Preparation method of methyl methacrylate polymer

A technology of methyl methacrylate and a production method, which is applied in the chemical industry, can solve the problems of multiple dimers, and achieve the effects of reducing the generation of dimers, stabilizing performance, and shortening the residence time of polymerization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

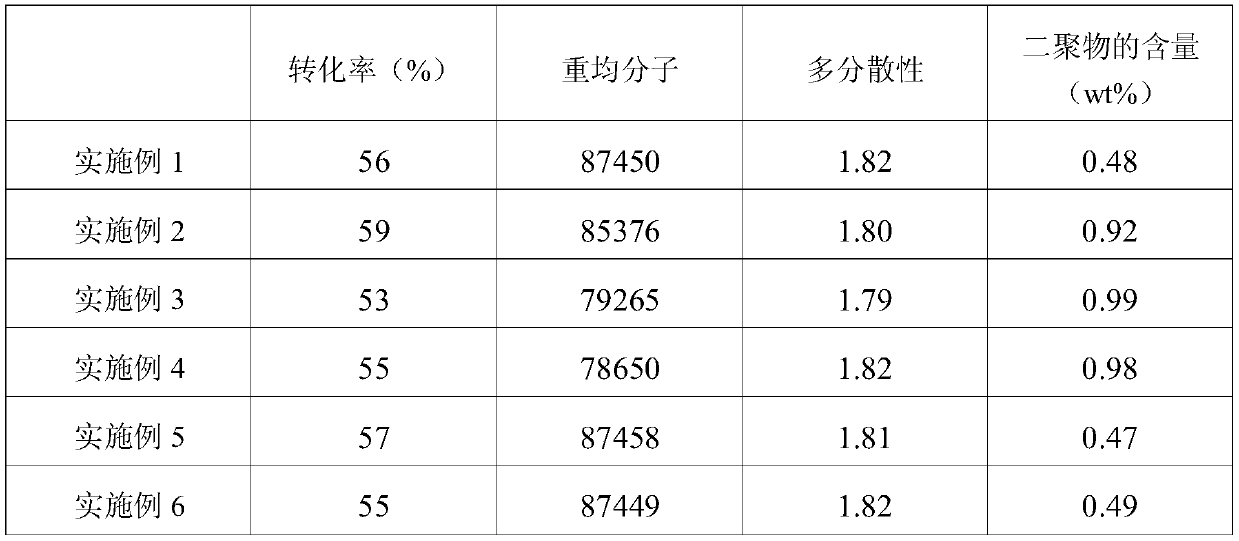

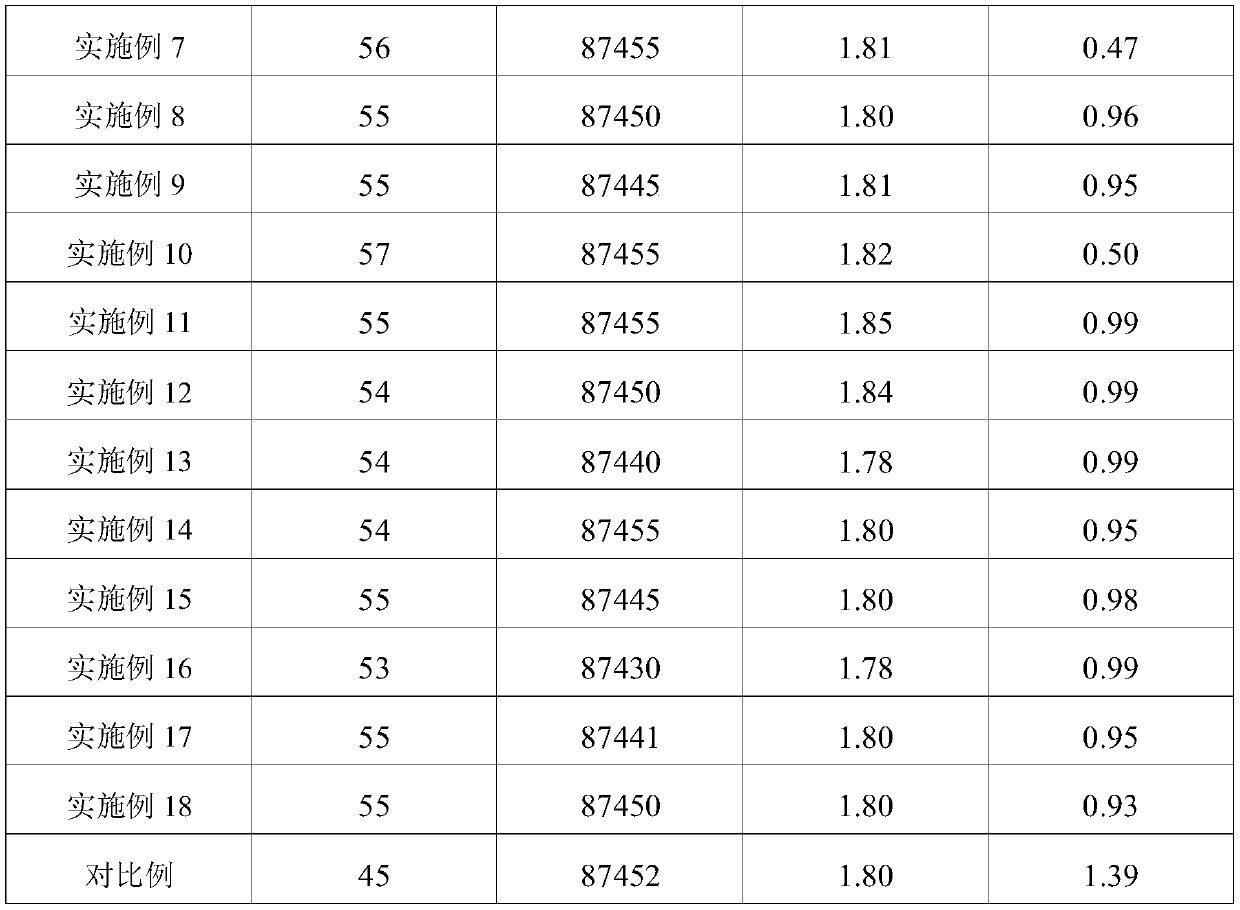

Examples

Embodiment 1

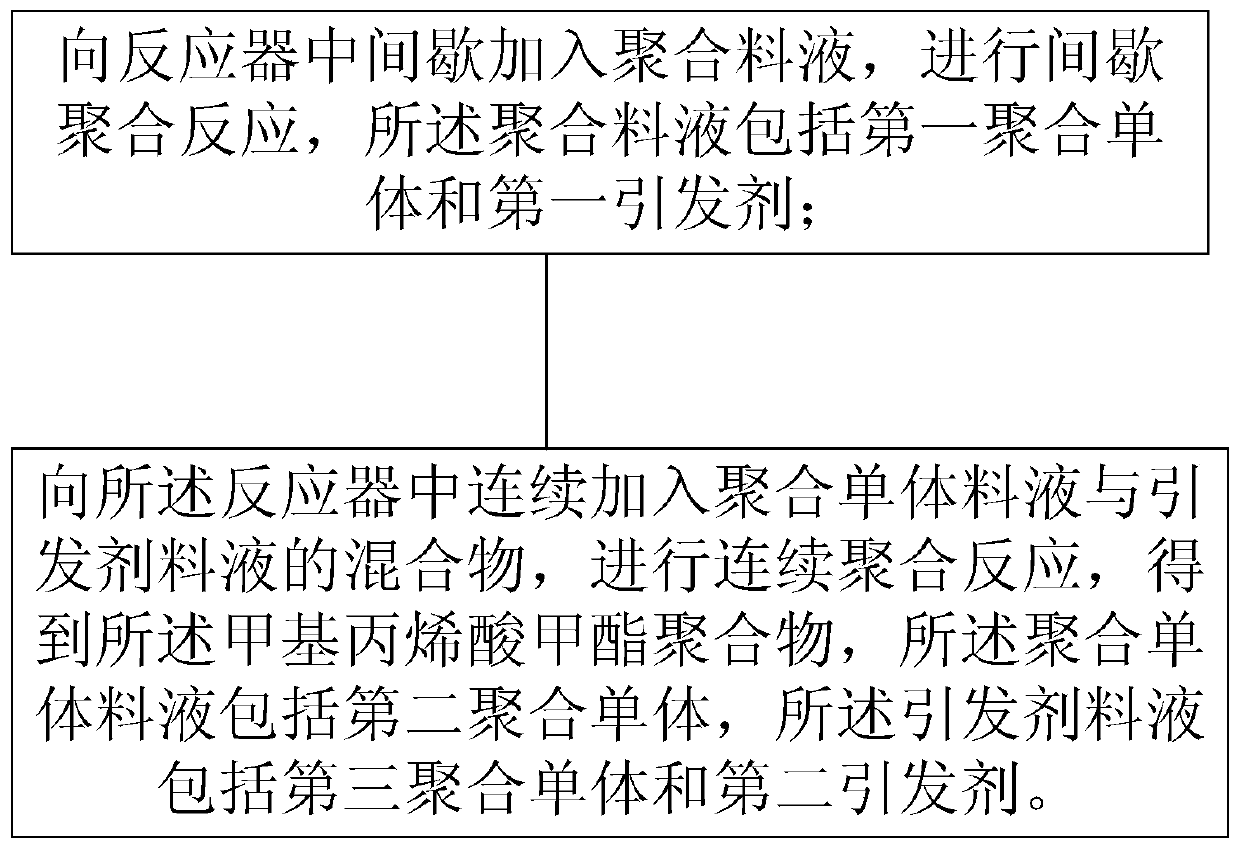

[0060] The preparation method of methyl methacrylate polymer specifically comprises:

[0061] First, the fully mixed reactor was purged with nitrogen.

[0062] Second, a gap reaction is performed.

[0063] Next, add to the reactor the polymerization liquid that comprises the first polymerized monomer, the first initiator and the first chain transfer agent, and the first polymerized monomer is 100 parts, specifically including 90 parts of the first main monomer and 10 parts of the first comonomer, wherein the first main monomer is ethyl methacrylate, and the first comonomer is methyl acrylate. The first initiator is tert-butyl peroxyacetate, and its weight part is 0.0025 part. The first chain transfer agent is 0.01 part, and is specifically n-butyl mercaptan.

[0064] The temperature in the reactor was controlled to 150° C., the pressure was controlled to 0.6 MPa, and batch polymerization was carried out.

[0065] Again, continuous polymerization was carried out.

[0066] ...

Embodiment 2

[0072] The difference from Example 1 is that the second initiator is 0.041 parts of 1,1-bis(tert-amylperoxy)cyclohexane, the feeding rate of the initiator liquid is 1.9g / min, and the polymerization temperature is 150°C. The pressure is 0.5 MPa, and during the continuous polymerization reaction, the average residence time of the controlled polymerization is 126 minutes.

Embodiment 3

[0074] The difference with Example 1 is: the second initiator is 0.042 parts of peroxy (2-ethylhexyl) tert-amyl carbonate, the feed rate of the initiator feed solution is 2.2g / min, and the polymerization temperature is 160°C, continuous During the polymerization reaction, the average residence time of the controlled polymerization was 120 min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com