Patents

Literature

100 results about "Monoethyl maleate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

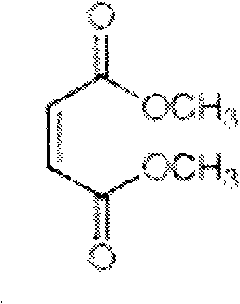

Dimethyl maleate is used in many organic syntheses as a dienophile for diene synthesis. It is used as an additive and intermediate for plastics, pigments, pharmaceuticals, and agricultural products. It is also an intermediate for the production of paints, adhesives, and copolymers.

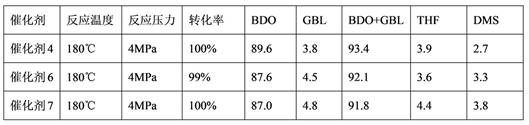

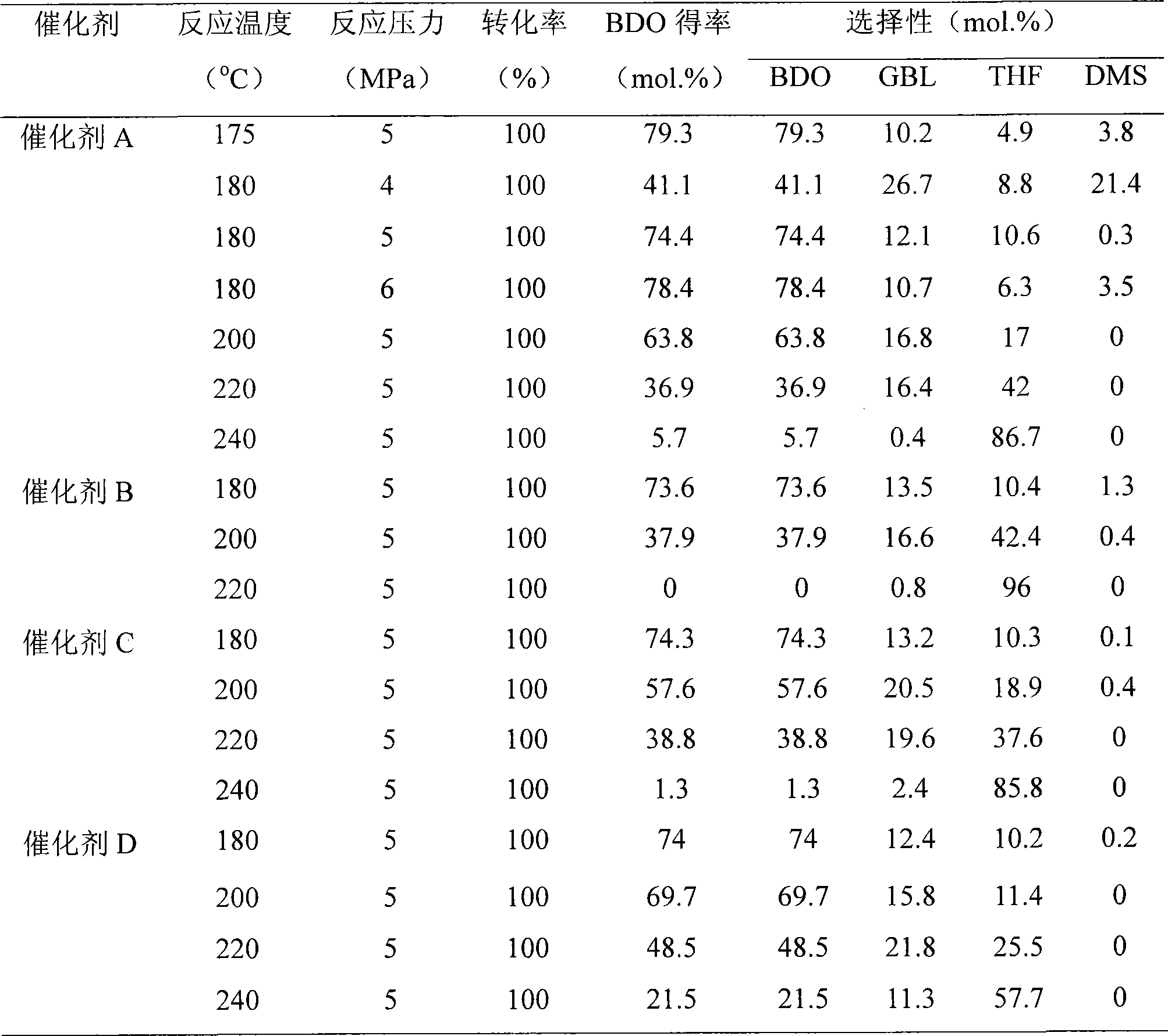

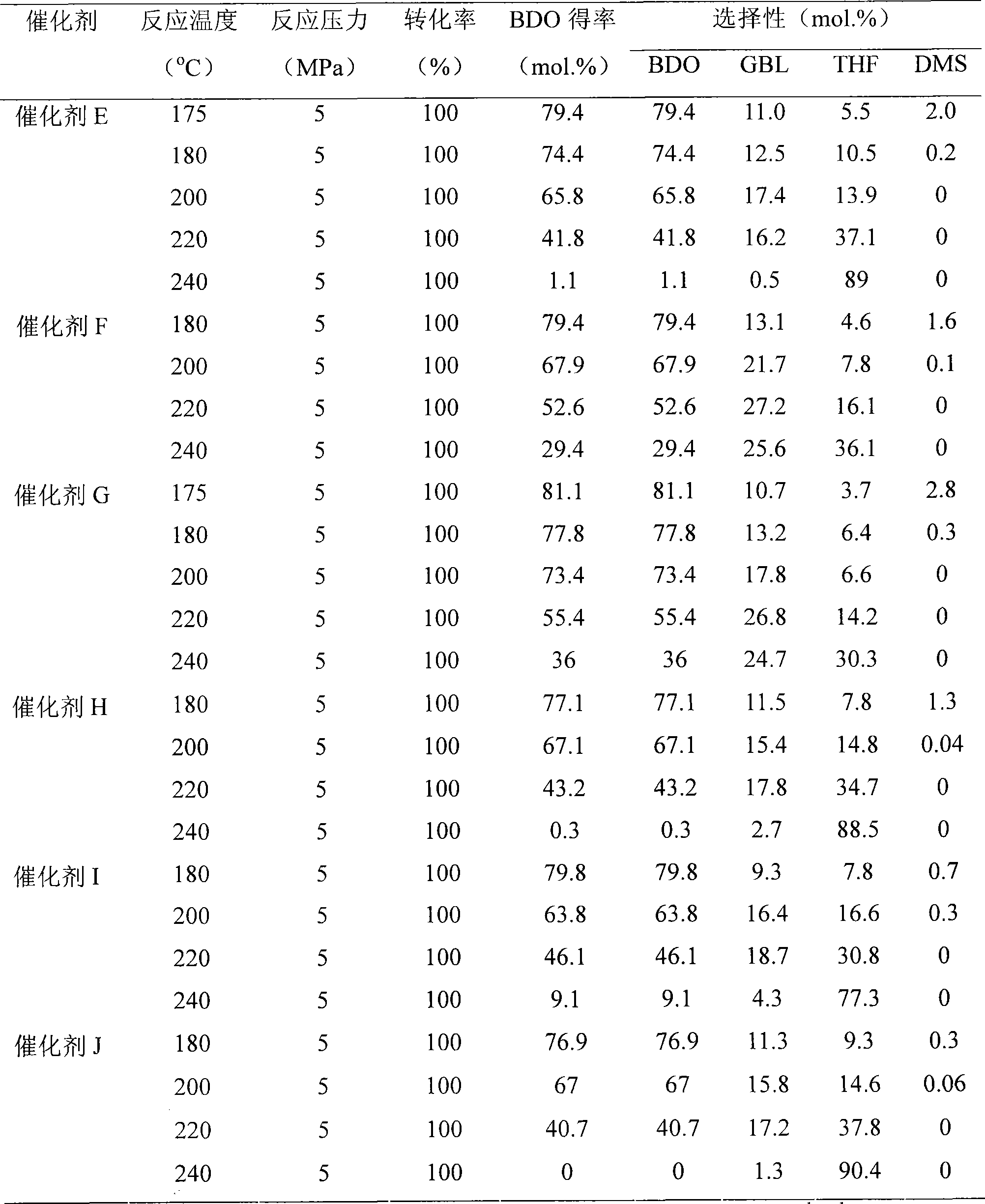

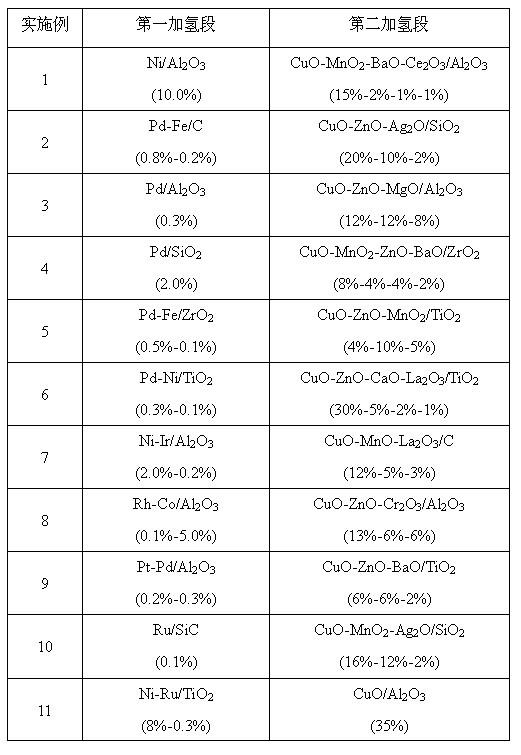

Catalyst for preparing 1,4-butanediol or tetrahydrofuran from selective hydrogenation of dimethyl maleate and preparation method thereof

ActiveCN101502803AHigh selectivitySolve filterabilityOrganic compound preparationHydroxy compound preparationMonoethyl maleateHydrogenation reaction

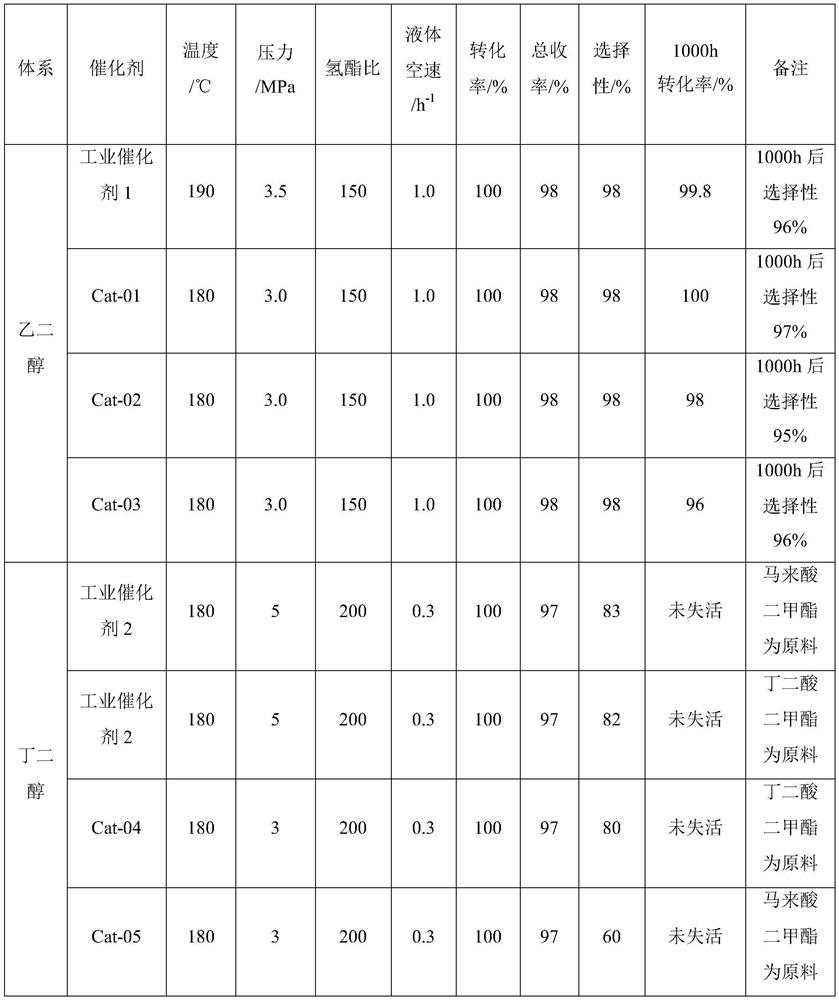

The invention belongs to the field of chemical technology, and in particular relates to a catalyst for preparing 1, 4-butanediol or tetrahydrofuran by selective hydrogenation of dimethyl maleate and a preparation method thereof. The catalyst consists of Cu, Zn, Al, M and O, and the mol content of each metal element is as follows: 30 to 60 percent of Cu, 10 to 50 percent of Zn, 5 to 20 percent of Al and 0 to 10 percent of M, wherein M is any one of Mn, Mg and Cr. The preparation method for the catalyst comprises precipitation, ageing, washing, drying and baking of a catalyst precursor, and reduction activation before use. The catalyst is applied to the hydrogenation reaction of the dimethyl maleate, and the yield of the 1, 4-butanediol at a reaction temperature of 180 DEG C is 73.6 percent; and the yield of the tetrahydrofuran is 96 percent at a reaction temperature of 220 DEG C. Product composition of the catalyst can be well adjusted by changing the reaction condition to adapt to different market demands, and the catalyst has extremely high industrial application value.

