System for continuous production of conjugated diene-based polymer

A conjugated diene, preparation system technology, applied in the direction of rolling resistance optimization, etc., to achieve the effect of improving polymerization conversion rate, high productivity, and excellent rolling resistance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

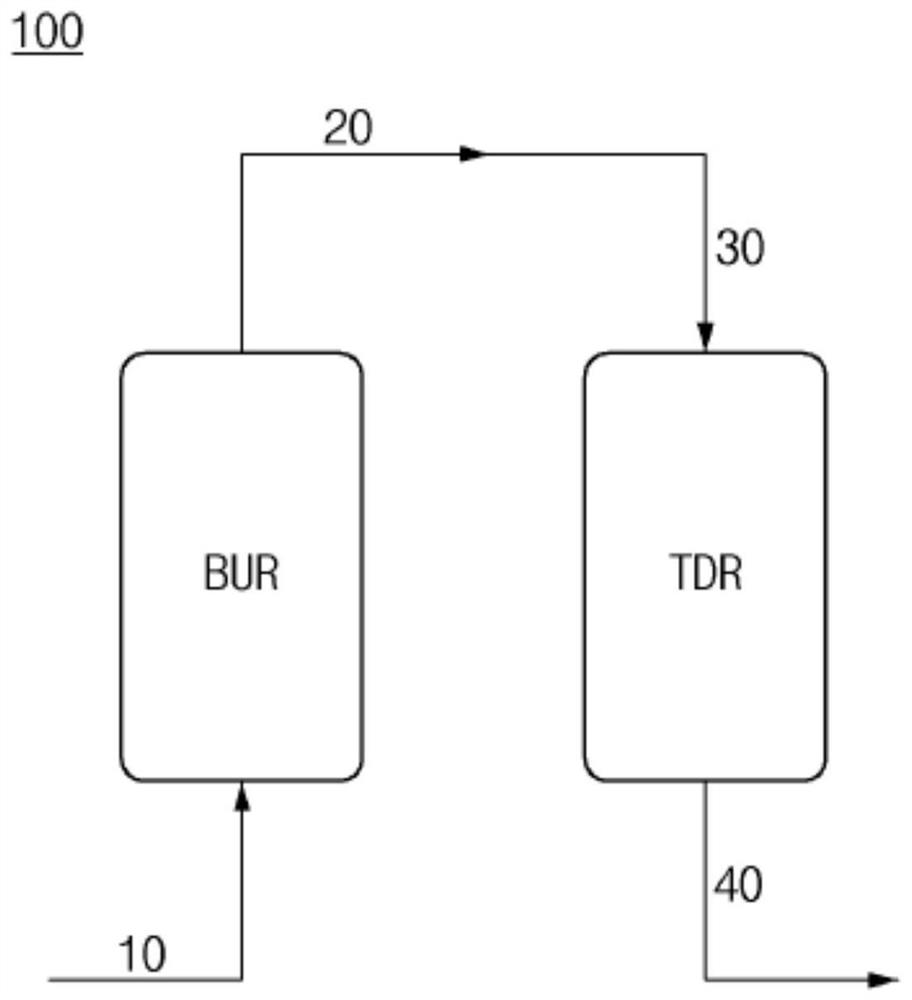

[0086] Such as figure 1 As shown, the polymer is produced continuously using a continuous production system (100) comprising one upflow reactor and one downflow reactor.

[0087] Specifically, a continuous polymerization reactor comprising an upflow reactor and a downflow reactor comprising a raw material supply line (10) at the bottom and a first polymer product discharge line (20) at the top was prepared. ) of an upflow reaction chamber (BUR) comprising a downflow reaction chamber with a first polymer product supply line (30) at the top and a second polymer product discharge line (40) at the bottom (TDR).

[0088] As a raw material, 4.7kg (1,3-butadiene content of 500g) of 1,3-butadiene / hexane mixed solution was injected into the upflow reaction chamber (BUR ), and the catalyst composition was injected into the upflow reaction chamber (BUR) at 200 g / hr through the feedstock supply line (10). In this case, diisobutylaluminum hydride (DIBAH) and diethylaluminum chloride (DE...

example 2

[0090] A 1,3-butadiene polymer was prepared in the same manner as in Example 1, except that, in Example 1, the polymerization reaction was performed until the polymerization conversion in the upflow reaction chamber reached 70%.

example 3

[0092] A 1,3-butadiene polymer was prepared in the same manner as in Example 1, except that, in Example 1, the polymerization reaction was performed until the polymerization conversion in the upflow reaction chamber reached 40%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com