Catalyst for preparing 1,4-butanediol or tetrahydrofuran from selective hydrogenation of dimethyl maleate and preparation method thereof

A technology of dimethyl maleate and selective hydrogenation, which is applied in the chemical industry, can solve the problem of a small adjustment range of the composition of the hydrogenation product, and achieves good industrial application prospects and the effect of enhancing elasticity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

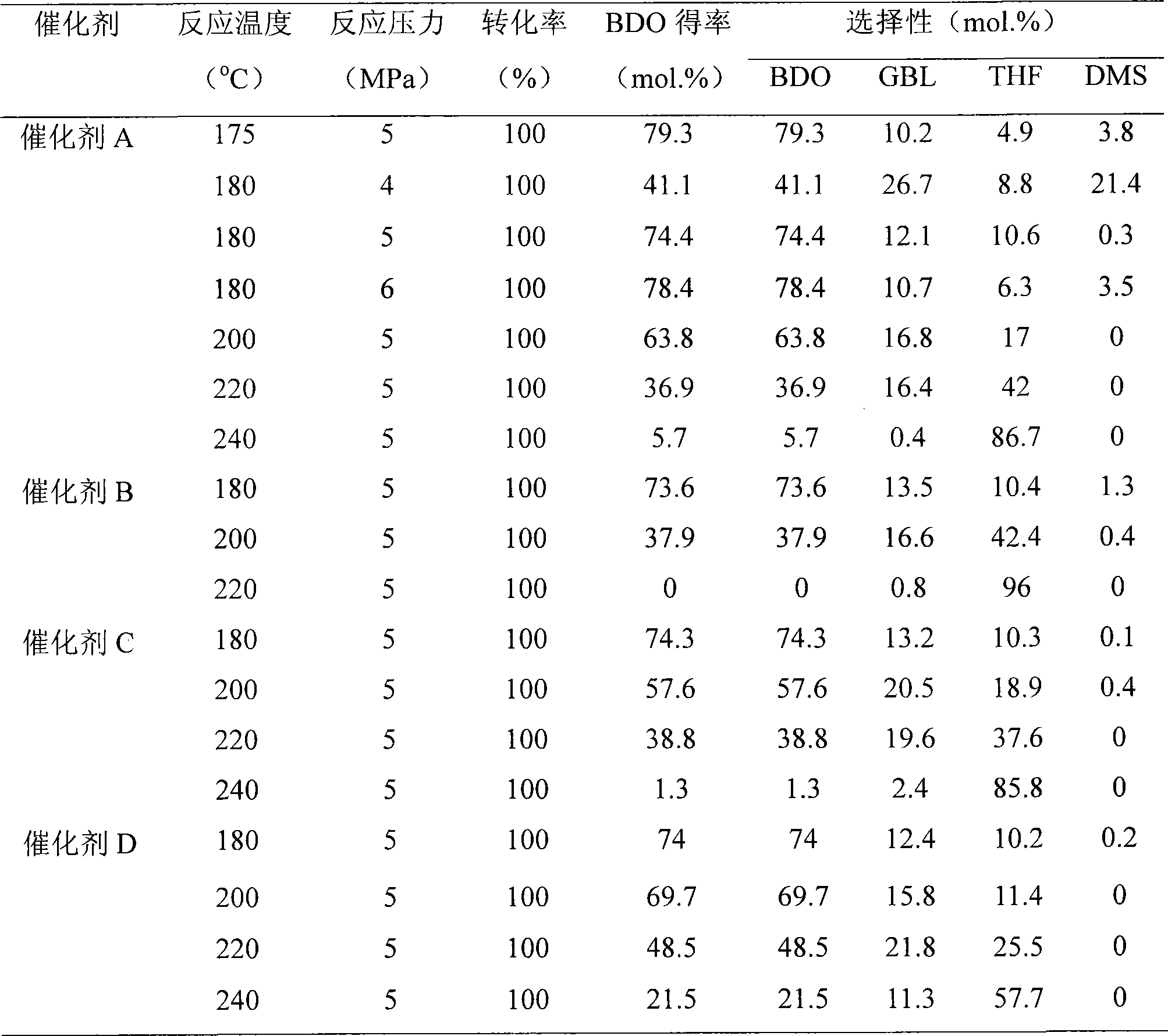

Embodiment 1

[0020] 10.0g Cu(NO 3 ) 2 ·3H 2 O, 9.8g Zn(NO 3 ) 2 ·6H 2 O dissolved in 75ml H 2 O is made into a metal ion solution, 8.7gNa 2 CO 3 Dissolved in 82ml H 2 O to obtain a precipitant solution. In a water bath at 60°C, add the metal ion solution and the precipitant solution dropwise under stirring for co-precipitation. After the dropwise addition was completed, the mixture was aged for 1 hour. Wash the precipitate to remove impurity ions, then add 1.68g Al(OH) 3 . The mixture thus obtained was added with 150ml of deionized water, heated to 60°C and stirred for 30min. The filter cake obtained by suction filtration was dried at 120° C. overnight, and the temperature was raised to 450° C. in a muffle furnace at 10 K / min and calcined for 4 hours to obtain catalyst A.

