Patents

Literature

35results about How to "Slightly corroded" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

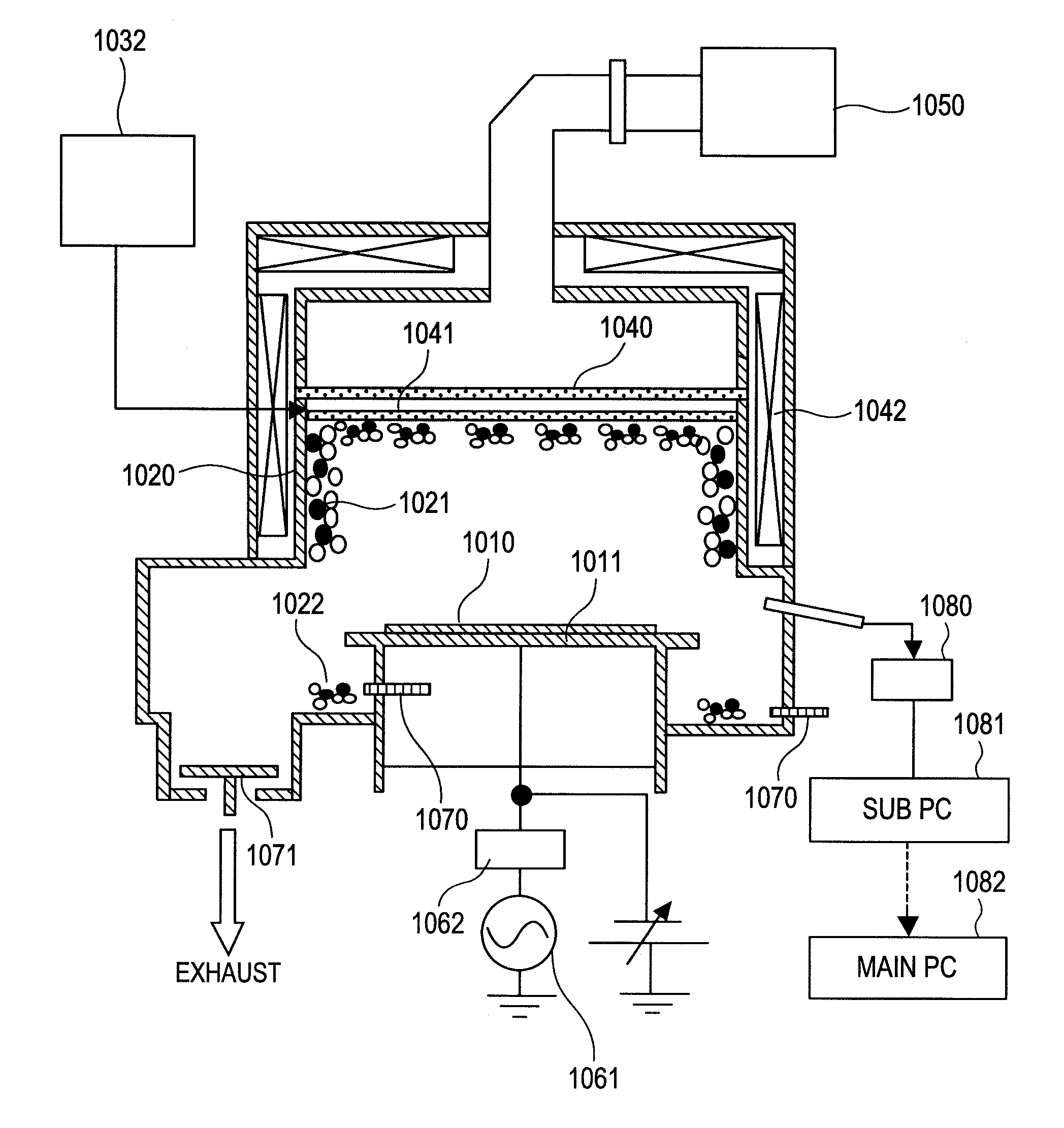

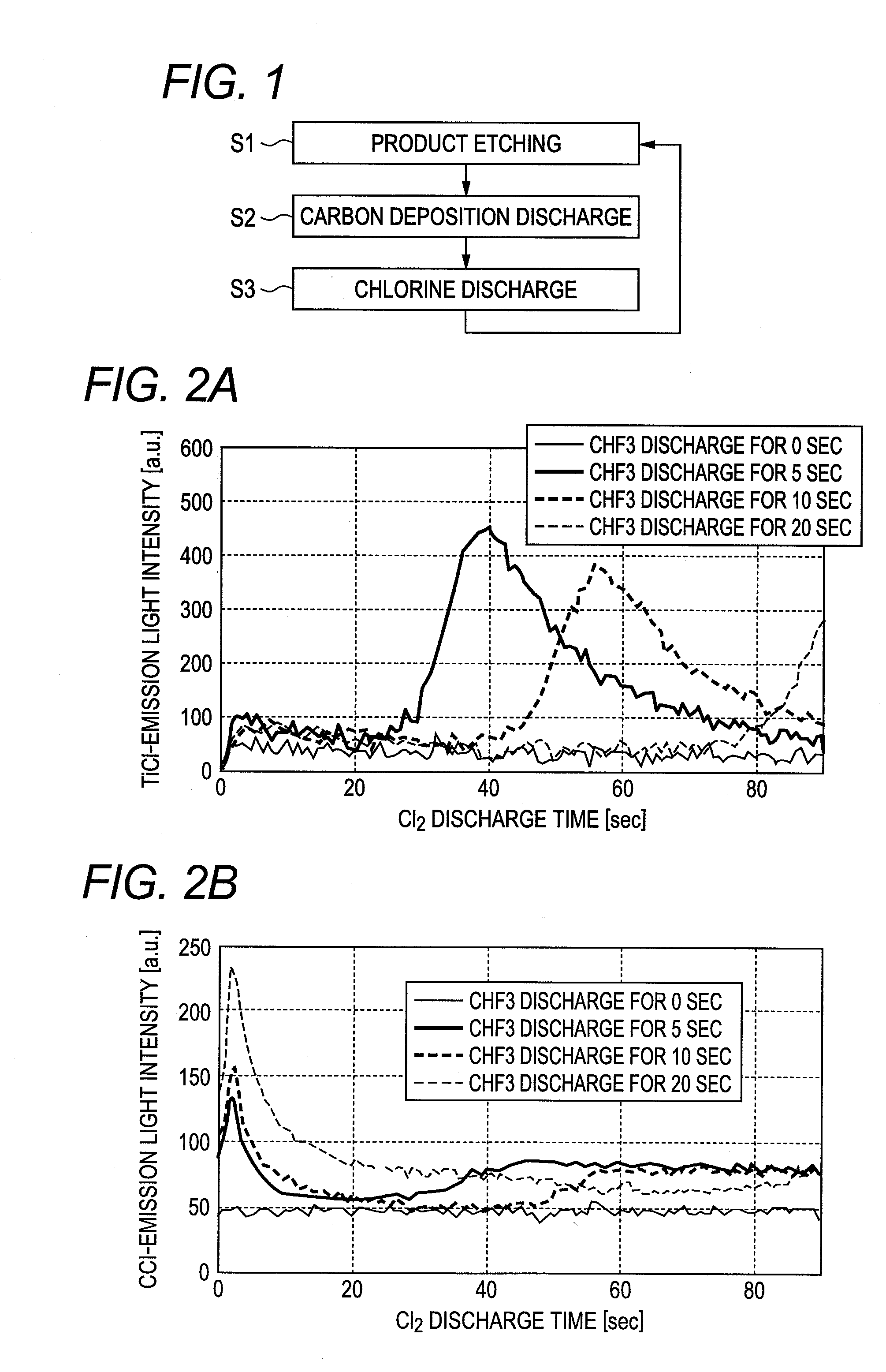

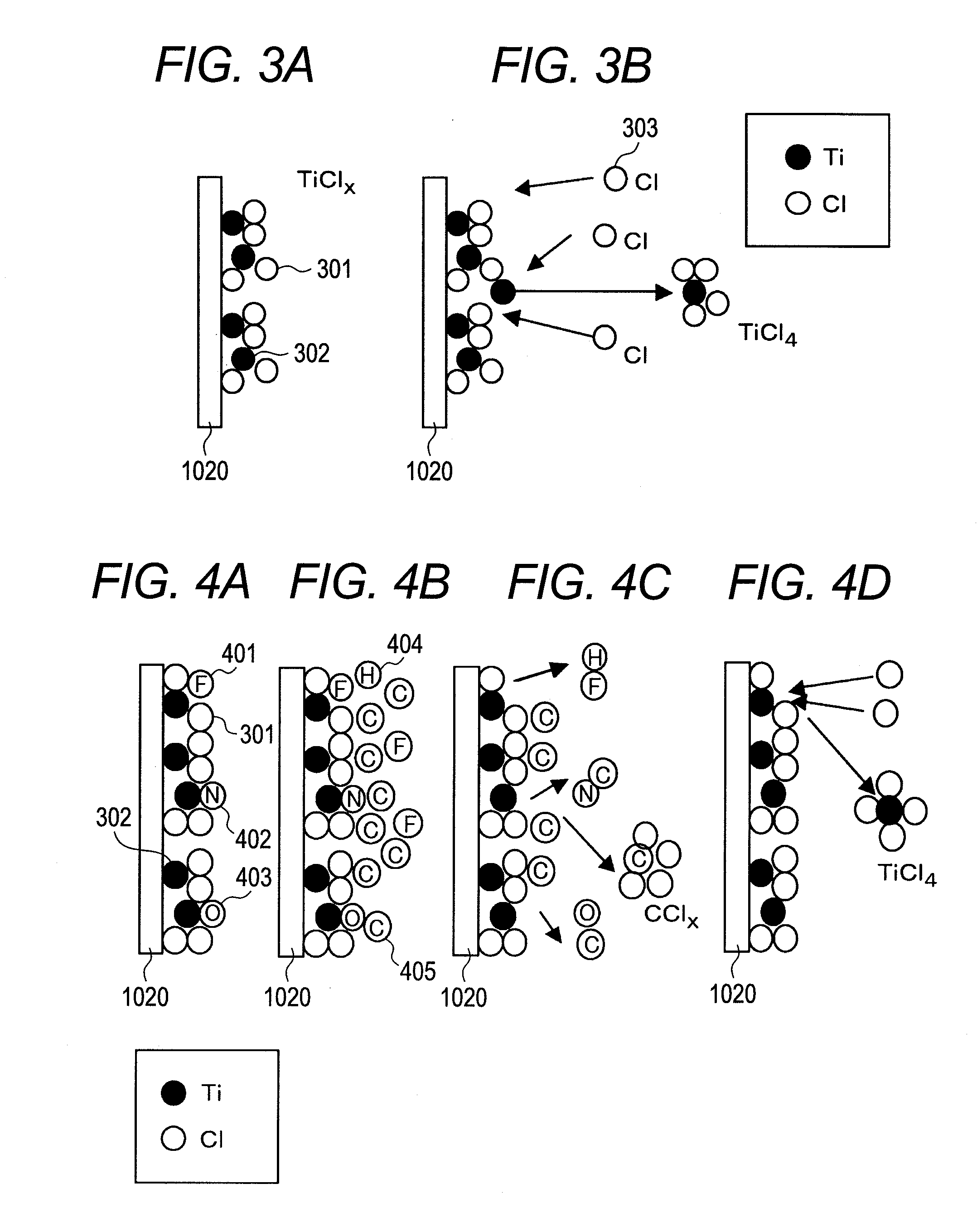

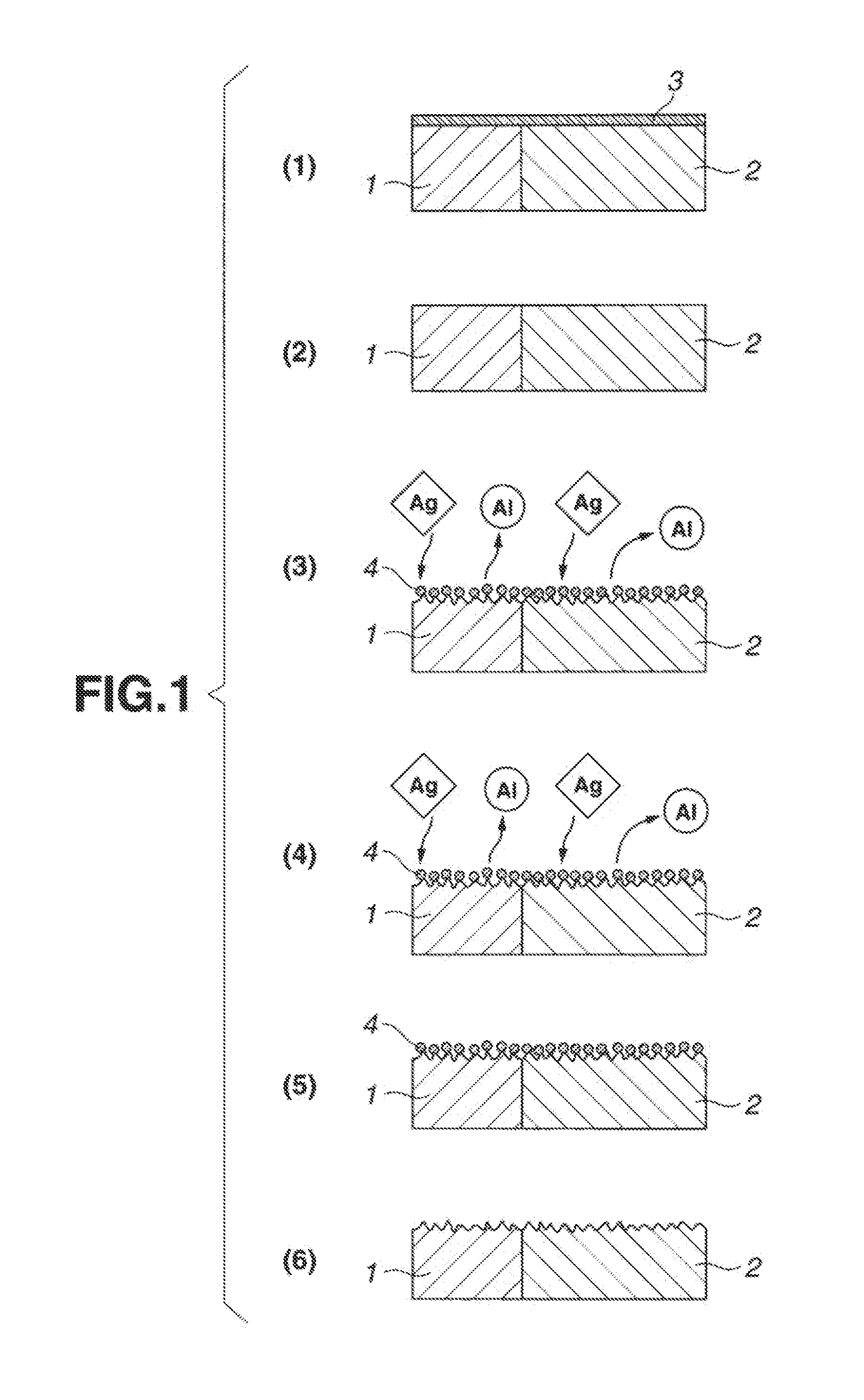

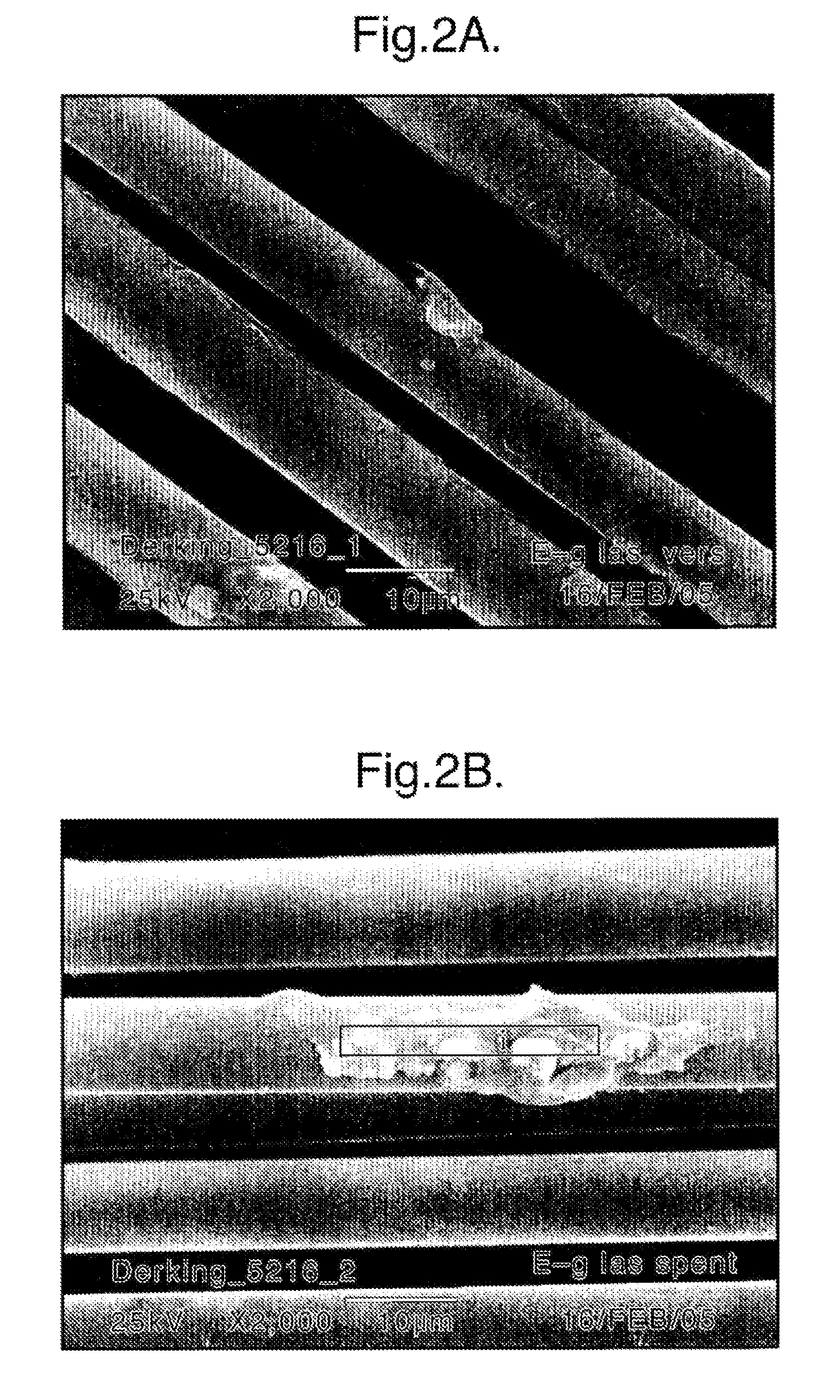

Plasma processing method and plasma processing apparatus

ActiveUS20120085366A1Strong oxidation abilityAccelerated corrosionElectric discharge tubesSemiconductor/solid-state device manufacturingForeign matterBoron oxide

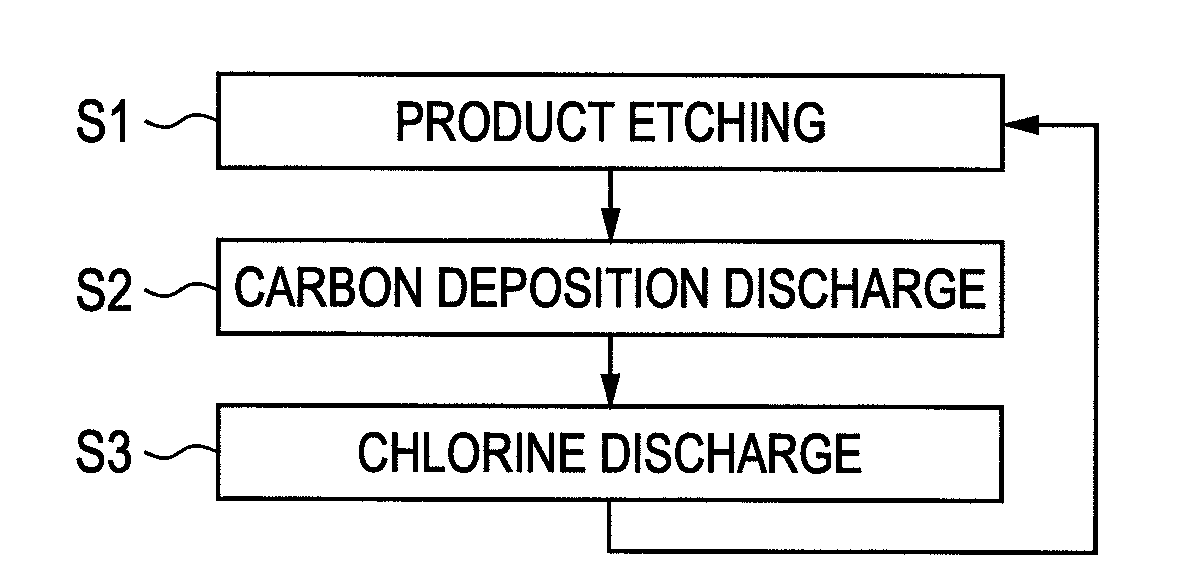

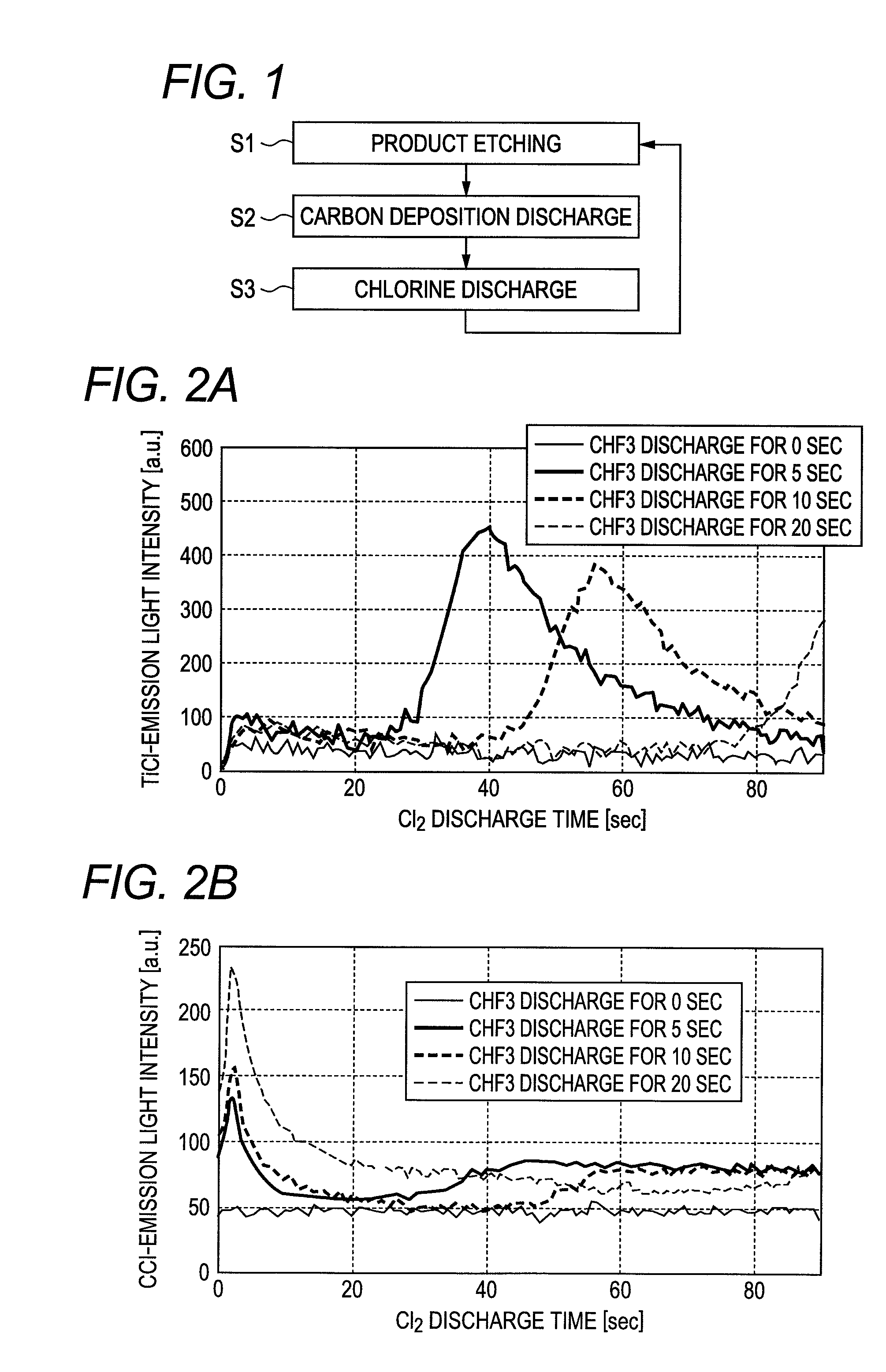

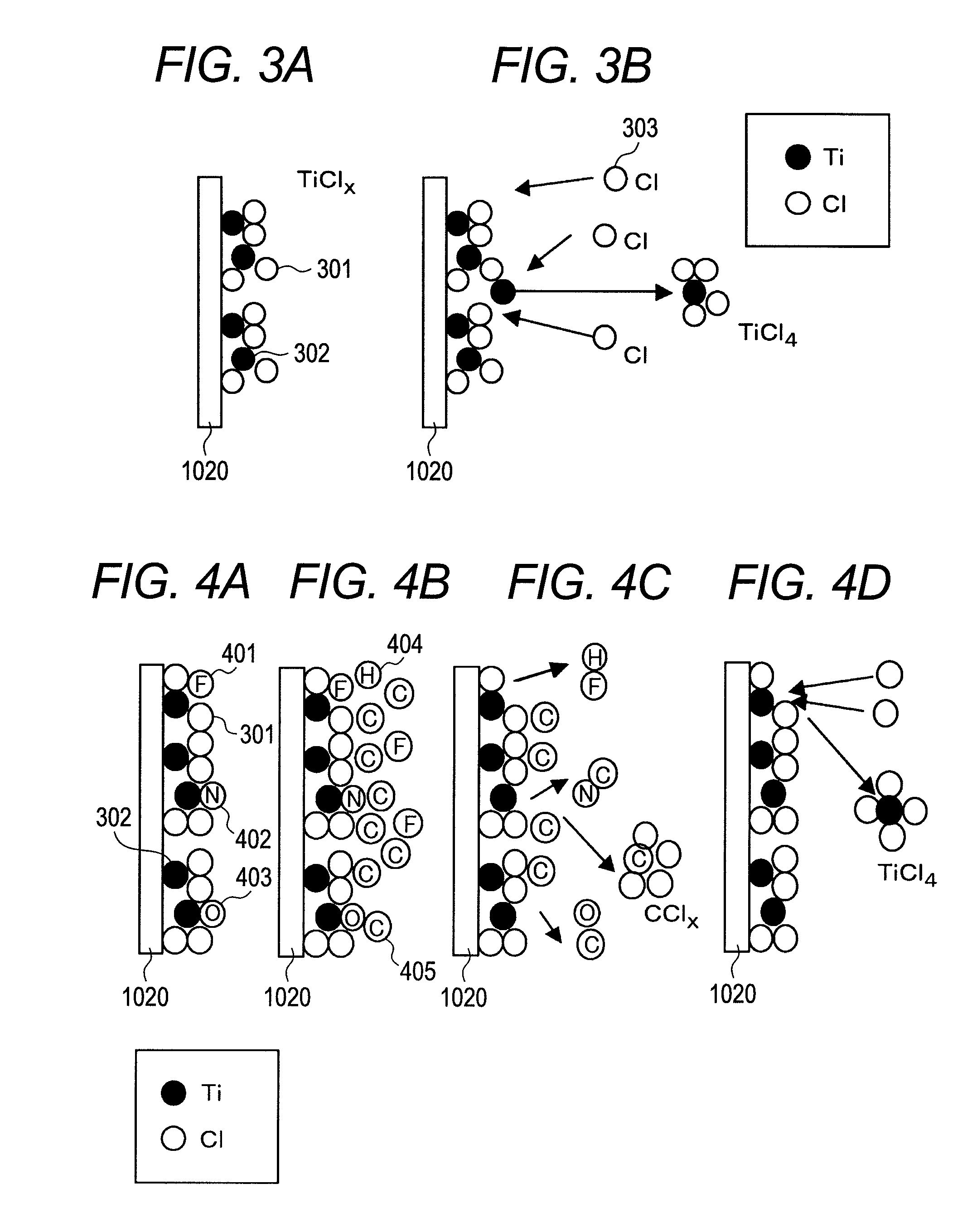

Provided is a plasma processing method capable of removing a Ti-series deposit from the surface of a processing chamber of a plasma processing apparatus without production of a foreign matter such as a boron oxide. The plasma processing method includes carbon-series deposition discharge which succeeds product etching during which a sample containing a Ti material is processed, and during which a carbon-series film is deposited on a Ti reaction by-product deposited on the surface of the processing chamber, and chlorine-series discharge which succeeds the carbon-series deposition discharge and during which the carbon-series film and Ti that are deposited on the surface of the processing chamber are removed.