Owner:FUDAN UNIV +1

Method for preparing dimethyl succinate

ActiveCN102070448ASimple separation processImprove responseOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystSolid acid

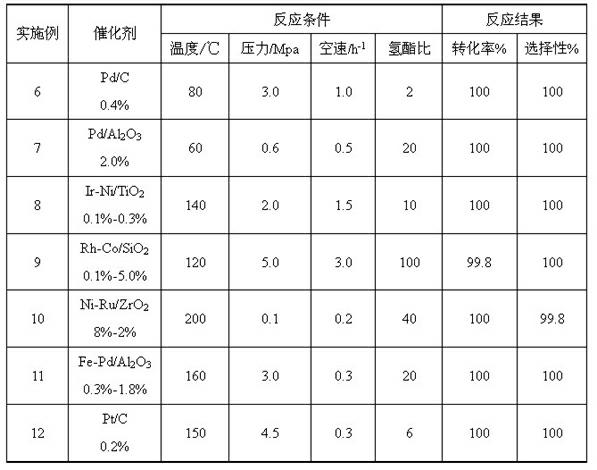

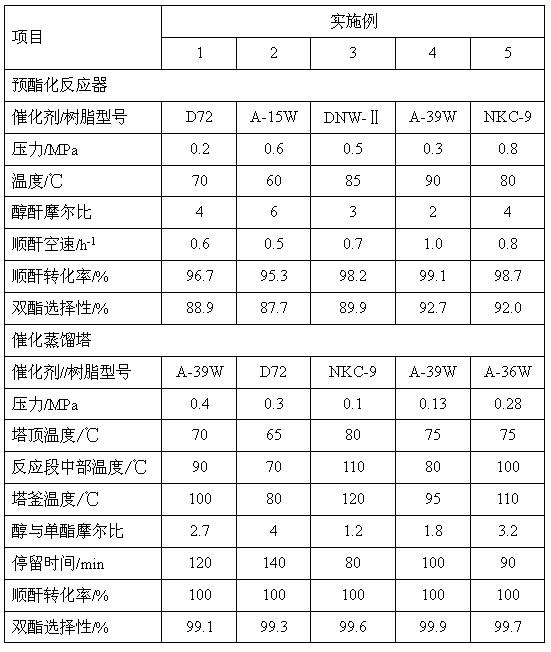

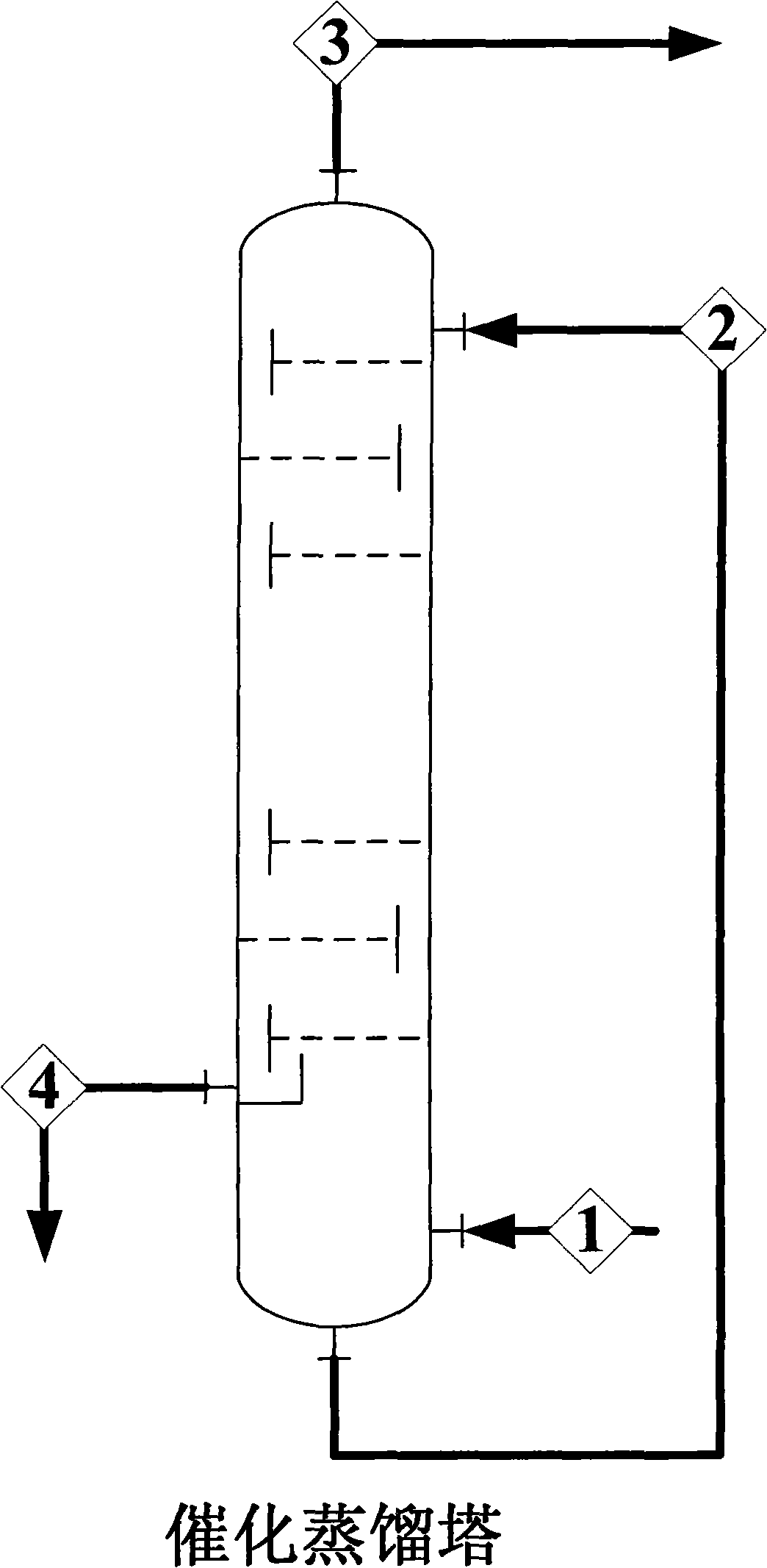

The invention discloses a method for preparing dimethyl succinate. The method comprises two reaction processes of esterification and hydrogenation and the reaction processes are as follows: (1) after pre-esterification reaction, maleic anhydride-methanol solution enters a catalytic distillation tower from the upper rectifying section of the tower, methanol enters the tower from the lower stripping section of the catalytic distillation tower, the reaction section is filled with solid acid catalyst, the two material flows perform countercurrent contact on the surface of the catalyst to perform esterification reaction and synthetize dimethyl maleate; and (2) dimethyl maleate and hydrogen are placed in a fixed bed reactor to perform hydrogenation reaction and generate the dimethyl succinate product in the presence of hydrogenation catalyst under a certain reaction condition. The method of the invention has the advantages of high raw material conversion rate and good product selectivity; and the process flow is simple, the energy consumption is low, no pollution can be caused and the scale production of dimethyl succinate can be realized.

Owner:HUNAN CHANGLING PETROCHEM SCI & TECH DEV CO LTD

Method for preparing catalyst for preparing 1,4-cis-butanediol by dimethyl maleate hydrogenation

InactiveCN1935375AEasy to prepareSimple processMolecular sieve catalystsOrganic compound preparationMonoethyl maleateButanediol

The present invention belongs to the field of chemical engineering technology. It relates to a new catalyst for preparing 1,4-butanediol by utilizing hydrogenation of dimethyl maleate. Said invention uses mesopore molecular sieve MCM-41 as carrier and impregnates it with Cu salt solution to prepare catalyst precursor, then the precursor is calcined so as to obtain the invented Cu / MCM41 catalyst. Said catalyst has higher activity and higher 1,4-butanediol selectivity.

Owner:FUDAN UNIV

Preparation method of hydrogenation catalyst

ActiveCN103769158AOrganic compound preparationHydroxy compound preparation1,4-ButanediolMonoethyl maleate

The invention discloses a preparation method of a hydrogenation catalyst. The catalyst is a Cu-Al-Zn-M-O catalyst, wherein the M represents one or more components selected from: Ba, Mn, Mg, Ti, and Cr. The hydrogenation catalyst is prepared through a two-step parallel-flow precipitation method, namely subjecting a solution containing Cu, Al and a precipitant and a solution containing Cu, Zn, M, and a precipitant to a parallel-flow precipitation treatment under different conditions so as to obtain the hydrogenation catalyst. The hydrogenation catalyst is suitable for being used during the process of hydrogenation preparation of 1,4-butanediol from dimethyl maleate, and the reaction activity, reaction selectivity and stability of the catalyst are all improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation of maleic acid di-methyl ester

InactiveCN101314564AEfficient use ofThe process is compact and reasonableOrganic compound preparationCarboxylic acid esters preparationCatalytic distillationCounter current

The invention relates to an improved method for preparing dimethyl maleate through reaction of maleic anhydride and methanol. The method completes preparation of the dimethyl maleate in a single catalysis and distillation tower, namely the method comprises the following steps that: mono-esterification reaction is performed in a tower kettle of the catalysis and distillation tower, and reaction heat is used for directly generating methanol steam; and simultaneously, liquid-phase reaction products containing monomethyl maleate are added to the upper part of the catalysis and distillation tower through a pipeline and flow down and generate counter current contact with the gradually dried methanol steam which flows up to complete the reaction. According to the method, not only the esterification reaction heat can be effectively utilized but also heat exchange and mono-esterification reaction equipment in the prior art can be saved, thereby the flow is more compact and more reasonable.

