Deoxygenating drying agent for precise instrument and preparation method of deoxygenating drying agent

A technology for precision instruments and desiccants, used in the field of deoxidizing desiccants for precision instruments and their preparation, can solve the problems of heat release, expansion, non-bentonite desiccant water retention, and unsatisfactory stability, etc. In large-scale promotion and application, to avoid the effect of mildew

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

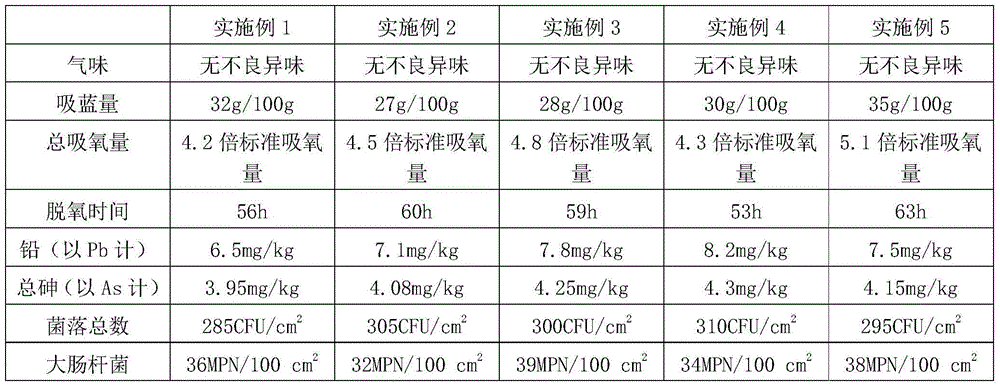

Examples

Embodiment 1

[0019] A deoxidizing desiccant for precision instruments, comprising in parts by weight: 3 parts of bentonite, 2 parts of attapulgite, 1 part of calcium chloride, 2 parts of macroporous silica gel, 1 part of magnesium chloride, 1 part of aluminum oxide, and 2 parts of dimethyl ester, 1 part of diatomaceous earth, 2 parts of cornstarch, and 0.5 part of deionized water.

[0020] The alumina is activated alumina, and the cornstarch is dry cornstarch.

[0021] The preparation method of the deoxidizing desiccant for the above-mentioned precision instrument comprises the following steps:

[0022] Step 1: Add cornstarch to 2 / 3 parts by weight of deionized water, stir and disperse, heat up to 70°C, keep warm for 2 hours, cool to room temperature, add calcium chloride and attapulgite, and mix well to obtain mixture I;

[0023] Step 2, adding bentonite and alumina to dimethyl maleate, stirring and dispersing, calcining at 400°C for 1 hour, and cooling to room temperature to obtain mixt...

Embodiment 2

[0027] A deoxidizing desiccant for precision instruments, comprising in parts by weight: 5 parts of bentonite, 4 parts of attapulgite, 2 parts of calcium chloride, 3 parts of macroporous silica gel, 2 parts of magnesium chloride, 3 parts of aluminum oxide, 4 parts of dimethyl ester, 3 parts of diatomaceous earth, 4 parts of cornstarch, and 1.4 parts of deionized water.

[0028] The alumina is activated alumina, and the cornstarch is dry cornstarch.

[0029] The preparation method of the deoxidizing desiccant for the above-mentioned precision instrument comprises the following steps:

[0030] Step 1: Add cornstarch to 2 / 3 parts by weight of deionized water, stir and disperse, heat up to 85°C, keep warm for 1 hour, cool to room temperature, add calcium chloride and attapulgite, and mix well to obtain mixture I;

[0031] Step 2, adding bentonite and alumina to dimethyl maleate, stirring and dispersing, calcining at 500°C for 0.5h, and cooling to room temperature to obtain mixtur...

Embodiment 3

[0035] A deoxidizing desiccant for precision instruments, comprising in parts by weight: 6 parts of bentonite, 7 parts of attapulgite, 3 parts of calcium chloride, 4 parts of macroporous silica gel, 4 parts of magnesium chloride, 4 parts of aluminum oxide, and 5 parts of dimethyl ester, 6 parts of diatomaceous earth, 5 parts of cornstarch, and 1.9 parts of deionized water.

[0036] The alumina is activated alumina, and the cornstarch is dry cornstarch.

[0037] The preparation method of the deoxidizing desiccant for the above-mentioned precision instrument comprises the following steps:

[0038] Step 1: Add cornstarch to 2 / 3 parts by weight of deionized water, stir and disperse, heat up to 70°C, keep warm for 2 hours, cool to room temperature, add calcium chloride and attapulgite, and mix well to obtain mixture I;

[0039] Step 2, adding bentonite and alumina to dimethyl maleate, stirring and dispersing, calcining at 500°C for 0.5h, and cooling to room temperature to obtain m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com