High-temperature-resistant polyacrylate composition and preparation method thereof

A technology of polyacrylate and acrylic esters, which is applied in the field of acrylic rubber and its preparation, can solve the problems of not significantly increasing the temperature of thermal weight loss, and achieve the effect of mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: The preparation method of the high temperature resistant polyacrylate composition of this embodiment:

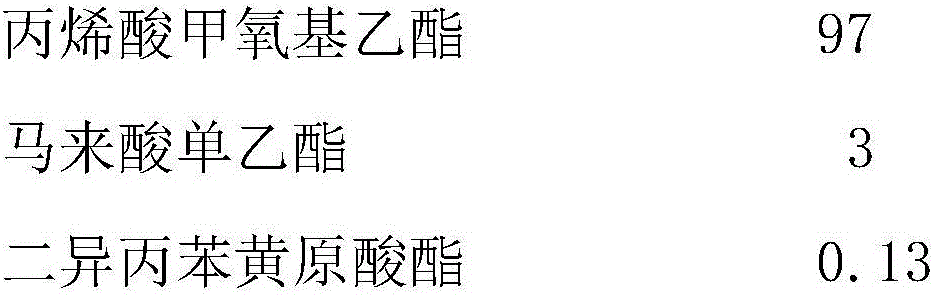

[0024] 1) formula comprises by weight:

[0025]

[0026]

[0027] 2) Dilute cumene hydroperoxide, sodium bisulfite, dilute hydrochloric acid and polyacrylamide with deionized water into a 1% solution for later use;

[0028] 3) Put methoxyethyl acrylate, monoethyl maleate, dicumyl xanthate, deionized water, disproportionated rosin soap, and sodium dodecylsulfonate into a stirring vessel, stir for 1 hour, and pass into nitrogen. Heat the container to 40°C, stop heating, put in cumene hydroperoxide and half a quantity of sodium bisulfite, the temperature of the emulsion system starts to rise, and the polymerization reaction starts. The polymerization time is about 1 hour, and the temperature rises to the highest point of 59°C. Add half an amount of sodium bisulfite and continue stirring for 1 hour. After the container is cooled to normal temperatur...

Embodiment 2

[0029] Embodiment 2: The preparation method of the high temperature resistant polyacrylate composition of this embodiment:

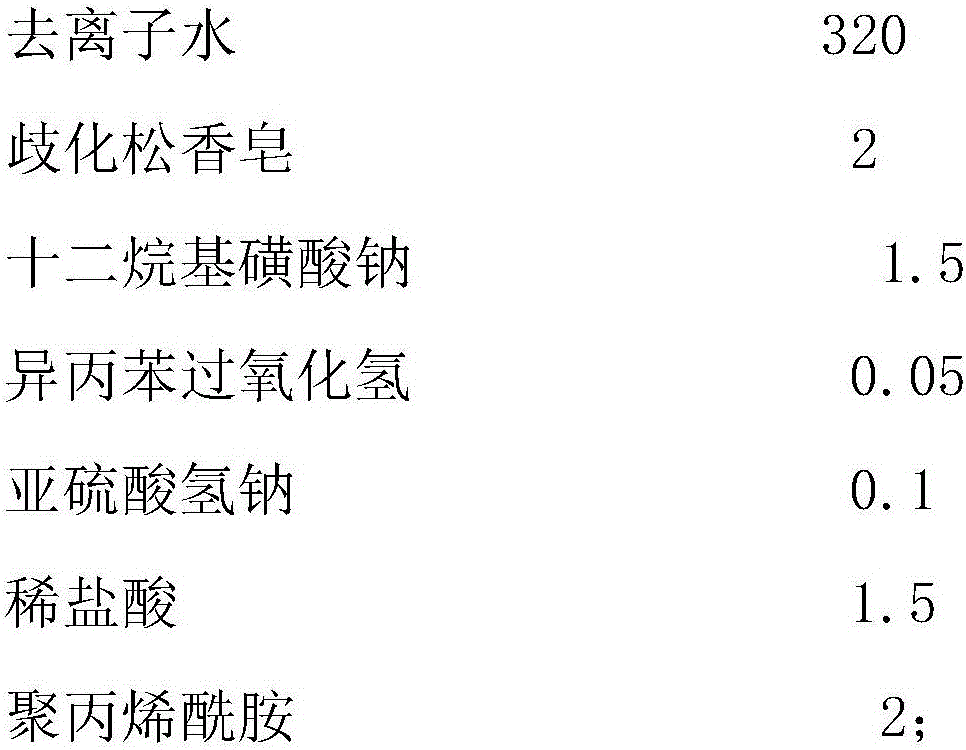

[0030] 1) formula comprises by weight:

[0031]

