Production method of dimethyl maleate

A technology of dimethyl maleate and its production method, which is applied in the separation/purification of carboxylic acid esters, preparation of carboxylic acid esters, chemical instruments and methods, etc., and can solve the problems of easy isomerization of products, complicated follow-up treatment, and equipment corrosion and other problems, to achieve the effect of easy separation, good absorption effect, and small equipment corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

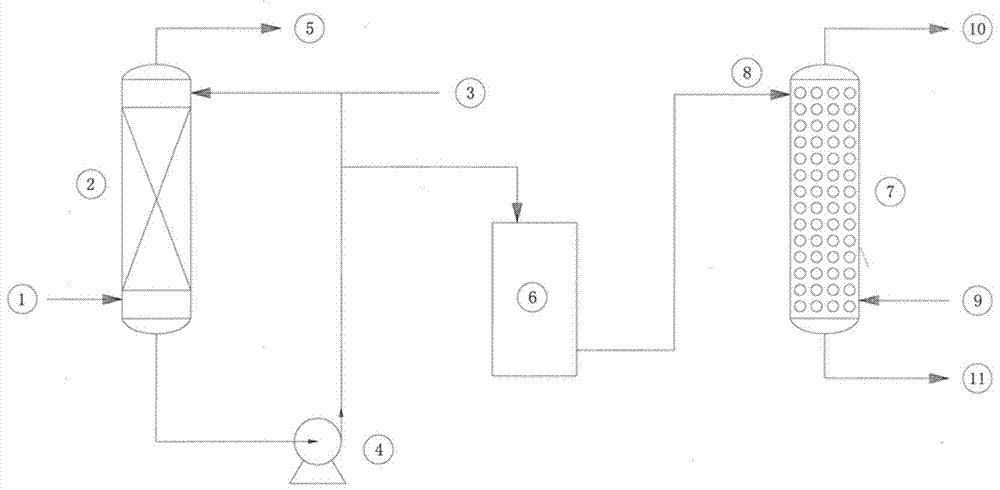

[0023] 1. Absorption process

[0024] The reaction gas produced by the benzene oxidation method to produce maleic anhydride is initially cooled by heat exchange, and the content of maleic anhydride in the cooled gas is 0.5 mol %. The cooling gas is fed from the lower part of the absorption tower 2 through the gas pipeline 1, and the dimethyl maleate is fed from the upper part of the absorption tower 2 through the solvent pipeline 3. Anhydrides are absorbed and cooled. The absorption liquid obtained from the bottom of the absorption tower 2 enters the upper part of the absorption tower 2 again through the absorption tower circulation pump 4 for circulation absorption, and the tail gas discharged from the top of the absorption tower 2 enters the tail gas treatment system through the tail gas pipeline 5 .

[0025] After preliminary cooling, the gas temperature is 130°C, the dimethyl maleate feed temperature is 40°C, and the mass ratio of dimethyl maleate to gas is 0.04:1. The p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com