Patents

Literature

62results about How to "Fast paint removal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Green alkaline paint remover for eliminating coating from electronic circuit board and its prepn and usage

InactiveCN1887979AReduce poisonNo corrosionChemical paints/ink removersAqueous sodium hydroxideEngineering

The present invention is green alkaline paint remover for eliminating coating from electronic circuit board and its preparation and usage, and belongs to the field of paint remover technology. The paint remover consists of NaOH in 40-150 g / L, surfactant in 0.5-50 g / L, additive in 0-50 g / L, corrosion retardant 0.1-2.5 g / L, and water for the rest. It is prepared through mixing and heating at 50-80 for dissolving completely. When the paint remover is used, the electronic circuit board is soaked in the paint remover and heated at 50-100 deg.c for 10-60 min to eliminate its paint layer. The present invention has the advantages of low cost, fast paint eliminating speed, low toxicity, use safety and capacity of being used repeatedly.

Owner:UNIV OF SCI & TECH BEIJING

Water-base depainting agent

InactiveCN100999627AReduce poisonNo pollution in the processChemical paints/ink removersWater basedHalohydrocarbon

The water-base paint remover consists of potassium hydroxide or sodium hydroxide 5-30 wt%, alkyl phosphate and / or imidazoline surfactant 1-15 wt%, no-halohydrocarbon solvent 0.5-15 wt%, solubilizer 0.1-3 wt% and water for the rest. It has the advantages of low cost, fast paint removing speed, no corrosion on the iron and steel base, wide application range, environment friendship, etc.

Owner:DALIAN SANDAAOKE CHEM

General efficient paint remover

InactiveCN1743389AFast paint removalHigh paint removal efficiencyChemical paints/ink removersChlorideSURFACTANT BLEND

The invention relates to a general efficient paint remover and its preparing method. The paint remover is prepared by mixing methylene chloride, methanol, formic acid, resordinol, paraffin, surfactant and corrosion inhibitor according to rated proportion and making then react under a certain condition. It has fast depainting speed, good depainting effect, wide application range, and little corrosion to keelson, and non-combustible and hypotoxicity.