Owner:SHANGHAI HUAYI ENERGY CHEM

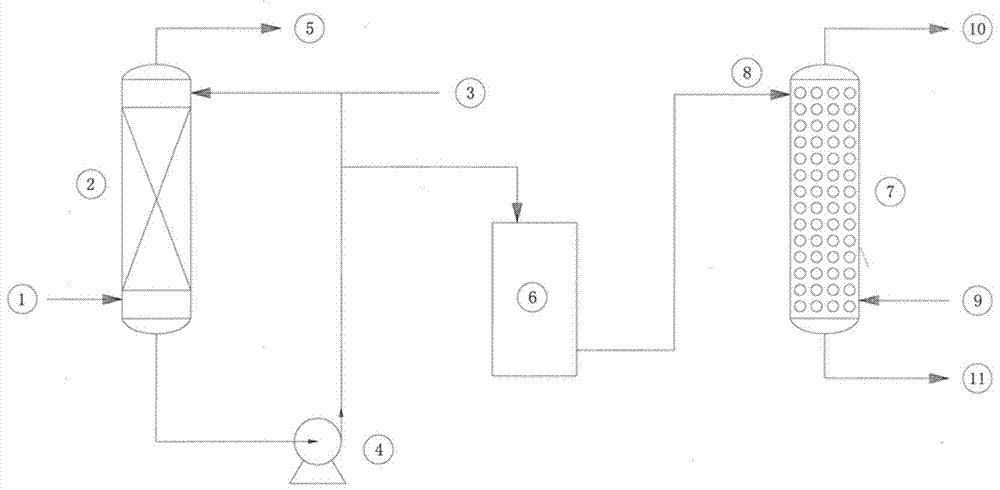

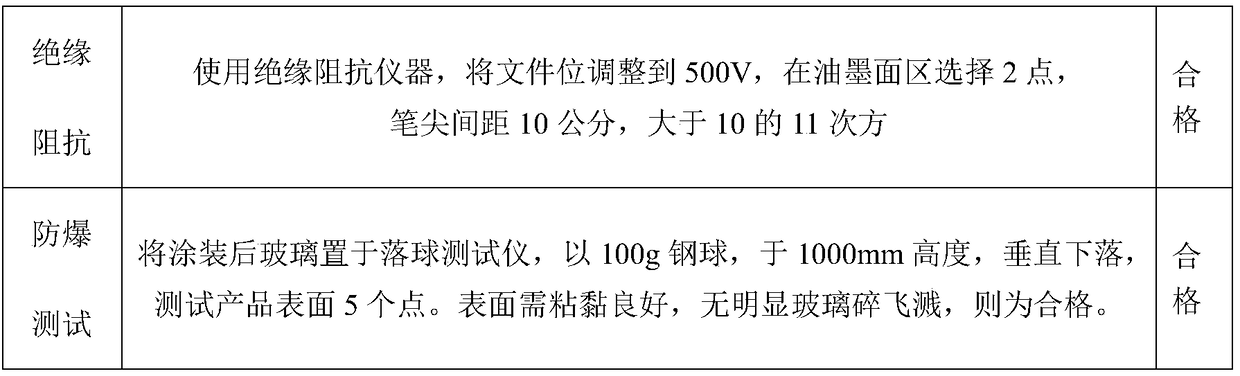

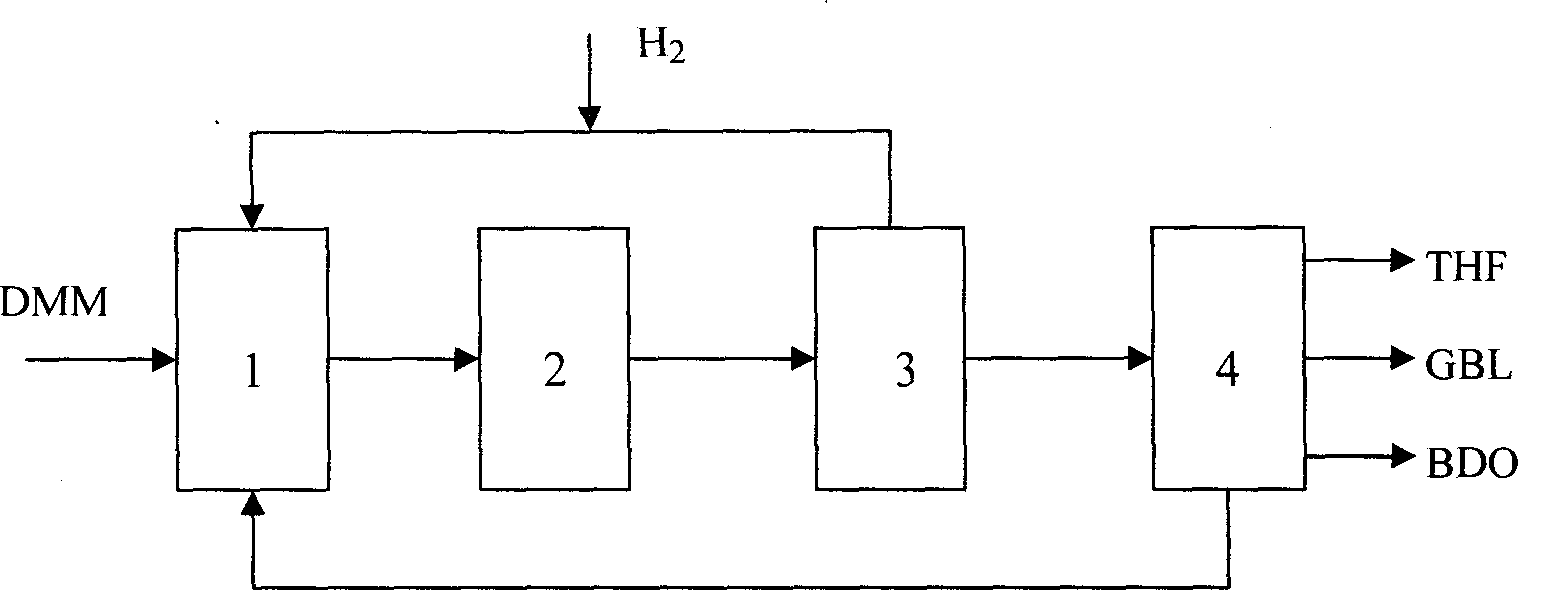

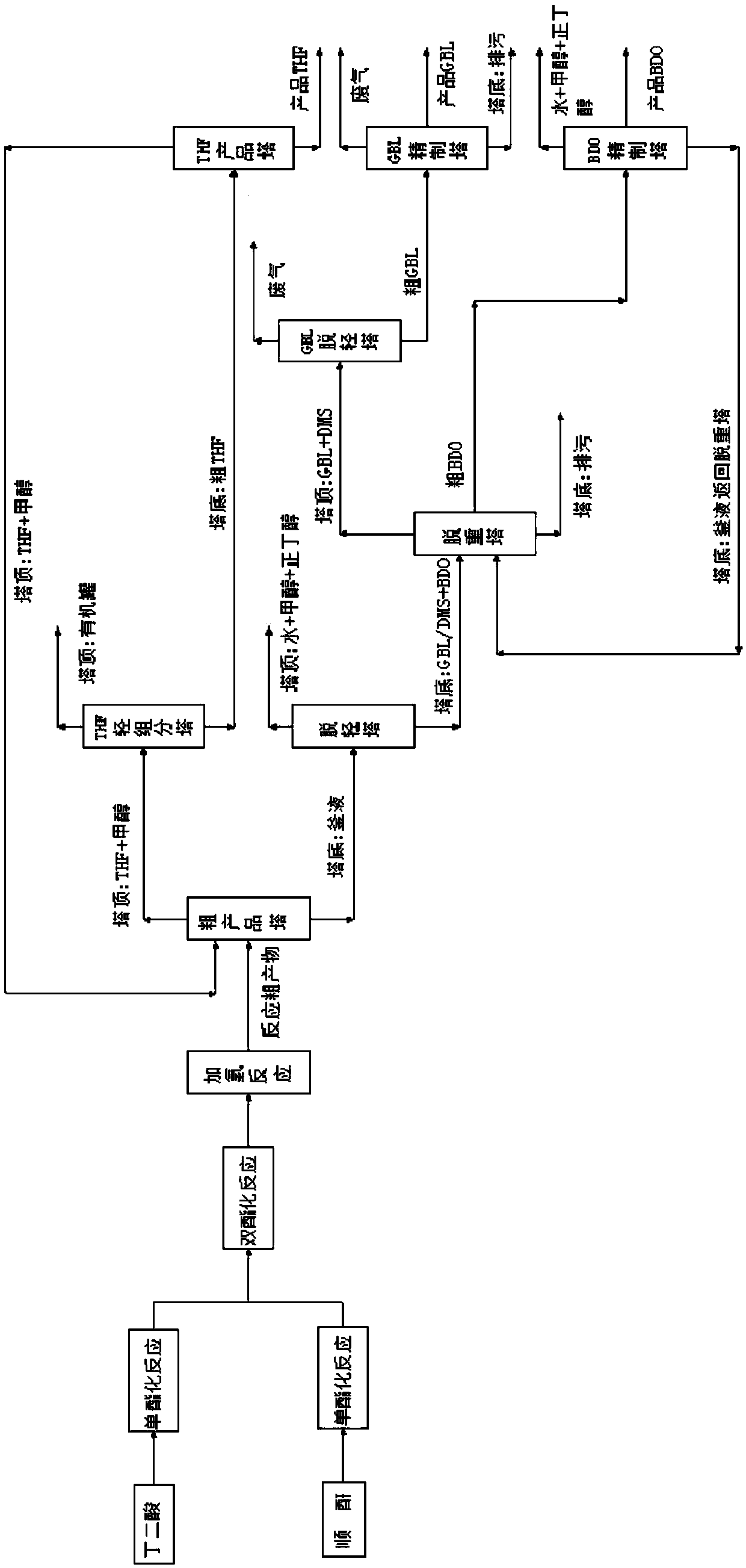

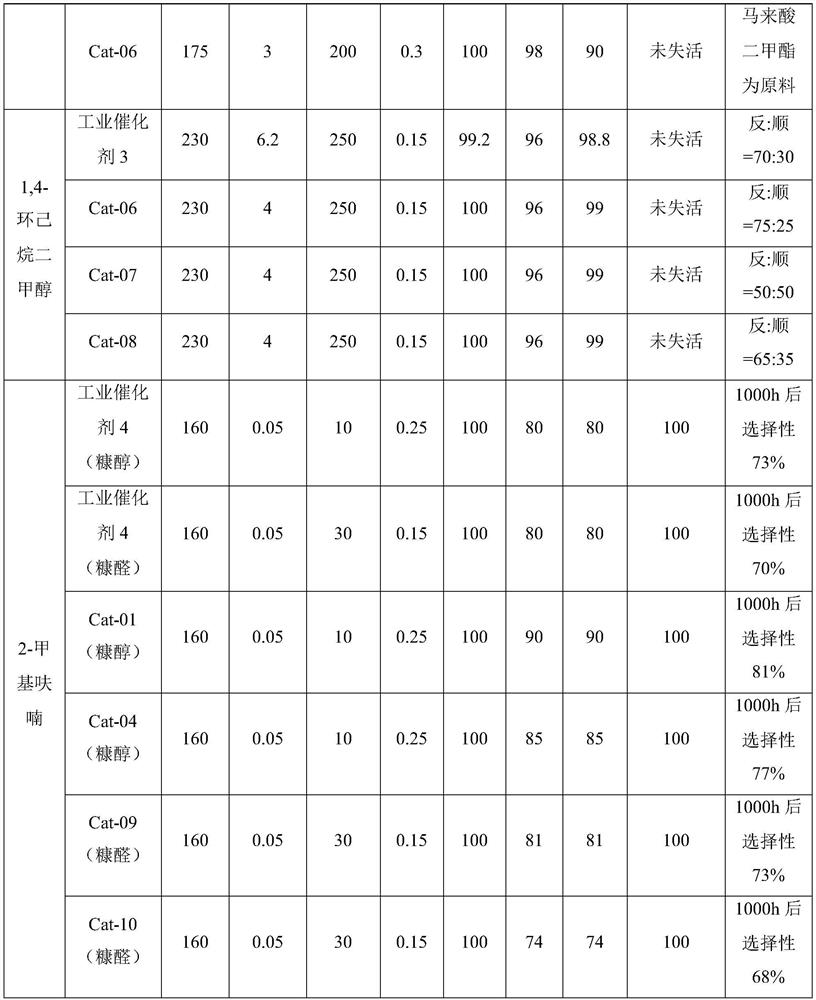

Method of simultaneously producing dimethyl succinate and 1,4-butyl glycol

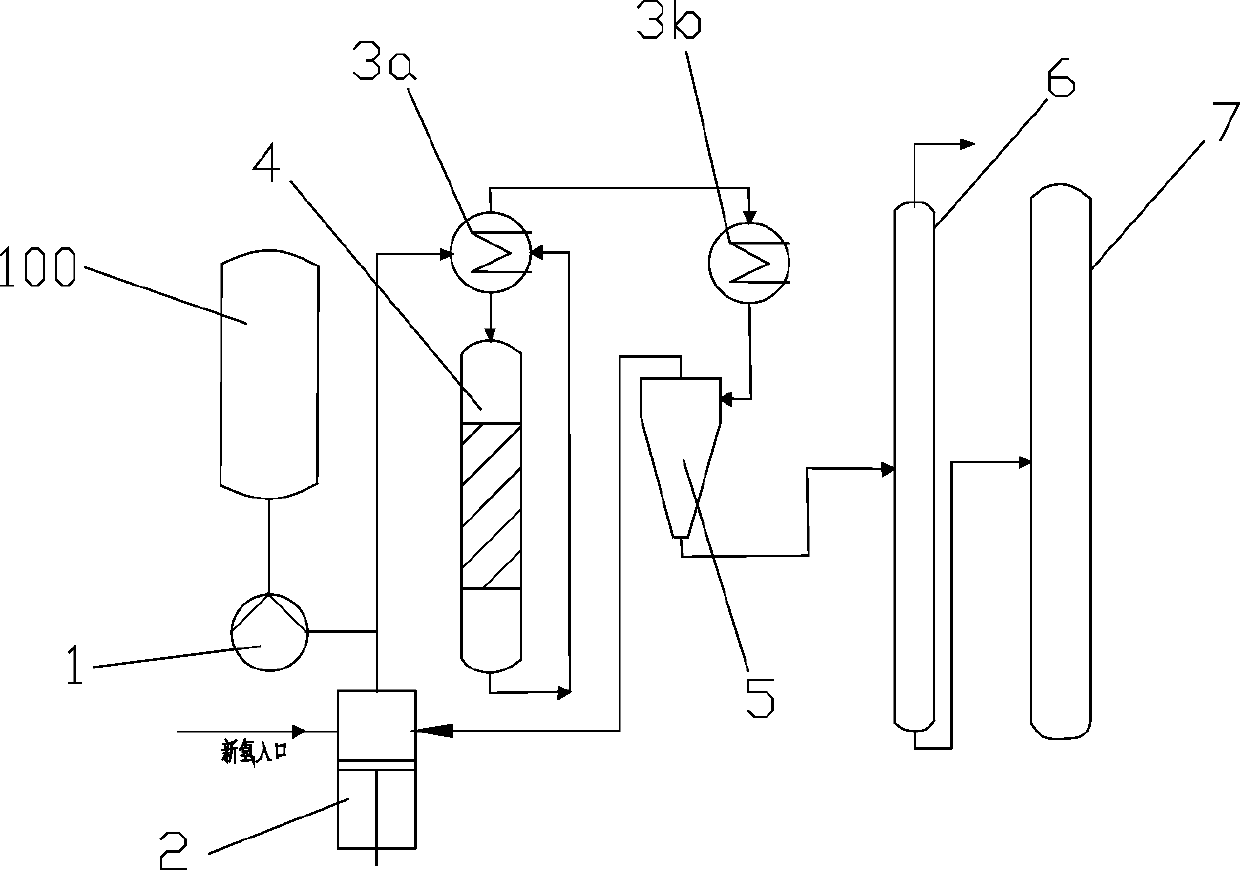

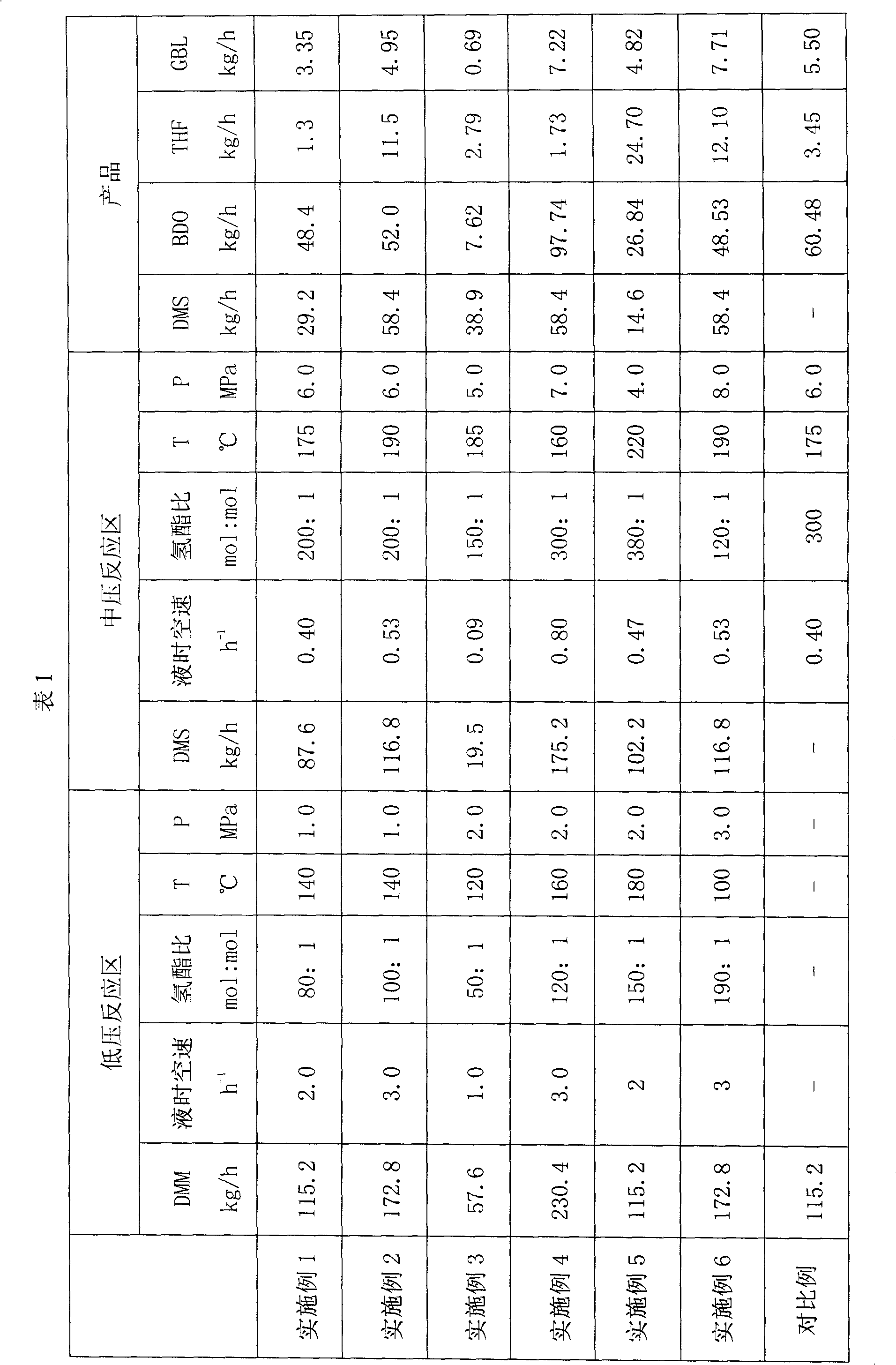

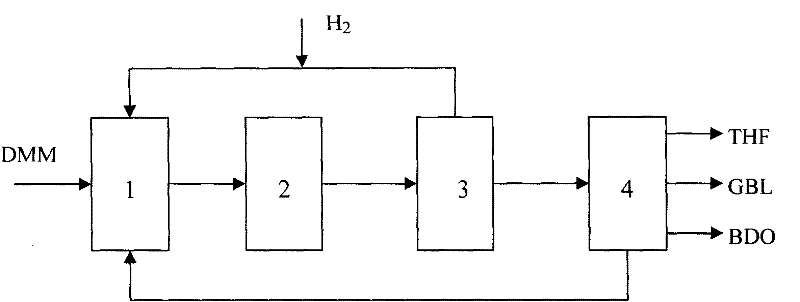

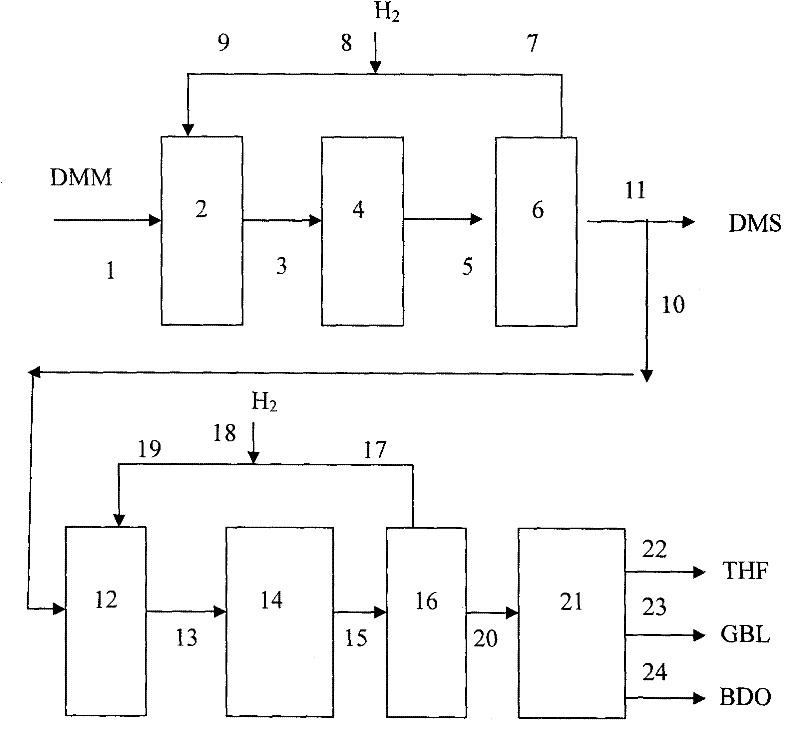

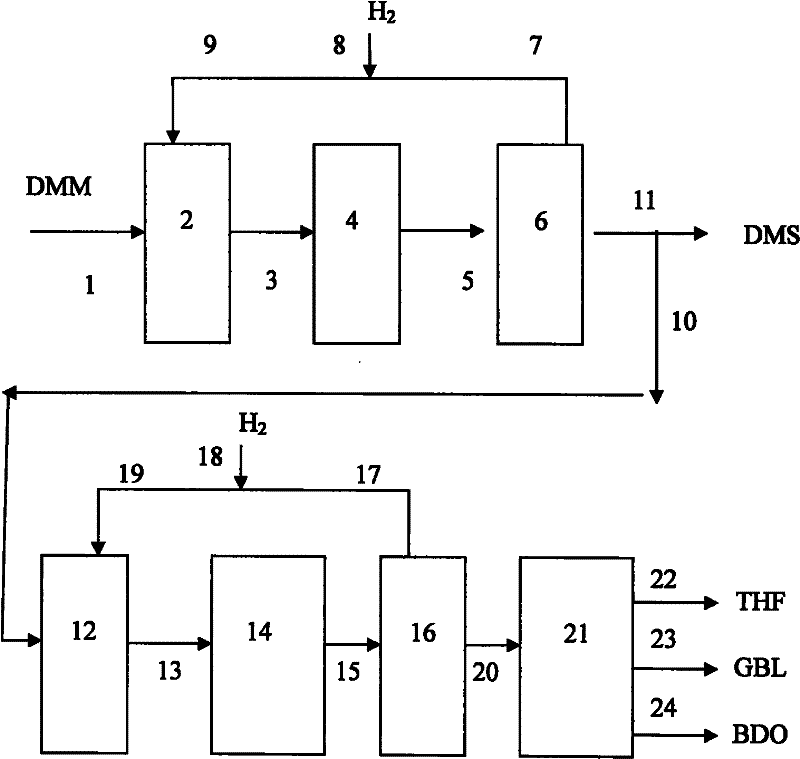

ActiveCN102190582AFlexible productionOvercome defectsOrganic compound preparationCarboxylic acid esters preparationFuranGas phase

