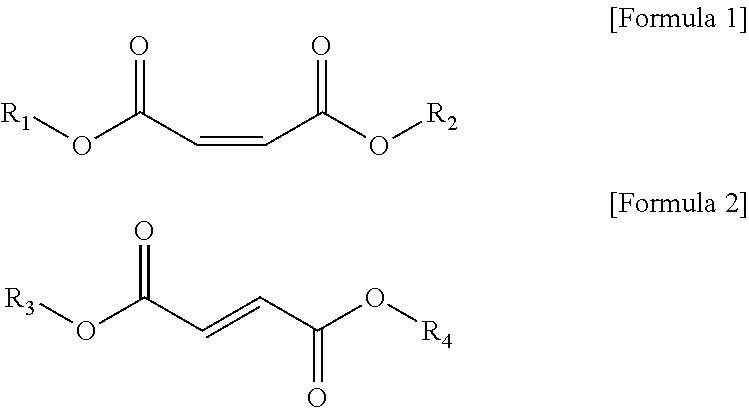

Synthesizing process and use of unsaturation cyclic aliphatic carbonate monomer and its polymer

This invention involves unsaturated cyclic aliphatic carbonate monomer and polymer synthesis and uses, and is biomedical polymer materials. From 2,2 - dimethylolpropionic acid departing, to synthesize 2-methyl-2-allyl-oxygen carbonyl trimethylene carbonate and 2-methyl-2-propargyl oxygen carbonyl trimethylene carbonate, and then through ring-opening polymerization or aliphatic monomers cycloate monomer opening loop and copolymerization, gain copolymer of aliphatic polycarbonate or aliphatic polyester-carbonate that side group contains double and Triple bond. Such polymer has advantage of both aliphatic polyester and carbonate, is biodegradable, degradation products is non-toxic. Use the functional side group of Double and Triple bond can connect drugs, active peptides or other bioactive elements with the polymer, improving the biocompatibility and biological activity of polymer, which may has real application in controlled-release drug, polymer pro-drug and tissue engineering fields.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Method of producing monodisperse chelate resins

ActiveUS20090045137A1High degree of substitutionImprove separation efficiencyWaste water treatment from quariesGas treatmentNitrogenCrosslinked polymers

The present invention relates to a method of producing novel monodisperse chelate resins based on crosslinked polymer beads containing aminomethyl groups and / or aminomethyl nitrogen heterocyclic groups that have a high uptake capacity for heavy metals and rapid kinetics.

Owner:LANXESS DEUTDCHLAND GMBH

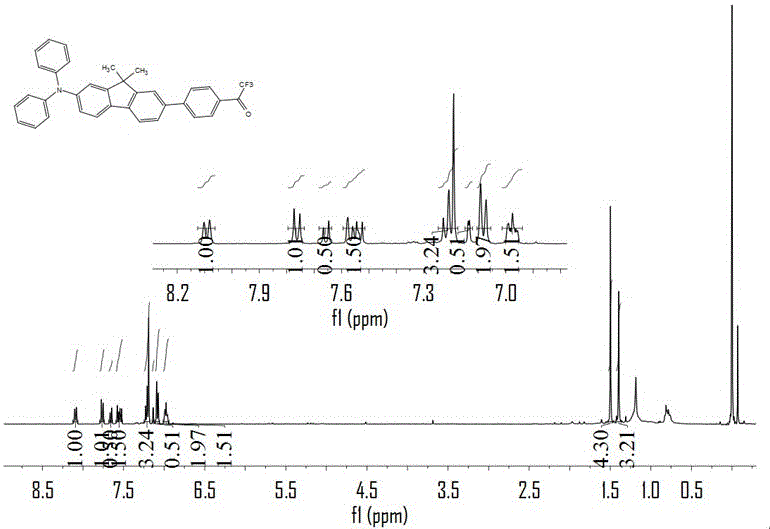

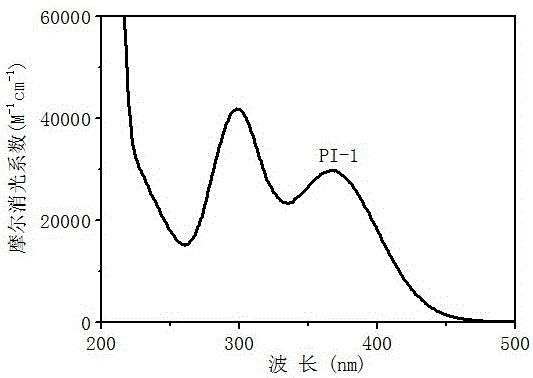

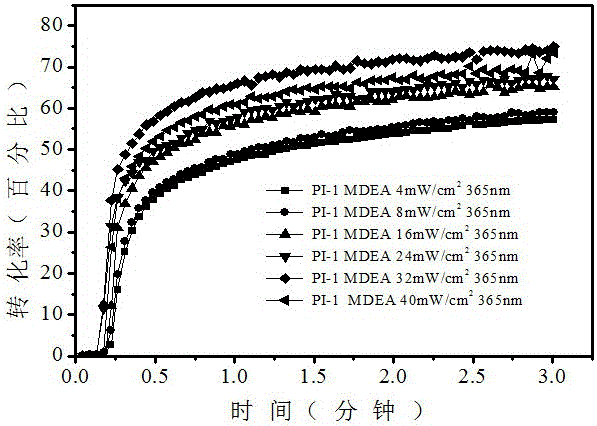

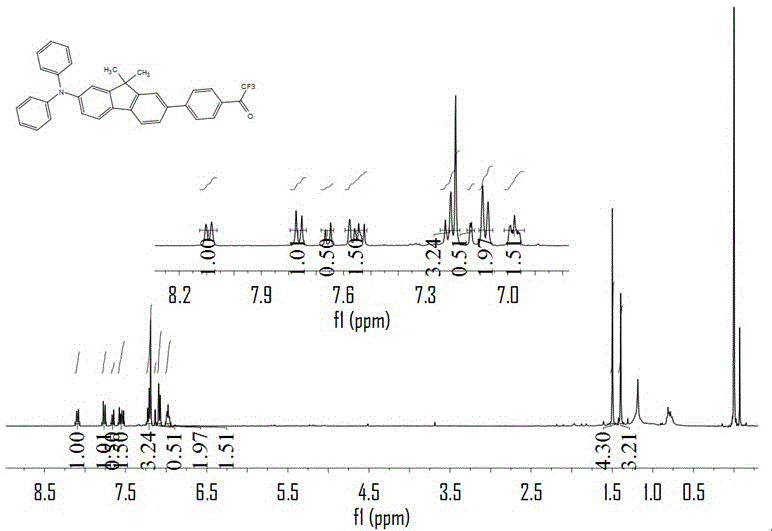

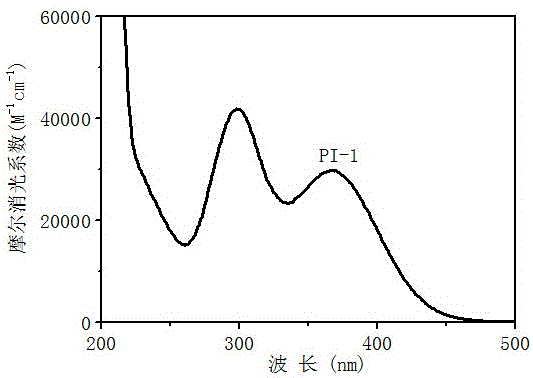

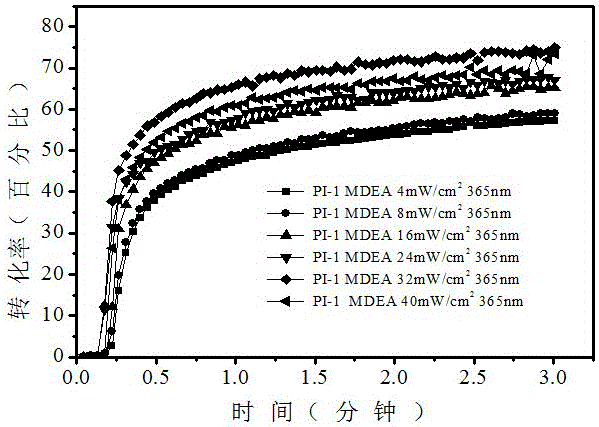

Acetophenone type photoinitiators using fluorene as conjugated structure as well as preparation method and application of acetophenone type photoinitiators

InactiveCN105153329AThe synthesis steps are simpleEasy to purifyOrganic chemistryOrganic compound preparationCationic polymerizationHigh electron

The invention relates to acetophenone type photoinitiators using fluorene as a conjugated structure as well as a preparation method and an application of the acetophenone type photoinitiators. According to the photoinitiators, substituted acetophenone with high electron-attracting capability is taken as an electron-attracting group, and fluorene molecules with different lengths are taken as the conjugated structure and form a D-pi-A type molecule system with electron-donating triphenylamine groups. Two types of Type II photoinitiators are provided according to different conjugated structures and different acetophenone substituted positions. The synthesis steps of the photoinitiators are simple, purification is easy, the yield is high, the light absorption property is good, the photoinitiators are easy to dissolve in a monomer, the absorption peak of the photoinitiators ranges from 365 nm to 405 nm, and the photoinitiators can initiate free radical and cationic polymerization under the initiation of ultraviolet and visible light and has a faster initiation speed and very high polymerization conversion rate. Two types of photoinitiators have wide application in the field of UV photocuring.

Owner:TONGJI UNIV

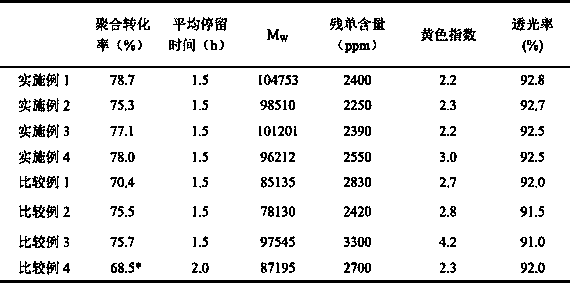

Method for continuously preparing optical-grade polymethyl methacrylate

The invention relates to a method for continuously preparing optical-grade polymethyl methacrylate. The method comprises the following steps of: continuously supplying (meth)acrylate monomer or the solution containing not more than 5% of inert solvent into a circulating tube type reactor for polymerization, wherein the polymerization temperature is controlled within the range of 130-160 DEG C and the polymer content is controlled within the range of 40-65%; continuously sending the reaction material into a heater for further polymerization, wherein the polymerization temperature is set within the range of 140-170 DEG C, and the content of the polymer is increased to 55-80%; sending the obtained reaction mixture into a devolatilization extruder to continuously remove a volatile substance by separation, wherein the ratio of material circulation rate to feeding rate inside the circulating tube type reactor is controlled within the range of 40:1-120:1. A highly-pervious pure polymethyl methacrylate molding compound product can be stably prepared by adopting the method provided by the invention.