Owner:HITACHI HIGH-TECH CORP

General efficient paint remover

InactiveCN1743389AFast paint removalHigh paint removal efficiencyChemical paints/ink removersChlorideSURFACTANT BLEND

The invention relates to a general efficient paint remover and its preparing method. The paint remover is prepared by mixing methylene chloride, methanol, formic acid, resordinol, paraffin, surfactant and corrosion inhibitor according to rated proportion and making then react under a certain condition. It has fast depainting speed, good depainting effect, wide application range, and little corrosion to keelson, and non-combustible and hypotoxicity.

Owner:BEIJING UNIV OF CHEM TECH

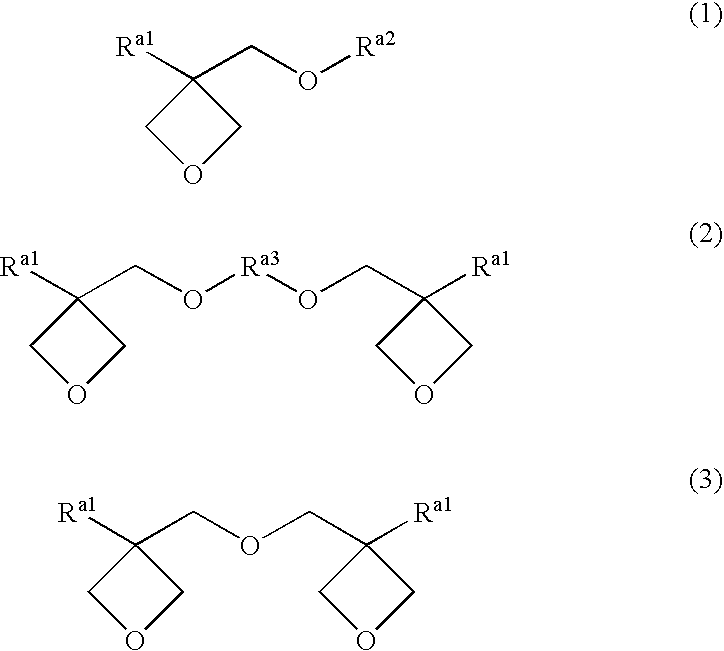

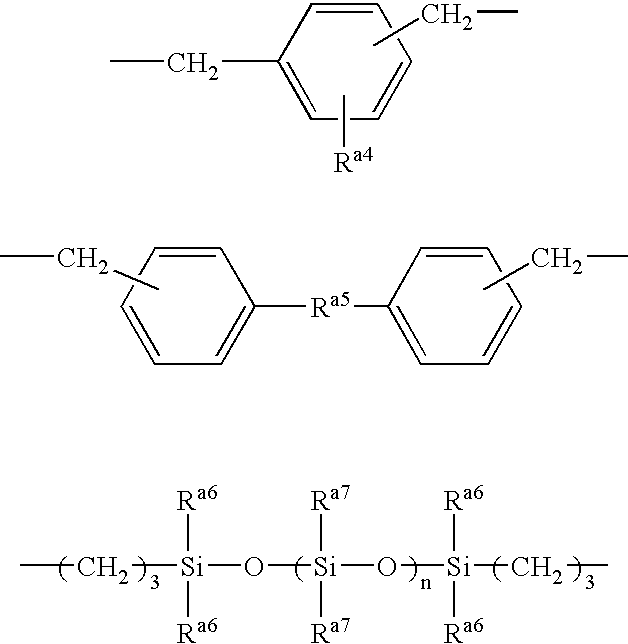

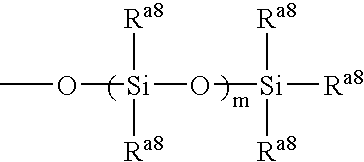

Ink composition, inkjet recording method, printed material, process for producing lithographic plate, and lithographic printing plate

InactiveUS20060262174A1High sensitivitySlightly corrodedMeasurement apparatus componentsDuplicating/marking methodsHalogenCompound (substance)

An ink composition is provided that comprising a) a polymerizable compound, b) a polymerization initiator, and c) a coloring agent, the ink composition having a halogen ion content of no greater than 500 ppm. There is also provided an inkjet recording method that includes a step of discharging the ink composition onto a recording medium, and a step of irradiating the discharged ink composition with radiation so as to cure the ink composition.

Owner:FUJIFILM CORP +1

Prepn of cholrinated paraffin-70

InactiveCN1526796AAvoid pollutionAvoid destructionPetroleum chemical modificationParaffin waxTemperature control

The preparation of chlorinated paraffin-70 with liquid chlorine and solid paraffin as material includes mixing gasified chlorine and molten paraffin in the reactor, and three-stage substitution reaction in temperature controlled in 50-200 deg.c and controlled time to produce chlorinated paraffin-70. The product has no carbon tetrachloride contained, high chlorine content, high softening point and good use performance. The preparation process has low cost and no corrosion to apparatus.

Owner:JINGXIE CHEM PLANT MOUPING DISTRICT YANTAI

Method for biologically treating industrial circulating water and stabilizing quality thereof

InactiveCN103204589AImprove water qualitySlightly corrodedFungiBiological water/sewage treatmentBiotechnologyMicrobial agent

The invention discloses a method for biologically treating industrial circulating water and stabilizing the quality thereof. The method is characterized by comprising a, separately breeding bacterial strains; b, performing acclimatization for the bacterial strains; c, culturing and preparing the bacteria; d, culturing the bacteria in an industrial expanding manner to produce medicinal products; and e, directly adding the produced medicinal products into a circulating water pond. The method has the advantages that the quality of the industrial circulating cooling water is stabilized by the aid of the biotechnology and method, in a circulating water system, currently preferred chemical corrosion and scale inhibitors, bactericides and other chemical agents are replaced by microbial agents; and the microbial agents are produced by a special process, and aerobic bacteria, anaerobic bacteria and facultative anaerobic bacteria which have biological reaction functions are optimized, are subjected to acclimatization and then are cultured in an industrial expanding manner to obtain the microbial agents (medicament or microbiological products in short).