The invention relates to a method of simultaneously producing dimethyl succinate (DMS) and 1, 4-butyl glycol. The method can also be used to simultaneously produce at least one of Tetrahydro furan (THF) and gamma-irradiation butyl lactone (GBL). In the invention, dimethyl maleate (DMM) is used as raw materials and contacts with hydrogen under the condition of gas phase in a low pressure reaction district and a middle pressure reaction district respectively. A low-pressure reactor and a middle-pressure reactor are equipped with a catalyst. DMS products are produced in the low pressure reaction district and 1, 4-butyl glycol products are produced in the middle pressure reaction district. Simultaneously, at least one of the GBL and THF can be produced in the middle pressure reaction district. Purity of DMS can reach over 99.5% without refining through using a gas-liquid separator. In the invention, the method is used in mild condition; heavier component does not need to be circulated; operation is simple; transesterification type polymerization and other side reactions are greatly reduced in a system.

Owner:SHANGHAI HUAYI ENERGY CHEM

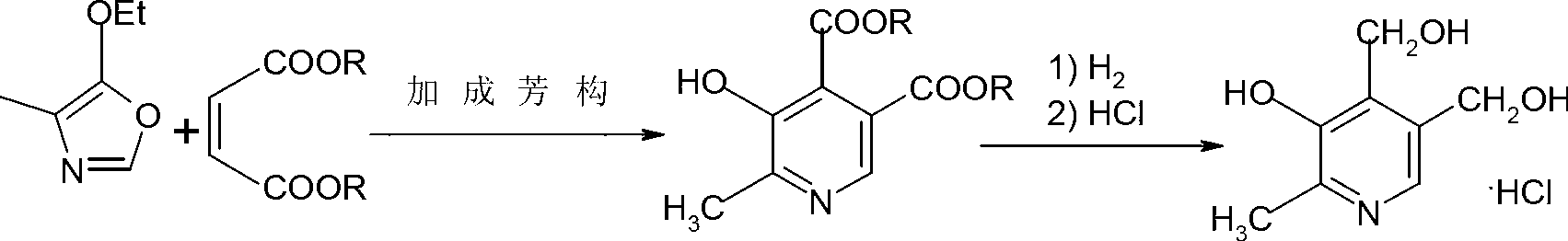

One-pot preparation method of vitamin B6

The invention relates to a new one-pot preparation method of vitamin B6. The method includes that 5-ethoxy-4-methyloxazole which is a key intermediate of vitamin B6 and dimethyl maleate or diethyl maleate are subjected to Diels-Alder addition reaction and aromatization to further form pyridine rings, and then the pyridine rings undergo hydrogenation to be catalytically reduced to vitamin B6. The one-pot method is adopted, so that the intermediates can directly react without separation. The period of technological processes is shortened, and the one-pot preparation method of vitamin B6 is simple in operation, environment-friendly and low in cost. Moreover, the selectivity, the yield and the purity of the product are high, and the method is more suitable for being used for large-scale industrial production.

Owner:XINFA PHARMA

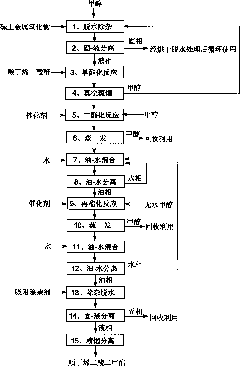

Method for preparing dimethyl maleate

ActiveCN101823962AThorough responseReduce generationOrganic compound preparationCarboxylic acid esters preparationEvaporationCis-Butenedioic Acid

The invention relates to a method for preparing dimethyl maleate, which comprises the following steps of : (1) dehydration and impurity removal: methanol is mixed with alkaline-earth metal oxide to be dehydrated and removed impurity; (2) separation of solid and liquid; (3) monoesterification reaction: maleic anhydride is added in liquid-phase material which is obtained in the previous step; (4) vacuum distillation; (5) two-esterification reaction: acid catalyst and methanol are added in the material after the vacuum distillation in the previous step; (6) evaporation; (7) mixing of oil and water; (8) separation of oil and water; (9) re-esterification reaction; (10) evaporation; (11) mixing of oil and water; (12) separation of oil and water; (13) impurity removal and dehydration; (14) separation of solid and liquid: liquid-phase material enters the next step; (15) rectification separation: the product dimethyl maleate is obtained. The method is simple and has reasonable process, low preparation cost, high product purity and good product quality.

Owner:河北彩客新材料科技股份有限公司

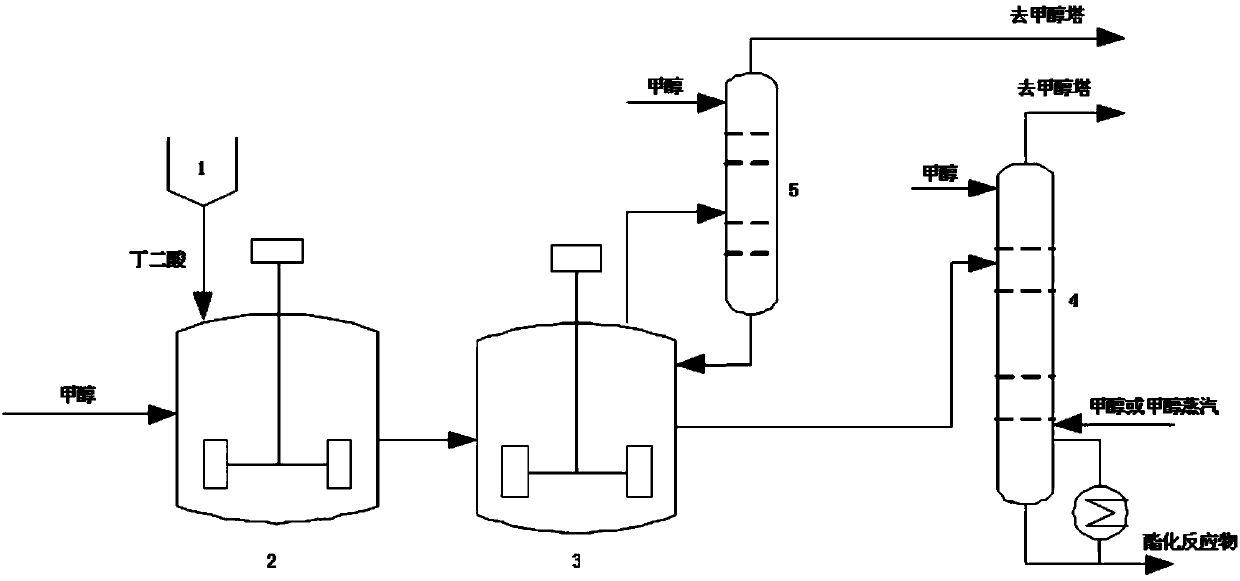

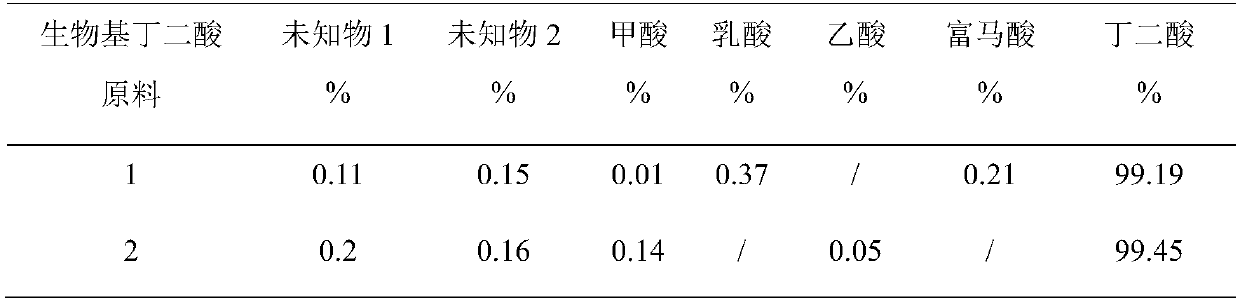

Continuous preparation method of 1,4-butanediol

ActiveCN111018669AAvoid mutual influence of co-monoesterificationAvoid interactionOrganic compound preparationCarboxylic acid esters preparationSuccinic acid monomethyl esterButanedioic acid

The invention discloses a continuous preparation method of 1,4-butanediol. The method comprises the following steps: carrying out a monoesterification reaction on bio-based succinic acid and methanolto obtain a succinic acid monoesterification liquid containing succinic acid monomethyl ester; mixing with monomethyl maleate to obtain a mixed esterification liquid; feeding into a double esterification reaction tower, and carrying out a double esterification reaction to generate a mixture of dimethyl succinate and dimethyl maleate; feeding the mixture into a hydrogenation reactor, and carrying out a hydrogenation reaction, wherein the the dimethyl maleate in the mixture is hydrogenated to generate dimethyl succinate; and performing a cascade reaction to convert into an intermediate product gamma-butyrolactone, and then generating 1,4-butanediol and tetrahydrofuran. According to the method, the bio-based succinic acid is adopted to partially replace monomethyl maleate to produce 1,4-butanediol, so that the consumption of petroleum chemicals is reduced, and the production cost of 1, 4-butanediol is reduced; and bio-based succinic acid and methanol are subjected to a monoesterificationreaction, and then mixing is performed with monomethyl maleate, so that the mutual influence caused by co-monoesterification of succinic acid and maleic anhydride is avoided.

Owner:CHINA PETROLEUM & CHEM CORP +1

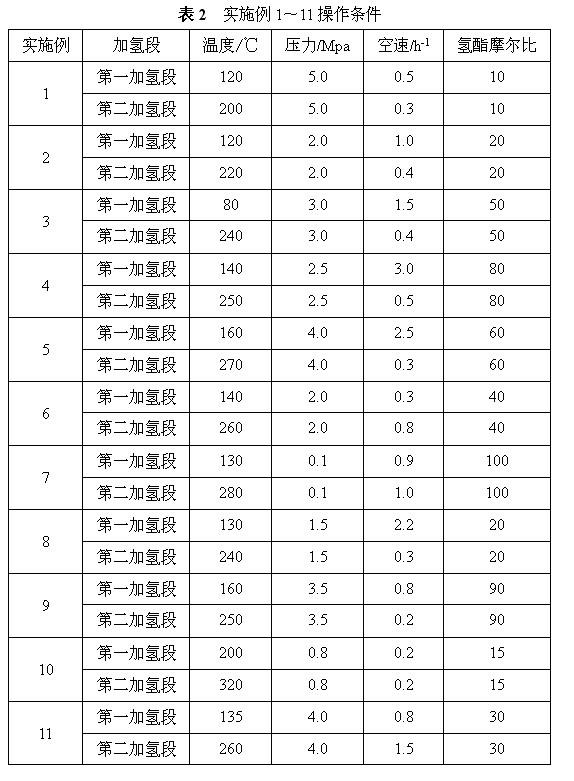

Method for producing tetrahydrofuran

ActiveCN101891714ASolve the problem of selectivityImprove stabilityOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsMonoethyl maleateHydrogenation process

The invention discloses a method for producing tetrahydrofuran by using dimethyl maleate as a raw material and adopting two sections of hydrogenation processes. In a first hydrogenation section, a supported hydrogenation catalyst taking VIII-group metals as active ingredients is adopted; and in a second hydrogenation section, a supported CuO catalyst is adopted. The method has the advantages of high catalytic reactivity, relatively higher catalyst stability, high tetrahydrofuran selectivity, low byproduct selectivity and the like; when continuously operated for not longer than 1,500 hours, the percent conversion of the raw material reaches 100 percent, the tetrahydrofuran selectivity reaches over 95 percent, and the selectivity of a byproduct normal butanol is below 4 percent.

Owner:HUNAN CHANGLING PETROCHEM SCI & TECH DEV CO LTD

Preparation method of copper hydrogenation catalyst

PendingCN113649021AHigh porositySize porosityOrganic compound preparationHydroxy compound preparationPtru catalystWarm water

The invention relates to a preparation method of a copper hydrogenation catalyst, which comprises the following steps: adding a mixed salt solution of soluble copper salt and other metal soluble salts into an alkali solution to prepare corresponding hydroxide precipitate, filtering, washing with water, uniformly mixing with a sodium hydroxide solid phase, adding warm water and aluminum powder paste into the mixed material, and uniformly stirring, and maintaining for a certain time at a certain temperature, then transferring into a still kettle for treatment, then replacing sodium ions in the system through hydrothermal treatment, and finally drying and roasting to obtain the copper-based catalyst. The copper-based catalyst prepared by the method has the characteristics of small stacking density, large porosity, high activity and multiple catalytic functions, and is particularly suitable for and simultaneously used as a catalyst for preparing ethylene glycol by hydrogenation of dimethyl oxalate, preparing butanediol by hydrogenation of dimethyl maleate / dimethyl succinate, preparing 1, 4-cyclohexanedimethanol by hydrogenation of 1, 4-cyclohexanedicarboxylic acid dimethyl ester, preparing 2-methyl furan by hydrogenation of furfural / furfuryl alcohol, and the like.

