Vinyl chloride-based polymer, preparation method therefor, and thermoplastic resin composition containing same

A technology of vinyl chloride and polymers, applied in the field of thermoplastic resin moldings, which can solve the problems of weak fisheye reduction effect and inability to significantly improve the transparency of molded products, and achieve excellent appearance characteristics, a small amount of fisheyes, and improve processing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] In addition, the invention provides a preparation method of vinyl chloride polymer.

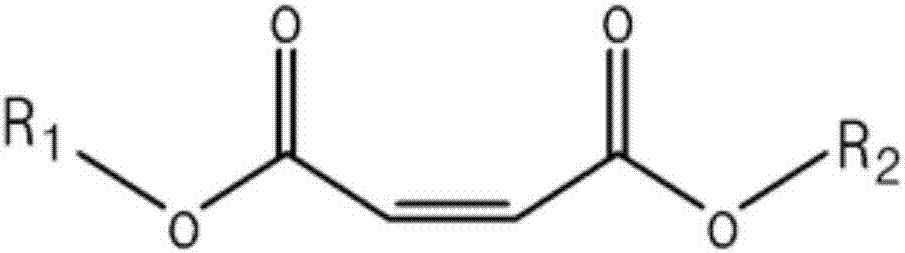

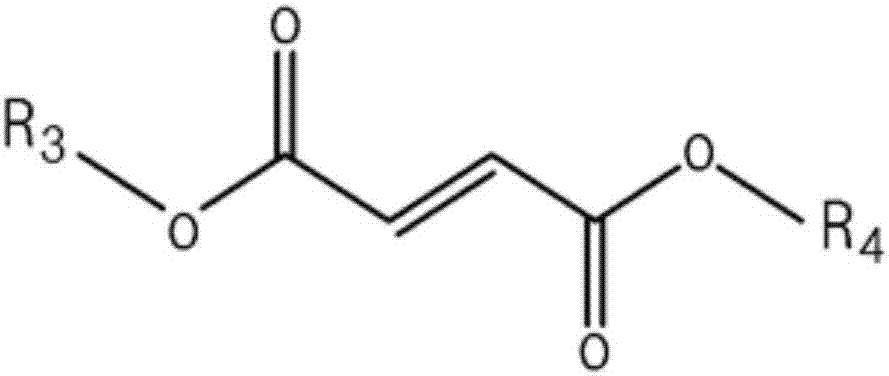

[0049] The preparation method of the vinyl chloride polymer according to one embodiment of the present invention comprises: in the presence of polymerization initiator and protective colloid auxiliary agent, in vinyl chloride monomer, add unsaturated fatty acid ester and carry out suspension polymerization (step A), wherein the unsaturated fatty acid ester is added at one time, continuously, or added in at least two stages within the range of the polymerization conversion rate of 85% or less.

[0050] Step A is a step of preparing a vinyl chloride-based polymer containing an unsaturated fatty acid ester in a specific ratio, which can be performed by adding an unsaturated fatty acid ester to a vinyl chloride-based monomer and polymerizing it.

[0051] In particular, Step A may be performed by adding an unsaturated fatty acid ester mixture to a polymerization reactor having a vinyl chlor...

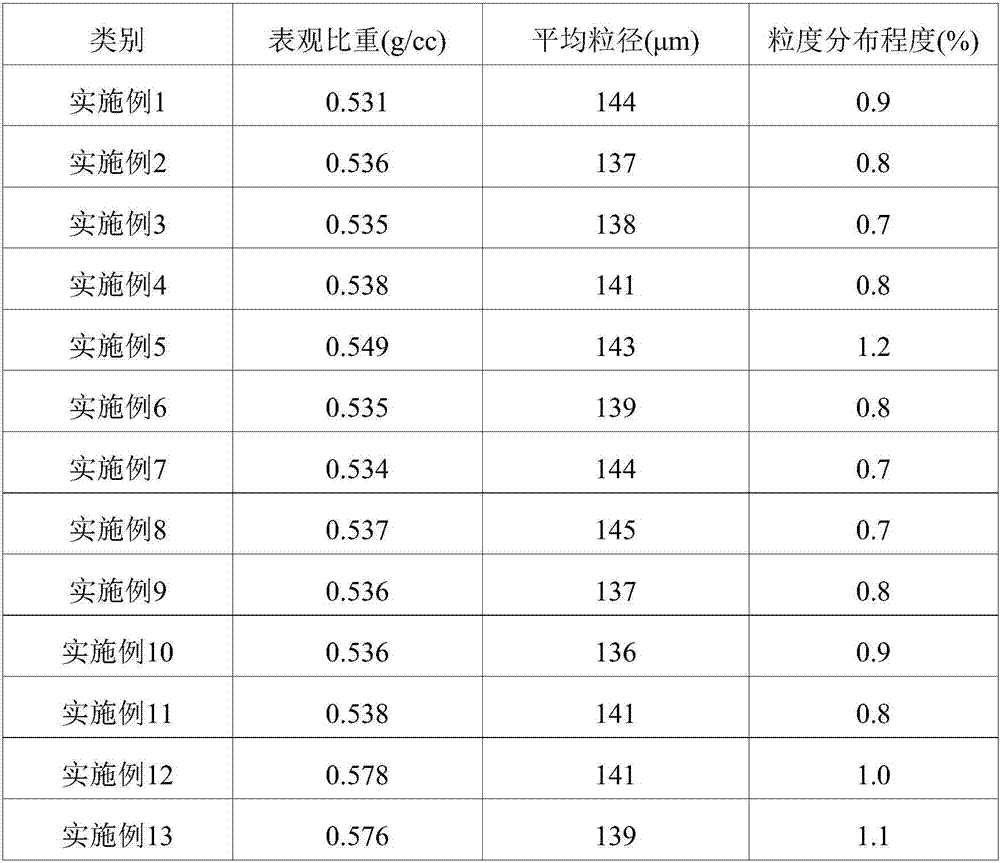

Embodiment 1

[0086] Add 390kg of deionized water to an internal volume of 1m 3 And be equipped with in the reactor of reflux condenser, the hydration degree of 150g is 80.5% polyvinyl alcohol, the hydration degree of 120g is the polyvinyl alcohol of 42.3% and the hydroxypropyl methylcellulose of 30g in the reactor , and to which 300kg of vinyl chloride monomer is added. Then, 60 g of di-2-ethylhexylperoxydicarbonate and 120 g of t-butylperoxyneodecanoate were added to initiate the reaction. Addition of bis(2-ethylhexyl) ester to the reactor was started when the polymerization conversion rate was 20%, and was terminated when the polymerization conversion rate was 35%. The added bis(2-ethylhexyl) ester was 3 g in total and was a mixture of bis(2-ethylhexyl) maleate and bis(2-ethylhexyl) fumarate in a weight ratio of 90:10. mixture. In order to achieve an average degree of polymerization of 1,000, the reaction temperature was maintained at 57 °C throughout the polymerization reaction, and ...

Embodiment 2

[0088] A vinyl chloride-based polymer was prepared by the same method as described in Example 1 except that the added amount of di(2-ethylhexyl) ester was increased to 1,500 g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com