Owner:BEIJING UNIV OF CHEM TECH

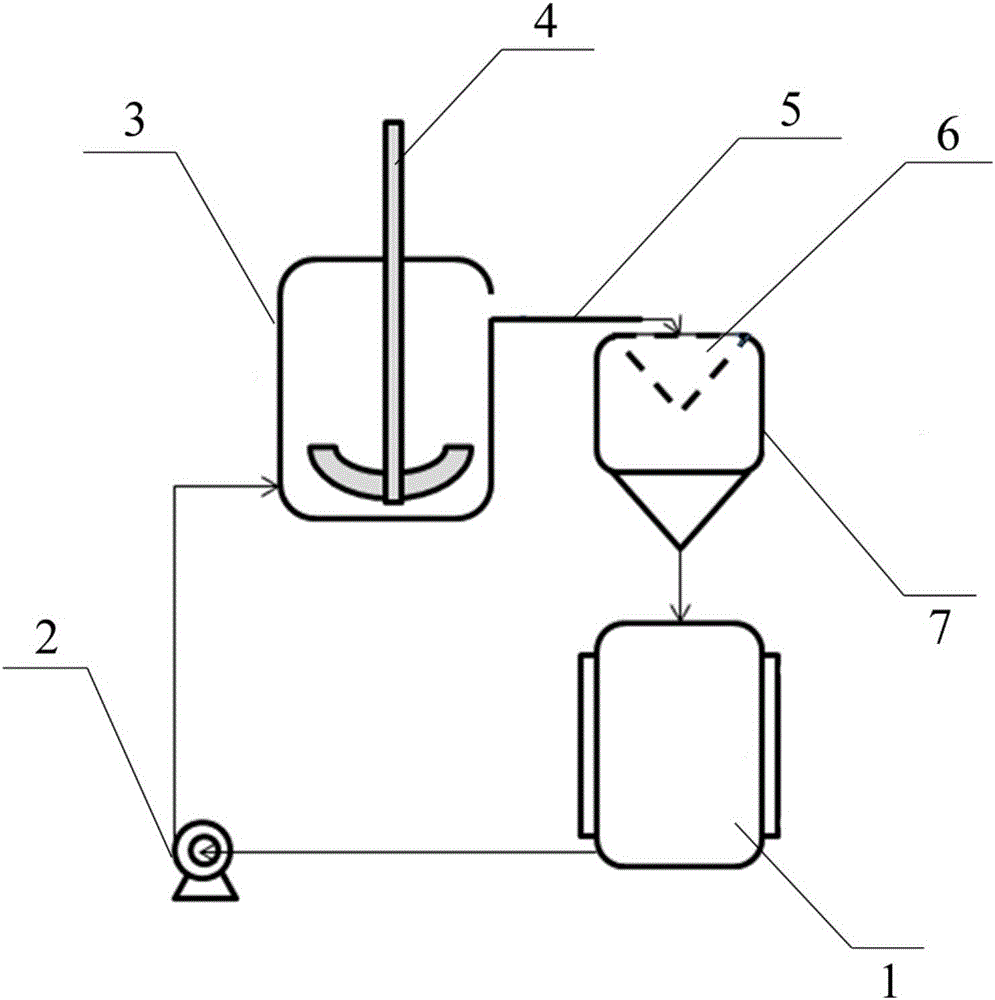

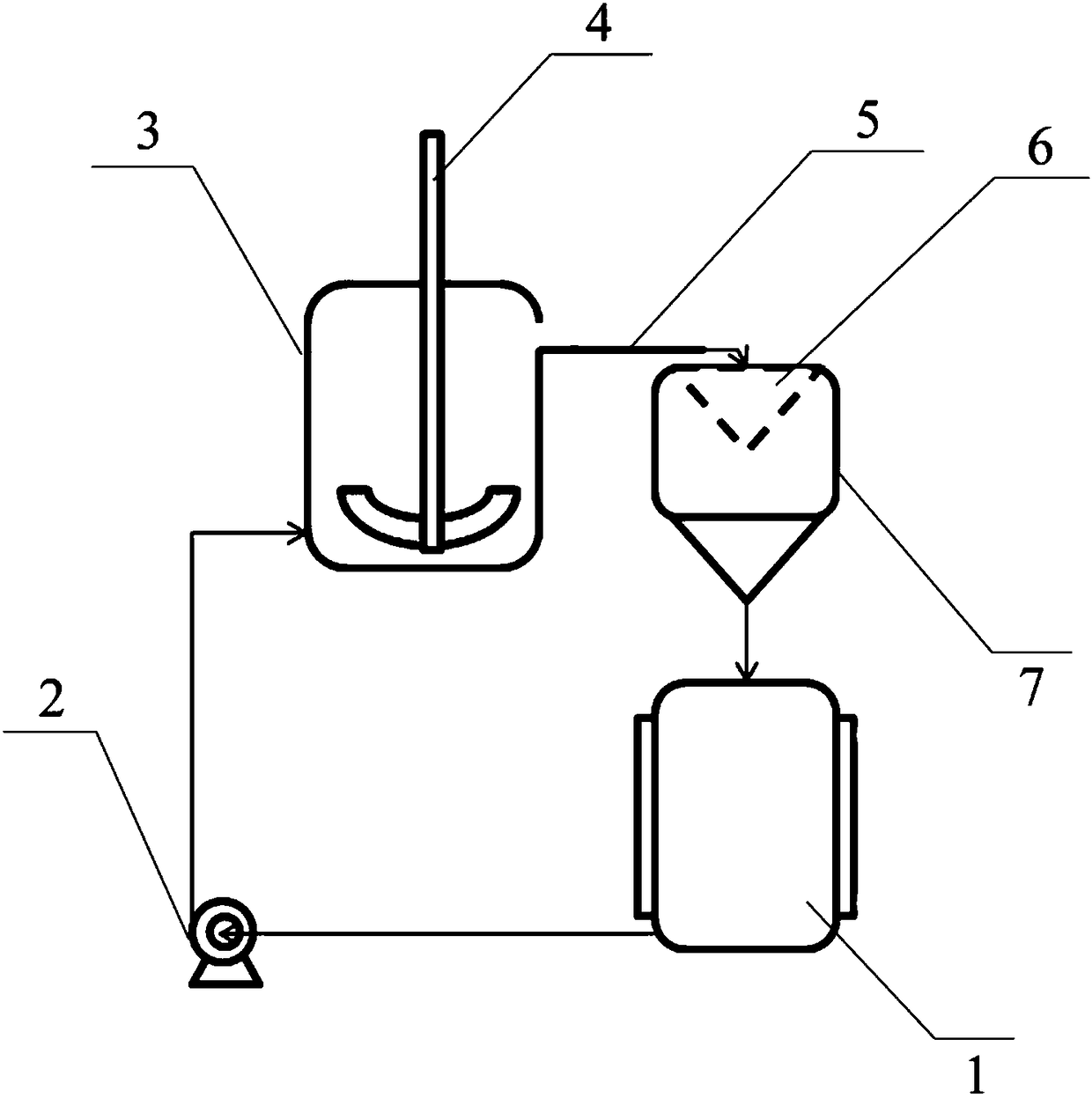

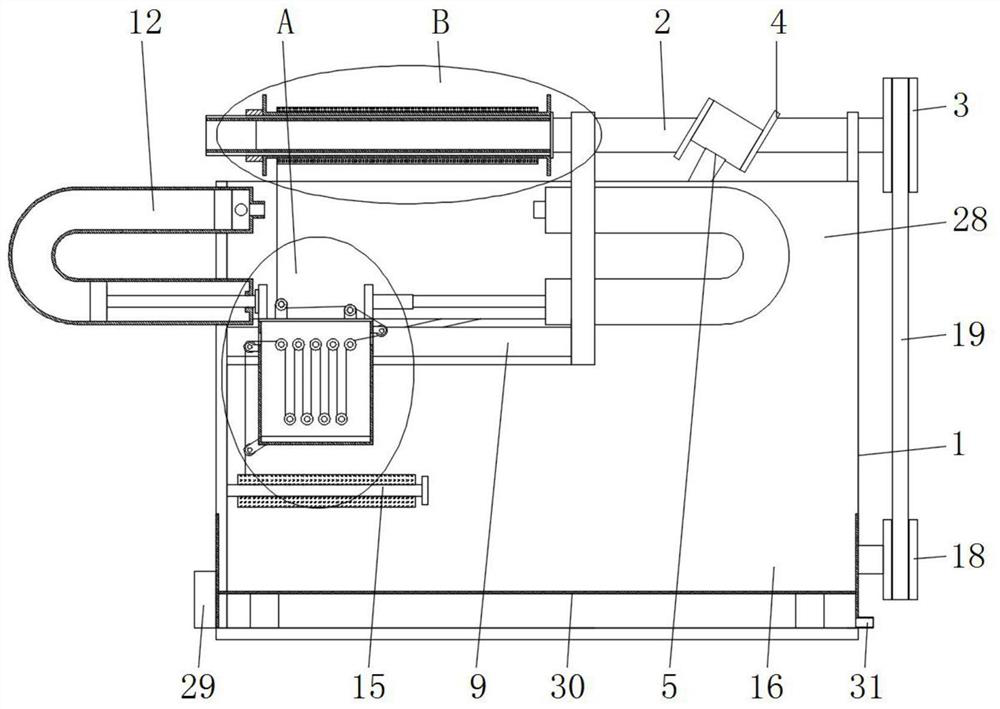

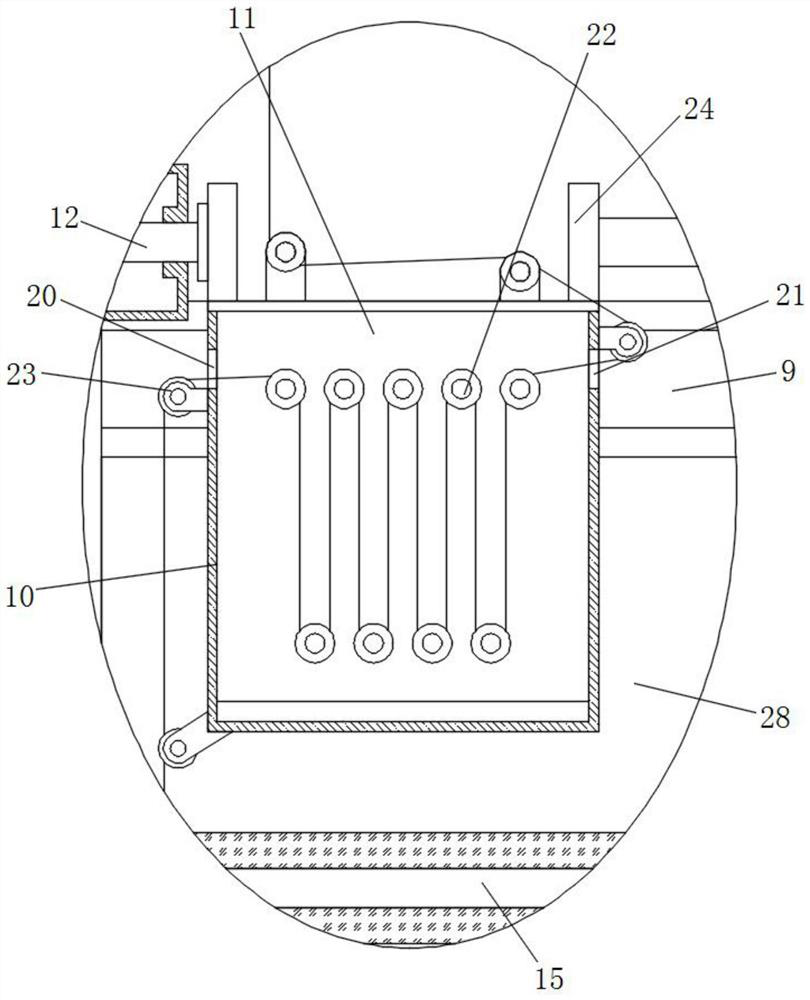

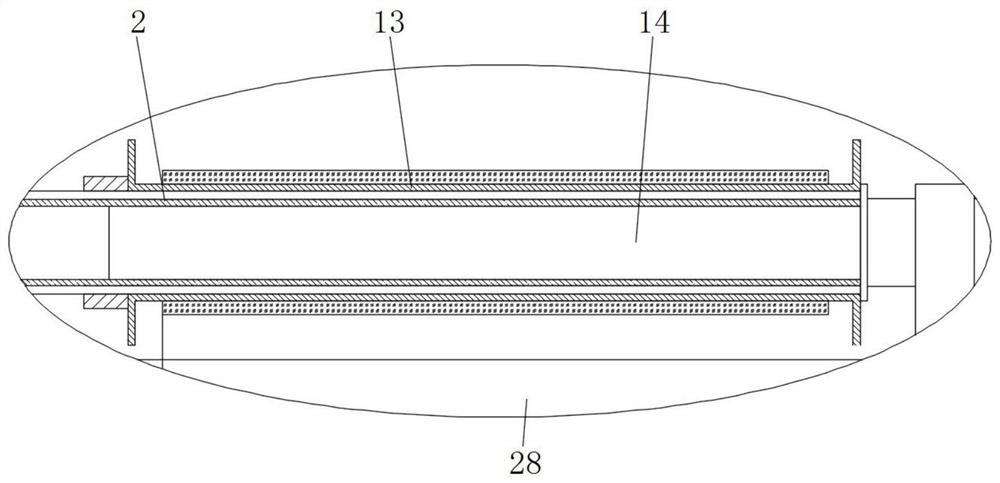

Polyester enamelled wire enamel removing process and device

ActiveCN105670375ARemove completelyFast paint removalChemical paints/ink removersPolyesterPotassium hydroxide

The invention relates to a polyester enamelled wire enamel removing process. The process includes following steps: 1), adding an enamel removing agent into an alkaline liquid tank, heating enamel film treatment temperature of a polyester enamelled wire, wherein the enamel removing agent is a sodium hydroxide and / or potassium hydroxide inorganic alkaline solution of 10-40% in mass concentration; 2), pumping the enamel removing agent in the alkaline liquid tank into the bottom of an enamel removing bucket with a stirring paddle, and placing the polyester enamelled wire to be subjected to enamel removing into the enamel removing bucket; 3), starting stirring after overflowing, and enabling rotating speed to be 30-300 rpm, wherein a shedding enamel film overflows along with the enamel removing agent from an overflowing tank at the top of the enamel removing bucket and flows into a filtering bucket; 4), separating the shedding enamel film from the enamel removing agent in the filtering bucket, wherein the enamel removing agent continues entering the alkaline liquid tank. The invention further relates to a polyester enamelled wire enamel removing device. The polyester enamelled wire enamel removing process and device is convenient to operate, wide in application range, good in enamel removing effect, free of volatilization, little in metal base material corrosion and capable of realizing mass enamel removing.

