Alkaline paint remover and preparation method thereof

A paint remover and alkaline technology, which is applied in the field of alkaline paint remover and its preparation, can solve the problems of complicated sewage discharge treatment, fast volatilization and undurability, and high toxicity of paint remover, so as to achieve enhanced paint removal effect and low cost. Low, fast paint stripping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

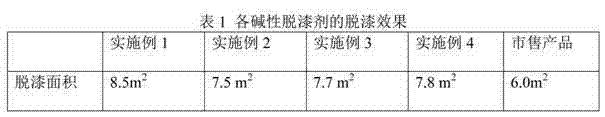

Examples

Embodiment 1

[0017] An alkaline paint remover, the components are by weight: 35 parts of sodium hydroxide, 25 parts of benzyl alcohol, 6 parts of hydroxyethyl cellulose, 2 parts of alkylphenol polyoxyethylene ether, 2 parts of benzotriazole 4 parts, dimethyl maleate 4, polyethylene glycol 2, water 12 parts.

[0018] Its preparation method comprises the following steps:

[0019] 1) Mix benzotriazole and benzyl alcohol to obtain liquid A;

[0020] 2) Add sodium hydroxide to the water, mix well, then add alkylphenol polyoxyethylene ether, mix well, then add water-soluble cellulose, mix well, then add dimethyl maleate, mix well, then add poly Ethylene glycol, mix well to obtain liquid B;

[0021] 3) Mix liquid A and liquid B evenly to obtain an alkaline paint remover.

Embodiment 2

[0023] An alkaline paint remover, the components are by weight: 37 parts of sodium hydroxide, 20 parts of benzyl alcohol, 7 parts of methyl cellulose, 3 parts of alkylphenol polyoxyethylene ether, 2.5 parts of benzotriazole , dimethyl maleate 3, polyethylene glycol 1, water 14.5 parts.

[0024] Its preparation method comprises the following steps:

[0025] 1) Mix benzotriazole and benzyl alcohol to obtain liquid A;

[0026] 2) Add sodium hydroxide to the water, mix well, then add alkylphenol polyoxyethylene ether, mix well, then add water-soluble cellulose, mix well, then add dimethyl maleate, mix well, then add poly Ethylene glycol, mix well to obtain liquid B;

[0027] 3) Mix liquid A and liquid B evenly to obtain an alkaline paint remover.

Embodiment 3

[0029] An alkaline paint remover, the components by weight: 30 parts of sodium hydroxide, 30 parts of benzyl alcohol, 5 parts of methyl cellulose, 3 parts of alkylphenol polyoxyethylene ether, 1 part of benzotriazole , dimethyl maleate 5, polyethylene glycol 3, water 15 parts.

[0030] Its preparation method comprises the following steps:

[0031] 1) Mix benzotriazole and benzyl alcohol to obtain liquid A;

[0032] 2) Add sodium hydroxide to the water, mix well, then add alkylphenol polyoxyethylene ether, mix well, then add water-soluble cellulose, mix well, then add dimethyl maleate, mix well, then add poly Ethylene glycol, mix well to obtain liquid B;

[0033] 3) Mix liquid A and liquid B evenly to obtain an alkaline paint remover.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com