Owner:付永全

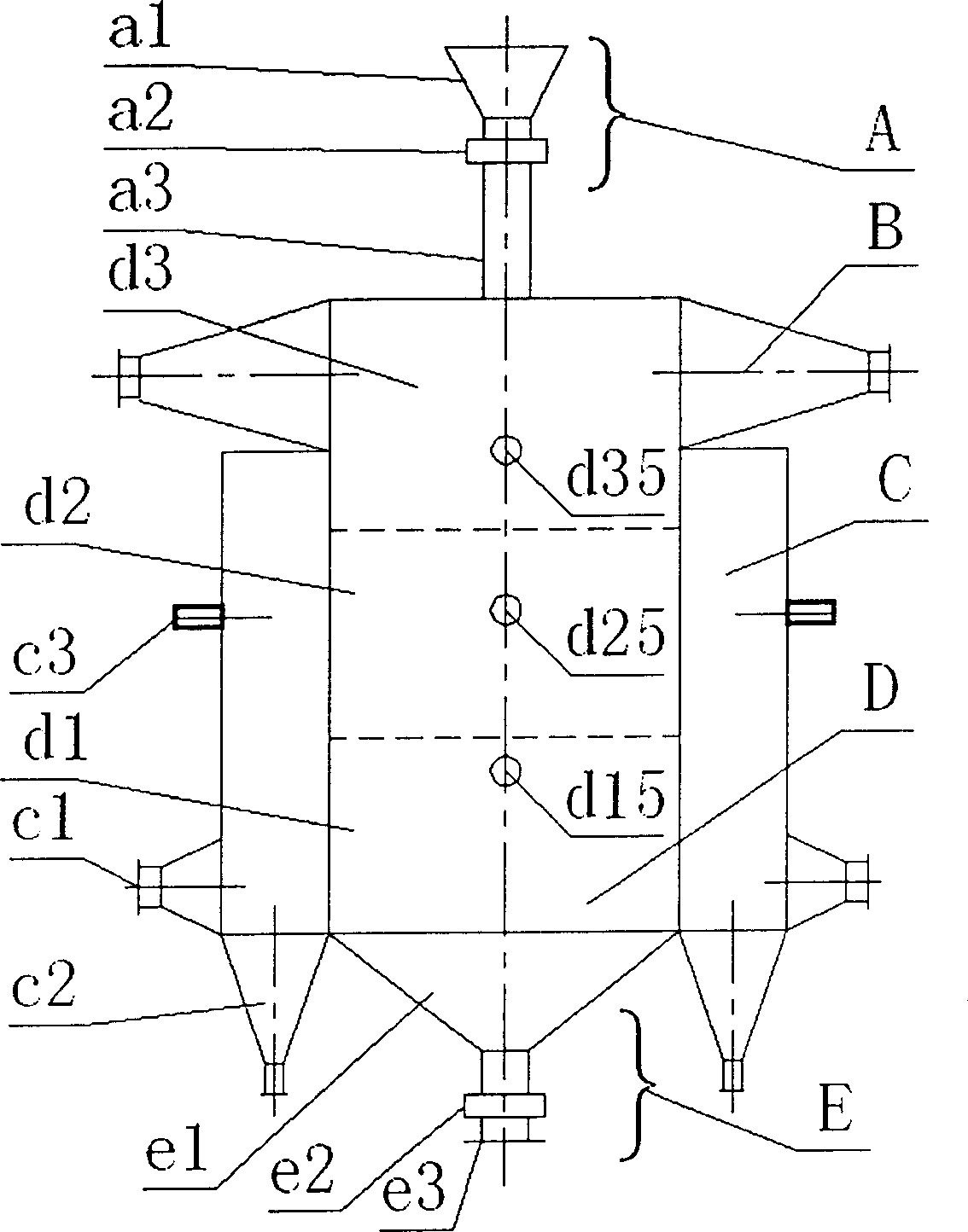

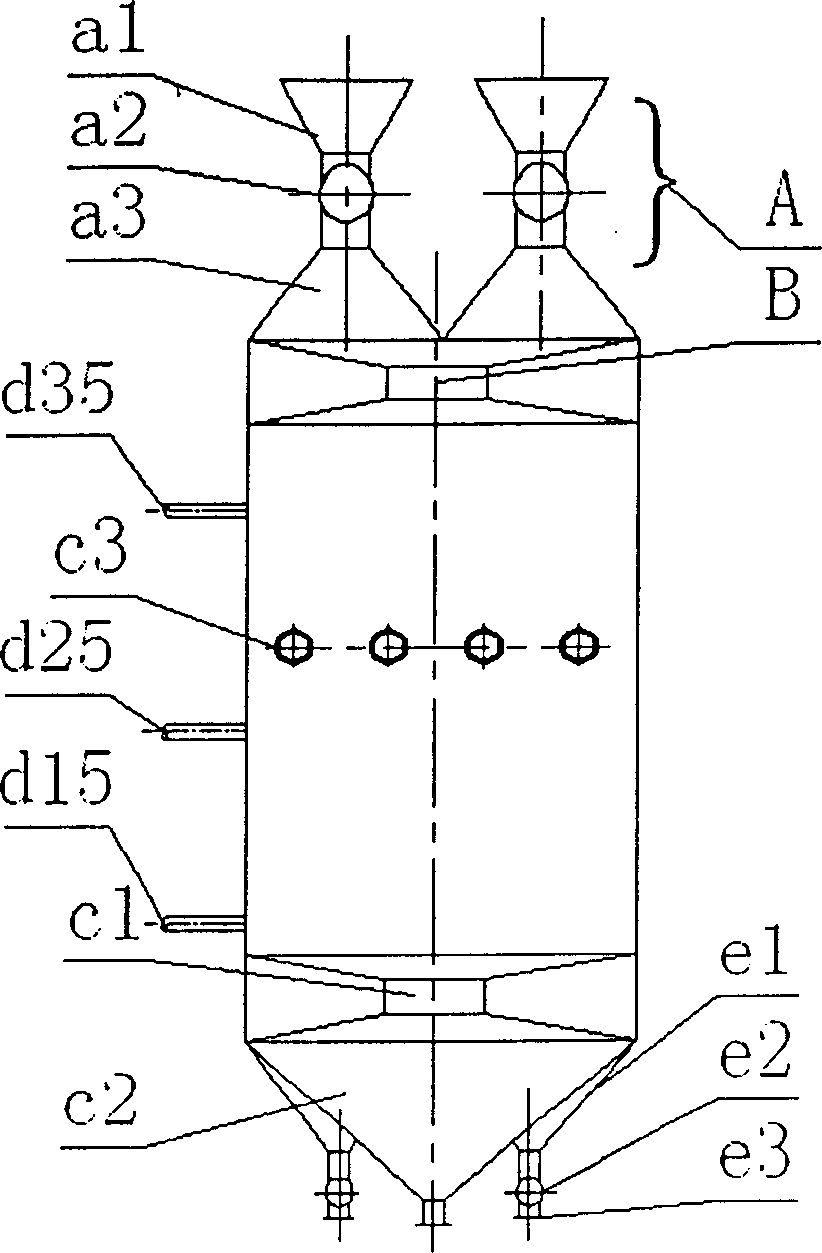

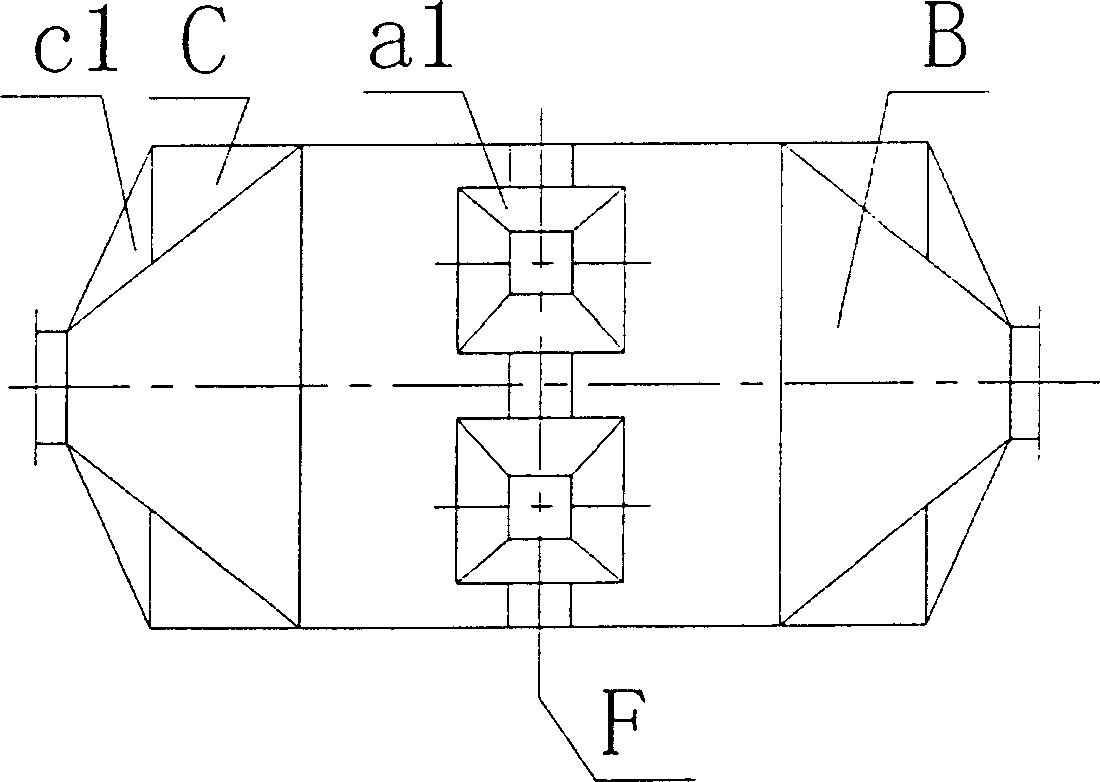

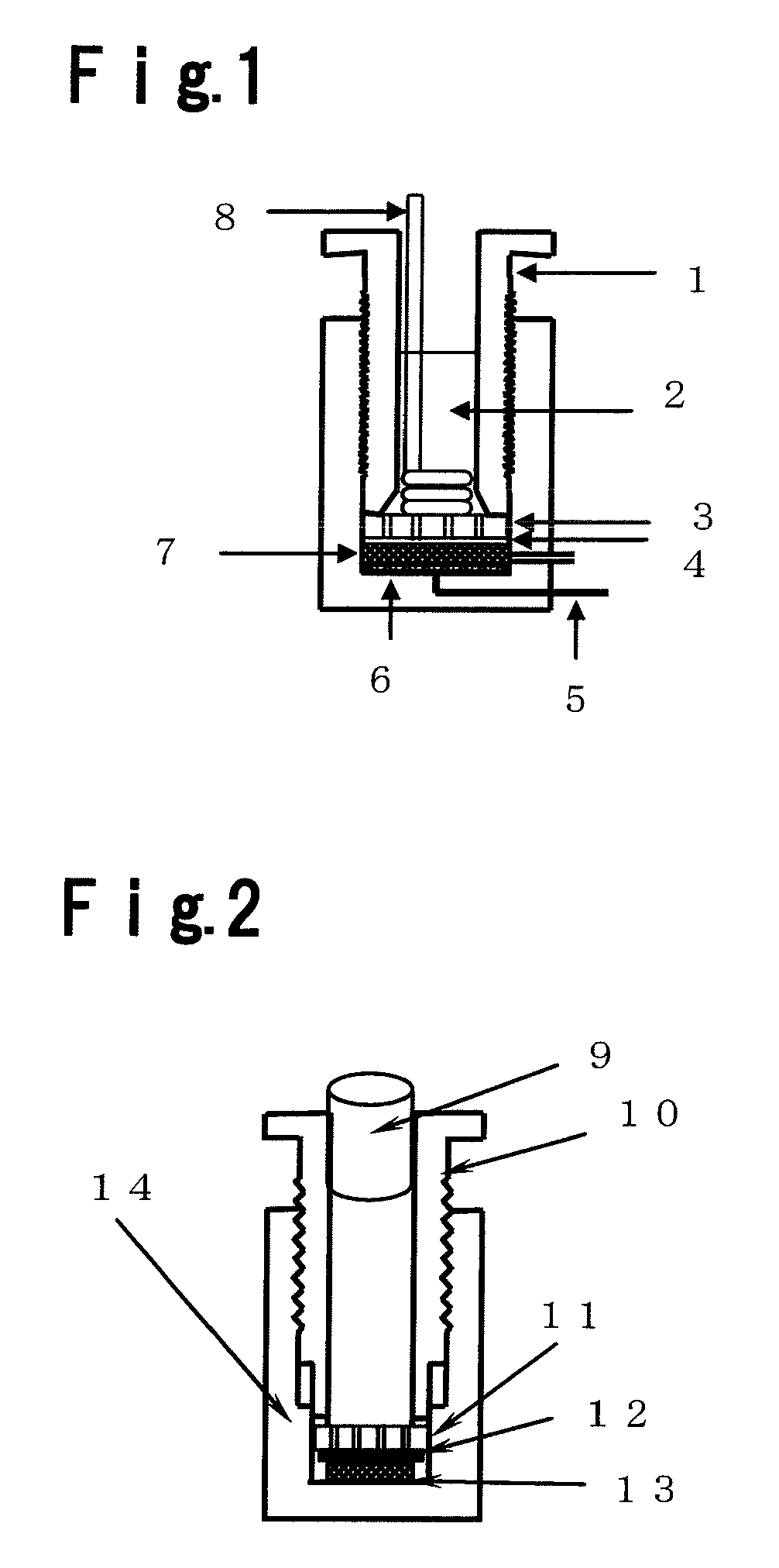

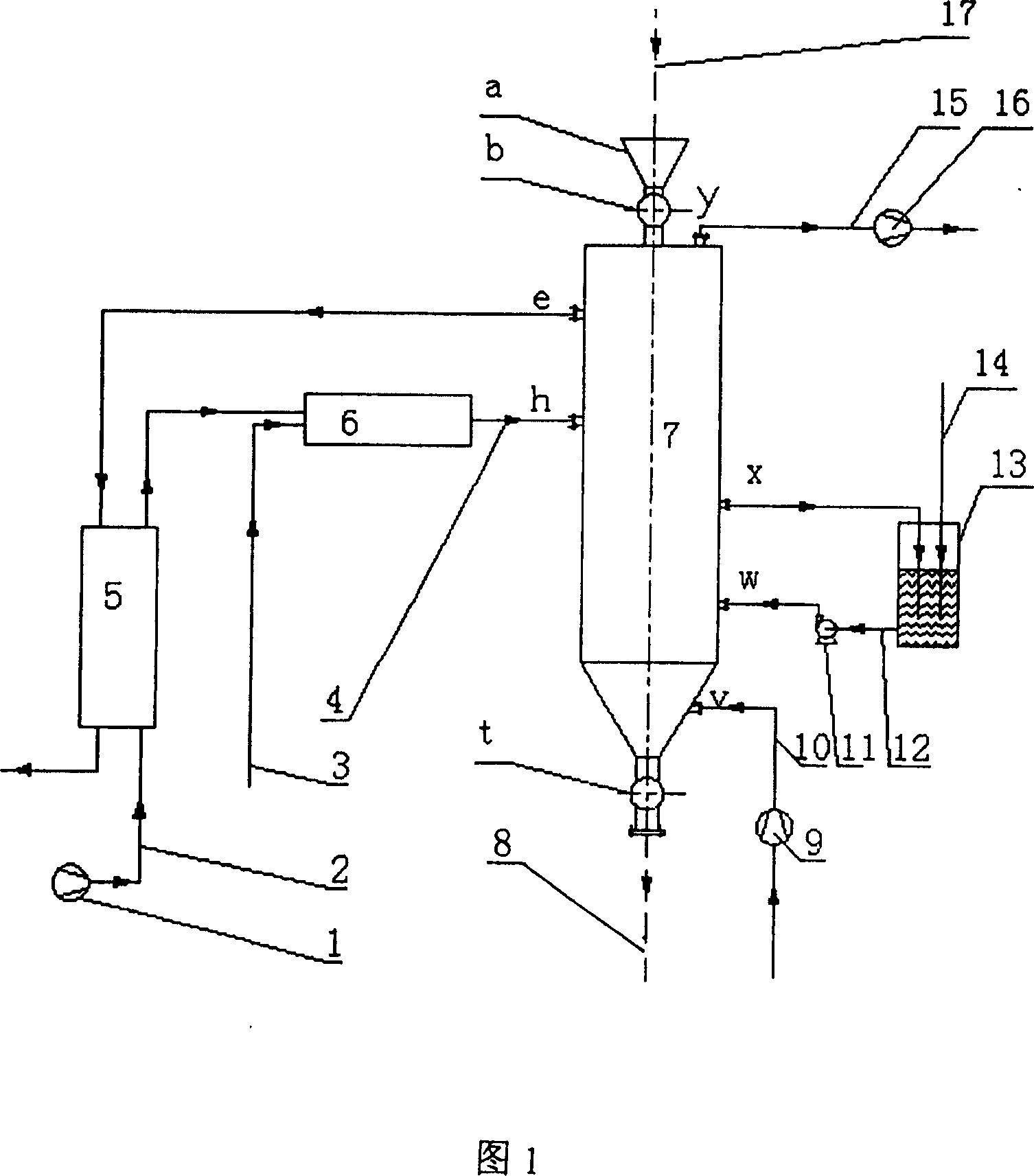

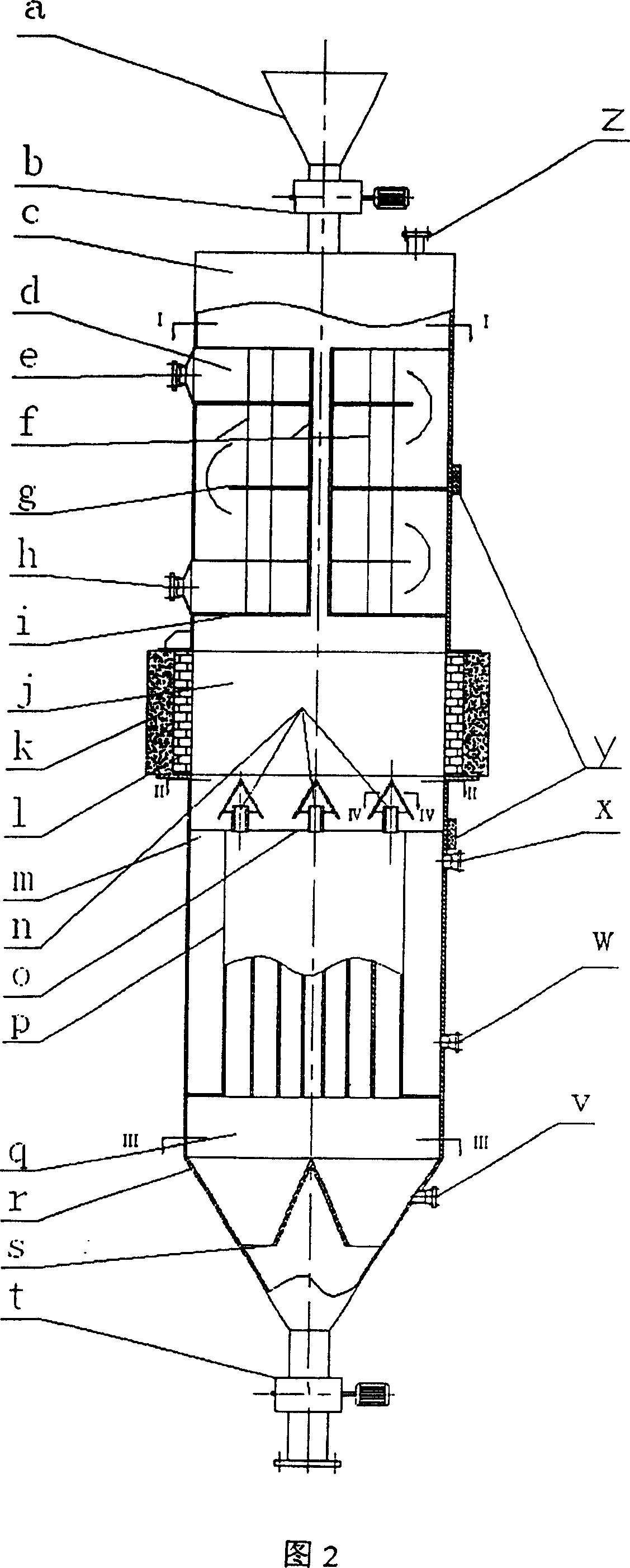

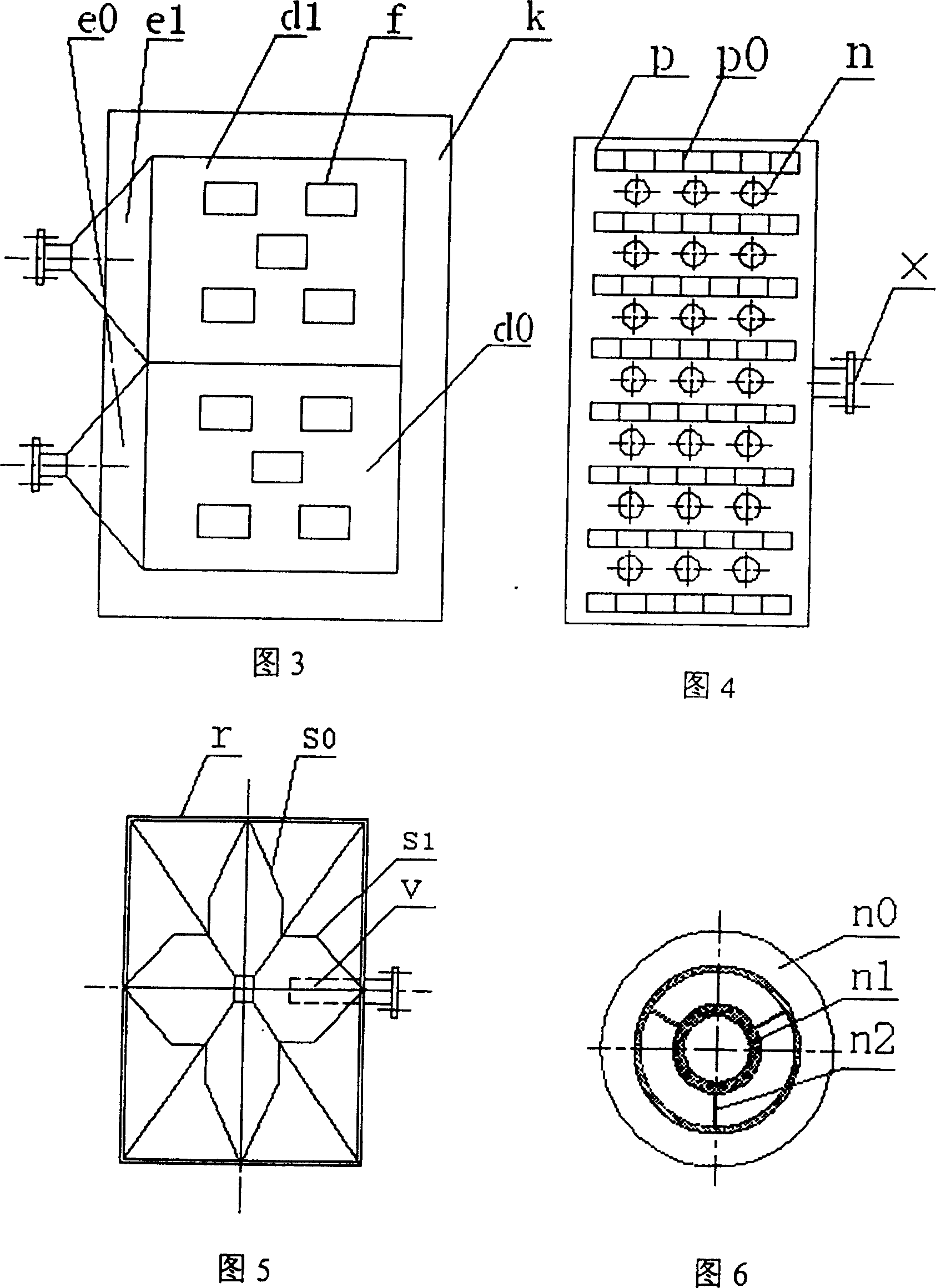

Coupling multistage device with active carbon purifying waste gas

InactiveCN1820819ATake advantage ofCompact structureDispersed particle separationActivated carbonMaterial distribution

