Technique for hydrogenation production of dimethyl succinate by using intermediate product of 1,4-butanediol device

A technology of dimethyl succinate and a process method, applied in the field of preparing dimethyl succinate, can solve the problems of complicated procedures, no industrialized embodiment, large investment in esterification, etc., and achieves simple process and reduced investment. Cost, effect of low-cost production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

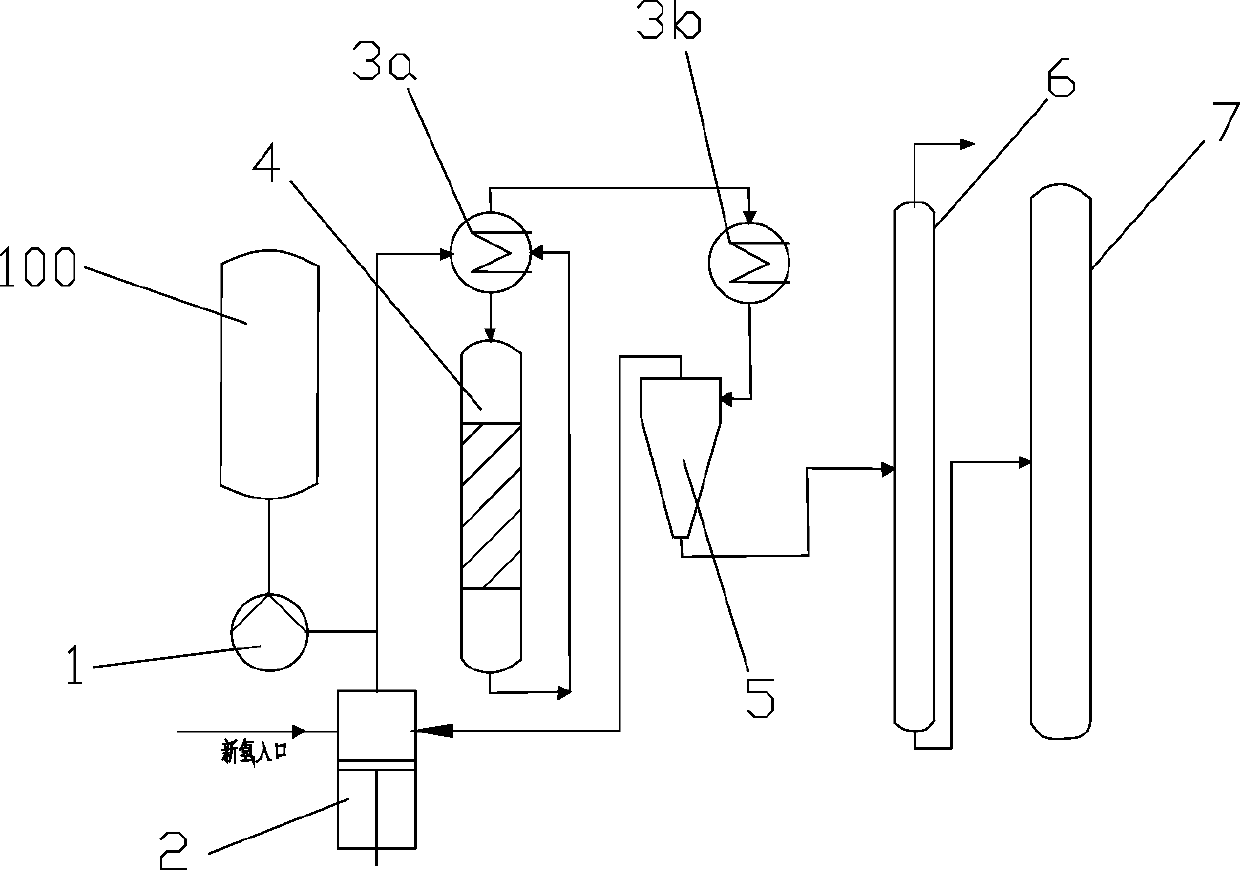

Method used

Image

Examples

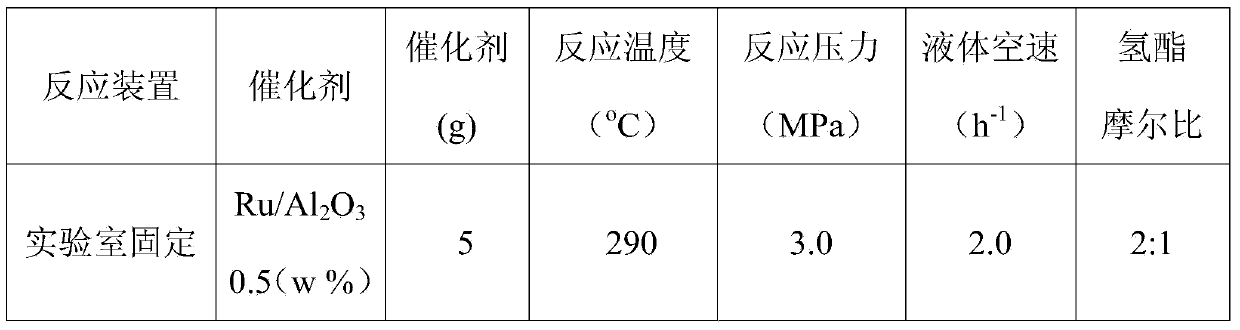

Embodiment 1

[0021] Embodiment 1: The content of each component of the intermediate product dimethyl maleate, dimethyl fumarate, dimethyl methoxysuccinate and methanol mixture in the esterification tower of the maleic anhydride method BDO plant is shown in Table 1 , the specific reaction conditions are shown in Table 2, and the reaction products and the contents of each component are shown in Table 3. After calculation, the reaction conversion rate of this embodiment is 98.6%, and the selectivity is 99.0%.

[0022]

[0023] (Table 1)

[0024]

[0025] (Table 2)

[0026] components

[0027] (table 3)

Embodiment 2

[0029] The content of each component of the intermediate product dimethyl maleate, dimethyl fumarate, dimethyl methoxysuccinate and methanol mixture in the esterification tower of the maleic anhydride method BDO plant is shown in Table 4, and the specific reaction conditions See Table 5, and see Table 6 for the reaction product and the contents of each component. After calculation, the reaction conversion rate of this embodiment is 99.2%, and the selectivity is 98.2%.

[0030]

[0031] (Table 4)

[0032]

[0033] (table 5)

[0034] components

[0035] Dimethyl succinate (DMS)

[0036] (Table 6)

Embodiment 3

[0038] The content of each component of the intermediate product dimethyl maleate, dimethyl fumarate, dimethyl methoxysuccinate and methanol mixture in the esterification tower of the maleic anhydride method BDO plant is shown in Table 7, and the specific reaction conditions See Table 8, and see Table 9 for the reaction product and the contents of each component. After calculation, the reaction conversion rate of this embodiment is 100%, and the selectivity is 99.4%.

[0039]

[0040] (Table 7)

[0041]

[0042] (Table 8)

[0043] components

[0044] (Table 9)

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com