Owner:PETROCHINA CO LTD

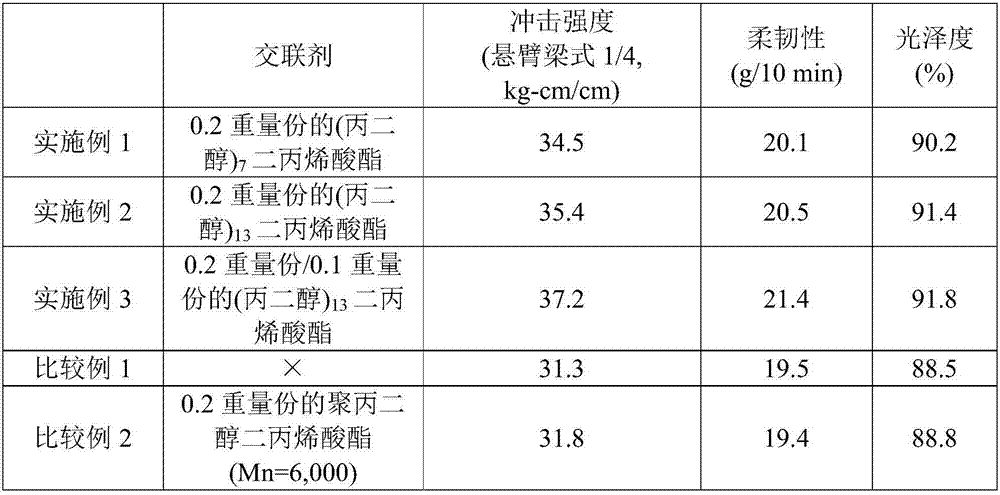

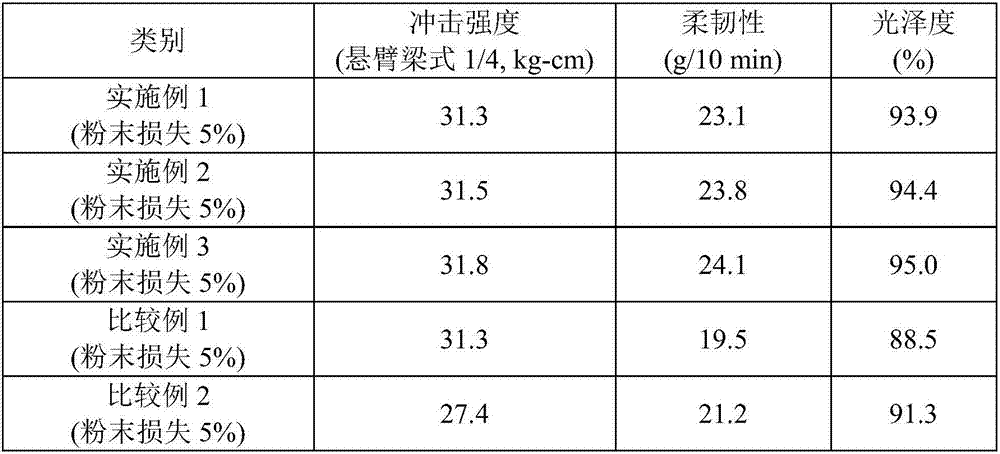

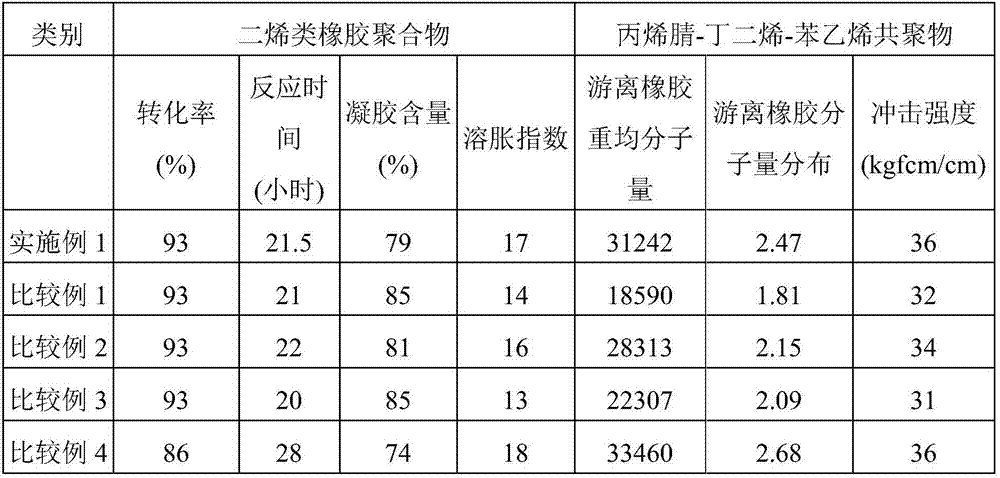

Method for preparing large-diameter diene-based rubber latex and acrylonitrile-butadiene-styrene graft copolymer including large-diameter diene-based rubber latex

The present invention relates to: a method for preparing diene-based rubber latex having improved impact strength, gloss, and mobility; the diene-based rubber latex prepared from the method; and an acrylonitrile-butadiene-styrene graft copolymer having, by including the diene-based rubber latex, a reduced rubbery solid content ratio but also having improved impact strength and production yield.

Owner:LG CHEM LTD

Di-oxime ester photoinitiator containing thiophene ring as well as preparation method and application thereof

InactiveCN106478843AEfficient aggregationImprove solubilityOrganic chemistryPhotosensitive materials for photomechanical apparatusNear ultravioletPhotoinitiator

The invention relates to a di-oxime ester photoinitiator having high light sensitivity in a near ultraviolet-visible light zone as well as a preparation method and an application thereof. The di-oxime ester photoinitiator is the nonionic and halogen-free photoinitiator which is effective in the ultraviolet-visible light zone of 365 nm-425 nm, an oxime esters group having strong electron-withdrawing capability is taken as an electron-withdrawing group, and forms a conjugated system with thiophene through connection, and the di-oxime ester photoinitiator has a disubstituted symmetrical structure. The photoinitiator has excellent performaces of storage stability, sensitivity, development performance and pattern integrity, compared with the same kind photoinitiator, the preparation method in the invention is simple, the applicable light source scope is wide, and the toxicity is low; disubstituted characteristic on the structure of the photoinitiator increases the acid generation performance by several times, and compared with the current single oxime esters photoinitiator products, the performance of the photoinitiator is better.

Owner:TONGJI UNIV

Method for preparing large-size diene-based rubber latex and acrylonitrile-butadiene-styrene graft copolymer comprising the same

The present invention relates to a method for preparing a diene-based rubber latex having improved impact strength, gloss and flexibility, diene-based rubber latex prepared therefrom, and an acrylonitrile-butadiene-styrene graft copolymer having improved impact strength and production yield while having reduced rubber solid content ratio by comprising the same.

Owner:LG CHEM LTD

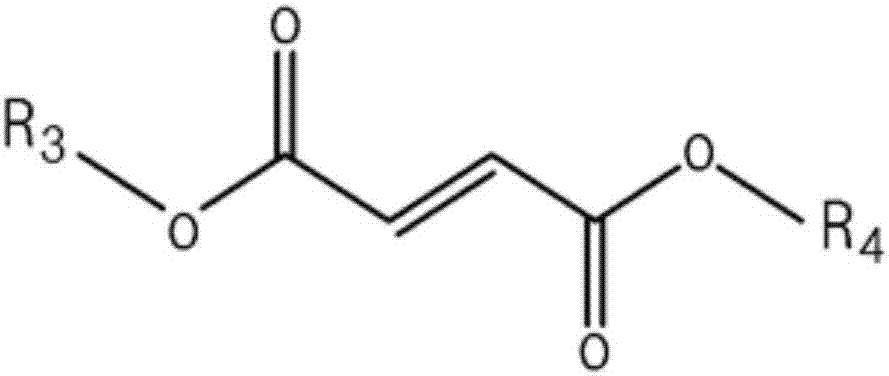

Vinyl chloride-based polymer, preparation method therefor, and thermoplastic resin composition containing same

The present invention relates to a vinyl chloride-based polymer containing a predetermined ratio of unsaturated fatty acid ester, a preparation method therefor, a thermoplastic resin composition containing same, and a thermoplastic molded product manufactured from the composition. The vinyl chloride-based polymer, according to the present invention, may exhibit excellent processability, and thus the thermoplastic molded product manufactured from the thermoplastic resin composition containing same may not only have high impact strength but also improved exterior properties.