Owner:ZHEJIANG UNIV

Neutral environment-friendly paint remover

The invention discloses a neutral environment-friendly paint remover. The neutral environment-friendly paint remover is a mixed solution formed by a main solvent, a volatile inhibitor, an activating agent, a cosolvent, an emulsifying agent, a corrosion inhibitor, a penetrating agent, an alkane odor remover and a thickening agent. The main solvent comprises a mixture of two or three of dichloromethane, ethyl acetate and acetone; the volatile inhibitor is liquid paraffin and water; the activating agent is ethanolamine; the cosolvent is ethanol; and the thickening agent is polyethylene glycol. The neutral environment-friendly paint remover comprises, by mass, 70-80% of the main solvent, 0.5-2% of liquid paraffin, 2-5% of water, 4-6% of ethanolamine, 5-10% of ethanol, 3-8% of the emulsifying agent, 0.2-1% of the corrosion inhibitor, 1-3% of the penetrating agent, 0.3-0.7% of the alkane odor remover and 0.5-1.5% of the polyethylene glycol. The neutral environment-friendly paint remover can effectively remove electrophoretic coatings with complex shapes on metal components thoroughly; a paint removal efficiency is higher than or equal to 98%; the neutral environment-friendly paint remover does not corrode metal, wood or cement, and has a wide application scope, no pungent smell, low volatility, and small harm to a human body and an environment. The neutral environment-friendly paint remover has high stability and can be cleaned easily.

Owner:SHANDONG WEIDA MASCH CO LTD

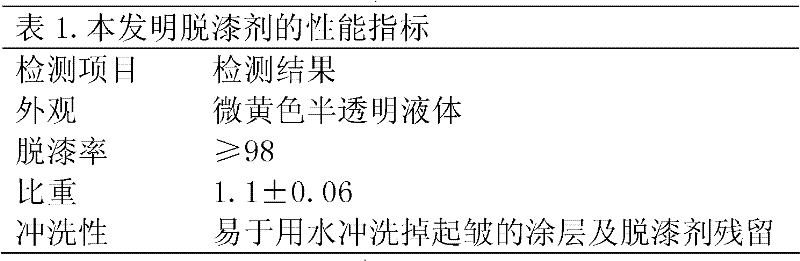

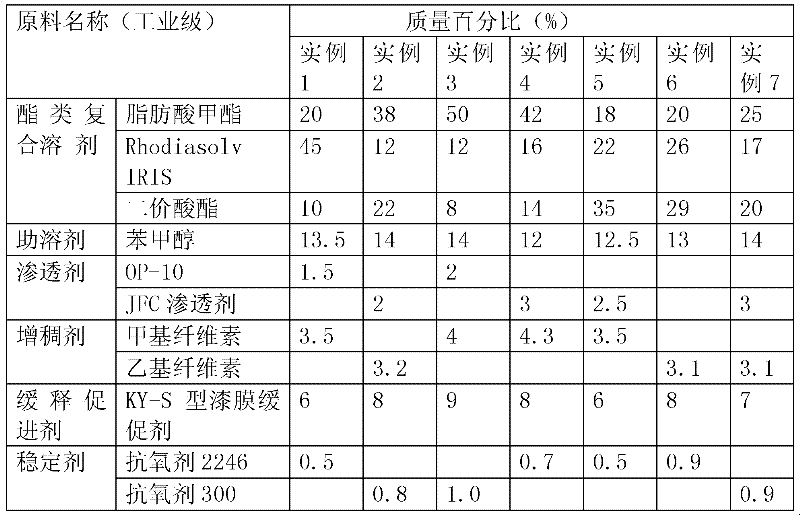

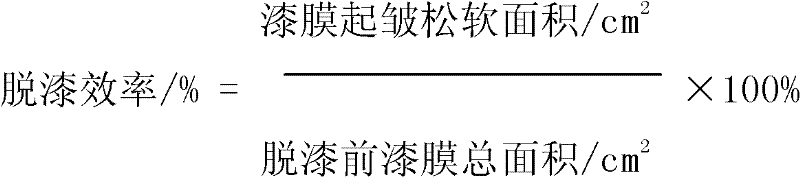

Nontoxic environment-friendly paint remover

InactiveCN102408775AFast paint removalHigh flash pointChemical paints/ink removersEnvironmental resistancePolymethyl methacrylate

