Dimethyl maleate hydrogenation reaction catalyst as well as preparation method and application thereof

A technology of dimethyl maleate and hydrogenation reaction, applied in chemical instruments and methods, preparation of hydroxyl compounds, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of 1,4-butanediol selection The problem of low solubility, easy to produce too much by-product tetrahydrofuran, and low value of by-product tetrahydrofuran has achieved good industrial application prospects, good selectivity, and simple preparation methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

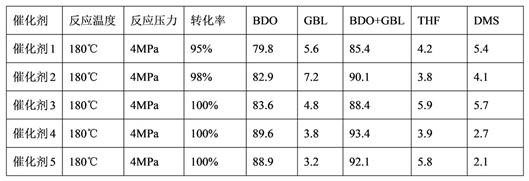

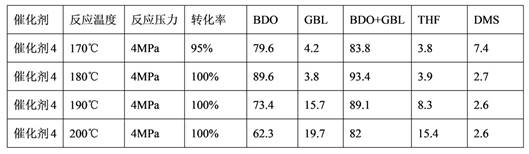

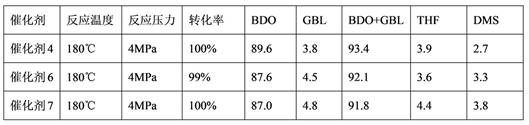

Examples

Embodiment 1

[0038] This example prepares a dimethyl maleate hydrogenation reaction catalyst containing Cu, Mn, Al, and Zn elements, wherein the molar percentages of each element are: Cu: 39.8%, Mn: 26.86%, Zn: 16.91% , Al: 16.43%.

[0039] The preparation method of described dimethyl maleate hydrogenation reaction catalyst comprises the steps:

[0040] (1) 12.0g Cu(NO 3 ) 2 ·3H 2 O, 6g Mn(NO 3 ) 2 and 4g Zn(NO 3 ) 2 ·6H2 O dissolved in 200ml H 2 O is made into a mixed solution of metal ions; 18g Na 2 CO 3 Dissolve in 200ml H 2 O is made into a precipitant solution;

[0041] (2) In a water bath at 80°C, add the mixed solution of metal ions and the solution of the precipitating agent side-by-side for co-precipitation reaction, stir while adding, keep the pH value of the precipitation system at 6.8, and stir at constant temperature for 90 minutes after the addition is completed , and then washed with water to remove impurity ions to obtain Cu-Mn-Zn-O precipitates;

[0042] (3) A...

Embodiment 2

[0045] This example prepares a dimethyl maleate hydrogenation reaction catalyst containing Cu, Mn, Al, Zn, and Ag elements, wherein the molar percentages of each element are: Cu: 38.86%, Mn: 26.23%, Zn: 16.51%, Al: 16.04%, Ag: 2.35%.

[0046] The preparation method of described dimethyl maleate hydrogenation reaction catalyst comprises the steps:

[0047] (1) 12.0g Cu(NO 3 ) 2 ·3H 2 O, 6g Mn(NO 3 ) 2 and 4g Zn(NO 3 ) 2 ·6H 2 O dissolved in 200ml H 2 O is made into a mixed solution of metal ions; 18g Na 2 CO 3 Dissolve in 200ml H 2 O is made into a precipitant solution;

[0048] (2) In a water bath at 80°C, add the mixed solution of metal ions and the solution of the precipitating agent side-by-side for co-precipitation reaction, stir while adding, and keep the pH value of the precipitation system at 7. After the addition is completed, stir at constant temperature for 100 minutes , and then washed with water to remove impurity ions to obtain Cu-Mn-Zn-O precipitates...

Embodiment 3

[0052] This example prepares a dimethyl maleate hydrogenation reaction catalyst containing Cu, Mn, Al, Zn, and Ru elements, wherein the molar percentages of each element are: Cu: 39.17%, Mn: 26.44%, Zn: 16.64%, Al: 16.17%, Ru: 1.58%.

[0053] The preparation method of described dimethyl maleate hydrogenation reaction catalyst comprises the steps:

[0054] (1) 12.0g Cu(NO 3 ) 2 ·3H 2 O, 6g Mn(NO 3 ) 2 and 4g Zn(NO 3 ) 2 ·6H 2 O dissolved in 200ml H 2 O is made into a mixed solution of metal ions; 18g Na 2 CO 3 Dissolve in 200ml H 2 O is made into a precipitant solution;

[0055] (2) In a water bath at 80°C, add the mixed solution of metal ions and the solution of the precipitating agent side-by-side for co-precipitation reaction, stir while adding, and keep the pH value of the precipitation system at 7. After the addition is completed, stir at constant temperature for 100 minutes , and then washed with water to remove impurity ions to obtain Cu-Mn-Zn-O precipitates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com