Owner:LG CHEM LTD

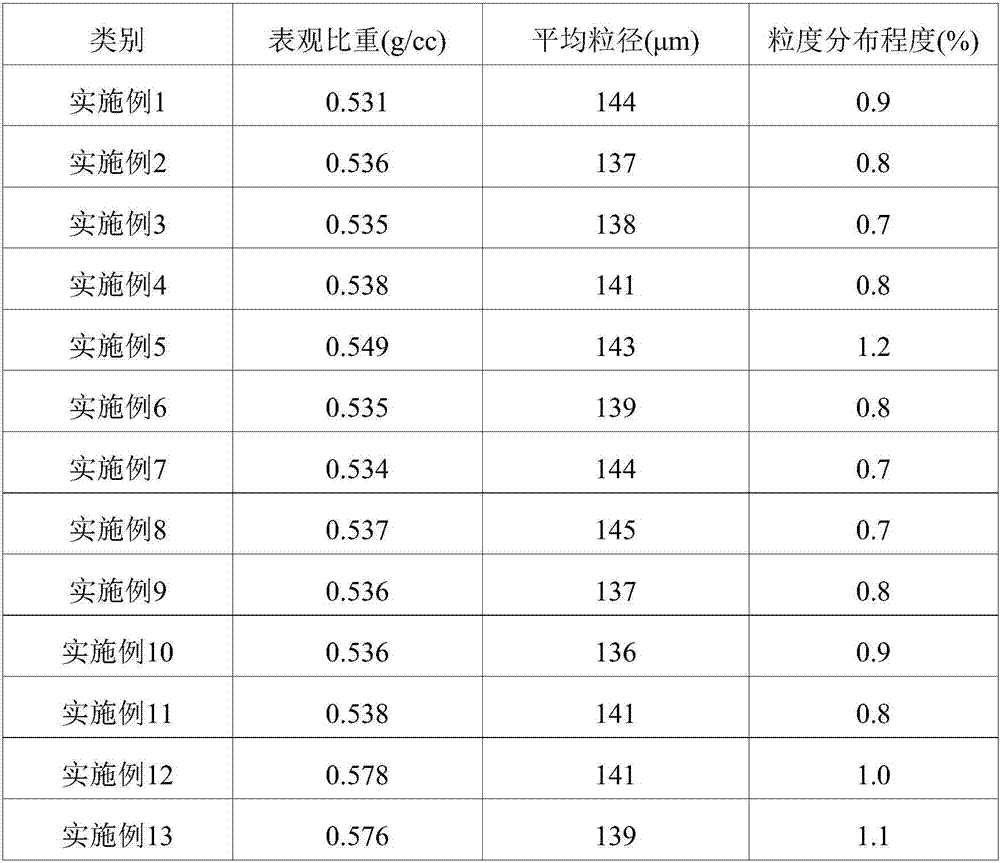

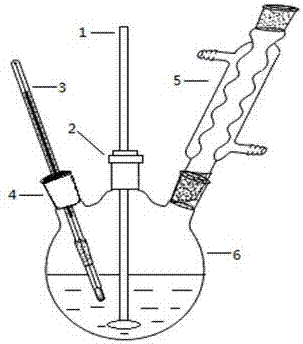

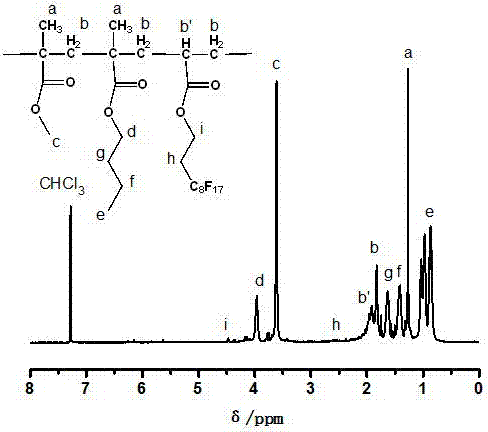

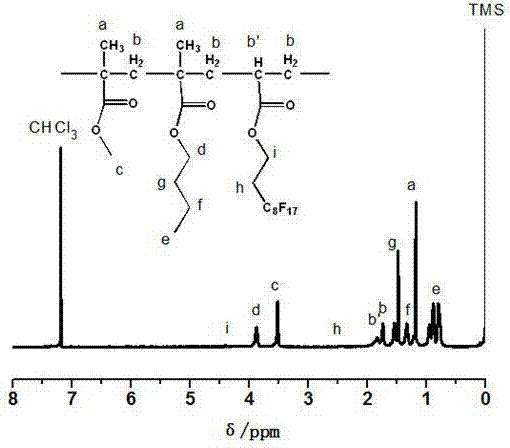

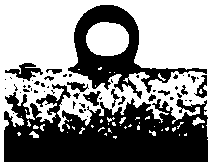

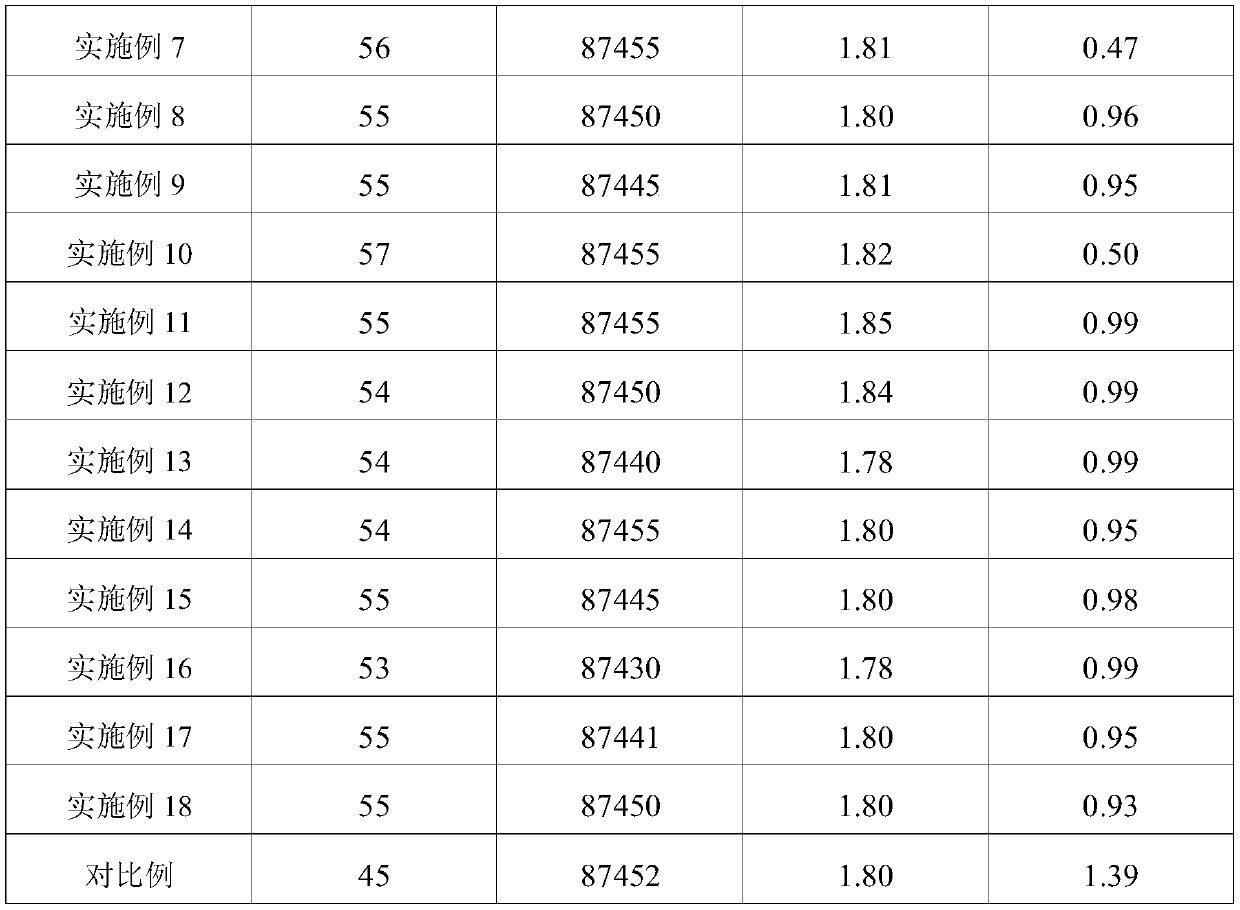

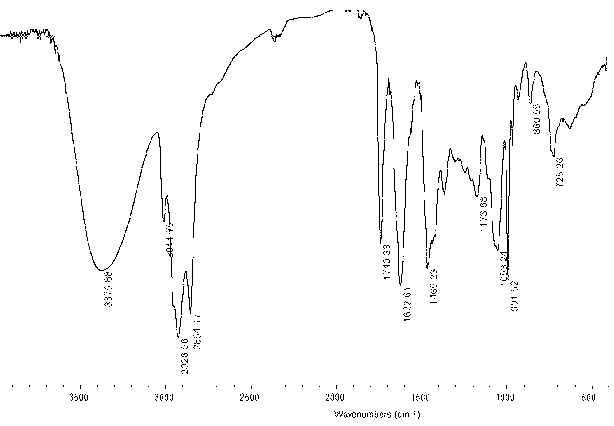

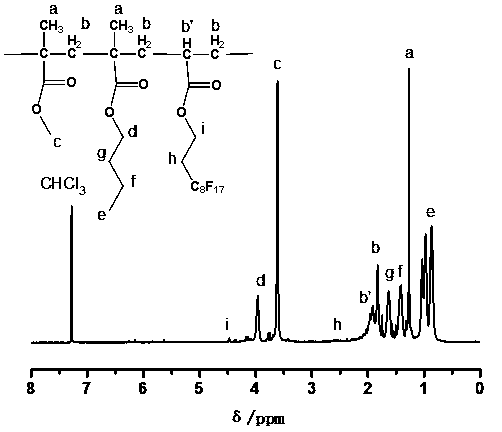

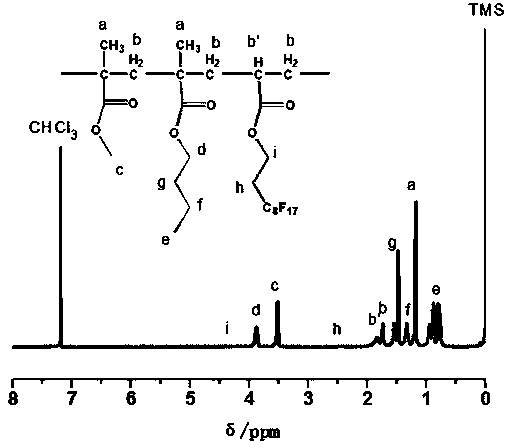

Fluorine-containing acrylate copolymer synthesis method

ActiveCN106947016AAvoid the disadvantages of lower fluoromonomer polymerization conversionEfficient removalSynthesis methodsMethylmethacrylates

The invention discloses a fluorine-containing acrylate copolymer synthesis method. The fluorine-containing acrylate copolymer synthesis method comprises the following steps of: obtaining mixed monomer miniemulsion of (perfluorooctyl) ethyl acrylate, n-butyl methacrylate and methylmethacrylate by taking methacryloyloxyethyl trimethyl ammonium chloride (DMC) as a cation emulsifying agent and cetane as co-stabilizer according to a mini-emulsification technology, and carrying out miniemulsion copolymerization under the initiation action of AIBN (2,2-azobisisobutyronitrile) to obtain miniemulsion of a fluorine-containing acrylate copolymer. The fluorine-containing acrylate copolymer has the beneficial effects that the fluorine-containing acrylate copolymer has a relatively high fluorine-containing monomer conversion rate; the cost is reduced; the utilization rate of a fluorine-containing monomer is effectively increased; and after polymerization is ended, an emulsifying agent can be removed by a simple and convenient demulsification precipitation method to obtain the fluorine-containing copolymer product with the relatively high purity, so that the copolymer has relatively good water and oil repellency and antifouling property.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

Synthesizing method for acrylate copolymers with hydrophobicity

ActiveCN109134741AEfficient removalAvoid the disadvantage of low polymerization conversion rateEmulsionSeparation technology

The invention discloses a synthesizing method for acrylate copolymers with hydrophobicity. A small amount of compound emulgator and co-stabilizer is used for making acrylate monomers form uniform andstable miniemulsion. A miniemulsion polymerization method is adopted for obtaining acrylate copolymer emulsion, and after polymerization is finished, through a separation technology of demulsificationcohesion and many-time dissolution-sediment circulating operation, the acrylate copolymer with hydrophobicity is obtained. No obvious emulgator residues are contained in the obtained copolymer, the purity and hydrophobicity performance of the acrylate copolymers with hydrophobicity are improved, the using amount of fluorine-containing monomers is reduced, and the cost is reduced; a polymerizationsite of miniemulsion polymerization is oily monomer drops, it is avoided that in the conventional emulsion polymerization process, acrylate monomers need to be diffused to solubilizing micelles through an aqueous phase, the polymerization conversion rate of the fluorine-containing acrylate monomers with hydrophobicity is effectively improved, the discharging amount of fluorine-containing monomersis reduced, and environmental pollution is reduced. The synthesizing method has a good application prospect in the field of water-proof antifouling paint.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

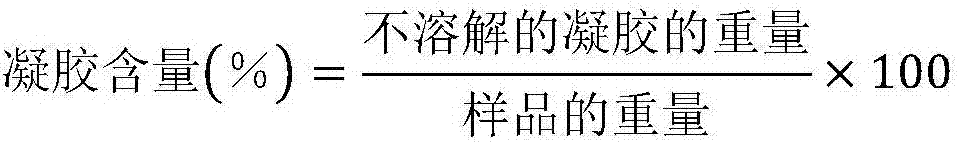

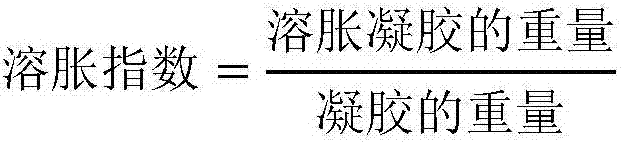

Method for preparing diene-based rubber polymer, diene-based rubber polymer prepared thereby, core-shell structured acrylonitrile-butadiene-styrene graft copolymer comprising same

ActiveCN107001515AImprove polymerization conversion rateImprove swelling indexChemistryAcrylonitrile butadiene styrene

The present invention relates to a method for preparing a diene-based rubber polymer having a relatively low gel content and a high swelling index while having a high polymerization conversion ratio, to a diene-based rubber polymer prepared thereby, and to a core-shell structured acrylonitrile-butadiene-styrene graft copolymer comprising the diene-based rubber polymer as a core. The method for preparing a diene-based rubber polymer and the core-shell structured acrylonitrile-butadiene-styrene graft copolymer comprising the diene-based rubber polymer prepared by the method can be easily applied in an industry in need thereof, especially, an industry of an impact modifier.