[0032] 2) Dilute azobisisobutyronitrile, ferrous sulfate, and calcium chloride with deionized water into a 1% solution for later use;

[0033] 3) Put methyl acrylate, monobutyl itaconate, n-dodecyl mercaptan, deionized water, and sodium lauryl sulfate into a stirring container, stir for 1 hour, and blow in nitrogen. Heat the container to 20°C, stop heating, add azobisisobutyronitrile and half of ferrous sulfate, the temperature of the emulsion system starts to rise, and the polymerization reaction starts. The polymerization time is about 1 hour, and the temperature rises to the highest point of 38.8°C. Add half a quantity of ferrous sulfate, and continue to stir for 1 hour. After the container is cooled to normal temperature, calcium chloride is added to precipitate white rubber particles, and the fi...

Embodiment 3

[0034] Embodiment 3: The preparation method of the high temperature resistant polyacrylate composition of this embodiment:

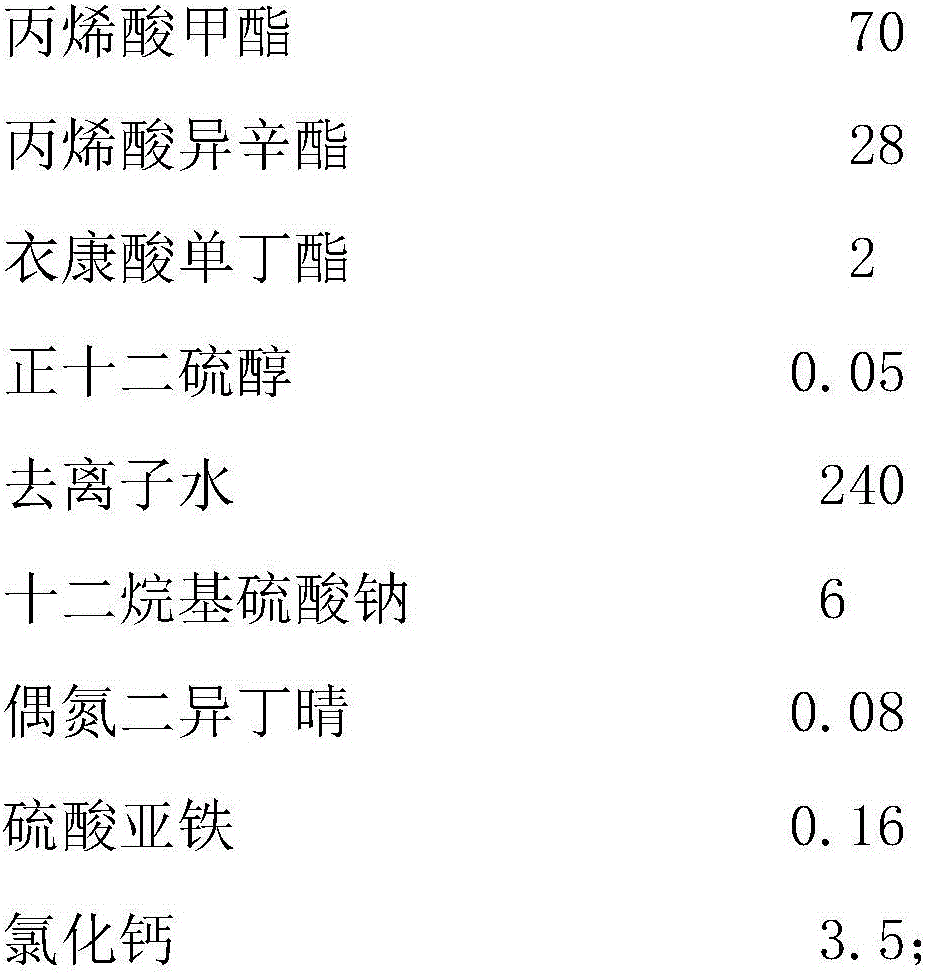

[0035] 1) formula comprises by weight:

[0036]

[0037] 2) Dilute ammonium persulfate, sodium sulfite, polyacrylamide, and sodium chloride into a 1% solution with deionized water for subsequent use;

[0038] 3) Put methyl acrylate, methacrylic acid, deionized water, and sodium lauryl sulfate into a stirring container, stir for 1 hour, and blow nitrogen gas. Heat the container to 30°C, stop heating, put in ammonium persulfate and half of sodium sulfite, the temperature of the emulsion system starts to rise, and the polymerization reaction starts. The polymerization time is about 1 hour, and the temperature rises to the highest point of 49.1°C. Throw in half an amount of sodium sulfite and continue stirring for 1 hour. After the container is cooled to normal temperature, sodium chloride and polyacrylamide are added to precipitate white rubber particl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com