Embodiment 2

[0022] 10.0g Cu(NO 3 ) 2 ·3H 2 O, 9.8g Zn(NO 3 ) 2 ·6H 2 O and 0.15g Mn(NO 3 ) 2 Dissolve in 75ml H 2 O is made into metal ion solution, 8.7g Na 2 CO 3 Dissolved in 82ml H 2 O to obtain a precipitant solution. In a water bath at 60°C, add the metal ion solution and the precipitant solution dropwise under stirring for co-precipitation. After the dropwise addition was completed, the mixture was aged for 1 hour. Wash the precipitate to remove impurity ions, then add 1.68g Al(OH) 3 . The mixture thus obtained was added with 150ml of deionized water, heated to 60°C and stirred for 30min. The filter cake obtained by suction filtration was dried at 120° C. overnight, and the temperature was raised to 450° C. in a muffle furnace at 10 K / min for 4 hours to obtain catalyst B with a Mn content of 1%. Change the added Mn(NO 3 ) 2 Using the same conditions to prepare catalysts C and D with Mn contents of 2% and 5%, respectively.

Embodiment 3

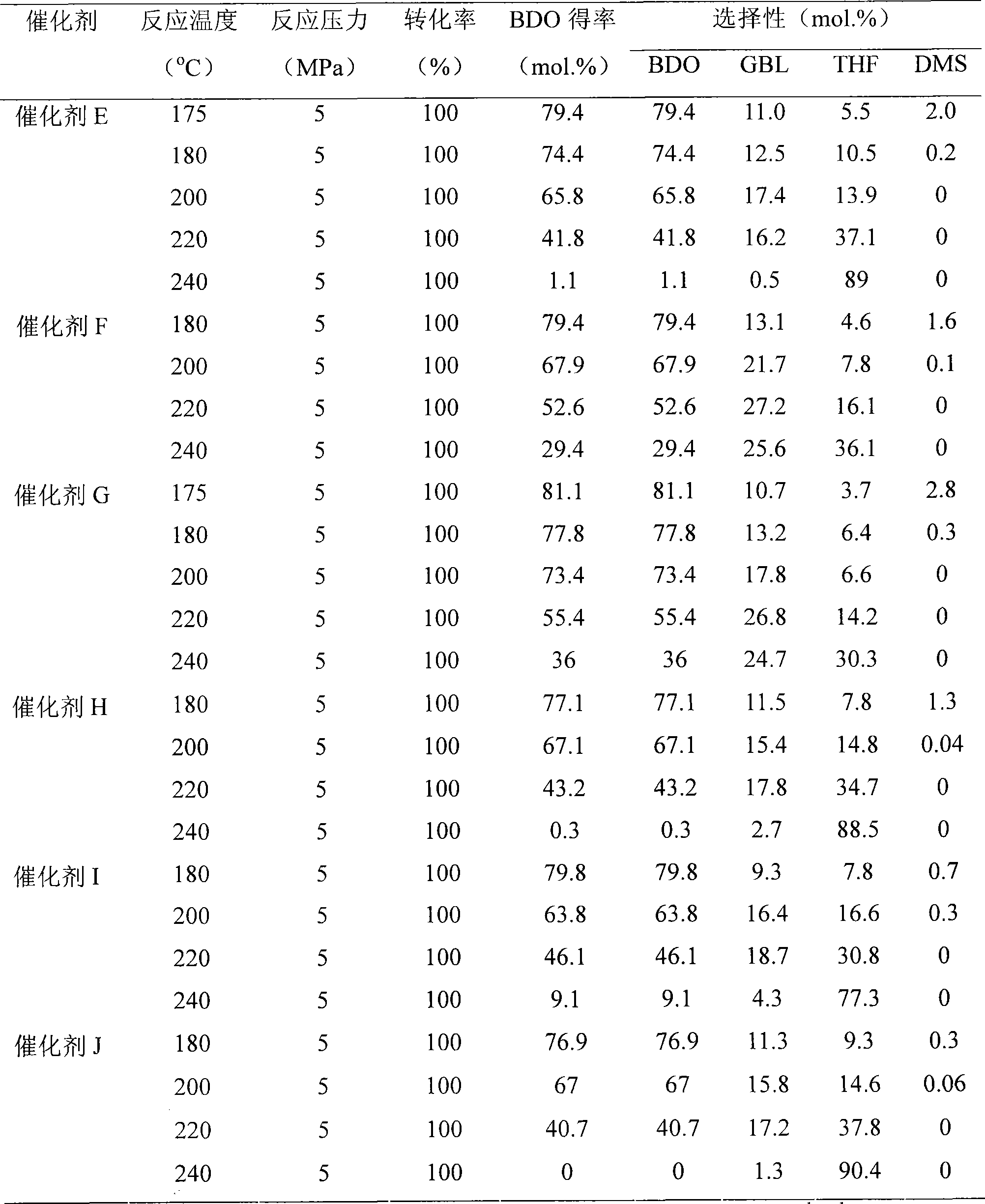

[0024] 10.0g Cu(NO 3 ) 2 ·3H 2 O, 9.8g Zn(NO 3 ) 2 ·6H 2 O and 0.21g Mg(NO 3 ) 2 ·6H 2 O dissolved in 75ml H 2 O is made into metal ion solution, 8.7g Na 2 CO 3 Dissolved in 82ml H 2 O to obtain a precipitant solution. In a water bath at 60°C, the metal ion solution and the precipitant are added dropwise under stirring for co-precipitation. After the dropwise addition was completed, the mixture was aged for 1 hour. Wash the precipitate to remove impurity ions, then add 1.68g Al(OH) 3 . The mixture thus obtained was added with 150ml of deionized water, heated to 60°C and stirred for 30min. The filter cake obtained by suction filtration was dried overnight at 120° C., and the temperature was raised to 450° C. in a muffle furnace at 10 K / min for 4 hours to obtain catalyst E with a Mg content of 1%. Change the added Mg(NO3 ) 2 Using the same conditions to prepare catalysts F and G with Mg contents of 2% and 5%, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com