Owner:LG CHEM LTD

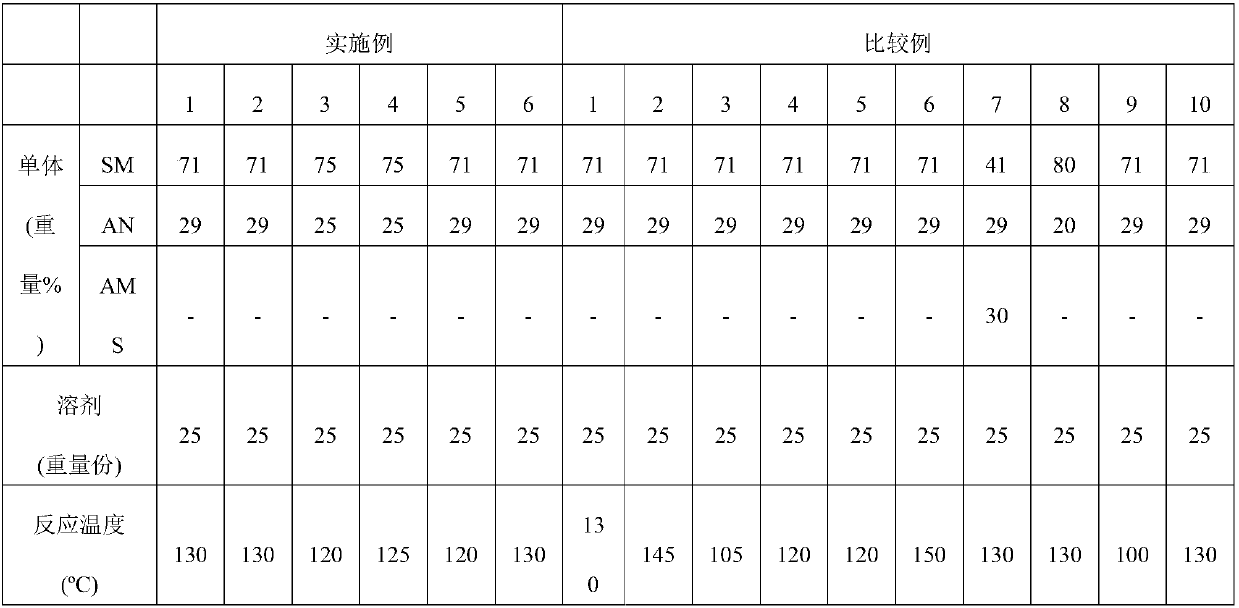

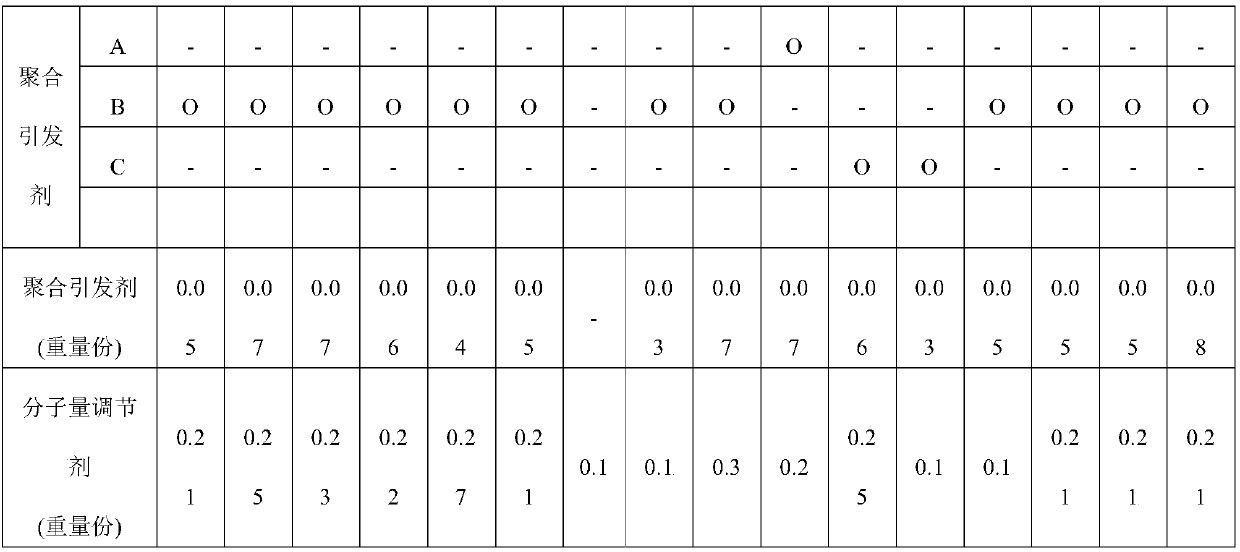

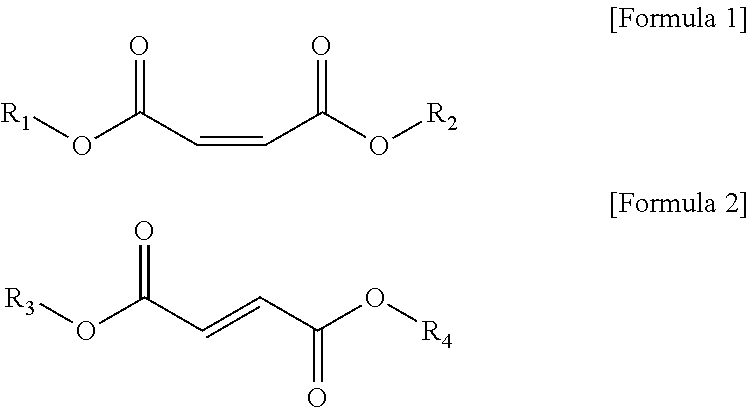

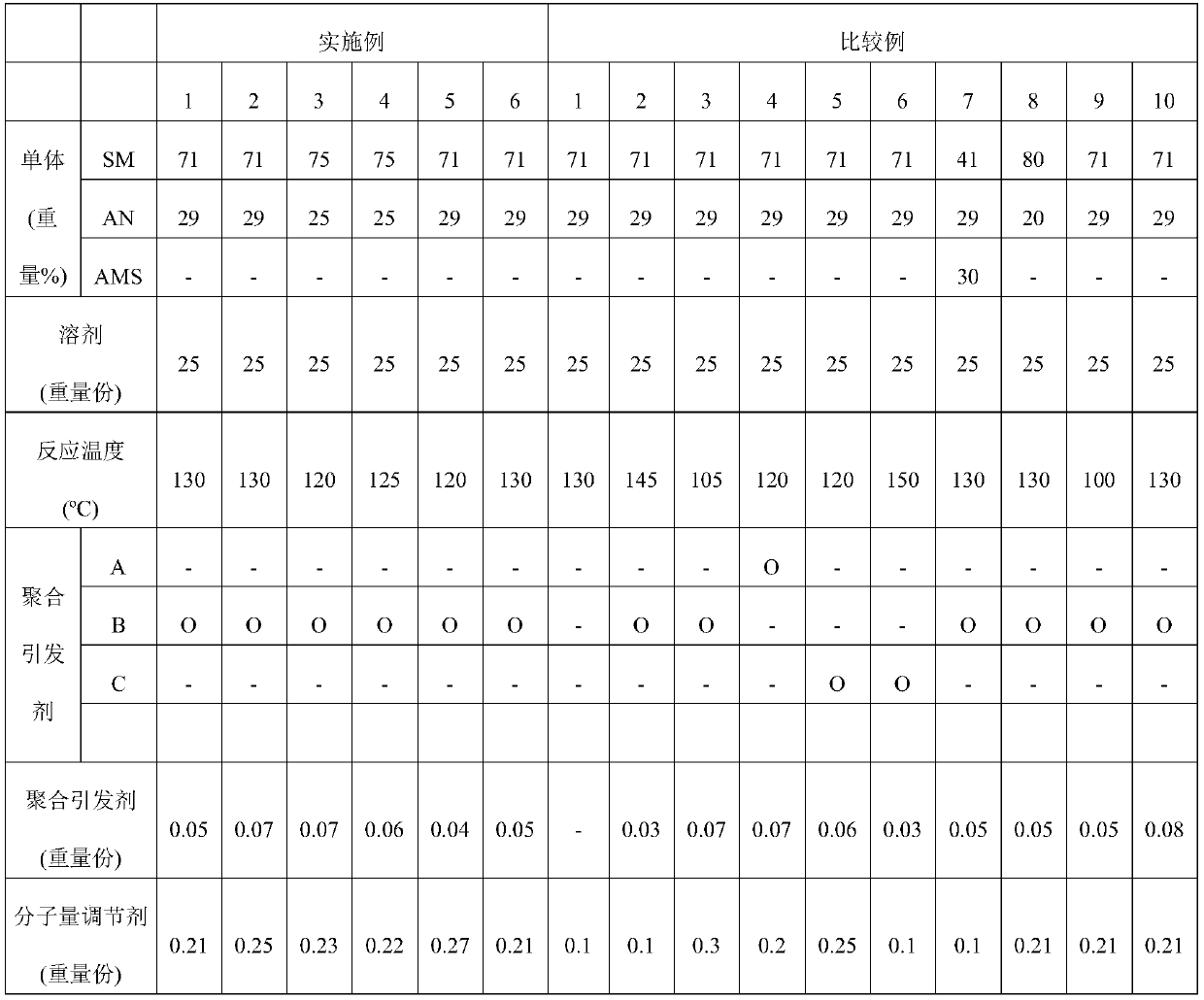

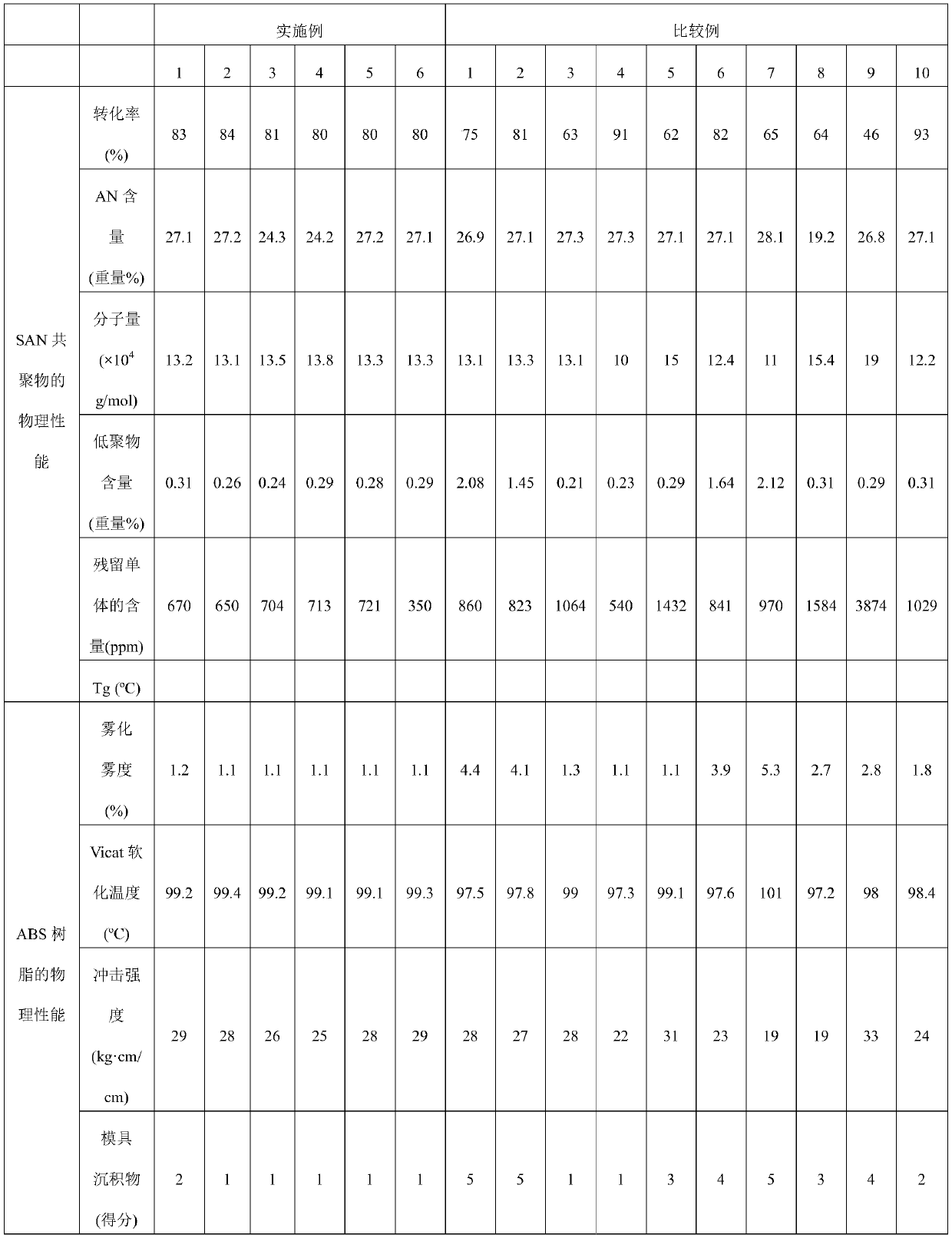

Method for preparing aromatic vinyl-unsaturated nitrile-based copolymer and aromatic vinyl-unsaturated nitrile-based copolymer prepared thereby

The present invention provides a method for preparing an aromatic vinyl-unsaturated nitrile-based copolymer and an aromatic vinyl-unsaturated nitrile-based copolymer prepared using the method, wherein, in the preparation of an aromatic vinyl-unsaturated nitrile-based copolymer, of which the content of unsaturated nitrile-based monomer-derived structural units in a copolymer is 22-30 wt%, the contents of oligomers and unreacted monomers are decreased, and as a result, excellent heat resistance and remarkably improved surface quality can be obtained, and particularly, when a product is used in aclosed high-temperature environment, the residues generated on a surface of the product and the mold deposits generated during injection molding can be reduced.

Owner:LG CHEM LTD

High-temperature-resistant polyacrylate composition and preparation method thereof

The invention discloses a high-temperature-resistant polyacrylate composition and a preparation method thereof. The high-temperature-resistant polyacrylate composition is a copolymer of an acrylic monomer and a carboxylic acid cross-linking monomer. The preparation method comprises the following steps: adding a raw material, namely the acrylic monomer, a raw material, namely the carboxylic acid cross-linking monomer, and a conditioning agent into an emulsifier solution, and in the presence of nitrogen for protection, initializing a copolymerization reaction through free radicals; after the copolymerization reaction is completed, adding a reducing agent for aftertreatment; finally, adding a polycoagulant for demulsification, bleaching with clean water, and dehydrating, thereby obtaining a composition product. Thermogravimetic analysis shows that the initial thermogravimetic weight of the high-temperature-resistant polyacrylate composition is 235-240 DEG C, and the high-temperature-resistant polyacrylate composition can be used for a long time under a condition within 190 DEG C; in addition, no extra heat exchange means are taken in the preparation method of the high-temperature-resistant polyacrylate composition, the temperature rise of a reaction system is within 20 DEG C, the polymerization conversion rate is as high as 98-99%, conditions are gentle, and industrial application conditions can be completely met.

Owner:鑫泓裕重庆复合材料有限公司

Method for producing high absorptive resin

InactiveCN1208352CHigh linear molecular weightHigh molecular weightAbsorption capacityAbsorption rate