The invention discloses a nontoxic environment-friendly paint remover which is prepared from compound solvent, cosolvent, corrosion inhibition accelerator, thickening agent, penetrant and stabilizer. The invention has the following advantages: 1. the paint removing speed is high: the paint remover can dissolve common coatings within 20 minutes; 2. the paint remover does not corrode ferrous metals and non-ferrous metals; 3. the paint remover has high flash point, and is nontoxic and free of methylene chlorides, and the raw materials are biodegradable; 4. the paint remover can be used at -15-50 DEG C, and is free from the environmental effects of high humidity and high heat; 5. different from other paint removers, the metal surface subjected to the paint remover disclosed by the invention can prevent rust for 1 week; and 6. the paint remover is free of volatile inhibitor paraffin, thickening agent polymethyl methacrylate and other substances contained in the traditional paint remover, and the residues after paint removal can be easily flushed and cleaned with water. The invention can be used for overhaul and paint removal of ships, tanks, nuclear facilities, airplanes, automobiles, seamount drogues and other facilities, and can also be used for overhaul and paint removal of oil storage tanks, bridges, wharves, electrical enclosures and the like.

Owner:HONGWEI THERMAL ENERGY TECH SHANGHAI

Paint remover and preparation method thereof, and paint removing method

InactiveCN111334115AAvoid over corrosionEfficient removalChemical paints/ink removersPolymer scienceActive agent