Owner:濮阳圣恺环保新材料科技股份有限公司 +1

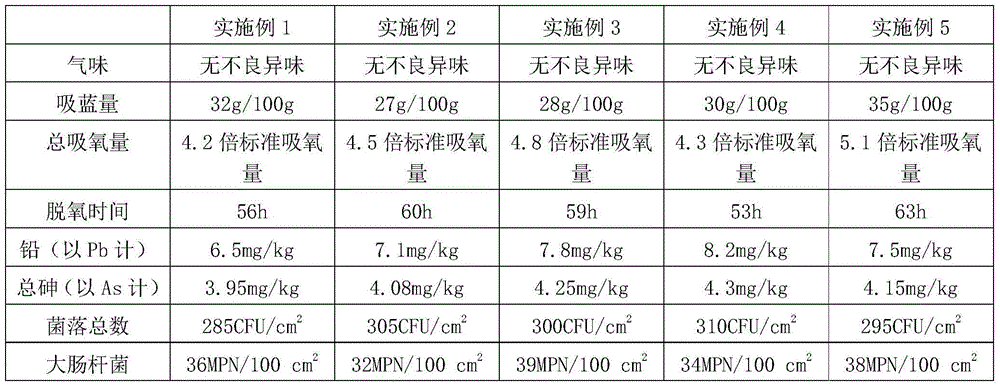

Deoxygenating drying agent for precise instrument and preparation method of deoxygenating drying agent

InactiveCN104383795APrevent oxidationPrevent mildewOther chemical processesDispersed particle separationSodium BentoniteOxidation resistant

The invention provides a deoxygenating drying agent for a precise instrument and a preparation method of the deoxygenating drying agent. The deoxygenating drying agent comprises bentonite, attapulgite, calcium chloride, macroporous silica gel, magnesium chloride, aluminum oxide, dimethyl maleate, diatomite, corn starch and deionized water. The preparation method comprises the following steps: firstly, adding the corn starch in 2 / 3 part by weight of deionized water, mixing for dispersing, adding the calcium chloride and the attapulgite to obtain a mixture I; then adding the bentonite and the aluminum oxide in the dimethyl maleate, and mixing for dispersing to obtain a mixture II; then adding magnesium oxide and diatomite into the left deionized water, mixing for dispersing, adding the macroporous silica gel to obtain a mixture III; and finally, mixing the mixture I, the mixture II and the mixture III, drying and cooling under a vacuum condition to obtain the deoxygenating drying agent. The deoxygenating drying agent can be used for keeping the instrument dry for a long time, preventing a part with a weak oxidation-resisting capability of the instrument from being oxidized, and can also be used for adsorbing mildews and preventing the interior and exterior of the instrument from mildewing.

Owner:DONGCHEN LEADER TESTING

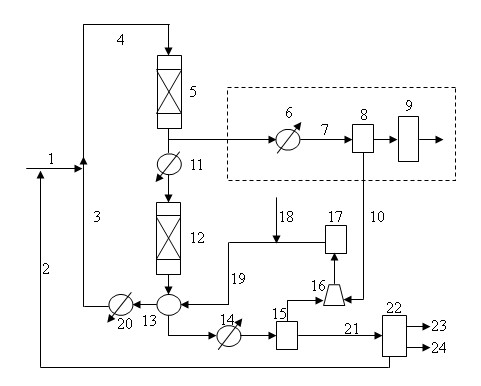

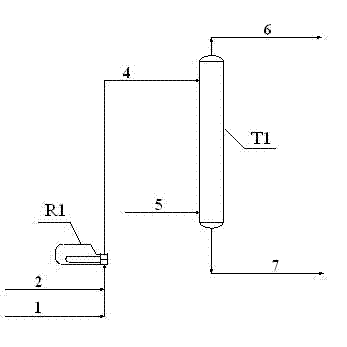

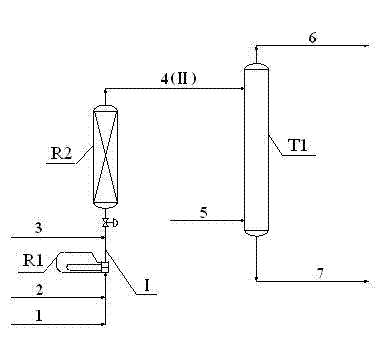

Method for producing dimethyl maleate

ActiveCN103360253AReduce lossExtended replacement cycleOrganic compound preparationChemical industryMonoethyl maleateFixed bed

The invention relates to a method for producing dimethyl maleate, mainly for solving the problems in the prior art that the operation is complex, a catalyst is seriously consumed, and the catalyst is not uniformly distributed on a reaction tower plate as a catalyst needs to be frequently replaced. The problems can be well dissolved by adopting the technical scheme disclosed by the invention. According to the technical scheme, the method comprises the following steps of: a) feeding maleic anhydride and a first path of methanol into a single esterification reactor R1, and reacting to obtain a material flow I containing monomethyl maleate; b) feeding the material flow I and a second path of methanol into a double-esterification fixed bed reactor R2, and coming into contact with a catalyst so as to obtain a material flow II containing monomethyl maleate and dimethyl maleate, wherein 80-90wt% of monomethyl maleate in the material flow I is converted into dimethyl maleate; c) feeding the material flow II and a third path of methanol into a double-esterification catalysis distilling reaction tower T1, coming into contact with the catalyst, so as to obtain a material flow containing methanol at the tower top and obtain a dimethyl maleate product from a tower kettle. The method can be applied to industrial production of dimethyl maleate.

Owner:CHINA PETROLEUM & CHEM CORP +1

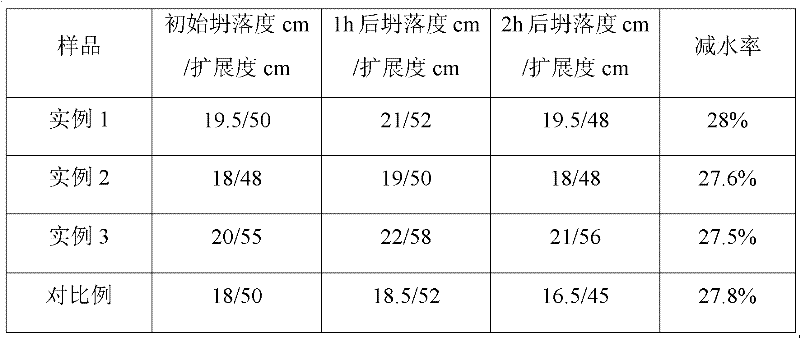

Preparation method for high-performance polycarboxylic acid water-reducing and slump-retaining agent

The invention provides a preparation method for a high-performance polycarboxylic acid water-reducing and slump-retaining agent. The method comprises the following steps of: (1) reacting polyethylene glycol and maleic anhydride in an enclosed reaction kettle at the temperature of 80-130 DEG C for 2-6 hours to obtain a maleic anhydride polyethylene glycol ester; (2) uniformly mixing diluted water, vitamin C serving as a reducting agent, maleic anhydride, 2-acrylamide-2-methyl propane sulfonic acid and the maleic anhydride polyethylene glycol ester obtained in the step (1), pumping into a high-level groove 1, uniformly stirring dimethyl maleate or a mixture of the dimethyl maleate and monomethyl maleate, and pumping into a high-level groove 2 for later use; and (3) adding a polyether monomer, hydrogen peroxide and water into a polymerizing kettle, heating, controlling the temperature between 50 DEG C and 70 DEG C, uniformly dropwise adding materials in the high-level groove 1 and the high-level groove 2 into the polymerizing kettle simultaneously, preserving heat for 0.5-2 hours after adding, neutralizing the pH value to 5-7 with liquid alkali, adding water till needed concentration is reached, and discharging to obtain the high-performance polycarboxylic acid water-reducing and slump-retaining agent. The polycarboxylic acid water-reducing and slump-retaining agent prepared with the method has excellent slump-retaining performance, and is environmentally-friendly.

Owner:ZHEJIANG JISHENG CHEM BUILDING MATERIALS

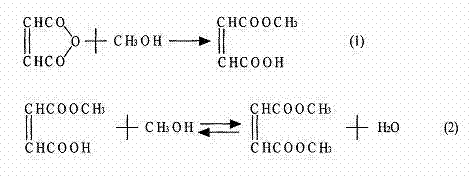

New synthesis process of maleic anhydride monomethyl and dimethyl maleate concrete polycarboxylic acid slump retaining agent

InactiveCN106977660AReduce the labor burden of configuration operationsSimple processMonoethyl maleateVitamin C

The invention provides a new synthesis process of a maleic anhydride monomethyl and dimethyl maleate concrete polycarboxylic acid slump retaining agent, the new synthesis process is characterized in that the process is polymerization of maleic anhydride monomethyl and dimethyl maleate and polyoxyethylene ether under effect of an initiator and a redox agent, the initiator is hydrogen peroxide; and the process is simple and easy to operate. The polymerization process is short, and production efficiency is high. The maleic anhydride monomethyl and dimethyl maleate concrete polycarboxylic acid slump retaining agent can be synthesized at normal temperature, and can also be heated and synthesized. The polymerization process has the advantages of flexible selection of temperature and low production cost. A polymerization drop solution is prepared only by use of deionized water to dissolve vitamin C, only needing dropwise addition, preparation operating labor burden of an operator can be reduced, the preparation is single, and has small error probability, and a basis for stable product quality is provided from operational aspects.

Owner:四川金江建材科技有限公司

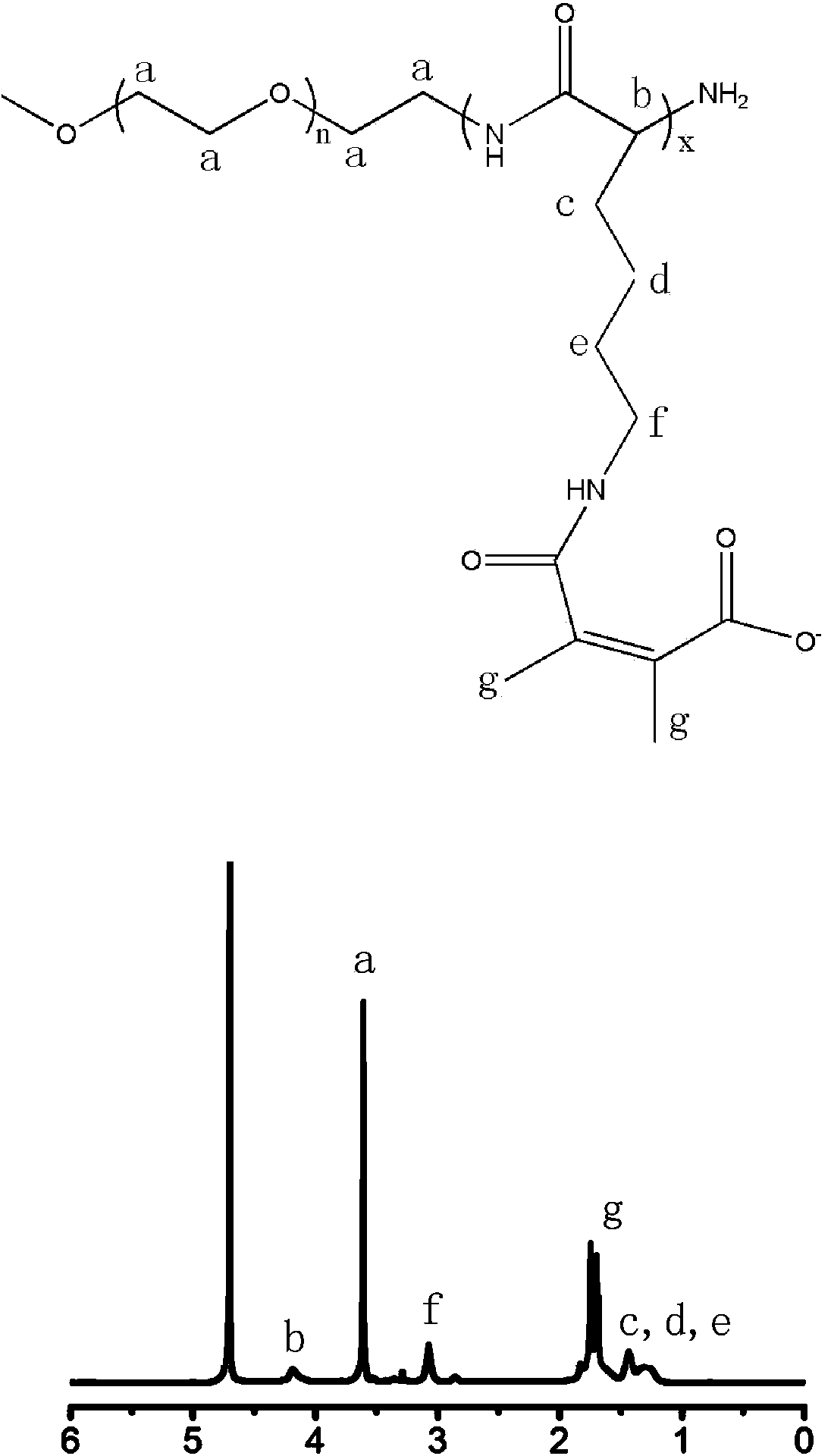

Sensitively responsive polymer nano-particles, and preparation method and application thereof

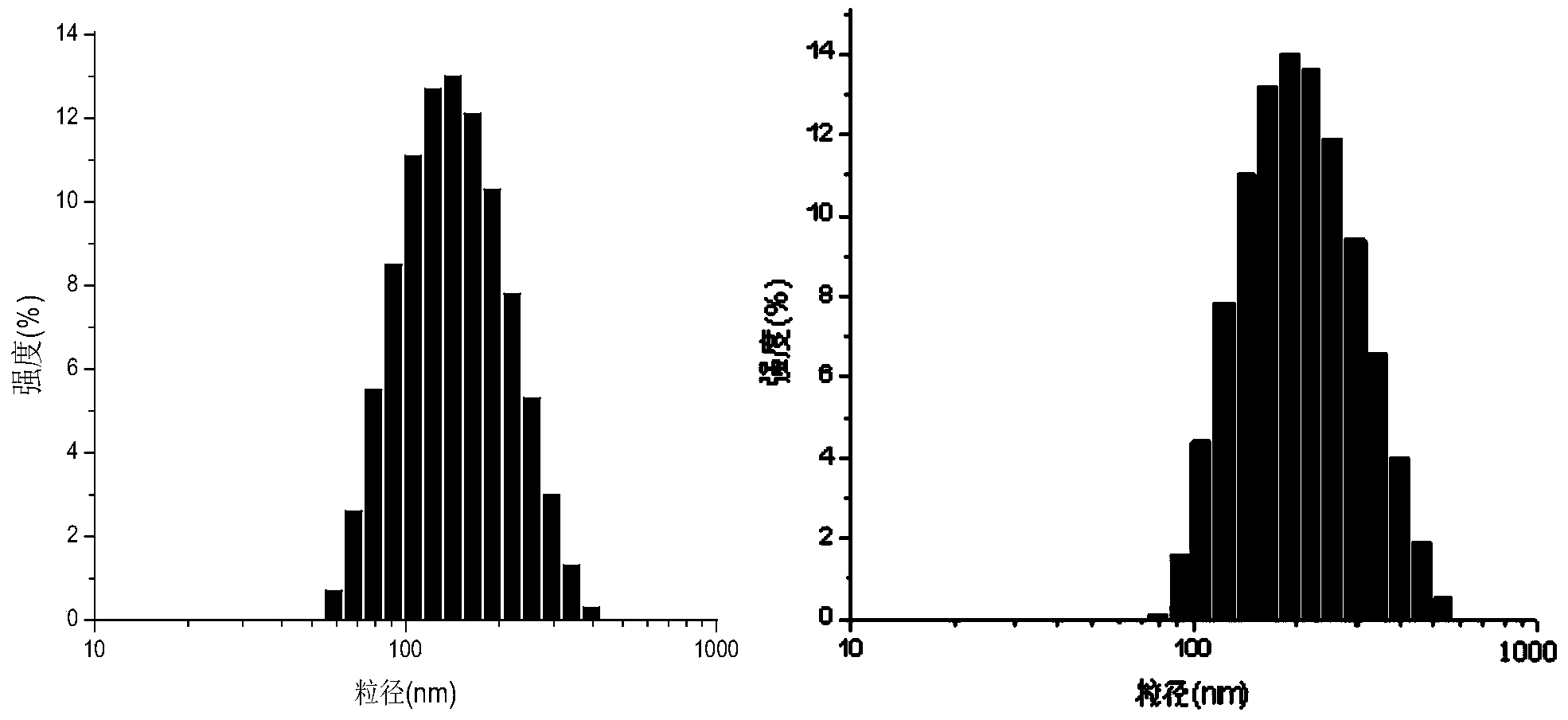

ActiveCN104224721AAvoid combiningProlong blood circulation timePowder deliveryPharmaceutical non-active ingredientsPolymer scienceParticle stability

The embodiment of the invention provides sensitively responsive polymer nano-particles which comprise poly(cystamine bisacrylamide-alt-spermine) and polyethylene glycol-b-polylysine(2,3-dimethyl maleate); in poly(cystamine bisacrylamide-alt-spermine), a cystamine bisacrylamide monomer and a spermine monomer are connected through a carbon-nitrogen bond; in polyethylene glycol-b-polylysine(2,3-dimethyl maleate), a polyethylene glycol chain segment is methyl-polyethylene glycol-amino; one end of a polylysine chain segment is connected with the amino end of the polyethylene glycol chain segment through an amide bond; and 2,3-dimethyl maleate is connected with amino on the side chain of the polylysine chain segment through an amide bond. The sensitively responsive polymer nano-particles are good in stability and can be effectively enriched at a tumor site; loaded medicinal molecules can enter tumor cells easily; in addition, the sensitively responsive polymer nano-particles are good in biocompatibility and easy to degrade.