Owner:KEYUAN PRODIVE POWER PROMOTION CENT OF PETROCHEM IND SHANDONG

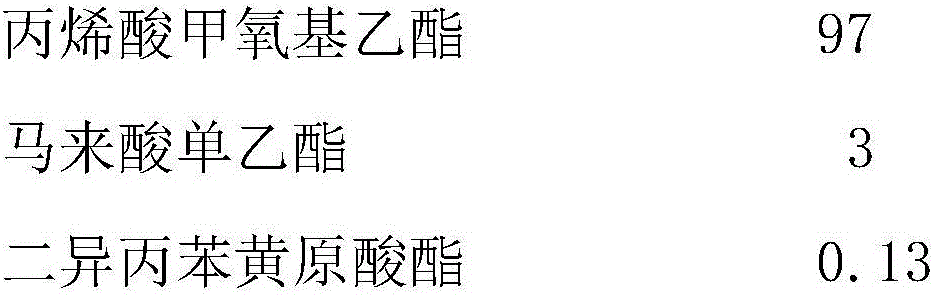

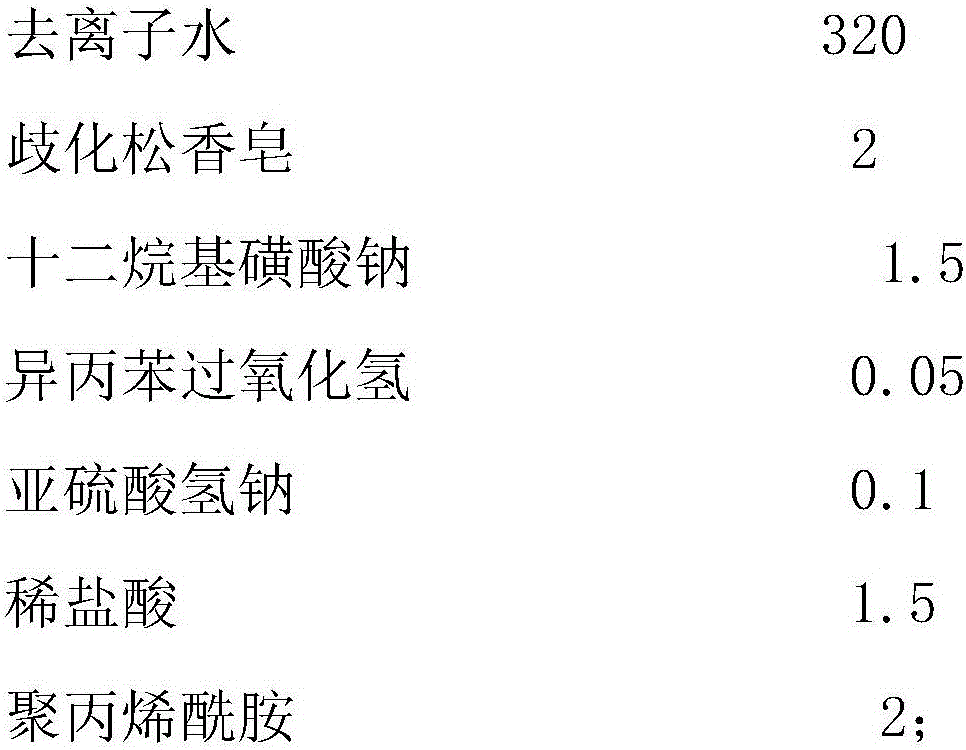

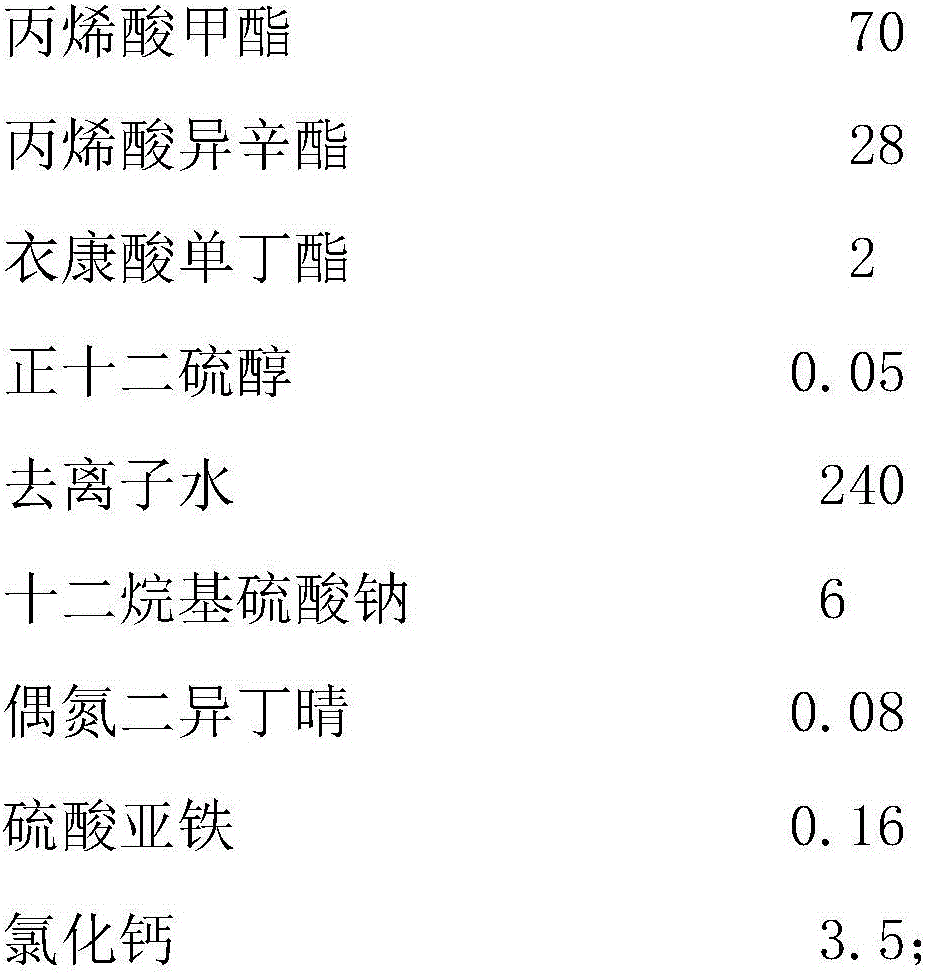

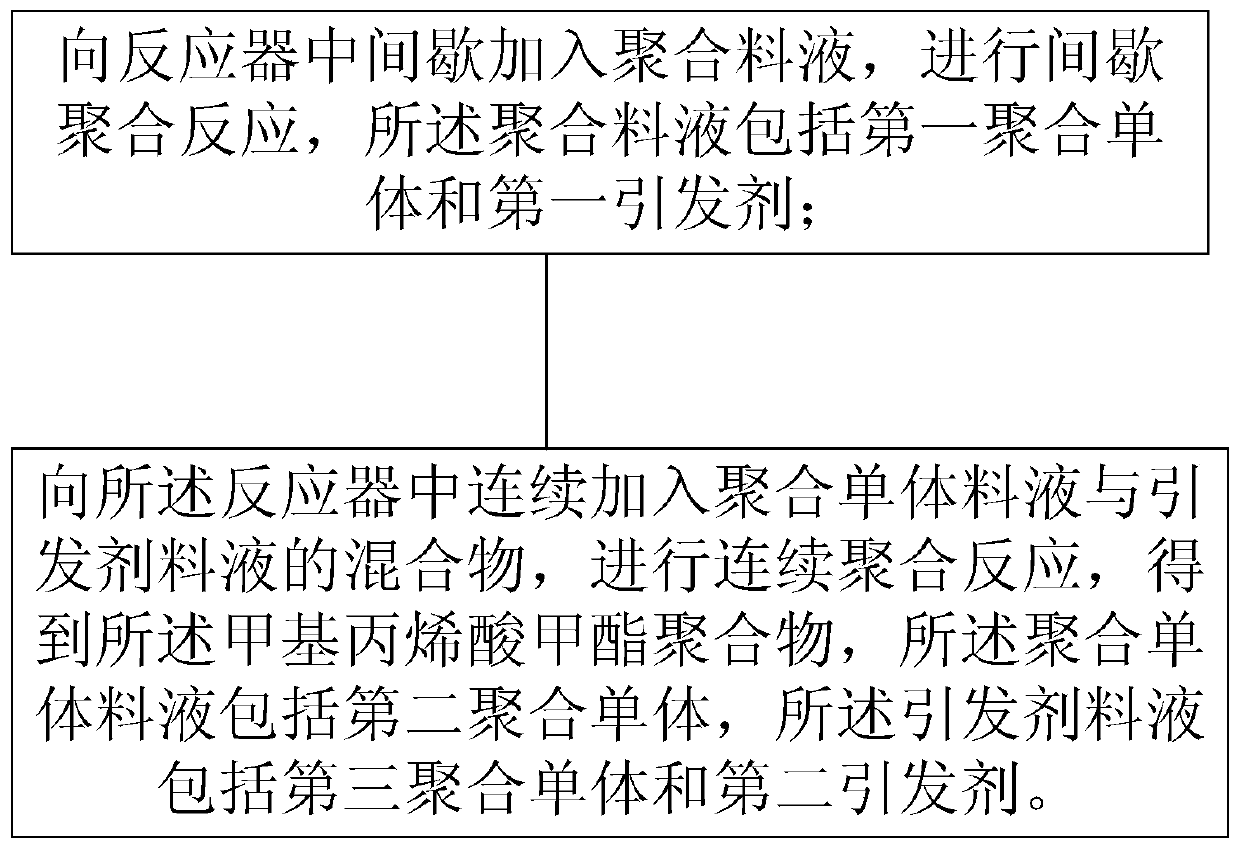

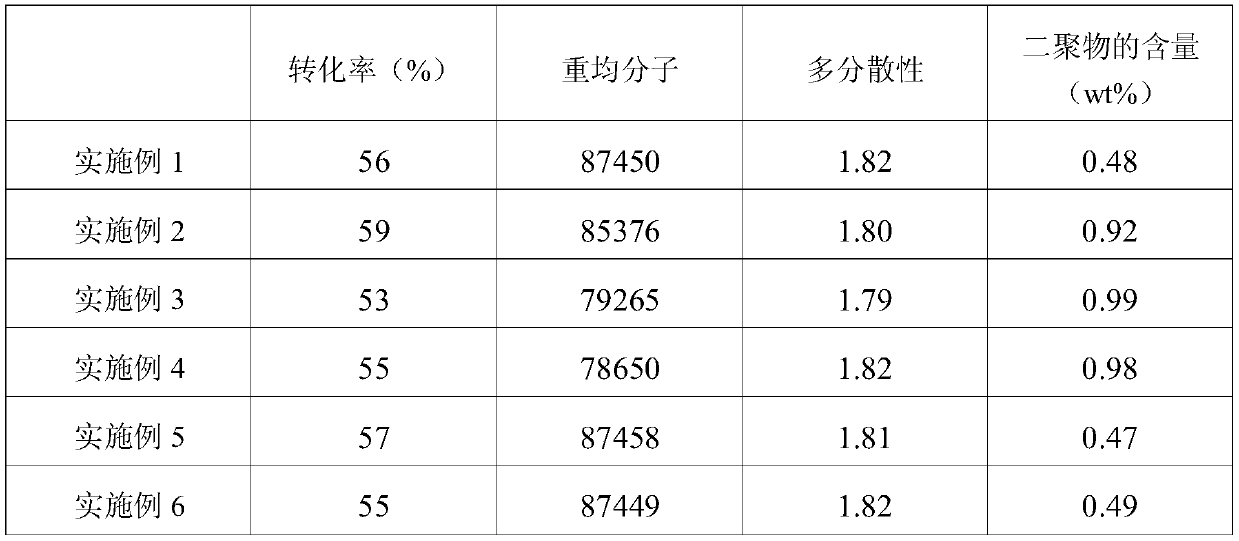

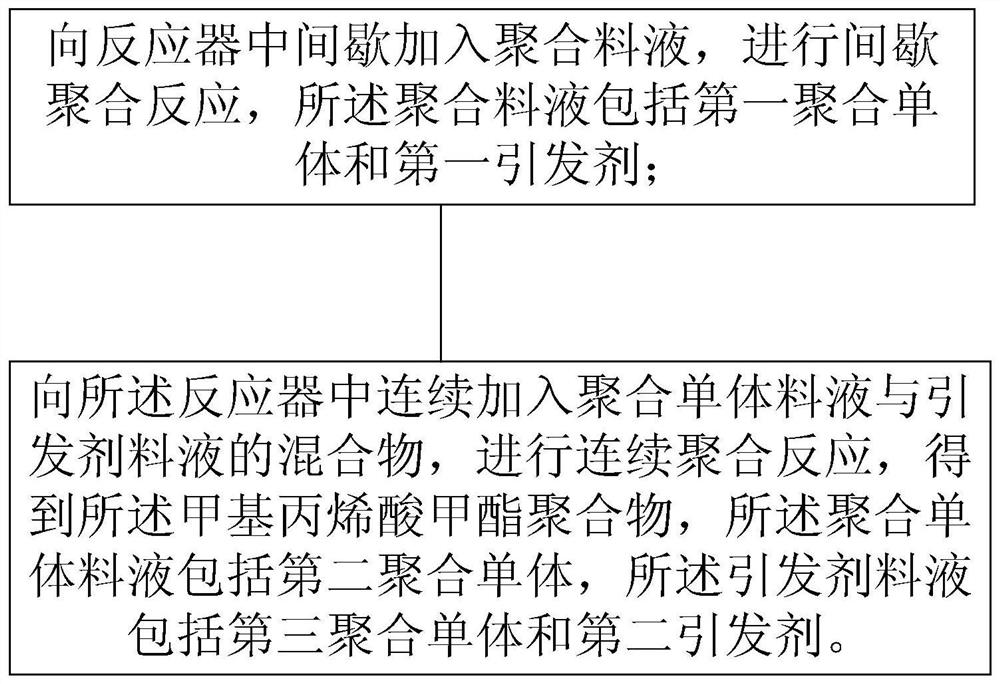

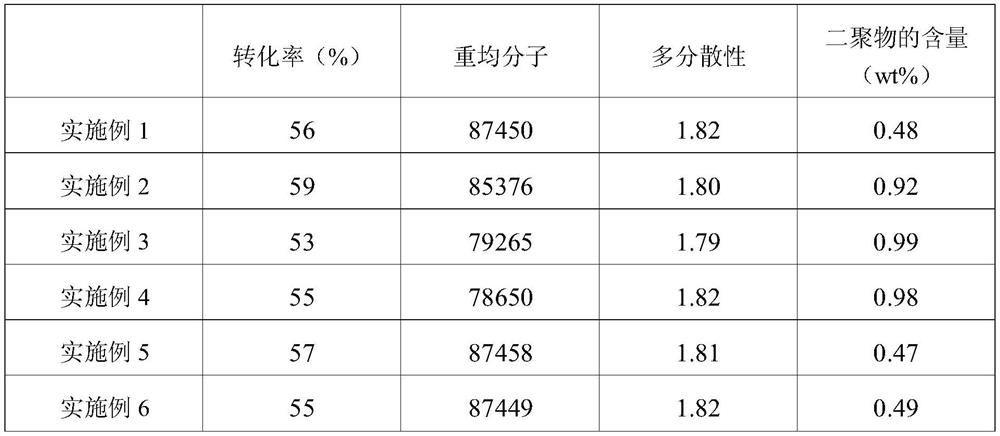

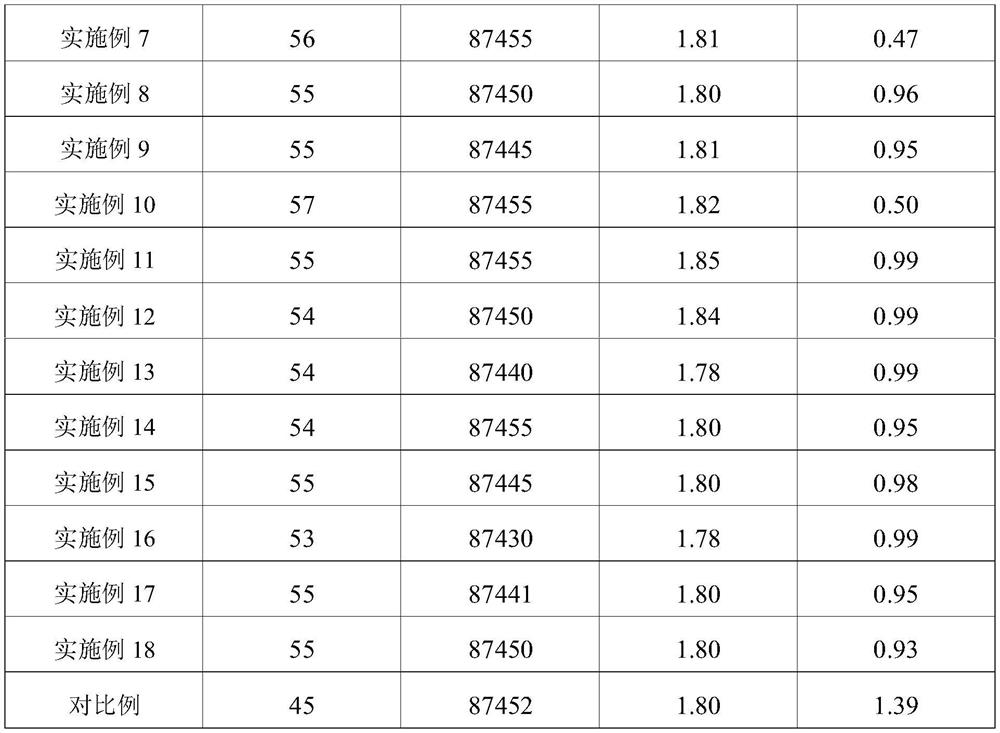

Preparation method of methyl methacrylate polymer

The invention provides a preparation method of a methyl methacrylate polymer. The preparation method comprises the following steps: intermittently adding polymerization feed liquid into a reactor, andcarrying out intermittent polymerization reaction, wherein the polymerization feed liquid comprises a first polymerization monomer and a first initiator; and continuously adding a mixture of a polymeric monomer feed liquid and an initiator feed liquid into the reactor, and carrying out a continuous polymerization reaction to obtain the methyl methacrylate polymer, the polymeric monomer feed liquid comprising a second polymeric monomer, and the initiator feed liquid comprising a third polymeric monomer and a second initiator. The preparation method can realize stable operation of bulk polymerization; according to the present invention, the high polymerization conversion rate of 45-75% can be obtained at the low polymerization temperature by using the low addition amount of the initiator, the polymerization residence time is shortened to 120-150 min, the production efficiency is improved, the generation of the dimer is reduced, the content of the dimer in the polymer is less than 1%, and the high-purity polymer is obtained.

