Preparation method for high-performance polycarboxylic acid water-reducing and slump-retaining agent

A polycarboxylic acid and high-performance technology, which is applied in the field of preparation of high-performance polycarboxylic acid water-reducing and slump-retaining agent, can solve the problems of low esterification rate, harm, environmental protection and other problems, achieve high esterification rate and avoid volatilization High performance and cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

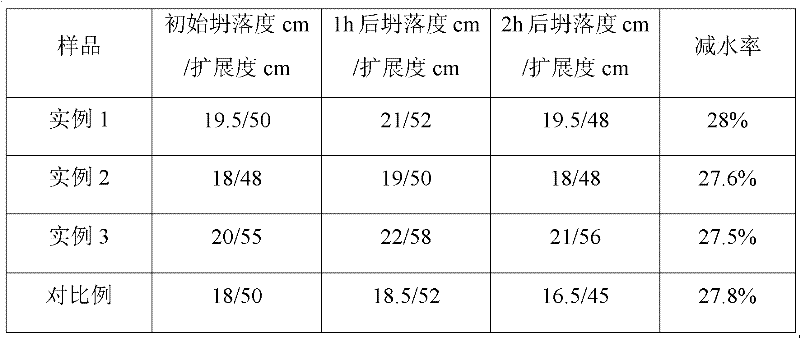

Examples

Embodiment 1

[0023] Esterification reaction:

[0024] Add 2000Kg of polyethylene glycol (PEG200) and 1100Kg of maleic anhydride to the esterification kettle in sequence, start stirring, seal the esterification kettle, start to heat up to 105°C, keep the temperature for 4 hours, cool to 50°C to obtain the maleic anhydride poly Ethylene glycol ester, spare;

[0025] Polymerization:

[0026] Add 2500Kg deionized water into the stirring tank 1, start stirring and put in the following materials in sequence: 25kg vitamin C, 20kg 2-acrylamide-2-methylpropanesulfonic acid, 300kg maleic anhydride, 600kg maleic anhydride polyethylene glycol The esterified product is stirred into the head tank 1 for subsequent use, and 300kg dimethyl maleate is squeezed into the head tank 2 for subsequent use;

[0027] Add 4500Kg of deionized water to the polymerization reactor, start stirring and heat up, and then put 2400Kg of methallyl alcohol polyoxyethylene ether, 3-methyl-3-butene-1-ol polyoxyethylene ether i...

Embodiment 2

[0030] Esterification reaction:

[0031] Add 2000Kg of polyethylene glycol (PEG400) and 800Kg of maleic anhydride to the esterification kettle in turn, start stirring, seal the esterification kettle, start to heat up to 102°C, keep the temperature for 4.5h, cool to 50°C to obtain maleic anhydride Polyethylene glycol ester, standby;

[0032] Polymerization:

[0033] Add 3000Kg deionized water into the stirring tank 1, start stirring and put in the following materials in sequence: 20kg vitamin C, 10kg 2-acrylamide-2-methylpropanesulfonic acid, 300kg maleic anhydride, 800kg maleic anhydride polyethylene glycol The esterified product is stirred evenly, and is put into the head tank 1 for subsequent use, and after 100kg dimethyl maleate and 100kg monomethyl maleate are stirred in the stirring tank 2, they are put into the head tank 2 for subsequent use;

[0034] Add 4000Kg deionized water to the polymerization reactor, start stirring and raise the temperature, and then put 1200Kg...

Embodiment 3

[0037] Esterification reaction:

[0038] Add 2000Kg of polyethylene glycol (PEG400) and 800Kg of maleic anhydride to the esterification kettle in turn, start stirring, start to heat up to 98°C, keep the temperature for 4.5h, cool to 50°C to obtain maleic anhydride polyethylene glycol ester ,spare;

[0039] Polymerization:

[0040] Add 3000Kg deionized water to the stirring tank 1, start stirring and put in the following materials in sequence: 15kg vitamin C, 15kg 2-acrylamide-2-methylpropanesulfonic acid, 400kg maleic anhydride, 700kg maleic anhydride polyethylene glycol The esterified product is stirred evenly, and is put into the head tank 1 for subsequent use, and after 100kg dimethyl maleate and 100kg monomethyl maleate are stirred in the stirring tank 2, they are put into the head tank 2 for subsequent use;

[0041] Add 4000Kg deionized water to the polymerization reactor, start stirring and heat up, then put 4800Kg of 3-methyl-3-buten-1-ol polyoxyethylene ether into it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com