The present invention provides coupling multistage apparatus with active carbon to purify waste gas, and the apparatus is used in desulfurizing, denitrating, dedusting, eliminating heavy metal and eliminating organic compound of waste gas. It consists of pre-purifying room, movable adsorption bed, purified gas outlet, material feeding mechanism, and discharging mechanism. Each of the material feeding mechanism and the discharging mechanism consists of material bin, material guide pipe and gas trap valve. The movable adsorption bed consists of one or several adsorption sections superposed sequentially, the material feeding mechanism is set on the top, the discharging mechanism is set in the bottom, and the pre-purifying room and the purified gas outlet are set in the side. The apparatus has compact structure, simple material distribution, complete functions, less resistance, high purifying effect, fully use of active carbon, long service life and low running cost.

Owner:史鱼海

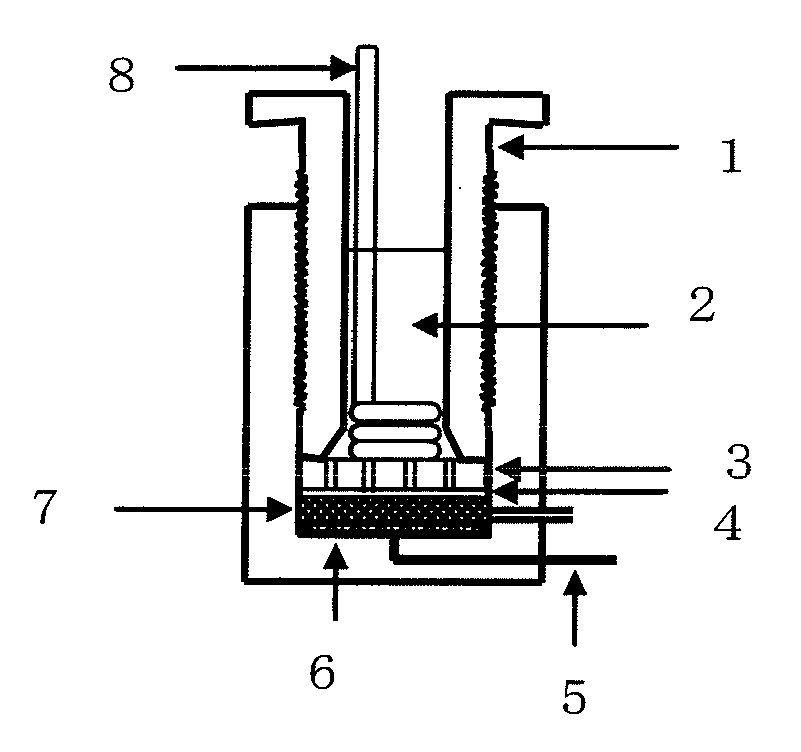

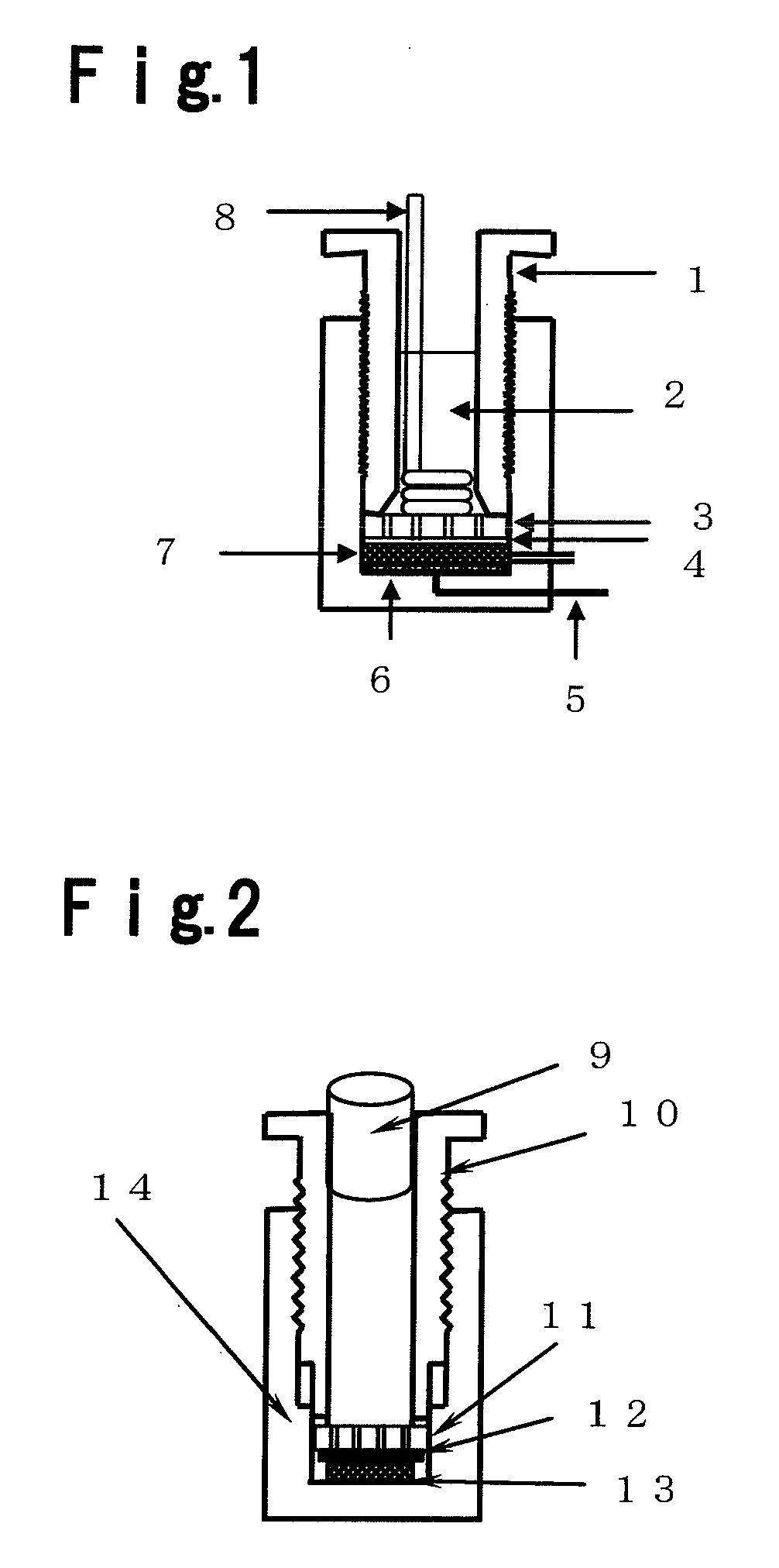

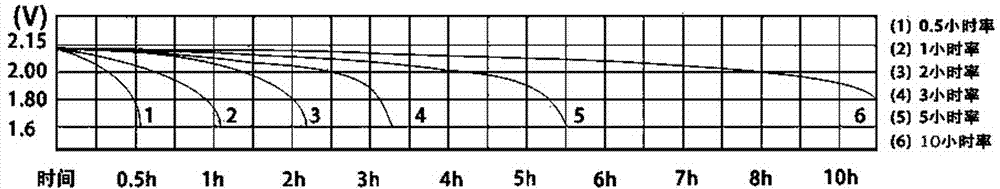

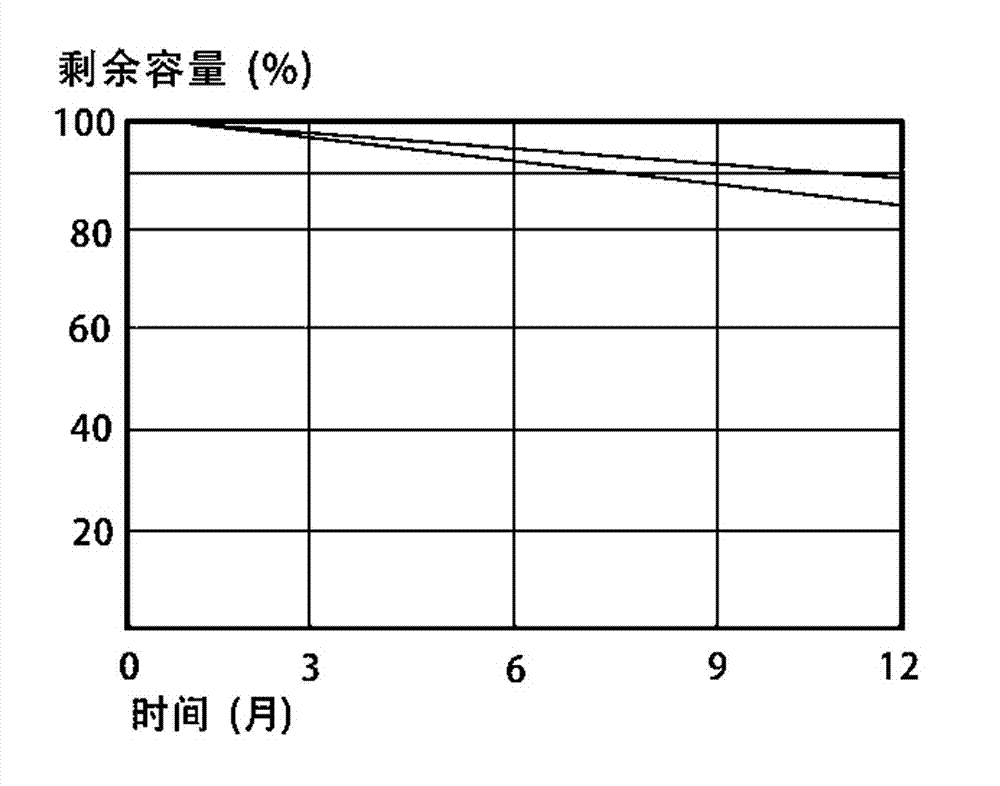

Electrolytic manganese dioxide, and method for its production and its application

ActiveUS20120141361A1Excellent in middle rate discharge characteristicSlightly corrodedElectrolysis componentsCell electrodesHigh rateElectrolysis

An object of the present invention is to provide electrolytic manganese dioxide to be used as a cathode active material for an alkali-manganese dry cell, which has a high alkali potential and is provided with a high reactivity and packing efficiency as a cathode for the cell, and which is excellent in the middle rate discharge characteristic, and electrolytic manganese dioxide excellent in the high rate discharge characteristic and the middle rate discharge characteristic, which will not cause corrosion of metal materials, and a method for its production.In the present invention, electrolytic manganese dioxide having an alkali potential of at least 280 mV and less than 310 mV, and FWHM of at least 2.2° and at most 2.9°, is used. It is preferred that of the electrolytic manganese dioxide, the (110) / (021) peak intensity ratio in the X-ray diffraction peaks is at least 0.50 and at most 0.80, and the (110) interplanar spacing is at least 4.00 Å and at most 4.06 Å. Further, electrolytic manganese dioxide wherein the JIS-pH (JIS K1467) is at least 1.5 and less than 2.6, the sodium content is at least 0.02 wt % and less than 0.10 wt %, the sulfate group content is less than 1.30 wt %, the median diameter is at least 30 μm and at most 50 μm, and the BET specific surface area is at least 20 m2 / g and at most 50 m2 / g, is preferred.

