Nylon-6 slice production method capable of improving polymerization conversion rate

A production method and conversion rate technology, which is applied in the field of spinning, can solve the problems of low polymerization conversion rate and unsuitability for large-scale production and use of enterprises, and achieve the effects of improving economic benefits, improving raw material utilization, and reducing pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

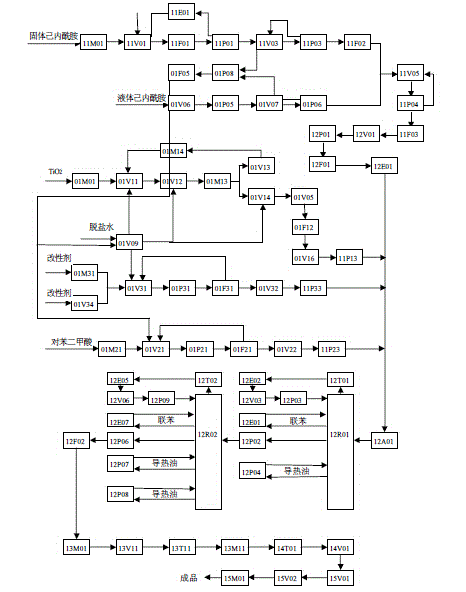

[0023] Embodiment 1, technological process such as figure 1 Shown:

[0024] (1) Raw material melting and storage

[0025] The purchased solid caprolactam raw materials are pulverized by 11M01 and put into the horizontal melting kettle 11V01, heated to melting by low-pressure steam in the kettle, filtered by 11F01 and sent to the melting caprolactam storage tank 11V03; the purchased liquid caprolactam raw materials are transported to the factory by tanker The caprolactam unloading pump 01P05 is sent into the liquid caprolactam storage tank 01V07. The two are compounded according to a certain ratio, and after being finely filtered by 11F03, they are sent to the monomer high tank 12V01 for polymerization.

[0026] (2) Additive preparation

[0027] Matting agent preparation:

[0028] The present invention adopts the titanium dioxide suspension as the matting agent, and its preparation is divided into two batchings: the first batching, the suspension in the crude titanium dioxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com