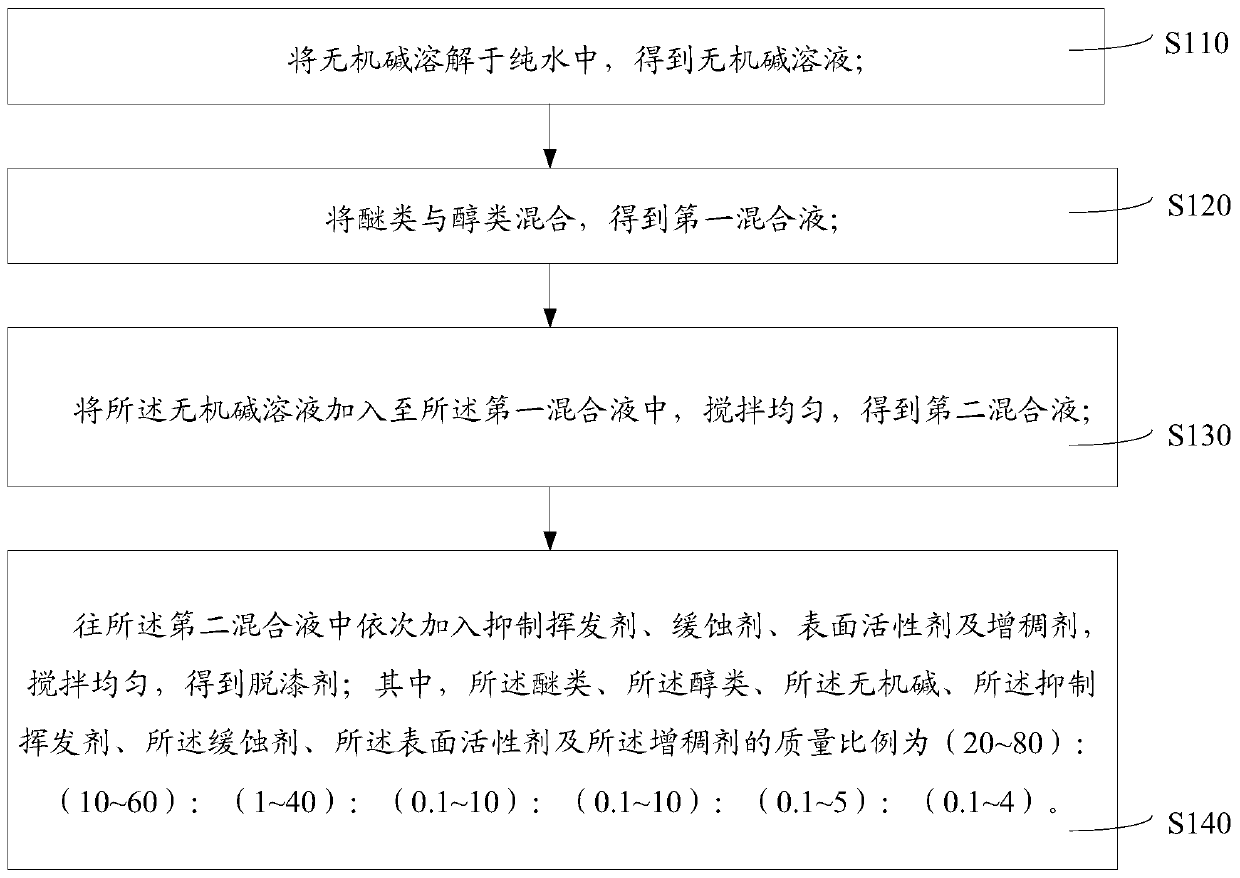

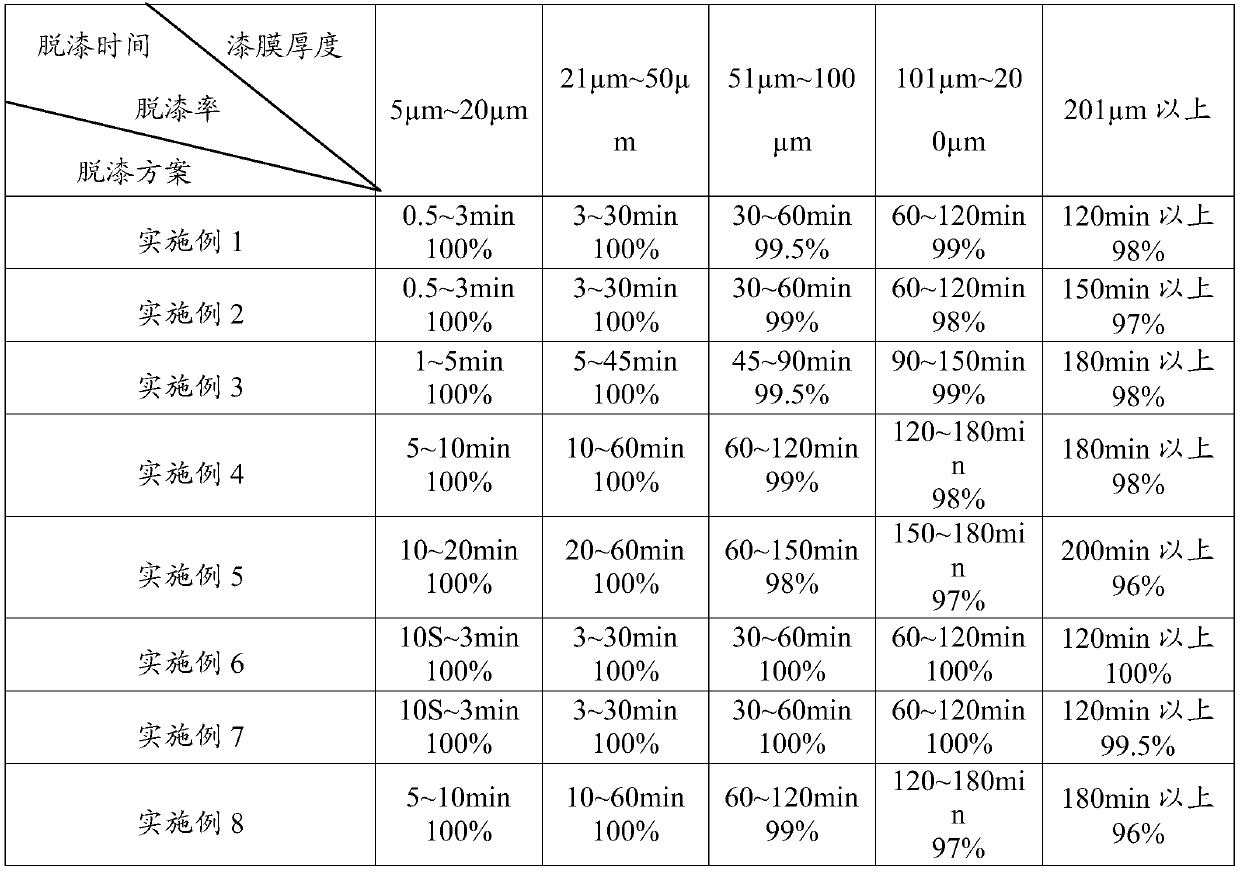

The invention relates to the field of paint removers, and discloses a paint remover and a preparation method thereof, and a paint removing method. The paint remover is prepared from the following components in parts by mass: 20 to 80 parts of ether, 10 to 60 parts of alcohol, 1 to 40 parts of inorganic alkali, 0.1 to 10 parts of a volatile inhibitor, 0.1 to 10 parts of a corrosion inhibitor, 0.1 to 5 parts of a surfactant and 0.1 to 4 parts of a thickening agent. The preparation method of the paint remover comprises the following steps: mixing the inorganic alkali, the ether, the alcohol, thevolatile inhibitor, the corrosion inhibitor, the surfactant and the thickening agent, and uniformly stirring to obtain the paint remover. According to the invention, the paint remover is low in toxicity, environmentally friendly, high in paint removing speed and good in paint removing effect, can avoid corrosion on metal base materials, improve the rust resistance of iron materials, improve the painting adhesive force of iron materials and effectively remove phenolic aldehyde paint films, alkyd paint films, nitro paint films, polyurethane paint films, epoxy resin paint films, water-based paintfilms and electrostatic powder paint films.

Owner:广东东明新材科技有限公司

Paint remover for removing cathodic electrophoretic paint film on surface of steel plate

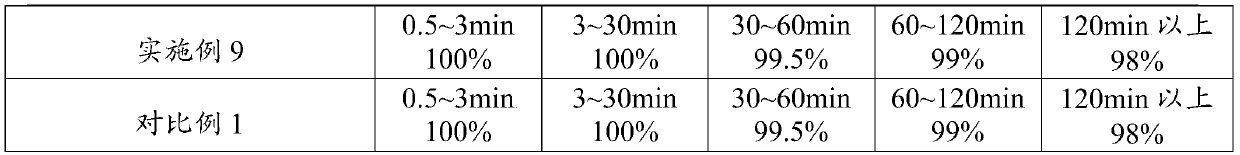

The invention relates to a paint remover for removing a cathodic electrophoretic paint film on the surface of a steel plate. The paint remover comprises the following components in volume ratio: 20-90 parts of amine compound and 10-80 parts of ether compound. The preferable volume ratio of the components of the paint remover is: 80-90 parts of amine compound and 10-20 parts of ether compound. The amine compound is one or two of formamide and N,N'-dimethylformamide; and the ether compound is one or two of butyl cellosolve and ethylene glycol. The two types of compounds are mixed proportionally to obtain the paint remover. During paint removal, the steel plate to be paint-removed is completely soaked in a solution of the paint remover, and the operating temperature range of the paint remover is 30-100 DEG C. The paint remover can meet the requirements of high pain removal speed, no corrosion to substrates, simple preparation, easy operation, convenient use and low toxicity to the human body.

Owner:BAOSHAN IRON & STEEL CO LTD

Glass optical lens paint remover and its preparation and use methods

ActiveCN104098950APrevent water mistHigh boiling pointChemical paints/ink removersPyrrolidinonesHeat stability

The invention relates to the technical field of paint removers and especially relates to a glass optical lens paint remover and its preparation and use methods. The glass optical lens paint remover comprises, by weight, 5-20 parts of sodium hydroxide, 1-10 parts of triethanolamine, 5-25 parts of diethyleneglycolmonomethylether, 1-10 parts of N-methyl pyrrolidone and 55-70 parts of water. The glass optical lens paint remover is an alkaline system. In paint removal, the alkaline sodium hydroxide does not react with sodium silicate in glass so that water mist on the glass surface is avoided and paint removal effects are guaranteed. The glass optical lens paint remover is prepared from the raw materials having high boiling points, has good heat stability, can be heated to a high temperature of 70-100 DEG C and is conducive to fast paint removal. The preparation method of the glass optical lens paint remover has simple processes, needs less devices, utilizes easily available raw materials, can be operated easily, has a low production cost and is conducive to general popularization application.