Owner:TOSOH CORP

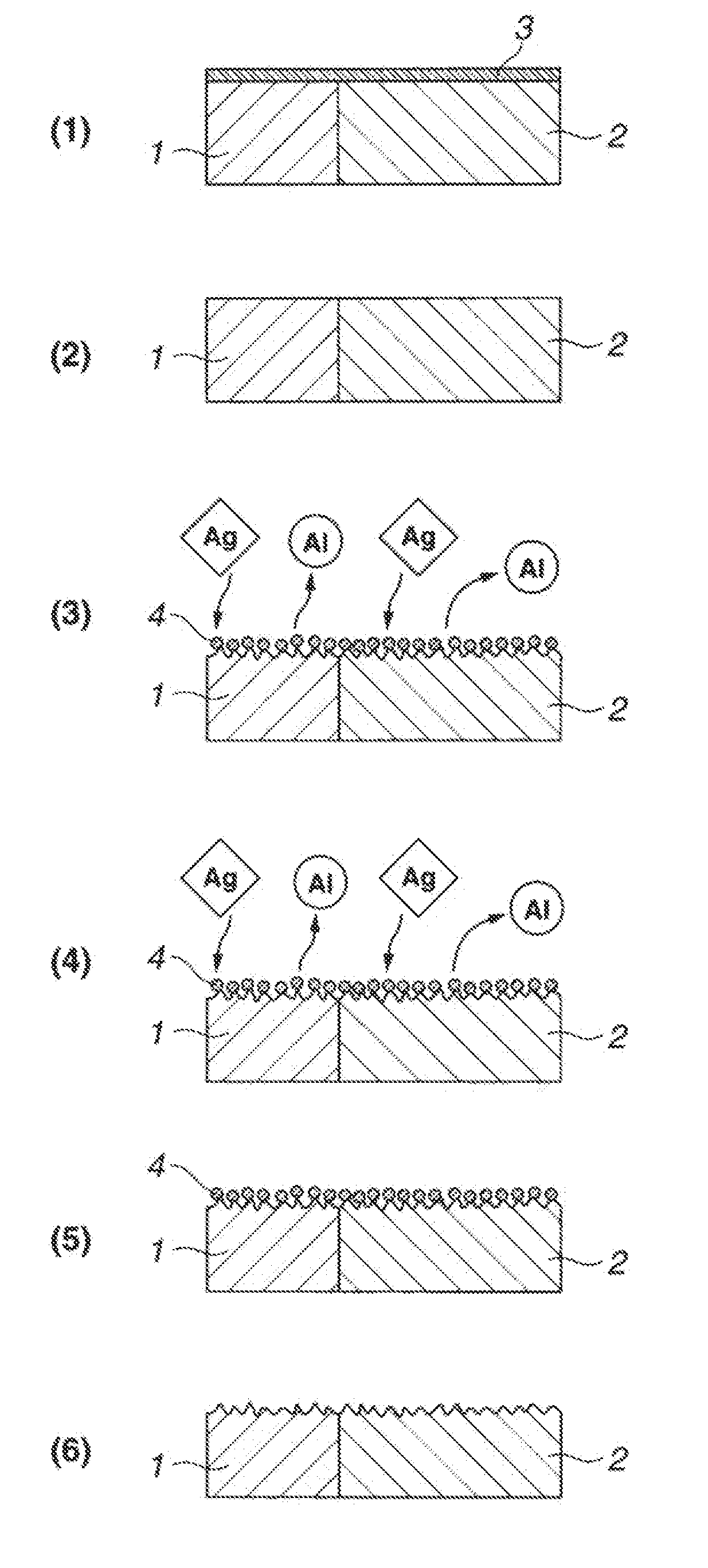

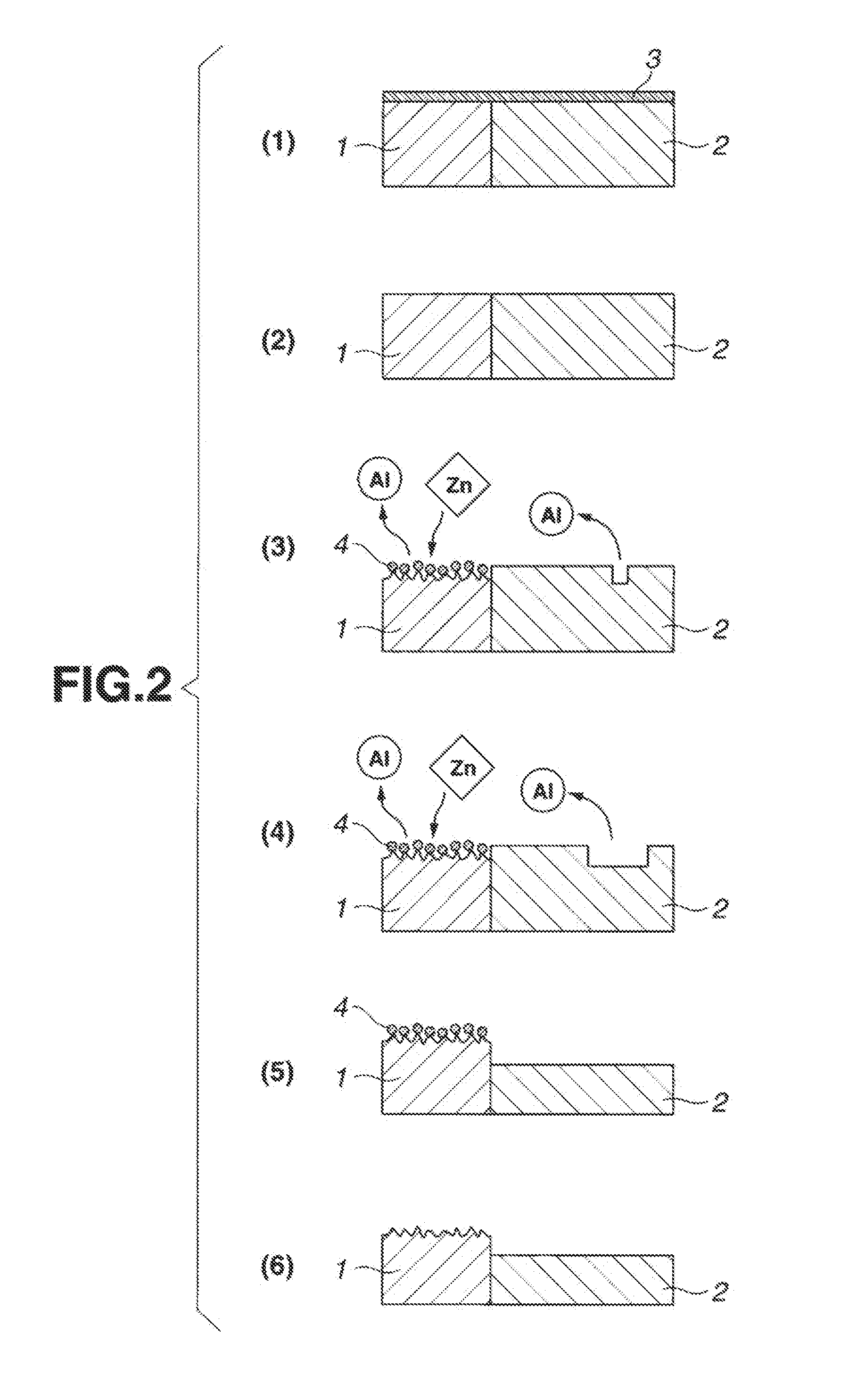

Aluminum oxide film remover and method for surface treatment of aluminum or aluminum alloy

ActiveUS20110315658A1Slightly corrodedAvoid corrosionDecorative surface effectsLiquid/solution decomposition chemical coatingAmmonium hydroxideSilver ion

Disclosed herein is an aluminum oxide film remover for removing an oxide film on the surface of aluminum or aluminum alloy, which comprises silver ions and / or copper ions, a solubilizing agent for silver ions and / or copper ions, and a quaternary ammonium hydroxide compound, and has a pH value of 10 to 13.5. A method for surface treatment of aluminum or aluminum alloy is also disclosed, which comprises immersing a workpiece having aluminum or aluminum alloy at least on the surface thereof in the aluminum oxide film remover, and depositing the silver and / or copper contained in the remover on the surface of aluminum or aluminum alloy while removing the aluminum oxide film.

Owner:C UYEMURA & CO LTD +1

Aluminium alloy surface alkaline degreasing agent

The invention discloses an aluminium alloy surface alkaline degreasing agent which is characterized by comprising the following components in parts by weight: 20 to 40 parts of mixed base, 1 to 5 parts of op-10 emulsifier and 1,000 parts of water, wherein the mixed base is a mixture of sodium carbonate, sodium hydroxide and trisodium phosphate and the weight ratio of the sodium carbonate to the sodium hydroxide to the trisodium phosphate is (3 to 4):(0.5 to 1.5):(3 to 4). The aluminium alloy surface alkaline degreasing agent has a strong effect of removing oil stain, has slight corrosion to an aluminium base and has good gloss. The aluminium alloy surface alkaline degreasing agent can be operated at normal temperature, energy is saved and the acid mist overflowing and the waste alkali discharge are reduced, so that the damage to human bodies and the pollution to the environment are reduced in the production link.

Owner:CHONGQING WANLI LIANXING IND GROUP

Spinel type nickel aluminate base metal ceramic inert electrode

The present invention relates to a spinelle type nickel aluminate base metal ceramic indifferent electrode for aluminium electrolysis. Said indifferent electrode component includes nickel aluminte base metal ceramics or nickel aluminate and nickel ferrite composite metal ceramics and copper-nickel series multicomponent alloy powder, and the above-mentioned materials and undergone the process of cold-press sintering or hot pressing method so as to obtain the indifferent anode with a certain size and thickness. The purity of said aluminium product is 99.6% Al.

Owner:NORTHEASTERN UNIV

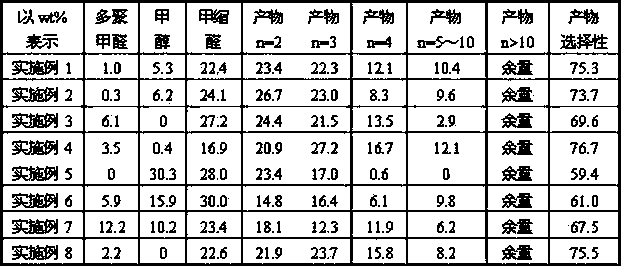

Method for preparing polyformaldehyde dimethyl ether from paraformaldehyde

ActiveCN103664543AStrong acidHigh selectivityOrganic chemistryOrganic compound preparationPolyoxymethylenePtru catalyst

The invention relates to a method for preparing polyformaldehyde dimethyl ether from paraformaldehyde, which is mainly used for solving the problems that the conventional method for synthesizing the polyformaldehyde dimethyl ether by taking trioxymethylene as a material is high in cost and not high in catalyst reaction selectivity. In order to solve the problems betters, a following technical scheme is as follows: methanol, methylal and polyformaldehyde are taken as materials in a mass ratio of (0-10):(0-10):1 to contact with a catalyst for reaction to generate polyformaldehyde dimethyl ether CH3O(CH2O)nCH3 under conditions with a reaction temperature of 70 DEG C-200 DEG C and reaction pressure of 0.2 MPa-0.6 MPa, wherein the dosages of the methanol and the methylal cannot be 0 at the same time, and the used catalyst comprises the following components in parts by weight: 30-80 parts of an oxide carrier and 20-70 parts of heteropoly acid. And therefore, the method can be used for industrial production of polyformaldehyde dimethyl ether.

Owner:CHINA PETROLEUM & CHEM CORP +1

Paint remover

InactiveCN102344711ASlightly corrodedFast paint removalChemical paints/ink removersAcrylic paintFormic acid

The invention discloses a paint remover which comprises the following components in percentage by weight: 60-80% of dichloromethane, 10-20% of formic acid, 5-15% of ethanol and 3-8% of methanol. The paint remover disclosed by the invention can be used for professionally removing acrylic paint, has the advantages of high paint removal speed, favorable effect, slight corrosion to the substrate, simple raw materials, low cost and simple preparation method, and is suitable for large-scale production.