Owner:PETROCHINA CO LTD

Caprolactone-tung oil copolymerized polyol polymer and synthesis method thereof

The invention discloses a caprolactone-tung oil copolymerized polyol polymer and a synthesis method thereof, and belongs to the field of macromolecular synthesis. According to the method, a mass polymerization one-step method is adopted, low molecular weight tung oil polyol prepared from diethanol amine and tung oil by aminolysis reaction and caprolactone are used as polymerizing monomers, and stannous octoate is used as a polymerization catalyst, and the caprolactone-tung oil copolymerized polyol polymer of which the molecular weight is 0.2*10<4> to 1.1*10<4> is synthesized by changing the molar ratio of the caprolactone to the tung oil under protection of an inert gas (N2) at the temperature of 150-170 DEG C. The caprolactone-tung oil copolymerized polyol polymer can be used as a novel polyester to be widely applied to preparation of polymers and copolymers.

Owner:HIGH & NEW TECH RES CENT OF HENAN ACAD OF SCI

Resin nano particle latex plugging agent for drilling fluid and preparation method thereof

ActiveCN105462568BHigh blocking rateWide particle size distributionDrilling compositionBenzeneNanoparticle

The invention discloses a resin type nanoparticle latex blocking agent for drilling fluids. The blocking agent comprises raw materials in parts by weight as follows: 20 parts of alkenyl benzene, 15 parts of acrylate, 1 part of acrylates and 10 parts of hard inorganic materials, wherein the mass ratio of short-chain monomers to long-chain monomers in acrylate monomers is 3:1. The blocking agent is a composite product of the inorganic materials and organic materials, combines the hard materials with soft materials, has a higher blocking rate and is wide in particle size distribution and wider in application range; the rheological property of the drilling fluids are seldom influenced after the blocking agent is added to the drilling fluids, the blocking capacity of the drilling fluids can be remarkably improved, and the filter loss of the drilling fluids is reduced.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Caprolactone-tung oil copolymerized polyol polymer and synthesis method thereof

InactiveCN103275307BImprove polymerization conversion rateQuality improvementPolyesterPolymer science

The invention discloses a caprolactone-tung oil copolymerized polyol polymer and a synthesis method thereof, and belongs to the field of macromolecular synthesis. According to the method, a mass polymerization one-step method is adopted, low molecular weight tung oil polyol prepared from diethanol amine and tung oil by aminolysis reaction and caprolactone are used as polymerizing monomers, and stannous octoate is used as a polymerization catalyst, and the caprolactone-tung oil copolymerized polyol polymer of which the molecular weight is 0.2*10<4> to 1.1*10<4> is synthesized by changing the molar ratio of the caprolactone to the tung oil under protection of an inert gas (N2) at the temperature of 150-170 DEG C. The caprolactone-tung oil copolymerized polyol polymer can be used as a novel polyester to be widely applied to preparation of polymers and copolymers.

Owner:HIGH & NEW TECH RES CENT OF HENAN ACAD OF SCI

Preparation method of polymer for polyacrylonitrile-based carbon fiber precursor without metal ions in polymerization system

PendingCN114437287AReduce manufacturing costHigh molecular weightFibre chemical featuresCarbon fibersAcrylonitrile

The invention relates to a preparation method of a polymer for a polyacrylonitrile-based carbon fiber precursor without metal ions in a polymerization system, which comprises the following steps: mixing monomer acrylonitrile, a second polymerization monomer, a third polymerization monomer and deionized water, heating and keeping at 45-65 DEG C, stirring at 100 rpm, respectively dropwise adding a water-soluble initiator into a reactor at the same titration rate at the same time, and reacting at the temperature of 45-65 DEG C for 2-3 hours; after dropwise adding the initiator, reacting for 30 to 120 minutes; removing residual monomers, washing and drying to obtain polyacrylonitrile powder; wherein in terms of the mass of all the polymerization monomers, the monomer acrylonitrile accounts for 92-99 wt%, the feeding amount of the second copolymerization monomer accounts for 1-7.0 wt%, the feeding amount of the third copolymerization monomer accounts for 0.1-3.0 wt%, and the use amount of the initiator accounts for 0.1-2.0 wt%; and an initiator. The method has the advantages of fast polymerization reaction speed, low reaction temperature, high polymerization conversion rate and low production cost. As the polymerization system does not contain metal ions, the polyacrylonitrile-based carbon fiber precursor with high purification and high quality can be obtained, and further the carbon fiber with high performance can be obtained.

