Preparation method of copper hydrogenation catalyst

A hydrogenation catalyst and copper-based technology, which is applied in the technical field of hydrogenation catalysts, can solve problems such as higher requirements and distance, and achieve the effects of superior performance, stable composition and superior reaction activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

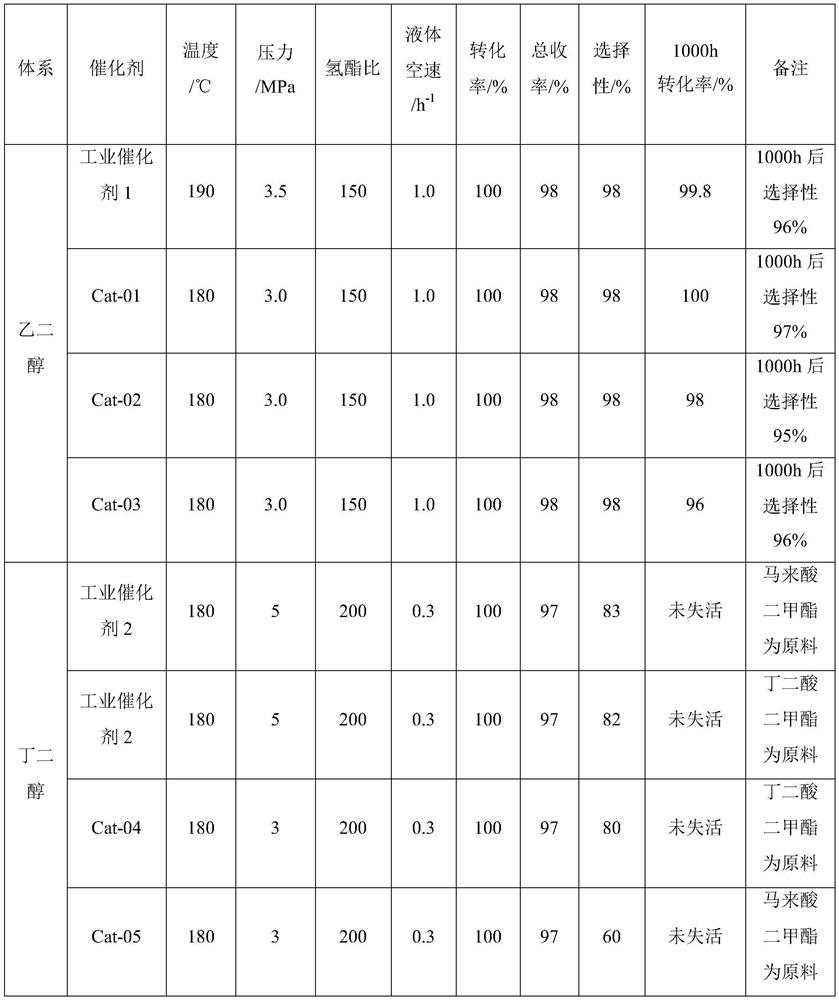

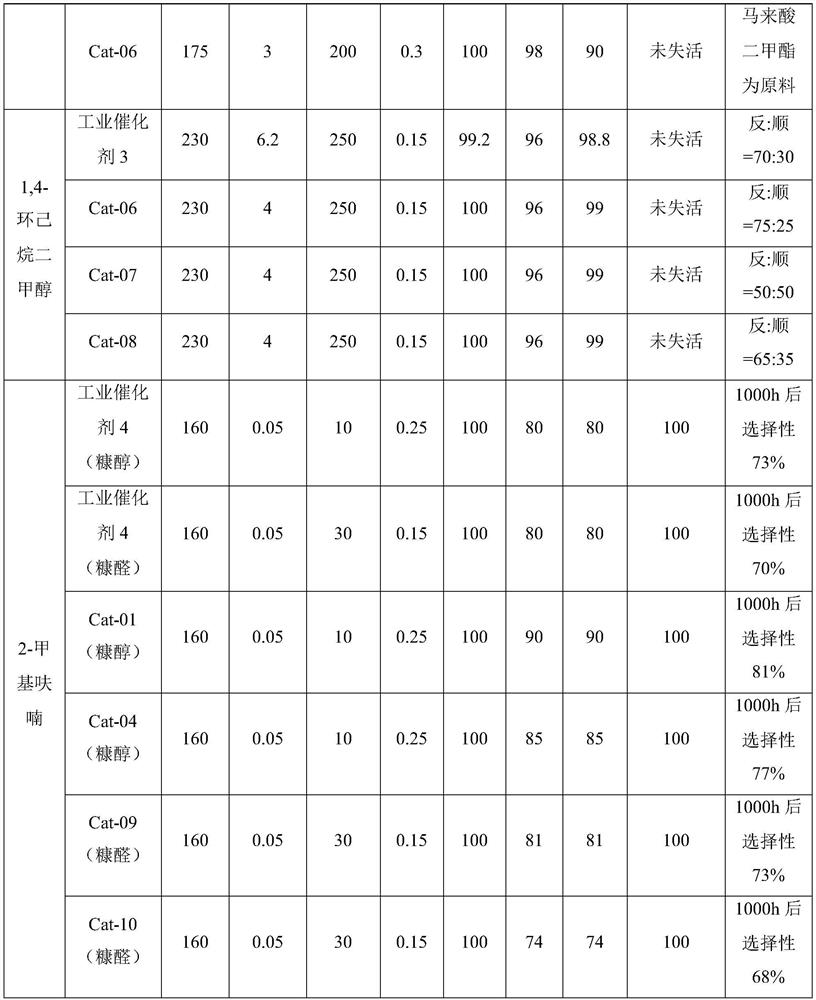

Examples

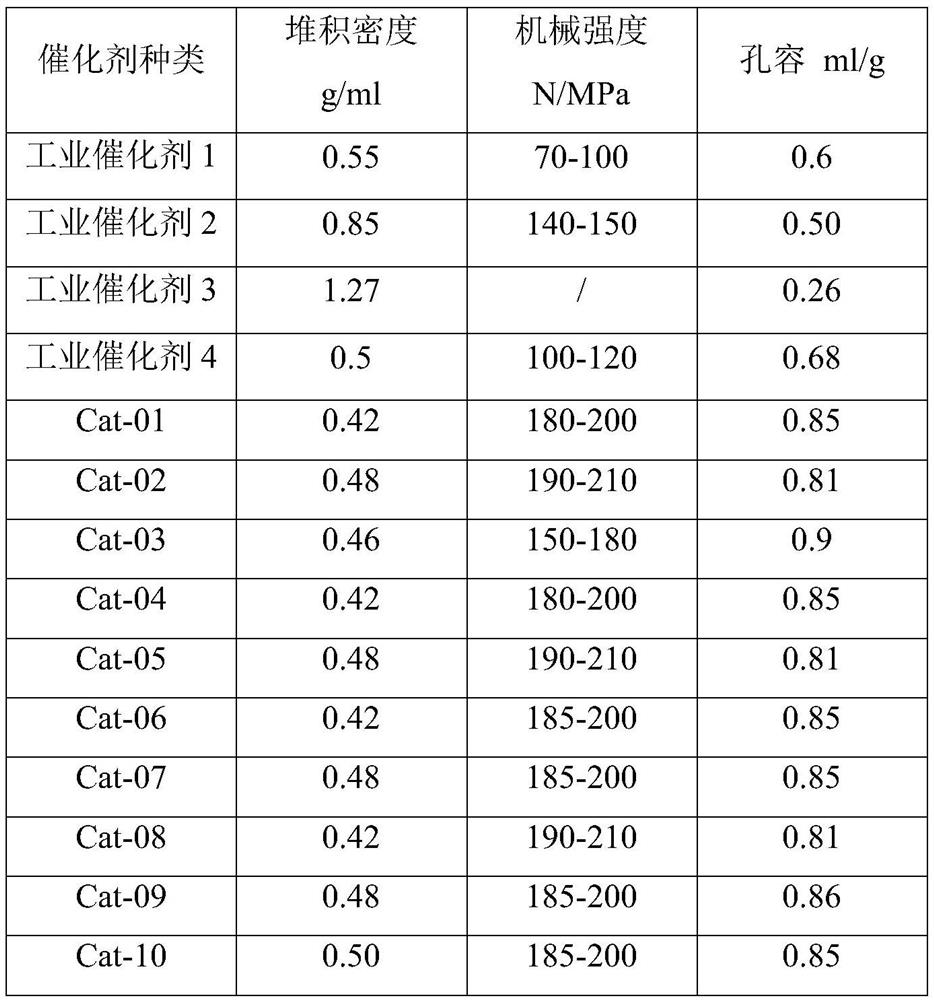

Embodiment 1

[0025] A method for preparing a copper-based hydrogenation catalyst, comprising the steps of:

[0026] 1) Weigh 120.0g Cu(NO 3 ) 2 ·3H 2 O, 60g Mn(NO 3 ) 2 and 40g Zn(NO 3 ) 2 ·6H 2 O dissolved in 2000mlH 2 O is made into mixed salt solution; under stirring condition, mixed salt solution is added alkali solution (alkali solution is dissolved in 2000ml H by 250g 25% ammoniacal liquor 2 Obtained in O), carry out precipitation reaction in 50 ℃ water bath 10h, after reaction finishes, filter, wash precipitation with deionized water to remove impurity ion, obtain corresponding hydroxide precipitation;

[0027] 2) Mix the precipitated hydroxide obtained in the above step 1) with 3.2 g of sodium hydroxide solid to obtain a solid phase mixture;

[0028] 3) Add 30ml of deionized water at 60°C to the solid phase mixture, stir vigorously to mix, add 0.72g of aluminum powder paste, continue to stir for 60s to mix, and then maintain at 60°C for 8h;

[0029] 4) Transfer the mainta...

Embodiment 2

[0032] The difference between this example and Example 1 is that the amount of sodium hydroxide added in step 2) is 1.6 g, and 0.36 g of aluminum powder paste is added in step 3) to obtain a copper-based hydrogenation catalyst Cat-02.

Embodiment 3

[0034] The difference between this example and Example 1 is that the amount of sodium hydroxide added in step 2) is 6.4g, and 1.44g of aluminum powder paste is added in step 3), and the alkaline solution used in step 1) is 10% sodium hydroxide solution (the molar number of sodium hydroxide is the same as that of ammonia water) to prepare copper-based hydrogenation catalyst Cat-03.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com