Owner:广东剑鑫科技股份有限公司

Paint remover

InactiveCN102344711ASlightly corrodedFast paint removalChemical paints/ink removersAcrylic paintFormic acid

The invention discloses a paint remover which comprises the following components in percentage by weight: 60-80% of dichloromethane, 10-20% of formic acid, 5-15% of ethanol and 3-8% of methanol. The paint remover disclosed by the invention can be used for professionally removing acrylic paint, has the advantages of high paint removal speed, favorable effect, slight corrosion to the substrate, simple raw materials, low cost and simple preparation method, and is suitable for large-scale production.

Owner:太仓市联林活性炭厂

Biodegradable environmentally-friendly paint remover

InactiveCN103396696AFast paint removalHigh boiling pointChemical paints/ink removersPolymer scienceBoiling point

The invention discloses a biodegradable environmentally-friendly paint remover. The biodegradable environmentally-friendly paint remover is prepared from the following raw materials: a main solvent, a macromolecule solvent, acetic acid, a surface active agent, a thickening agent, a corrosion inhibitor and water. The invention also discloses a preparation method of the biodegradable environmentally-friendly paint remover. The paint remover prepared by the method has the advantages of fast paint removal speed, wide application range, no corrosion and low corrosion to a substrate, no influence on repainting, high boiling point, good stability, operation at a room temperature, simplicity, convenience, practicability and low production cost. The biodegradable environmentally-friendly paint remover is biodegradable and is an environmentally-friendly paint remover.

Owner:张运泉

Electrolytic paint-stripping agent and paint-stripping method

ActiveCN108624946AFast paint removalLow toxicityElectrophoretic coatingsHazardous substanceWastewater

The invention discloses an electrolytic paint-stripping agent. The electrolytic paint-stripping agent comprises 5-55wt% of a paint-stripping main agent, 8-25wt% of a cosolvent, 3-15wt% of a penetrating agent, 3-5wt% of conductive salt and1-5wt% of a surfactant. The electrolytic paint-stripping agent is high in paint-removing speed, so that an electrophoretic paint film can be quickly removed fromthe surface of a workpiece; the paint-stripping agent does not corrode the workpiece; the paint-stripping agent does not contain toxic and harmful substances and has low toxicity to a human body, so that the personal safety of an operator is guaranteed, treatment on wastewater after paint stripping is simple, and environment friendliness is achieved.

Owner:浙江瑞特良微电子材料有限公司

Paint stripper

The invention discloses a paint stripper which comprises the following raw materials in parts by weight: 6-8 parts of ethylene glycol, 3-5 parts of ethanolamine, 60-70 parts of dichloromethane, 2-4 parts of triacetate fiber, 3-5 parts of sodium alkyl benzene sulfonate, 1-2 parts of paraffin, and 2-4 parts of water. The paint stripper is simple in raw materials, low in cost, fast in paint stripping and good in effect, and can be used for removing coating on epoxy resin paint, organic silicon and amino baking enamel.

Owner:HAIAN GUOLI CHEM

Multifunctional water-based paint stripper

InactiveCN104277570AFast paint removalSimplify the production processChemical paints/ink removersParaffin waxPaint stripper

The invention relates to a multifunctional water-based paint stripper. The paint stripper is prepared from the following raw materials: 75-80 parts of dichloromethane, 15-35 parts of ethyl acetate, 2.5-10 parts of methyl cellulose, 7-15 parts of formic acid, 15-35 parts of ethanol, 5-8 parts of corrosion inhibitor, 20-55 parts of paraffin, 2-15 parts of emulsifier, 20-60 parts of water. The paint layers on the surfaces of woods and metals can be effectively stripped through the multifunctional water-based paint stripper, the paint stripping speed is high and the multifunctional water-based paint stripper does not contain formaldehyde, benzene and harmful heavy metals, and thus cannot cause environment pollution and harm to construction workers; compared with the traditional paint stripper on the market, the paint stripper has the advantages of being high in paint stripping speed, incapable of causing secondary harm to a primer, simple in production procedures, low in cost, convenient to use, and the like.

Owner:QINGDAO JIASHANG CREATIVE CULTURE

Environment-friendly aqueous paint remover

InactiveCN104559432AGood paint removal effectFast paint removalChemical paints/ink removersChemical industryParaffin wax

The invention relates to the field of chemical industry paint, in particular to an environment-friendly aqueous paint remover. The paint remover is prepared by mixing and compounding the following components in parts by weight: 25-45 parts of dichloromethane, 7-8 parts of vinyl alcohol, 6-7 parts of propanol, 3-9 parts of methyl cellulose, 7-11 parts of diethyl carbonate, 3-4 parts of a surfactant, 20-24 parts of liquid paraffine, 5-6.5 parts of a thickening agent, 12-14 parts of phosphoric acid, 1-2 parts of sodium nitrite and 12-14 parts of a solvent. The environment-friendly aqueous paint remover disclosed by the invention is high in depainting speed and is unlikely to volatilize; the aqueous paint remover can be directly applied to a painting surface under a normal atmospheric temperature for depainting, and the paraffine for volatilization resistance is contained in the components, so that the paint remover is favorable for renewedly painting workpieces of which the paint films are removed; the paint surfaces of automobiles, electric appliances, furniture and the like can be effectively removed, and the surfaces of metal and wood are not damaged. The paint remover is simple in manufacturing working procedures, is convenient to operate, is low in cost of raw materials, and has no residues, so that the paint remover is suitable for factory type large-scale production.

Owner:QINGDAO JIASHANG CREATIVE CULTURE

Aerosol type wax-free paint remover

InactiveCN107641369AReduce dosageInhibit swellingChemical paints/ink removersEthylene glycol monophenyl etherMethanol

The invention discloses an aerosol type wax-free paint remover. A formula of the aerosol type wax-free paint remover comprises the following components in parts by weight: 16.0 to 24.0 parts of an environment-friendly high-boiling-point solvent AGSE, 2.0 to 6.5 parts of solvent oil, 0.8 to 3.6 parts of ethylene glycol monophenyl ether, 2.0 to 4.0 parts of propylene glycol monomethyl ether, 26.0 to40.0 parts of dichloromethane, 5.0 to 12.0 parts of methanol, 2.0 to 9.0 parts of formic acid microcapsules, 1.5 to 3.5 parts of a thickening agent and 12.0 to 26 parts of a propellents. With adoption of the technical scheme, the paint remover has the following advantages: 1, a low-boiling-point solvent and a high / medium-boiling-point solvent are compounded to cooperatively reduce the volatilization speed rate and achieve extremely high dissolving power and penetrability; 2, by dual formic acid microcapsulation, a tank body is prevented from being corroded by formic acid, a paint removing effect is enhanced; and the stability of the product is improved; 3, the thickening agent is added to retard product loss and increase the utilization rate of the product, and no wax is contained, so that influence on recoating after complete flushing is eliminated; 4, by vaporization heat absorption of the propellents, the surface temperature of a workpiece is reduced, the volatilization speed of the product is low, and the characteristics of flexibility and convenience for construction and good atomization are achieved.