Owner:太仓市联林活性炭厂

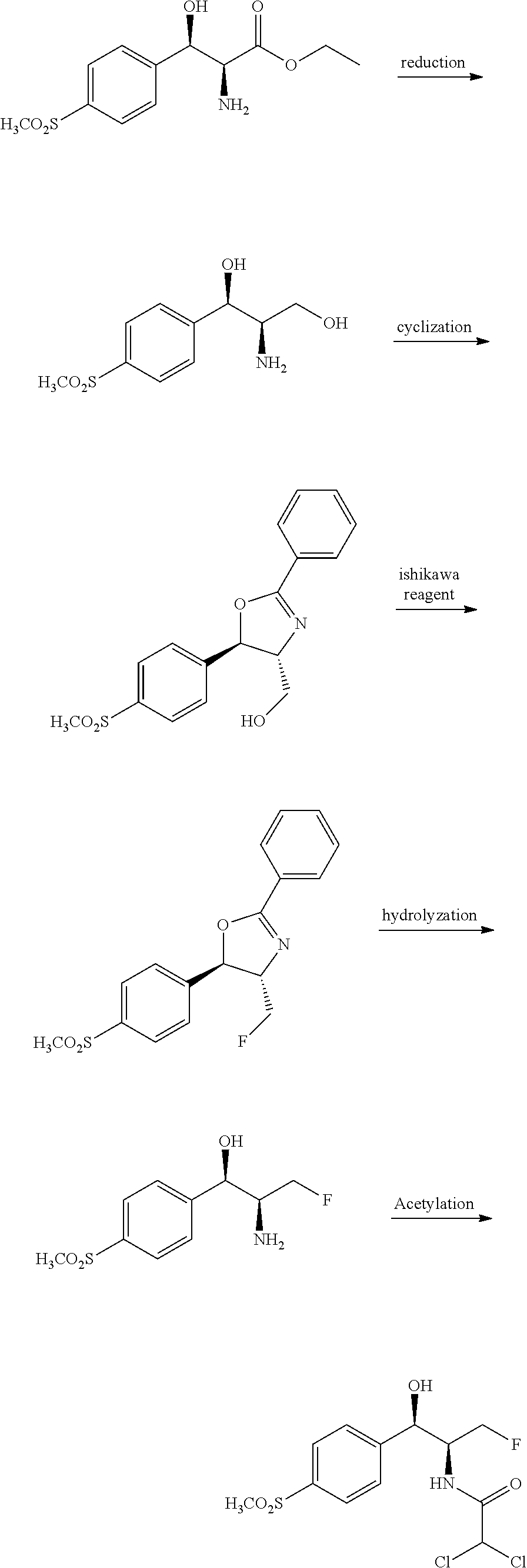

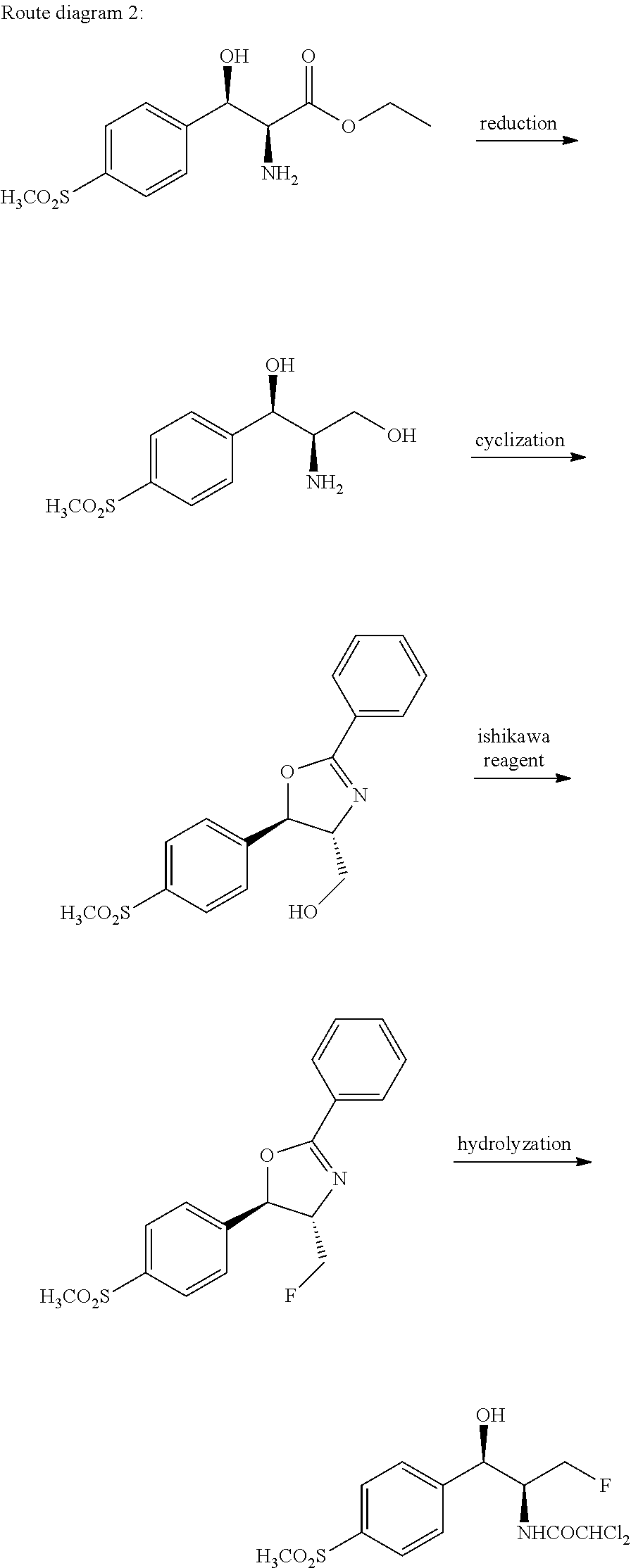

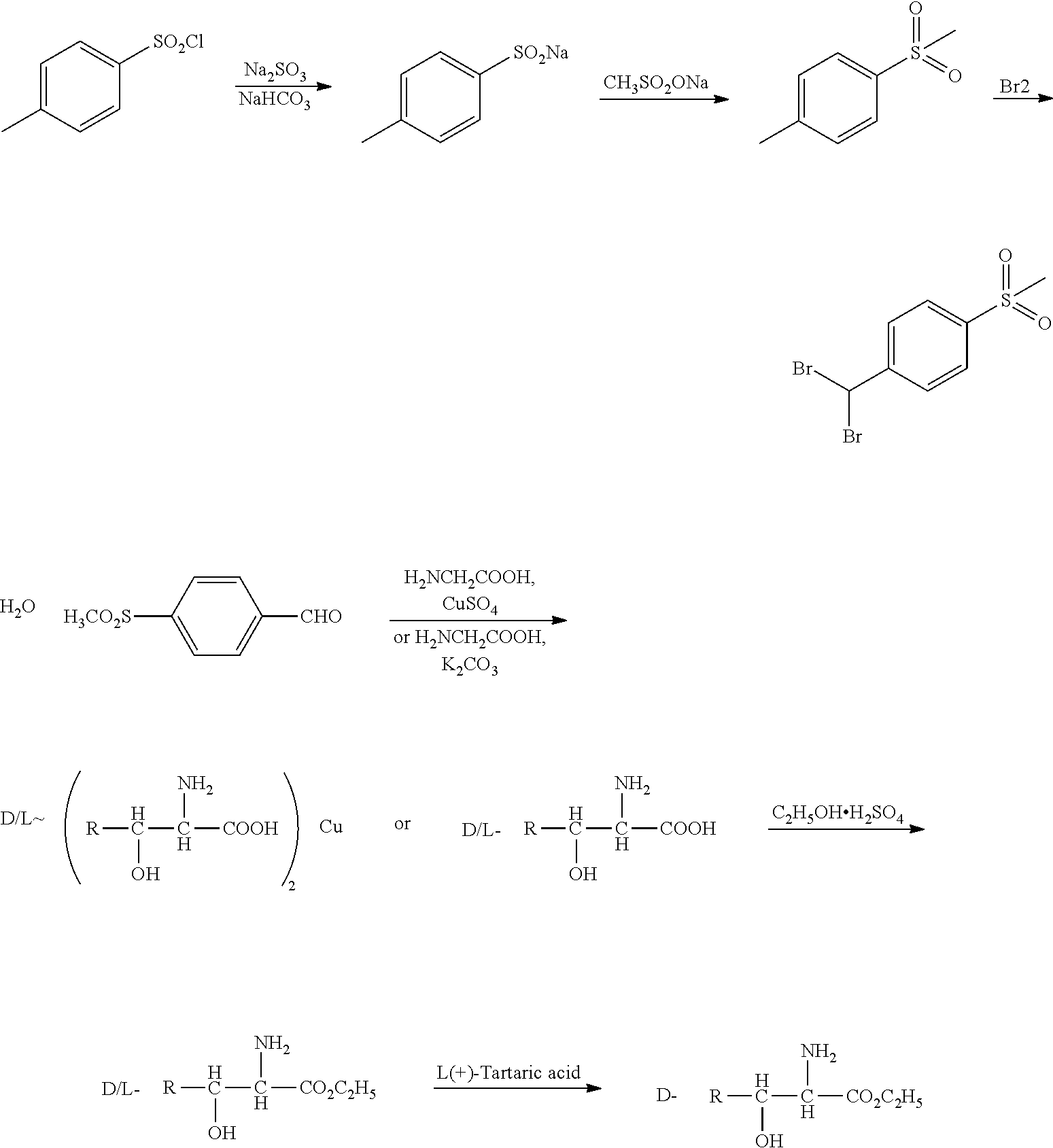

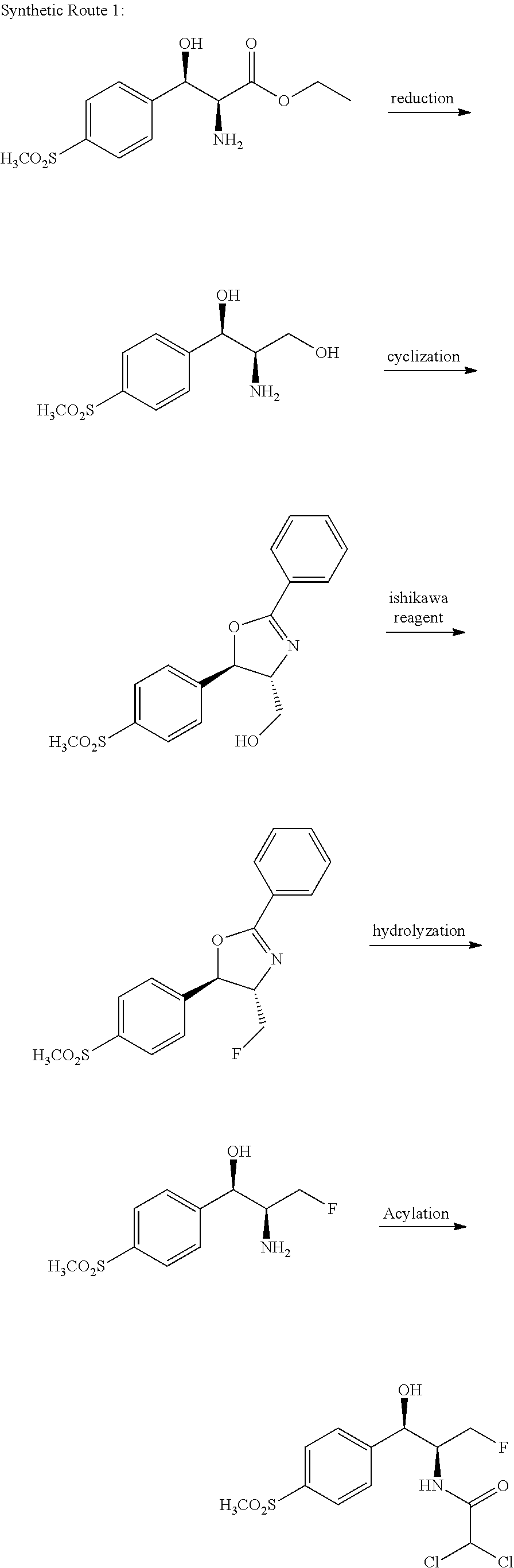

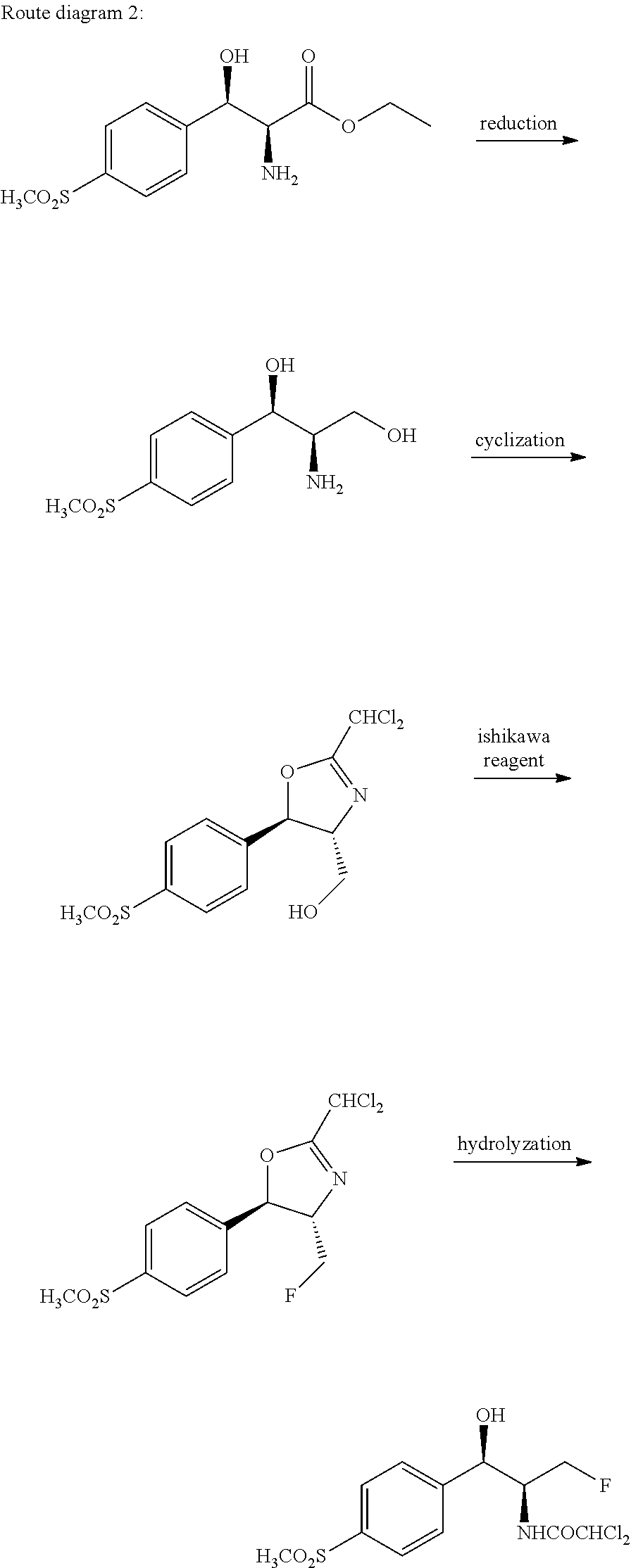

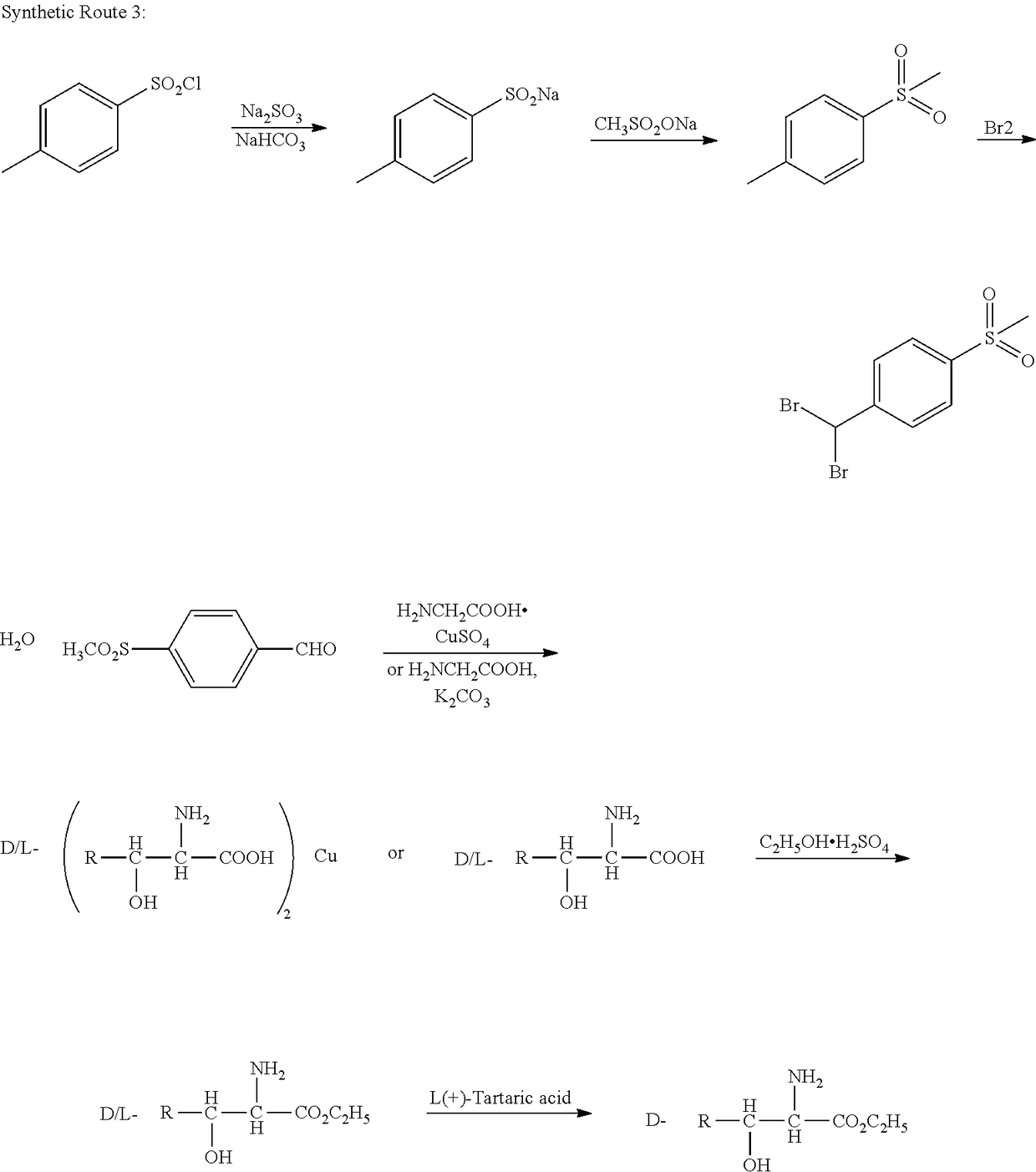

Florfenicol synthesizing method

ActiveUS20160318859A1Improve economySolve the real problemOrganic chemistryOrganic compound preparationAziridineDrug administration

The present invention discloses a new florfenicol synthesizing method. The method synthesizes florfenicol products meeting requirements of the Drug Administration by a series of combinations of cyclization, selective reduction, fluorinated open ring, deprotection and acylation, hydroxyl sulfoacid esterified configuration converting reaction, hydrolysis reaction and the like. The synthesizing method of the present invention utilizing chiral amine closed-ring aziridine three-membered ring uses a physical separation method to repeatedly purify chiral aminoketone of high yield obtaining single R configuration, and uses selective reduction and converts the configuration to obtain florfenicol, greatly improving atom economy, while avoiding waste water pollution caused by the existing process, and greatly reducing costs for treating waste water and reducing pollution to the environment, thus lowering costs and simplifying the process. In addition, the present invention uses triethylamine hydrofluoride as a fluorinated open-ring reagent, to improve safety of a liquid reaction compared to a gas reaction and reduce corrosion of equipment, facilitating industrial production.