Owner:SHENZHEN INST OF ADVANCED TECH

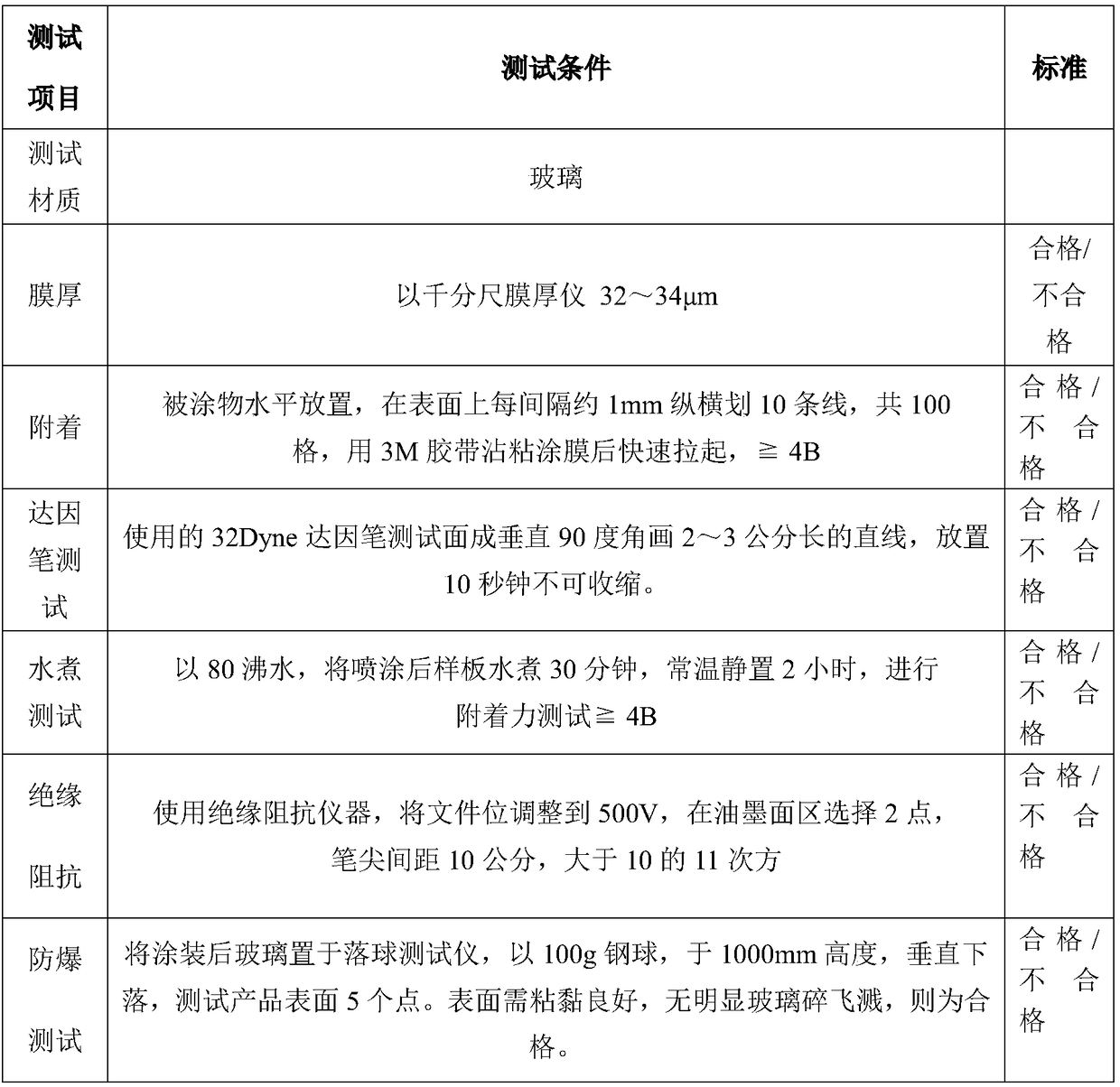

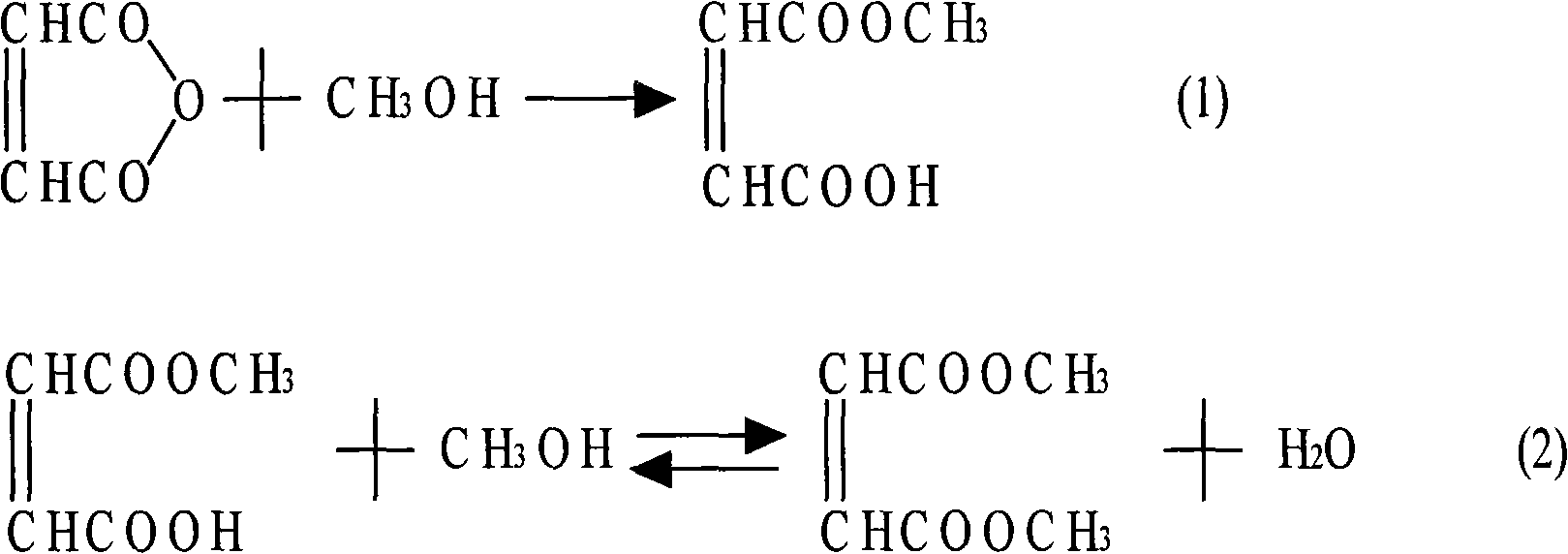

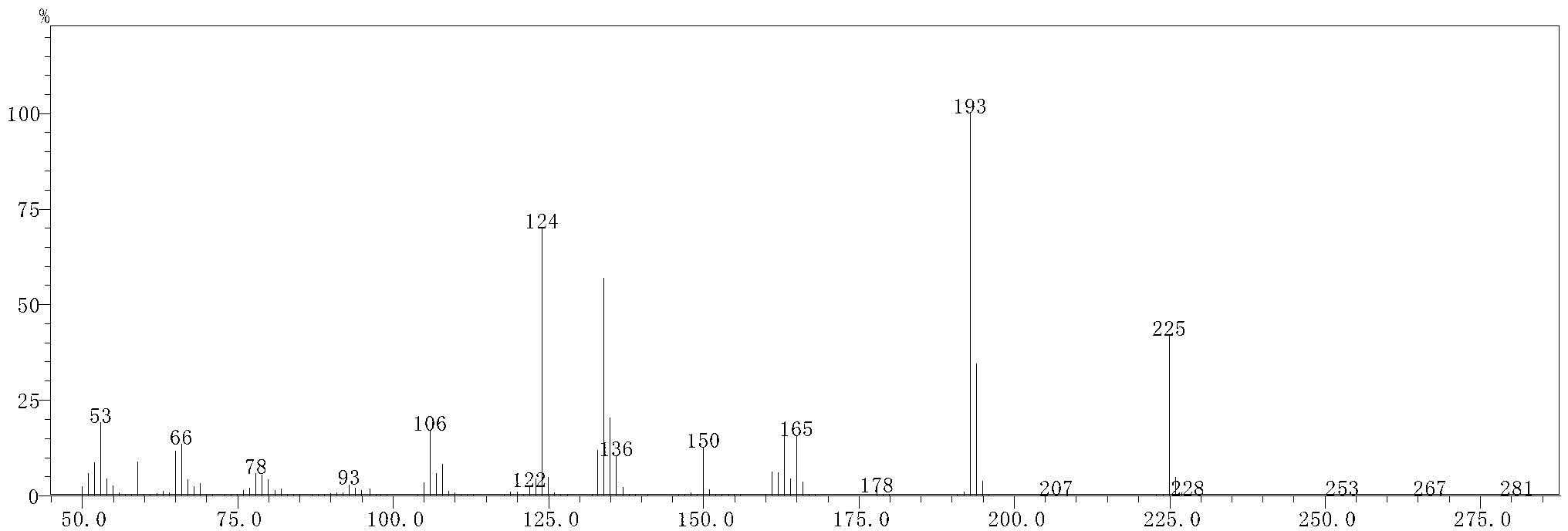

Preparation method of hexahydro-pyrrolo [3,4-c] pyrrole-1-ketone derivative

InactiveCN102070638AMild conditionsSimple post-reaction handlingOrganic chemistrySulfonyl chlorideSynthesis methods

The invention relates to a preparation method of a hexahydro-pyrrolo [3,4-c] pyrrole-1-ketone derivative, which mainly solves the technical problems of long route, low yield, difficult purification and difficult repetition and amplification of reaction of the conventional synthesis method. The preparation method comprises the following steps of: firstly, performing a 1,3-dipolar cycloaddition on monoethyl maleate and N-methoxy-methyl-N-(trimethylsilyl methyl) benzyl amine which serve as raw materials to obtain a benzyl-protected pyrrole ring so as to finish a basic skeleton of an intermediate; secondly, reducing carboxylic acid into hydroxyl groups by using borane, converting the hydroxyl groups into activated ester by using methane sulfonyl chloride, and alkylating 'N'; and finally, reducing azido ester groups under a hydrogenation condition, and closing the ring to obtain the hexahydro-pyrrolo [3,4-c] pyrrole-1-ketone derivative. The hexahydro-pyrrolo [3,4-c] pyrrole-1-ketone derivative prepared by the method is a useful intermediate or product of the synthesis of a number of medicaments.

Owner:上海药明康德新药开发有限公司 +1

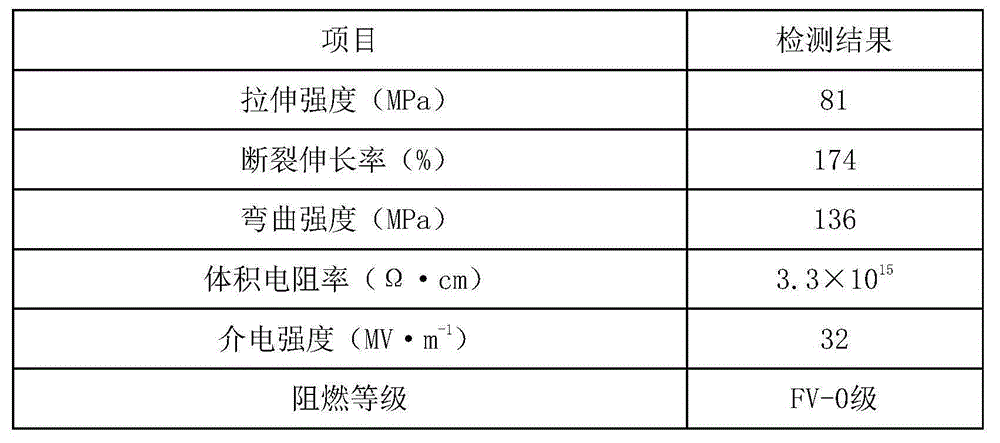

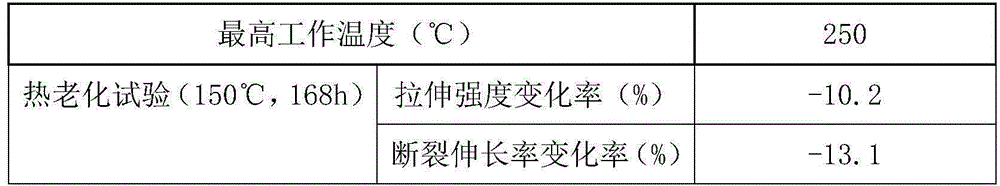

Nylon 66/polyaminated bismaleimide composite for inner sheaths of heat-resisting power lines and preparation method of nylon 66/polyaminated bismaleimide composite

InactiveCN105153694AImprove interface performanceImprove flame retardant performancePlastic/resin/waxes insulatorsSlagPotassium

The invention discloses a nylon 66 / polyaminated bismaleimide composite for inner sheaths of heat-resisting power lines and a preparation method of the nylon 66 / polyaminated bismaleimide composite. The nylon 66 / polyaminated bismaleimide composite comprises, by weight, 39-57 parts of nylon 66, 18-26 parts of polyaminated bismaleimide, 15-25 parts of poly(2(phenoxy) accidentally phosphorus nitrene), 24-32 parts of blast furnace water slag micro-powder, 2-4 parts of stannous chloride, 3-5 parts of N-methyl-p-toluenesulfonamide, 5-10 parts of potassium fluozirconate, 10-15 parts of dimethyl maleate, 4-8 parts of zinc hydroxystannate, 3-5 parts of cuproous bromide, 4-6 parts of oxidized polyethylene wax, 5-8 parts of perfluopolyether, 15-25 parts of colloidal graphite powder and 18-27 parts of flame retardant particles. The nylon 66 / polyaminated bismaleimide is good in mechanical property, wear-resisting property and aging resistance.