Owner:敖琪

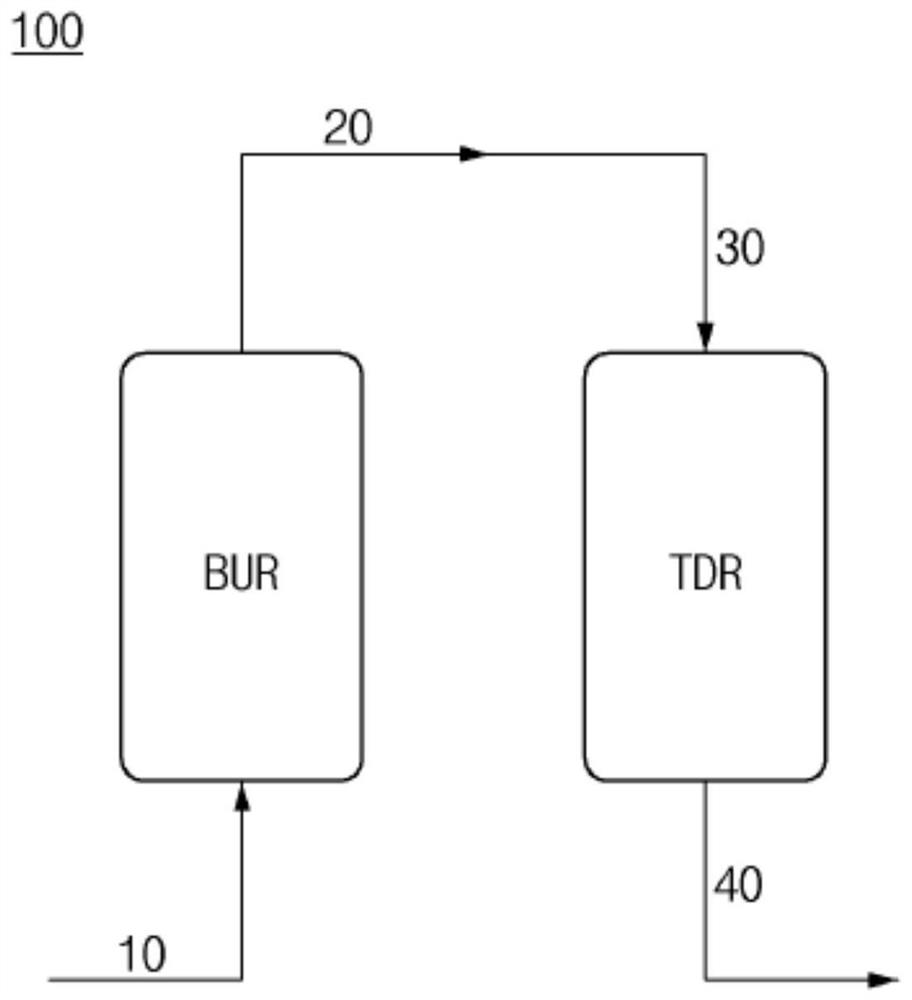

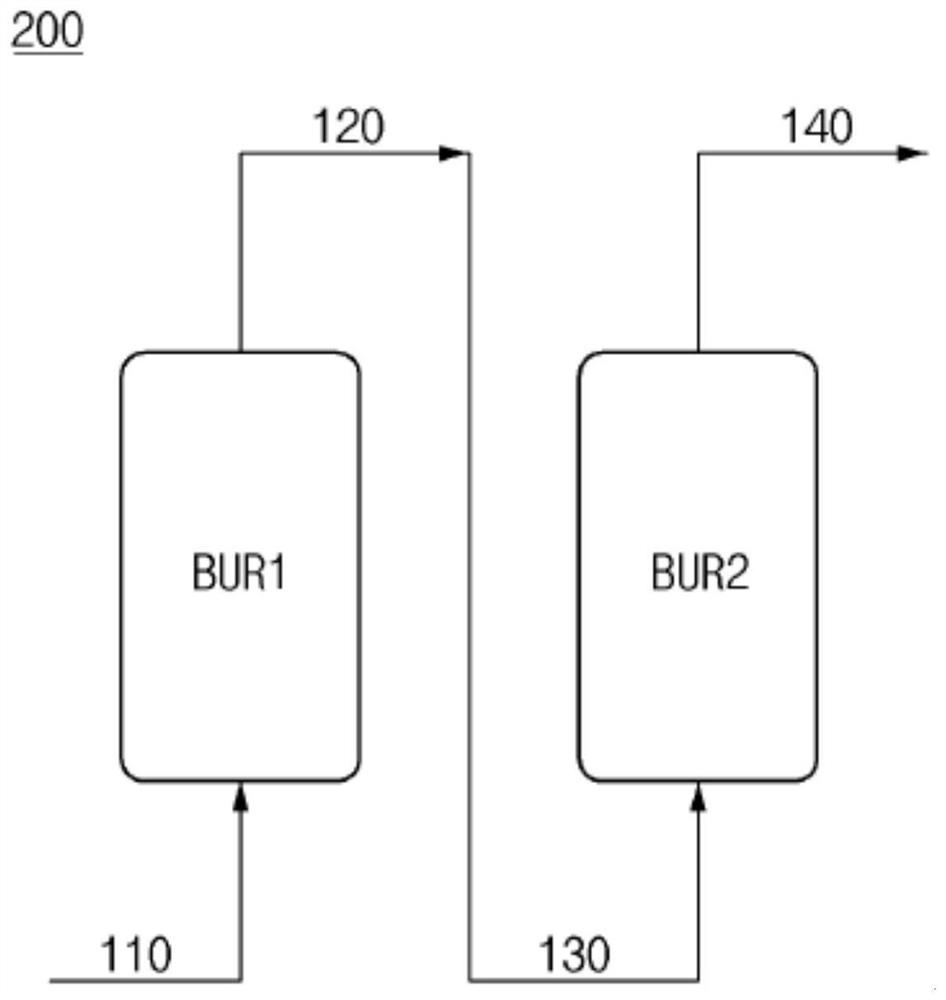

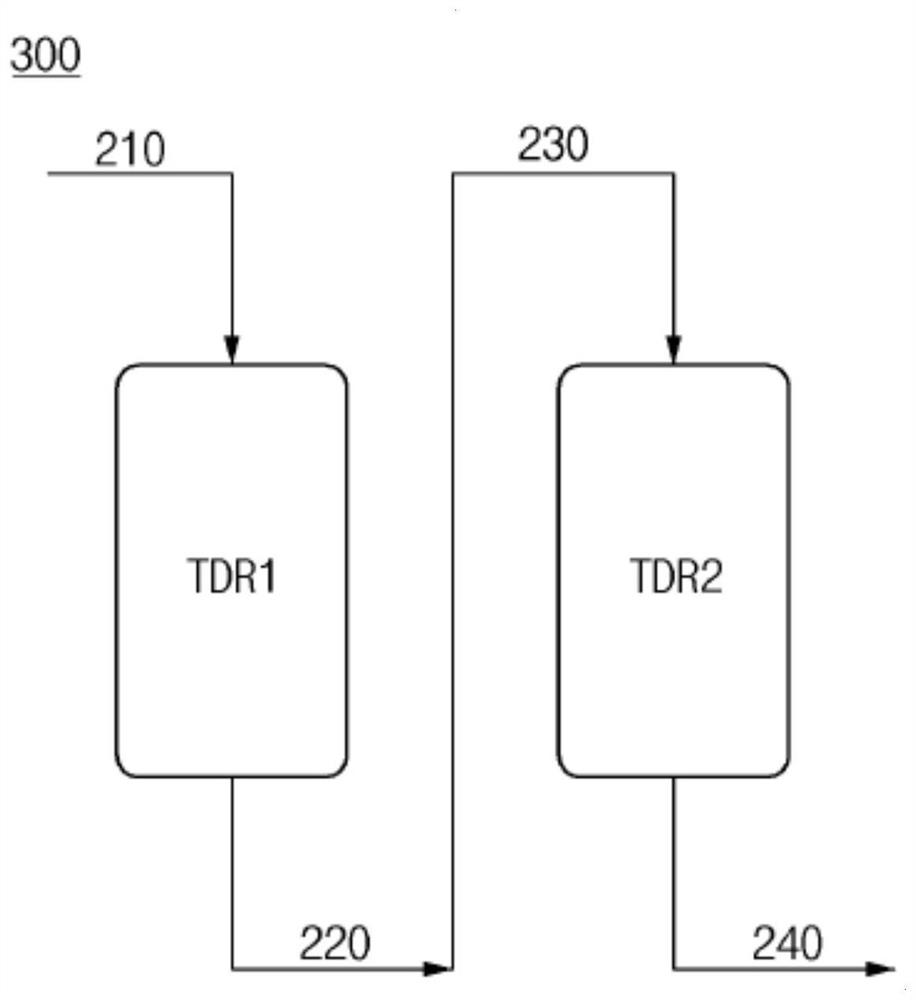

System for continuous production of conjugated diene-based polymer

ActiveCN113784994AImprove productivityImprove rolling resistance performanceRolling resistance optimizationPolymer scienceConjugated diene

The present invention relates to a system for continuous production of a conjugated diene-based polymer, which facilitates the adjustment of a polymerization conversion rate in the initial stage of polymerization and has superior productivity.

Owner:LG CHEM LTD

A kind of synthetic method of fluorine-containing acrylate copolymer

ActiveCN106947016BHigh purityImprove hydrophobicity and oleophobicitySynthesis methodsMethylmethacrylates

The invention discloses a fluorine-containing acrylate copolymer synthesis method. The fluorine-containing acrylate copolymer synthesis method comprises the following steps of: obtaining mixed monomer miniemulsion of (perfluorooctyl) ethyl acrylate, n-butyl methacrylate and methylmethacrylate by taking methacryloyloxyethyl trimethyl ammonium chloride (DMC) as a cation emulsifying agent and cetane as co-stabilizer according to a mini-emulsification technology, and carrying out miniemulsion copolymerization under the initiation action of AIBN (2,2-azobisisobutyronitrile) to obtain miniemulsion of a fluorine-containing acrylate copolymer. The fluorine-containing acrylate copolymer has the beneficial effects that the fluorine-containing acrylate copolymer has a relatively high fluorine-containing monomer conversion rate; the cost is reduced; the utilization rate of a fluorine-containing monomer is effectively increased; and after polymerization is ended, an emulsifying agent can be removed by a simple and convenient demulsification precipitation method to obtain the fluorine-containing copolymer product with the relatively high purity, so that the copolymer has relatively good water and oil repellency and antifouling property.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

Synthesis method of acrylonitrile and chloroethylene copolymer

InactiveCN1911974BHigh molecular weightHigh monomer conversion rateWet spinning methodsMonocomponent synthetic polymer artificial filamentEmulsionAcrylonitrile

The synthesis process of acrylonitrile-vinyl chloride copolymer relates to the preparation of no-additive fireproof acrylon resin. The synthesis process of acrylonitrile-vinyl chloride copolymer includes throwing vinyl chloride monomer into reaction kettle, throwing the solution compounded with sodium dodecyl sulfate, OP-10, initiator, anhydrous sodium acetate, glacial acetic acid and EDTA into reaction kettle, heating to 30-60 deg.c, adding solution compounded with acrylonitrile monomer, initiator, sodium dodecyl sulfate and water with two metering pumps, so as to react until the pressure islowered to 0.2 MPa; discharging to obtain white emulsion; demulsifying the emulsion with saturated sodium chloride solution to obtain paste; water washing in a centrifuge, dewatering and drying to obtain fireproof acrylon resin. The copolymer product has raised stability and conversion rate.

Owner:余天石 +1

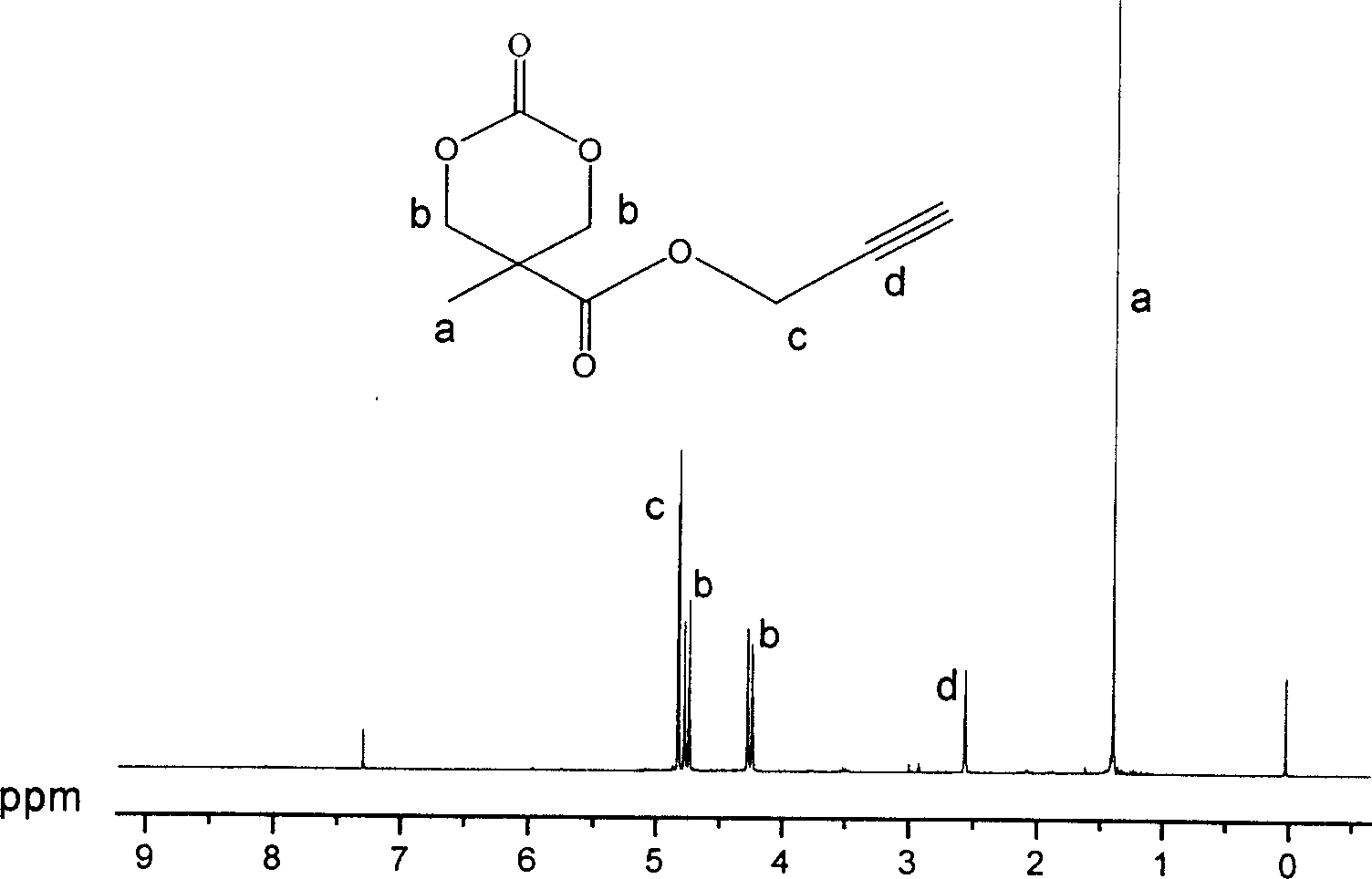

Synthesizing process and use of unsaturation cyclic aliphatic carbonate monomer

The invention relates to a cyclic aliphatic carbonate monomer with a triple bond side group, a preparation method and use thereof. 2-methyl-2-propargyl oxygen carbonyl trimethylene carbonate is synthesized from 2,2-dimethylolpropionic acid. The monomer can be used for ring-opening polymerization or ring-opening copolymerization with aliphatic cyclic ester monomer to obtain the aliphatic polycarbonate with triple bond side group or the copolymers of aliphatic polyester-carbonic ester. The polymers have advantages of the aliphatic polyester and carbonic ester, can be biodegradated. The degradation product is non-toxic. The polymers can be used for biomedical material.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Method for making methyl methacrylate polymer

The application provides a method for preparing a methyl methacrylate polymer. The production method comprises: intermittently adding polymerization material liquid into a reactor to carry out intermittent polymerization reaction. The polymerization feed liquid comprises the first polymerized monomer and the first initiator; the mixture of the polymerized monomer feed liquid and the initiator feed liquid is continuously added to the reactor to carry out continuous polymerization reaction to obtain methyl methacrylate polymer, and the polymerization unit The bulk feed liquid includes the second polymerized monomer, and the initiator feed liquid includes the third polymerized monomer and the second initiator. This production method can realize the stable operation of bulk polymerization. At a relatively low polymerization temperature, a relatively small amount of initiator is used to obtain a relatively high polymerization conversion rate of 45% to 75%, and the polymerization residence time is shortened to 120min to 120min. 150min, improve production efficiency, and then reduce the generation of dimers, so that the content of dimers in the polymer is below 1%, and high-purity polymers are obtained.

Owner:PETROCHINA CO LTD

A class of acetophenone-based photoinitiators with fluorene as a conjugated structure, preparation method and application thereof

InactiveCN105153329BThe synthesis steps are simpleEasy to purifyOrganic chemistryOrganic compound preparationCationic polymerizationKetone

Owner:TONGJI UNIV

Vinyl chloride-based polymer, method for preparing the same, and thermoplastic resin composition containing the same

The present invention relates to a vinyl chloride-based polymer containing an unsaturated fatty acid ester at a specific ratio, a method for preparing the same, a thermoplastic resin composition containing the same, and a thermoplastic resin molded article produced from the composition. The vinyl chloride-based polymer may have good processability, and thus, the thermoplastic resin molded article produced from the thermoplastic resin composition containing the vinyl chloride-based polymer may have high impact strength and improved appearance characteristics.

Owner:LG CHEM LTD

Preparation method of aromatic vinyl-unsaturated nitrile copolymer and prepared aromatic vinyl-unsaturated nitrile copolymer

The present invention provides a method of preparing an aromatic vinyl-unsaturated nitrile-based copolymer in which, when an aromatic vinyl-unsaturated nitrile-based copolymer in which a content of a structural unit derived from unsaturated nitrile monomers in the copolymer is in the range of 22 to 30 wt% is prepared, oligomer content and unreacted monomer content are decreased, resulting in excellent heat resistance, significantly improved surface quality, and particularly, reduced generation of residue on a product surface when used in a closed high temperature environment and reduced occurrence of mold deposits during injection molding, and an aromatic vinyl-unsaturated nitrile-based copolymer prepared using the method.

Owner:LG CHEM LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com