Owner:GUANGDONG SANVO CHEM IND TECH

Aluminium alloy paint stripper and preparation method thereof

ActiveCN102181199AFast paint removalHigh safety constructionChemical paints/ink removersTurpentinePhenol

The invention relates to a paint stripper used for removing metal, especially removing old paint films on the surface of aluminum alloy, and also relates to a preparation method of the paint stripper. The paint stripper is characterized by consisting of the following components according to parts by weight: 70-75 parts of dichloromethane, 1-5 parts of turpentine, 0.1-0.8 part of titanium dioxide,15-20 parts of phenol, 0.1-0.3 part of defoamer NXZ, 0.2-0.9 part of Octylphenols polyoxyethylene ether, 0.6-1.2 part of hydroxyethyl celluloses, 0.8-3parts of corrosion inhibitor A-40, 1-1.4 parts of water, 0.3-0.8 part of paraffin, 1-2 parts of Vaseline, 0.01-0.1 part of corrosion inhibitor AMP-95 and 1-2 parts of deodorant. The paint stripper is applicable to depriving metal of various old paint films, characterized by quick paint stripping speed, high construction safety, small toxicity, mild gas and the like. Especially, the product has no corrosion to aluminum alloy.

Owner:西安经建油漆有限责任公司

Corrosion-inhibition environment-friendly water-based paint remover and preparation method thereof

InactiveCN106519787AImprove stabilityImprove antioxidant capacityChemical paints/ink removersWater basedEthylenediamine

The invention discloses a corrosion-inhibition environment-friendly water-based paint remover which is prepared from the following raw materials in parts by weight: 1.2-1.4 parts of nano montmorillonite, 1.5-2 parts of penetrant T, 42-46 parts of benzyl alcohol, 11-12 parts of acetone, 10-11 parts of hydrogen peroxide, 3-3.5 parts of methyl cellulose, 2-2.4 parts of urotropine, 1.3-1.5 parts of dodecyl benzene sulfonate, 1.6-1.9 parts of microporous starch, 2.2-2.5 parts of microcrystalline wax, 0.8-1 part of tetrabutyl titanate, a right amount of ammonia water, a right amount of ethanol, 50-55 parts of water, 1-1.3 parts of tetrasodium ethylenediamine tetraacetate, 3-4 parts of nitromethane and 1-2 parts of dimethyl benzoxazole. The nitromethane can accelerate the dissolution of the paint and enhance the depainting speed; the tetrasodium ethylenediamine tetraacetate is combined to complex the dispersed and dissolved paint and metal ions to enhance the depainting effect; and the dimethyl benzoxazole can prevent metal corrosion.

Owner:MAANSHAN TUORUI METAL SURFACE TECH

Water-soluble paint peeling agent and paint peeling method

The invention discloses a water-soluble paint peeling agent. The water-soluble paint peeling agent comprises 5 to 60wt percent of a paint peeling main agent, 5 to 30wt percent of a solubilizing assistant, 3 to 15wt percent of a penetrant, 3 to 5wt percent of a dispersant, 1 to 5wt percent of a surfactant, and water for the surplus. The water-soluble paint peeling agent is high in paint peeling speed, can rapidly remove electrophoretic paint films on the surfaces of work pieces, does not corrode the work pieces, does not contain toxic and harmful substance, has little toxicity to human body, guarantees the personal safety of operating personnel, and ensures that waste water subjected to paint peeling is simple to treat and environmentally friendly.

Owner:SHANGHAI LVTONG CHEM TECH CO LTD +1

Environment-friendly paint remover

The application discloses an environment-friendly paint remover which comprises the following components in parts by mass: 50 parts of mixed chlorinated hydrocarbon, 30 parts of a paraffin-kerosene solution, 10 parts of ethoxyl propyl cellulose, 7 parts of a thickening agent, 5 parts of a surface active agent, 10 parts of ethyl ether, 15 parts of butanol, 5 parts of a dark-side eroding agent, 8 parts of methylbenzene and 15 parts of caprylic capric triglyceride. Therefore, the environment-friendly paint remover is simple in raw material, low in cost, high in paint removing speed, good in effect and low in toxicity, and can be used for removing epoxy paint as well as organosilicon and amino baking paint coating.

Owner:启东市欣德龙制衣有限公司

Low-volatile low-toxicity paint remover

The invention discloses a low-volatile low-toxicity paint remover. The low-volatile low-toxicity paint remover is prepared from components including, by weight, 50 parts of N-methylpyrrolidone, 30 parts of dimethyl carbonate, 10 parts of dimethylformamide, 7 parts of a thickener, 5 parts of sodium dodecyl benzene sulfonate, 20 parts of dichloromethane and 15 parts of sodium hexametaphosphate. The low-volatile low-toxicity paint remover is simple in raw material, low in cost, quick in paint removal, good in effect, low in toxicity and capable of being used for removal of epoxy paint, organosilicon and amino baking varnish coatings.

Owner:启东市奇赢服饰有限公司

Paint remover

InactiveCN105348903AFast paint removalImprove efficiencyChemical paints/ink removersEthyleneglycol monobutyl etherSodium phosphates

The invention discloses a paint remover. The paint remover is prepared from the following raw materials in parts by weight: 2-4 parts of sodium pyrophosphate, 2-5 parts of triethanolamine, 4-7 parts of chitosan, 2.2-3 parts of a stabilizer, 4.2-5.6 parts of tripoly sodium silicate, 3.5-5.6 parts of zinc chloride, 4-5 parts of sodium gluconate, 5-8 parts of sodium carbonate, 4-6 parts of ethyl alcohol, 7-14 parts of sulfamic acid, 2-4 parts of aluminum silicate fibers, 8-14 parts of dichloromethane, 3-4 parts of a surfactant, 5-7 parts of boric acid, 2-6 parts of ethylene glycol monobutyl ether, 5-8 parts of isopropanol and 3-7 parts of carbinolamine. The paint remover provided by the invention has the beneficial effects that the paint remover is high in paint removing speed, high in efficiency, short in cleaning time, so that energy is saved, and work efficiency is improved effectively; moreover, the paint remover is non-toxic.

Owner:QINGDAO XIANGJIA INTPROP SERVICE CO LTD

Paint remover

The invention discloses a paint remover. The paint remover comprises the following raw materials in parts by mass: 6-8 parts of ethylene glycol, 5-6 parts of potassium chloride, 3-5 parts of acetic acid, 60-70 parts of dichloromethane, 5-10 parts of toluic acid, 2-4 parts of triacetate fiber, 3-5 parts of lime, 1-2 parts of paraffin and 2-4 parts of distilled water. The paint remover has the characteristics of simple raw material, low cost, and fast paint removing speed and good paint removing effect, and can be used for removing epoxy resin paint, organic silicon and amino baking paint coating.