Owner:TIANCHANG FUXIN ELECTRONICS

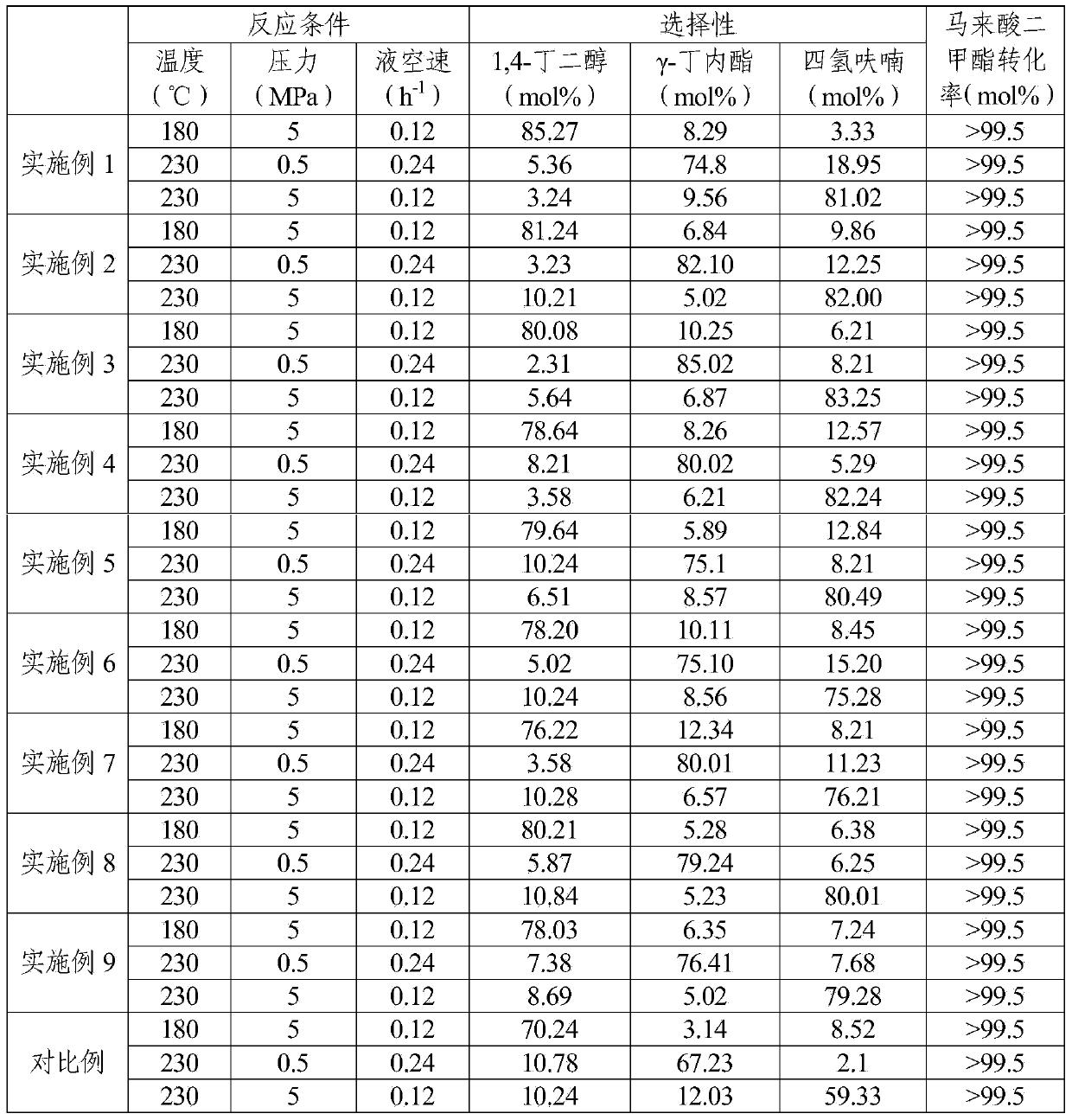

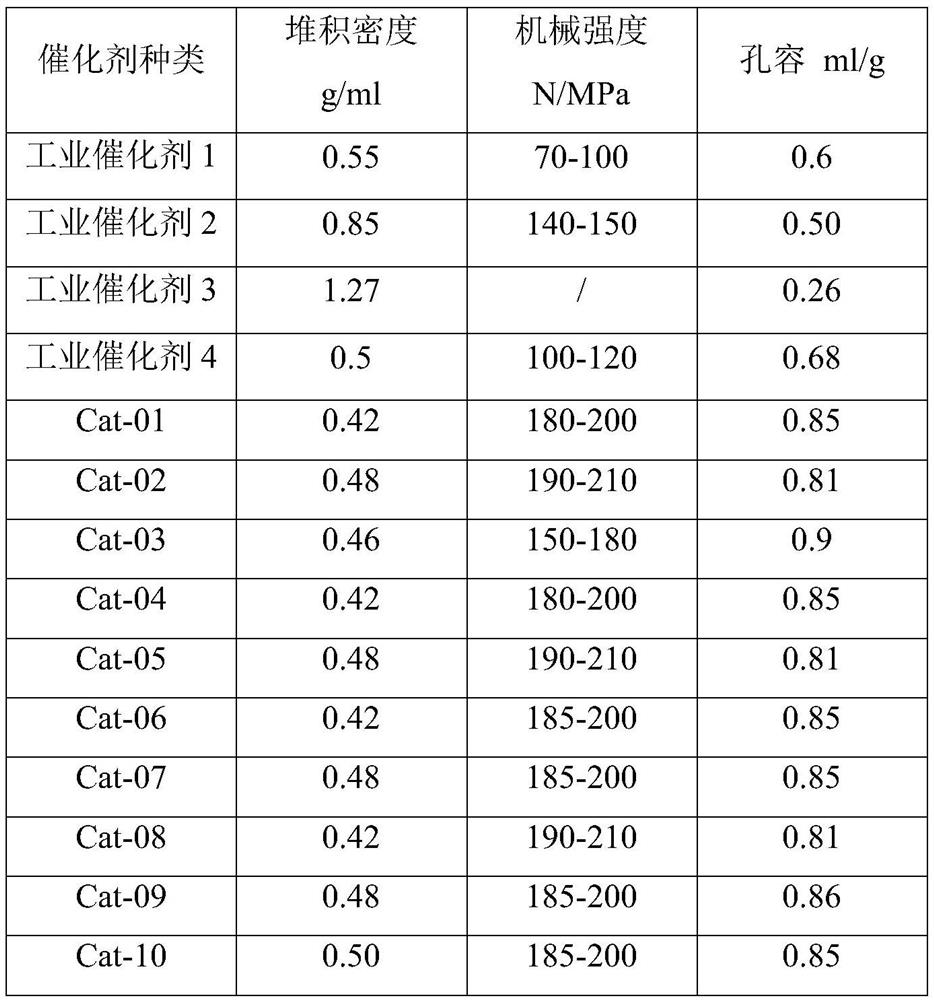

Preparation methods and catalysis method of dimethyl maleate hydrogenation catalyst

InactiveCN103551154AHigh strengthLow firing temperatureOrganic compound preparationHydroxy compound preparationMonoethyl maleateCoprecipitation

The invention discloses a preparation method of a dimethyl maleate hydrogenation catalyst, which comprises the following steps: 1, preparing a copper and zinc coprecipitation material; 2, preparing pseudo-boehmite colloidal sol; 3, preparing a catalyst precursor from the coprecipitation material and the pseudo-boehmite colloidal sol or from the coprecipitation material, the pseudo-boehmite colloidal sol and pseudo-boehmite powder; and 4, drying, roasting, and tabletting to obtain the catalyst. The invention also discloses another preparation method which comprises the following steps: preparing a catalyst precursor by mixing a coprecipitation material and pseudo-boehmite colloidal sol, drying, roasting, then mixing with pseudo-boehmite powder, and tabletting or granulating to obtain the catalyst. Besides, the invention also discloses a method for realizing catalytic dimethyl maleate hydrogenation by using the catalyst. The proportion of the product can be adjusted according to market demands. According to the invention, the prepared catalyst is good in strength and low in roasting temperature, has favorable catalytic property and can effectively reduce occurrence of polymerization reaction in the reaction process at the same time.

Owner:THE NORTHWEST RES INST OF CHEM IND

Method for preparing dimethyl succinate

ActiveCN102070448BSimple separation processImprove responseOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystSolid acid

The invention discloses a method for preparing dimethyl succinate. The method comprises two reaction processes of esterification and hydrogenation and the reaction processes are as follows: (1) after pre-esterification reaction, maleic anhydride-methanol solution enters a catalytic distillation tower from the upper rectifying section of the tower, methanol enters the tower from the lower stripping section of the catalytic distillation tower, the reaction section is filled with solid acid catalyst, the two material flows perform countercurrent contact on the surface of the catalyst to perform esterification reaction and synthetize dimethyl maleate; and (2) dimethyl maleate and hydrogen are placed in a fixed bed reactor to perform hydrogenation reaction and generate the dimethyl succinate product in the presence of hydrogenation catalyst under a certain reaction condition. The method of the invention has the advantages of high raw material conversion rate and good product selectivity; and the process flow is simple, the energy consumption is low, no pollution can be caused and the scale production of dimethyl succinate can be realized.

Owner:HUNAN CHANGLING PETROCHEM SCI & TECH DEV CO LTD

Production method of dimethyl maleate

ActiveCN107473966AImprove solubilityPromote absorptionOrganic compound preparationCarboxylic acid esters separation/purificationMonoethyl maleateDistillation

The invention provides a production method of dimethyl maleate, and in particular relates to a method used for producing the dimethyl maleate by enabling mixed liquid, which is obtained by using dimethyl maleate as a solvent to absorb maleic anhydride in maleic anhydride-containing mixed gas and is taken as a raw material, and methanol to be subjected to an esterification reaction. The production method comprises the following steps: enabling the maleic anhydride-containing mixed gas to be subjected to heat exchange and preliminary cooling, and then enabling the maleic anhydride-containing mixed gas to enter the bottom of an absorption tower and be in counter-current contact with the dimethyl maleate sprayed from the top of the tower so as to obtain absorption liquid; filling an esterification tower with solid acid esterification catalyst filler, pumping the absorption liquid from the top of the esterification tower, and enabling the pumped absorption liquid and the methanol at the bottom of the esterification tower to be subjected to a contact type reaction; obtaining a dimethyl maleate crude product at the bottom of the tower, distilling to obtain the dimethyl maleate product, and returning part of the dimethyl maleate product for absorbing the maleic anhydride in a spraying way; carrying out distillation and separation on water-containing methanol steam on the top of the tower to obtain methanol and water, and returning the methanol for the esterification reaction.

Owner:南京雪郎化工科技有限公司

Scale inhibitor, and preparation method thereof

InactiveCN108455736AWill not cause eutrophication pollutionPromote degradationScale removal and water softening(Hydroxyethyl)methacrylateTert butyl

The invention discloses a preparation method of a scale inhibitor. According to the preparation method, the scale inhibitor is prepared through copolymerization reaction of a monomer A and a monomer Bunder the action of a catalyst and an initiator; the initiator comprises an oxidizing agent and a reducing agent; the monomer A is at least one ingredient selected from itaconic acid, maleic anhydride, maleic acid, a monomethyl maleate, a monoethyl maleate, a monoisopropyl maleate, a isobutyl maleate, a mono-tert-butyl maleate, fumaric acid, monomethyl fumarate, monoethyl fumarate, and acomitic acid; and the monomer B is at least one selected from acrylic acid, methyl acrylate, ethyl acrylate, hydroxyethyl acrylate, hydroxy-propyl acrylate, methacrylic acid, hydroxyethyl methylacrylate, hydroxypropyl methacrylate, and vinyl acetate. The preparation method is simple in operation, and low in cost.

Owner:OCHEMATE MATERIAL TECH CO LTD

Technique for hydrogenation production of dimethyl succinate by using intermediate product of 1,4-butanediol device

InactiveCN104193619ALow cost productionEasy to scaleOrganic compound preparationCarboxylic acid esters preparationDistillationButanediol

The invention discloses a technique for hydrogenation production of dimethyl succinate by using an intermediate product of 1,4-butanediol device. Particularly, the invention invents a new production process of dimethyl succinate. The technique disclosed by the invention comprises the following steps: generating a mixture of dimethyl succinate and methanol by hydrogenation production of an intermediate product generated after esterification reaction in a maleic anhydride method BDO device, wherein the intermediate product is a mixture of dimethyl maleate, dimethyl fumarate, dimethyl methoxy butyl diacid and methanol; carrying out distillation separation on the mixture, thus preparing a polymer-grade dimethyl succinate product of which the purity reaches 99.95% or above. According to the technique, an esterification part device of the maleic anhydride method BDO and a hydrogen compressor are directly utilized, the productive investment of dimethyl succinate is reduced and good economic benefits can be obtained.

Owner:NINGBO ZHETIE JIANGNING CHEM

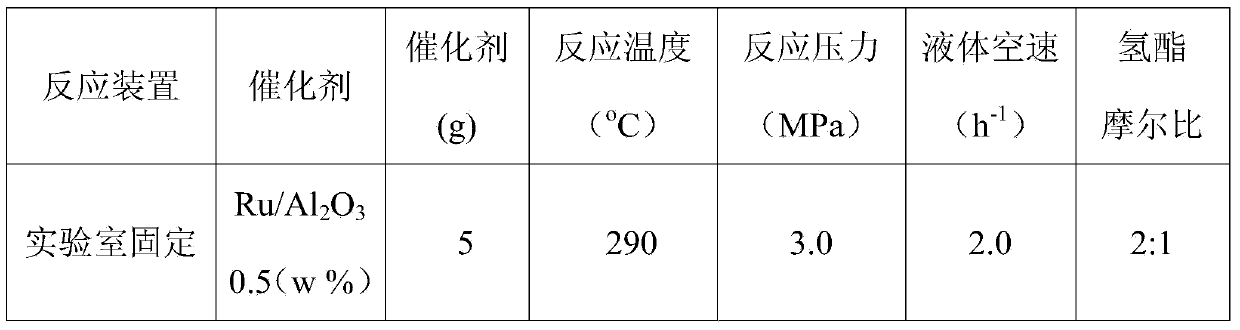

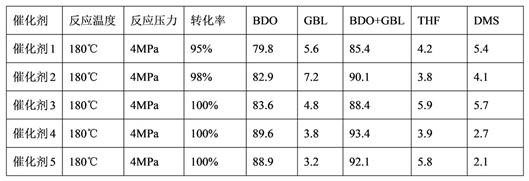

Dimethyl maleate hydrogenation reaction catalyst as well as preparation method and application thereof

PendingCN113731442AEasy to prepareLow costOrganic compound preparationHydroxy compound preparationMonoethyl maleatePtru catalyst

The invention belongs to the technical field of chemical products, and particularly relates to a dimethyl maleate hydrogenation reaction catalyst as well as a preparation method and an application thereof. The catalyst comprises the following elements in percentage by mole: 30 to 40 percent of Cu, 20 to 30 percent of Mn, 10 to 20 percent of Al, 10 to 20 percent of Zn, 0 to 5 percent of Ag and 0 to 5 percent of Ru. The Al element, the Ag element and the Ru element are added into the catalyst, so that dispersion and modification of active components in the catalyst are realized, the total selectivity of BDO and gamma-butyrolactone can reach 93%, the cost can be effectively reduced, and the catalyst is green and environment-friendly. According to the present invention, with the catalyst, the 1, 4-butanediol and / or gamma-butyrolactone can be prepared with high selectivity by changing the reaction conditions during the 1, 4-butanediol preparation process through the dimethyl maleate hydrogenation reaction catalyst; the preparation method of the catalyst is simple and low in cost, and the prepared catalyst is environmentally friendly and has long service life.