Owner:NANTONG SHUNYANG CHEM

Novel low-volatile paint remover

The invention relates to the field of chemical coating and particularly relates to a novel low-volatile paint remover. The novel low-volatile paint remover comprises the following components in parts by weight: 70-80 parts of a phenyl substituted alkanol, 2-3 parts of a thickener, 2.5-4.5 parts of a surfactant, 2-3 parts of a coalescing agent, 12-14 parts of diethyl carbonate, 6-9 parts of vinyl alcohol, 0.01-0.05 part of a corrosion inhibitor, 1.5-2.5 parts of a mildew preventive, 20-40 parts of paraffin and 40-60 parts of a solvent. The novel low-volatile paint remover provided by the invention is fast in paint removal speed and hard to volatilize, and can be directly smeared on a paint surface to remove the paint; the component comprises volatilization-preventing paraffin, so that a workpiece without a film is re-coated; the paint remover is simple in preparation step, convenient to operate and low in price of raw materials and suitable for industrial scaled production.

Owner:QINGDAO JIASHANG CREATIVE CULTURE

Process and device for removing paint from polyester enameled wire

ActiveCN105670375BRemove completelyFast paint removalChemical paints/ink removersPolyesterPotassium hydroxide

The invention relates to a polyester enamelled wire enamel removing process. The process includes following steps: 1), adding an enamel removing agent into an alkaline liquid tank, heating enamel film treatment temperature of a polyester enamelled wire, wherein the enamel removing agent is a sodium hydroxide and / or potassium hydroxide inorganic alkaline solution of 10-40% in mass concentration; 2), pumping the enamel removing agent in the alkaline liquid tank into the bottom of an enamel removing bucket with a stirring paddle, and placing the polyester enamelled wire to be subjected to enamel removing into the enamel removing bucket; 3), starting stirring after overflowing, and enabling rotating speed to be 30-300 rpm, wherein a shedding enamel film overflows along with the enamel removing agent from an overflowing tank at the top of the enamel removing bucket and flows into a filtering bucket; 4), separating the shedding enamel film from the enamel removing agent in the filtering bucket, wherein the enamel removing agent continues entering the alkaline liquid tank. The invention further relates to a polyester enamelled wire enamel removing device. The polyester enamelled wire enamel removing process and device is convenient to operate, wide in application range, good in enamel removing effect, free of volatilization, little in metal base material corrosion and capable of realizing mass enamel removing.

Owner:ZHEJIANG UNIV

Enameled wire recovery equipment

InactiveCN111703970AEasy to dryAchieve chemical strippingFilament handlingBasic electric elementsDrive wheelUniversal joint

The invention discloses enameled wire recovery equipment, and relates to the technical field of metal wire recovery. The enameled wire recovery equipment comprises a frame, a connecting shaft is rotationally connected to the top of the frame, a driving wheel is fixedly connected to one end of the connecting shaft, a Z-shaped frame is arranged on the side, close to the driving wheel, of the connecting shaft, a swing frame is rotationally connected to the center of the Z-shaped frame, a push-pull rod is movably connected to the bottom of the swing frame through a universal joint, a movable blockis rotationally connected to the outer end of the push-pull rod, guide rods are slidably connected to the two sides of the movable block correspondingly, a paint removing box is fixedly connected tothe front face of the movable block, and a wire winding frame is slidably connected into the paint removing box. The enameled wire recovery equipment solves the problem that an existing enameled wirecoil is directly subjected to chemical depainting, consequently the depainting effect is poor, and consumed time is long; and the problem that for mechanical scrapping, mechanical damage such as enameled wire abrasion and wire breakage is prone to be caused due to excessive force application, and meanwhile, personnel are prone to injury if improper using occurs.

Owner:范德霞

A kind of electrolytic paint stripping agent and stripping method

ActiveCN108624946BFast paint removalLow toxicityElectrophoretic coatingsHazardous substanceActive agent

The invention discloses an electrolytic paint-stripping agent. The electrolytic paint-stripping agent comprises 5-55wt% of a paint-stripping main agent, 8-25wt% of a cosolvent, 3-15wt% of a penetrating agent, 3-5wt% of conductive salt and1-5wt% of a surfactant. The electrolytic paint-stripping agent is high in paint-removing speed, so that an electrophoretic paint film can be quickly removed fromthe surface of a workpiece; the paint-stripping agent does not corrode the workpiece; the paint-stripping agent does not contain toxic and harmful substances and has low toxicity to a human body, so that the personal safety of an operator is guaranteed, treatment on wastewater after paint stripping is simple, and environment friendliness is achieved.

Owner:浙江瑞特良微电子材料有限公司

Green environmentally friendly efficient paint removal cream

InactiveCN106893393AAvoid polluting the environmentAvoid defects that are harmful to the human bodyChemical paints/ink removersDibasic esterSodium gluconate

The applicant of the invention provides a green environmentally friendly efficient paint removal cream. The green environmentally friendly efficient paint removal cream comprises the following raw materials in parts by weight: 35-50 parts of dibasic ester, 8-16 parts of dipropylene glycol monomethyl ether, 4-9 parts of phenylcarbinol, 12-26 parts of water, 0.2-2 parts of benzotriazole, 2-6 parts of formic acid, 2-6 parts of boric acid, 5-15 parts of ethyl alcohol, 0.2-1.2 parts of NP-10, 1-5 parts of sodium gluconate, 0.01-5 parts of hydroxyethyl methyl cellulose, and 0.05-1 part of polyepoxysuccinic acid. The paint removal cream is a cream, is directly applied on a matrix where a patient is to be removed, and does not flow down to affect the construction operation and the environment; and besides, the paint removal cream is water soluble, is safe and environmentally friendly, and is high in paint removal efficiency.

Owner:苏州市金纳润特科技有限公司 +1

Green alkaline paint remover for eliminating coating from electronic circuit board and its preparation and usage

InactiveCN100415836CReduce poisonNo corrosionChemical paints/ink removersAqueous sodium hydroxideSURFACTANT BLEND

The present invention is green alkaline paint remover for eliminating coating from electronic circuit board and its preparation and usage, and belongs to the field of paint remover technology. The paint remover consists of NaOH in 40-150 g / L, surfactant in 0.5-50 g / L, additive in 0-50 g / L, corrosion retardant 0.1-2.5 g / L, and water for the rest. It is prepared through mixing and heating at 50-80 for dissolving completely. When the paint remover is used, the electronic circuit board is soaked in the paint remover and heated at 50-100 deg.c for 10-60 min to eliminate its paint layer. The present invention has the advantages of low cost, fast paint eliminating speed, low toxicity, use safety and capacity of being used repeatedly.

Owner:UNIV OF SCI & TECH BEIJING

Aluminium alloy paint stripper and preparation method thereof

ActiveCN102181199BFast paint removalHigh safety constructionChemical paints/ink removersTurpentineDioxyethylene Ether

Owner:西安经建油漆有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com