Owner:河南省生物基材料产业研究院有限公司

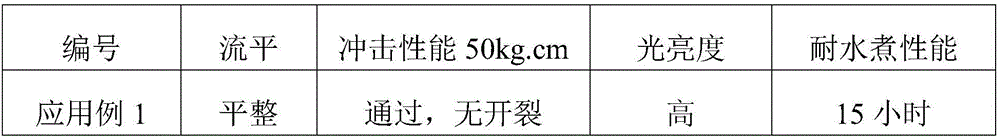

Luster-enhancing agent for powder coating as well as preparation method and application of luster-enhancing agent

ActiveCN105949859AImprove the level ofImprove water resistancePowdery paintsEpoxy resin coatingsMethacrylateMonoethyl maleate

The invention belongs to the technical field of powder coatings and in particular relates to a luster-enhancing agent for a powder coating as well as a preparation method and application of the luster-enhancing agent. The luster-enhancing agent for the powder coating, provided by the invention, is prepared from the following raw materials: dimethyl maleate, tert-butyl acrylate and (perfluoro cyclohexyl)methyl acrylate; an end capping agent, an initiating agent and an organic solvent are added and a copolymerization reaction is carried out to obtain the luster-enhancing agent. The luster-enhancing agent for the powder coating, provided by the invention, has better compatibility with the powder coating, and can be used for wetting base materials very well and improving the adhesive force; the coating prepared from the luster-enhancing agent has better anti-impact performance and can be cured into a film very well, and the leveling property of the powder coating is better; the luster-enhancing agent provided by the invention has obvious luster enhancing performance, and can be used for preparing the high-gloss powder coating; a fluoro raw material has the effect of improving the water-resistance property of the luster-enhancing agent, and the water boiling capability is remarkably improved.

Owner:HUANGSHAN HUAHUI TECH

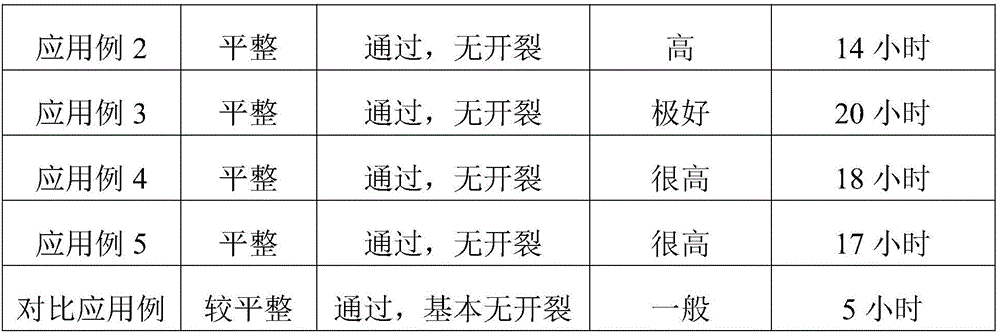

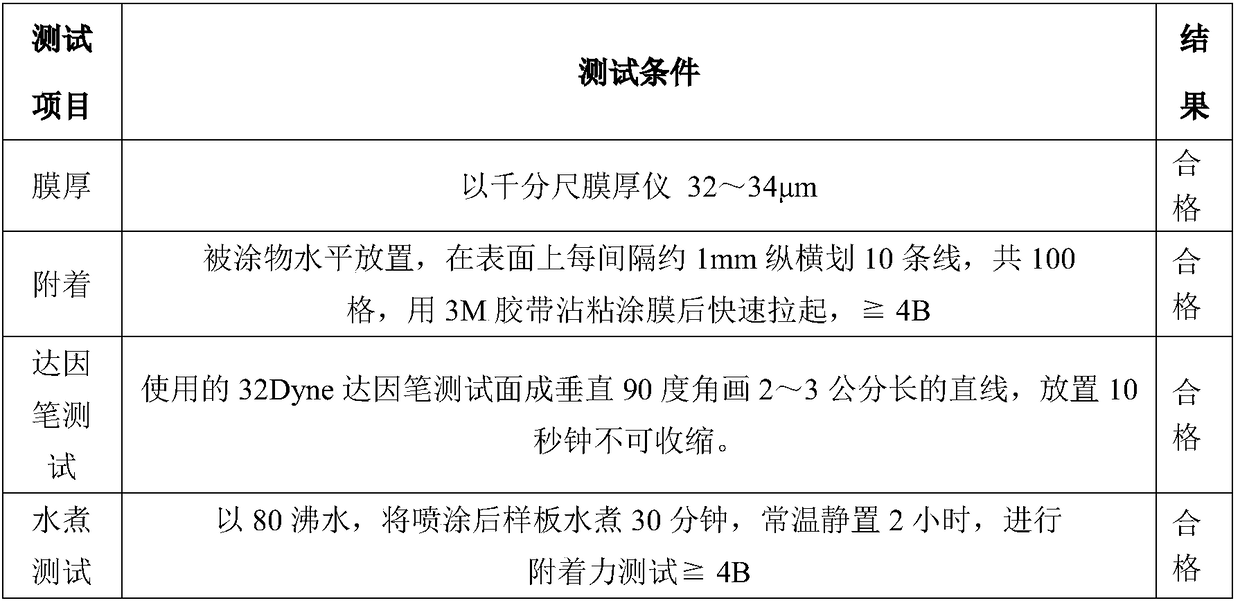

Composition of water-based high-extensibility explosion-proof coating

ActiveCN109096847AThere is no volatility problemAvoid scatterPolyurea/polyurethane coatingsWater basedExtensibility

The invention provides a composition of a water-based high-extensibility explosion-proof coating. The composition is prepared from, at least, water-based polyacrylate, anionic polyurethane water-baseddispersion, a leveling agent, a wetting agent, pure water and dimethyl maleate. The water-based glass explosion-proof adhesive is the coating with water as a diluent, and volatized organic solvent isvery little and is only 5%-10% of a solvent type coating, so there is no problem of free TDI volatilization, and the coating is an environment-friendly product. The water-based glass explosion-proofadhesive can be prevented from being scattered after bursting and can also produce no residue after tearing again.

Owner:东周化学工业(昆山)有限公司

Method of simultaneously producing dimethyl succinate and 1,4-butyl glycol

ActiveCN102190582BFlexible productionOvercome defectsOrganic compound preparationCarboxylic acid esters preparationFuranGas phase

The invention relates to a method of simultaneously producing dimethyl succinate (DMS) and 1, 4-butyl glycol. The method can also be used to simultaneously produce at least one of Tetrahydro furan (THF) and gamma-irradiation butyl lactone (GBL). In the invention, dimethyl maleate (DMM) is used as raw materials and contacts with hydrogen under the condition of gas phase in a low pressure reaction district and a middle pressure reaction district respectively. A low-pressure reactor and a middle-pressure reactor are equipped with a catalyst. DMS products are produced in the low pressure reaction district and 1, 4-butyl glycol products are produced in the middle pressure reaction district. Simultaneously, at least one of the GBL and THF can be produced in the middle pressure reaction district. Purity of DMS can reach over 99.5% without refining through using a gas-liquid separator. In the invention, the method is used in mild condition; heavier component does not need to be circulated; operation is simple; transesterification type polymerization and other side reactions are greatly reduced in a system.

Owner:SHANGHAI HUAYI ENERGY CHEM

Valve pressure resistant sealing ring material

The invention discloses a valve pressure resistant sealing ring material, and relates to the technical field of sealing ring manufacturing. The valve pressure resistant sealing ring material is prepared from the following raw materials in parts by weight: basic oil, dimethyl maleate, alkyl polyglucoside, kukui nut oil, sodium formate, carboxymethyl chitosan, poly-polyvinyl pyridine, nano ferroferric oxide microspheres, polyvinyl acetate, silicon dioxide powder, a beeswax matrix, plant extract oil, butyl rubber, modified butyl acrylate, a modified organic silicon phenolic aldehyde epoxy resin, high-pressure low-density PE (Polyethylene), graphene, a polyamide fiber and polytetrafluoroethylene. The valve pressure resistant sealing ring material disclosed by the invention is good in high pressure resistance, high temperature resistance, low temperature resistance and corrosion resistance, not liable to break, long lasting in use and applicable to preparation of sealing rings, and due to adoption of the high-pressure resistance PE and the graphite, the toughness and the tensile strength of the material are improved.

Owner:安徽英科成流体科技有限公司

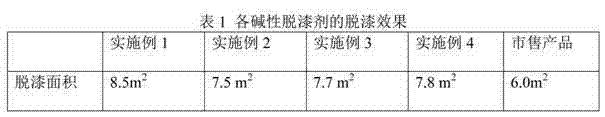

Alkaline paint remover and preparation method thereof

The invention discloses an alkaline paint remover and a preparation method thereof. The alkaline paint remover comprises the following components in part by weight: 30 to 40 parts of sodium hydroxide, 20 to 30 parts of benzyl alcohol, 5 to 8 parts of water-soluble cellulose, 1 to 3 parts of alkylphenol polyoxyethylene, 1 to 3 parts of benzotriazole, 3 to 6 parts of dimethyl maleate, 1 to 3 parts of polyethylene glycol and 10 to 15 parts of water. The alkaline paint remover is low in cost and toxicity, high in paint removing speed and environment-friendly and sewage is easy to discharge and treat. Different raw materials, proportioning ratios and preparation processes are adopted, so that the alkaline paint remover is safely used, the paint removing effect is enhanced, the using period is prolonged, the working efficiency is effectively improved, and the production cost is obviously saved.

Owner:GUANGDONG REDSUNSTAR IND

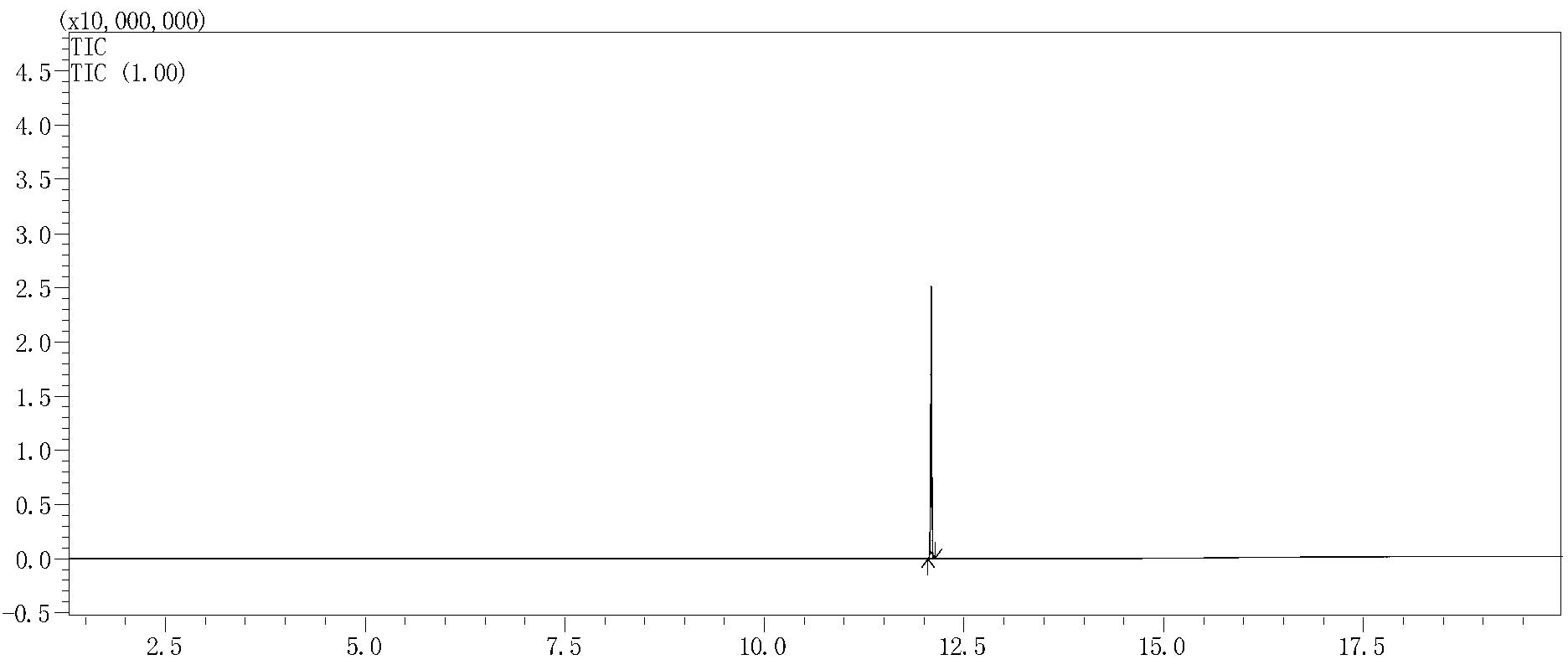

Gas-phase hydrocatalyst of dimethyl maleate

InactiveCN1190268COrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsMonoethyl maleateGas phase

A catalyst for gas-phase hydrogenation of dimethyl maleate to produce 1,4-butanediol and co-production of tetrahydrofuran has the following general formula: CuMnaAlbNicMdOx where M is a rare earth element La or Ce, a=0.05-10, b=0.1-30, c=0.01-8, d=0.02-1.5, X is the number of oxygen atoms satisfying the valence state of each metal atom. When the catalyst liquid space velocity of dimethyl maleate reaches 1.3h-1, the conversion rate of dimethyl maleate can reach 100%, the selectivity of 1,4-butanediol can reach 80%, tetrahydrofuran The selectivity can reach 15%.

Owner:NORTH HUAJIN CHEM IND GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Preparation method of hexahydro-pyrrolo [3,4-c] pyrrole-1-ketone derivative Preparation method of hexahydro-pyrrolo [3,4-c] pyrrole-1-ketone derivative](https://images-eureka.patsnap.com/patent_img/8eb5575a-5596-4a93-8576-66069183efe5/G2009102018598D00011.PNG)

![Preparation method of hexahydro-pyrrolo [3,4-c] pyrrole-1-ketone derivative Preparation method of hexahydro-pyrrolo [3,4-c] pyrrole-1-ketone derivative](https://images-eureka.patsnap.com/patent_img/8eb5575a-5596-4a93-8576-66069183efe5/G2009102018598D00021.PNG)

![Preparation method of hexahydro-pyrrolo [3,4-c] pyrrole-1-ketone derivative Preparation method of hexahydro-pyrrolo [3,4-c] pyrrole-1-ketone derivative](https://images-eureka.patsnap.com/patent_img/8eb5575a-5596-4a93-8576-66069183efe5/G2009102018598D00031.PNG)