Owner:MASTEAM BIO TECH

Aluminium alloy surface acid degreasing agent

The invention discloses an aluminium alloy surface acid degreasing agent which is characterized by comprising the following components in part by weight: 25 to 35 parts of concentrated sulphuric acid, 3 to 5 parts of sodium dodecyl sulfate, 0.1 to 2 parts of diethyl succinate sodium sulfonate and 1,000 parts of water. The aluminium alloy surface acid degreasing agent can be used for an acid pretreatment tank of products such as an aluminium section, an aluminium alloy and the like, has strong effects of removing oil stain and removing oxide, has slight corrosion to an aluminium base and has good gloss. The aluminium alloy surface acid degreasing agent can be operated at normal temperature, energy is saved and the acid mist overflowing and the acid pickle discharge are reduced, so that the damage to human bodies and the pollution to the environment are reduced in the production link.

Owner:CHONGQING WANLI LIANXING IND GROUP

Electrolytic manganese dioxide, and method for its production and its application

ActiveUS9103044B2Raise the potentialImprove efficiencyElectrolysis componentsCell electrodesElectrolysisElectrical battery

An object of the present invention is to provide electrolytic manganese dioxide to be used as a cathode active material for an alkali-manganese dry cell, which has a high alkali potential and is provided with a high reactivity and packing efficiency as a cathode for the cell, and which is excellent in the middle rate discharge characteristic, and electrolytic manganese dioxide excellent in the high rate discharge characteristic and the middle rate discharge characteristic, which will not cause corrosion of metal materials, and a method for its production.In the present invention, electrolytic manganese dioxide having an alkali potential of at least 280 mV and less than 310 mV, and FWHM of at least 2.2° and at most 2.9°, is used. It is preferred that of the electrolytic manganese dioxide, the (110) / (021) peak intensity ratio in the X-ray diffraction peaks is at least 0.50 and at most 0.80, and the (110) interplanar spacing is at least 4.00 Å and at most 4.06 Å. Further, electrolytic manganese dioxide wherein the JIS-pH (JIS K1467) is at least 1.5 and less than 2.6, the sodium content is at least 0.02 wt % and less than 0.10 wt %, the sulfate group content is less than 1.30 wt %, the median diameter is at least 30 μm and at most 50 μm, and the BET specific surface area is at least 20 m2 / g and at most 50 m2 / g, is preferred.

Owner:TOSOH CORP

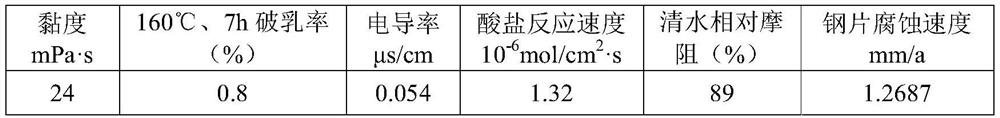

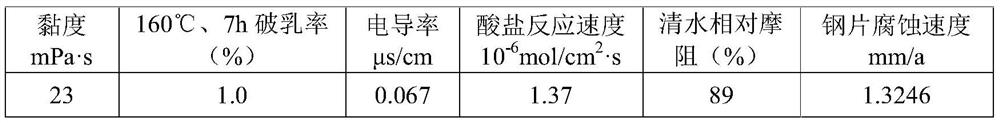

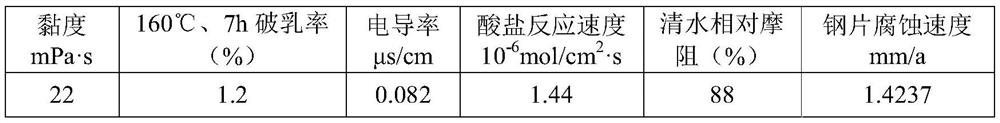

Ultrahigh-temperature-resistant low-viscosity low-corrosion emulsifier and preparation method thereof, and emulsified acid system and preparation method thereof

The invention discloses an ultrahigh-temperature-resistant low-viscosity low-corrosion emulsifier and a preparation method thereof, and an emulsified acid system and a preparation method thereof, andbelongs to the technical field of oil and gas field development and acidification. The emulsifier is prepared by taking butanol amine, 1, 6-butanediamine and diallylamine as raw materials, and the emulsified acid system has very high applicability at different temperatures, particularly has very high stability in an ultrahigh-temperature well, and has the advantages of low viscosity, low frictionresistance, slight corrosion to metal pipes and the like.

Owner:SOUTHWEST PETROLEUM UNIV

Plasma processing method and plasma processing apparatus

ActiveUS8500912B2Strong oxidation abilityAccelerated corrosionElectric discharge tubesElectrostatic cleaningForeign matterBoron oxide

Provided is a plasma processing method capable of removing a Ti-series deposit from the surface of a processing chamber of a plasma processing apparatus without production of a foreign matter such as a boron oxide. The plasma processing method includes carbon-series deposition discharge which succeeds product etching during which a sample containing a Ti material is processed, and during which a carbon-series film is deposited on a Ti reaction by-product deposited on the surface of the processing chamber, and chlorine-series discharge which succeeds the carbon-series deposition discharge and during which the carbon-series film and Ti that are deposited on the surface of the processing chamber are removed.

Owner:HITACHI HIGH-TECH CORP

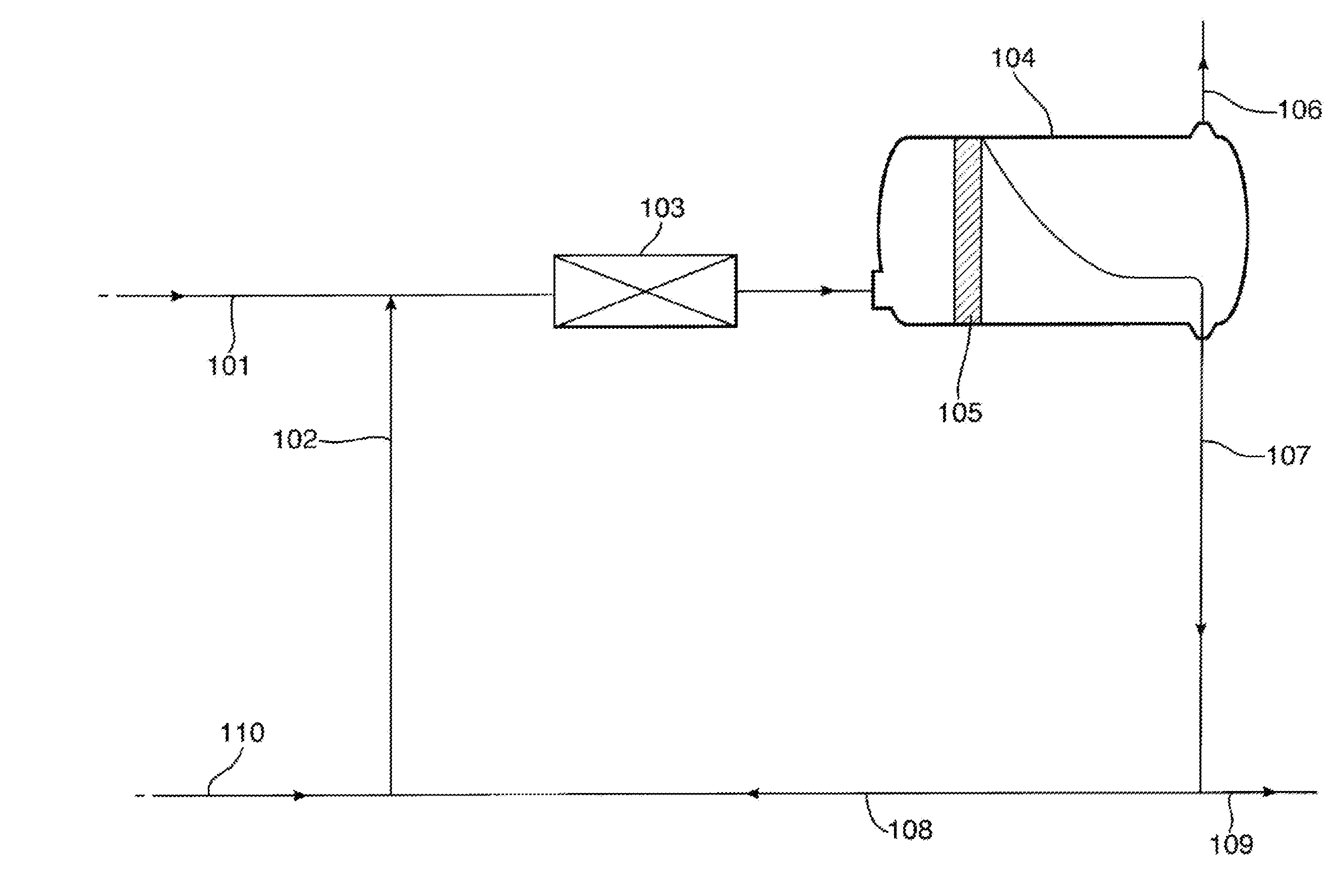

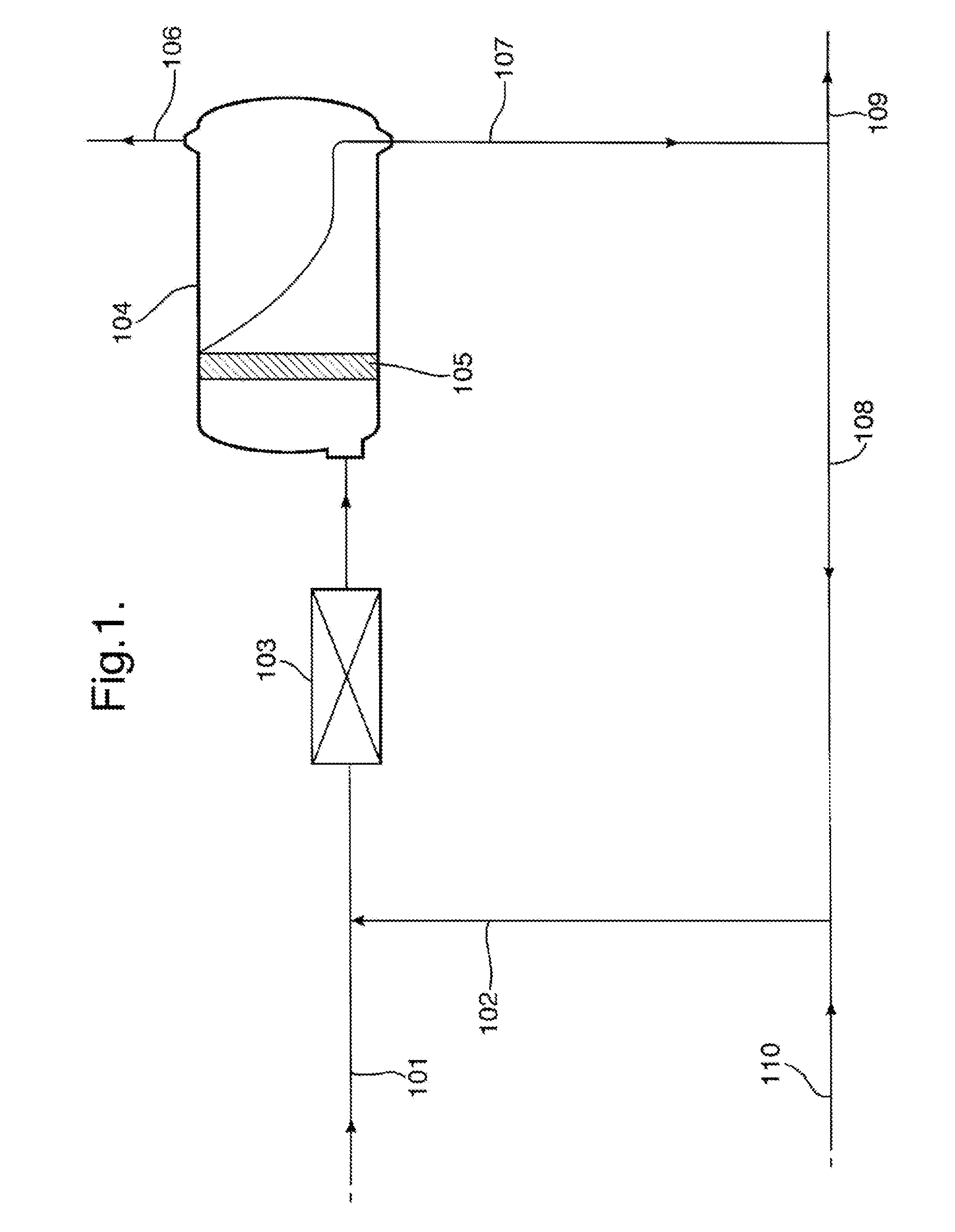

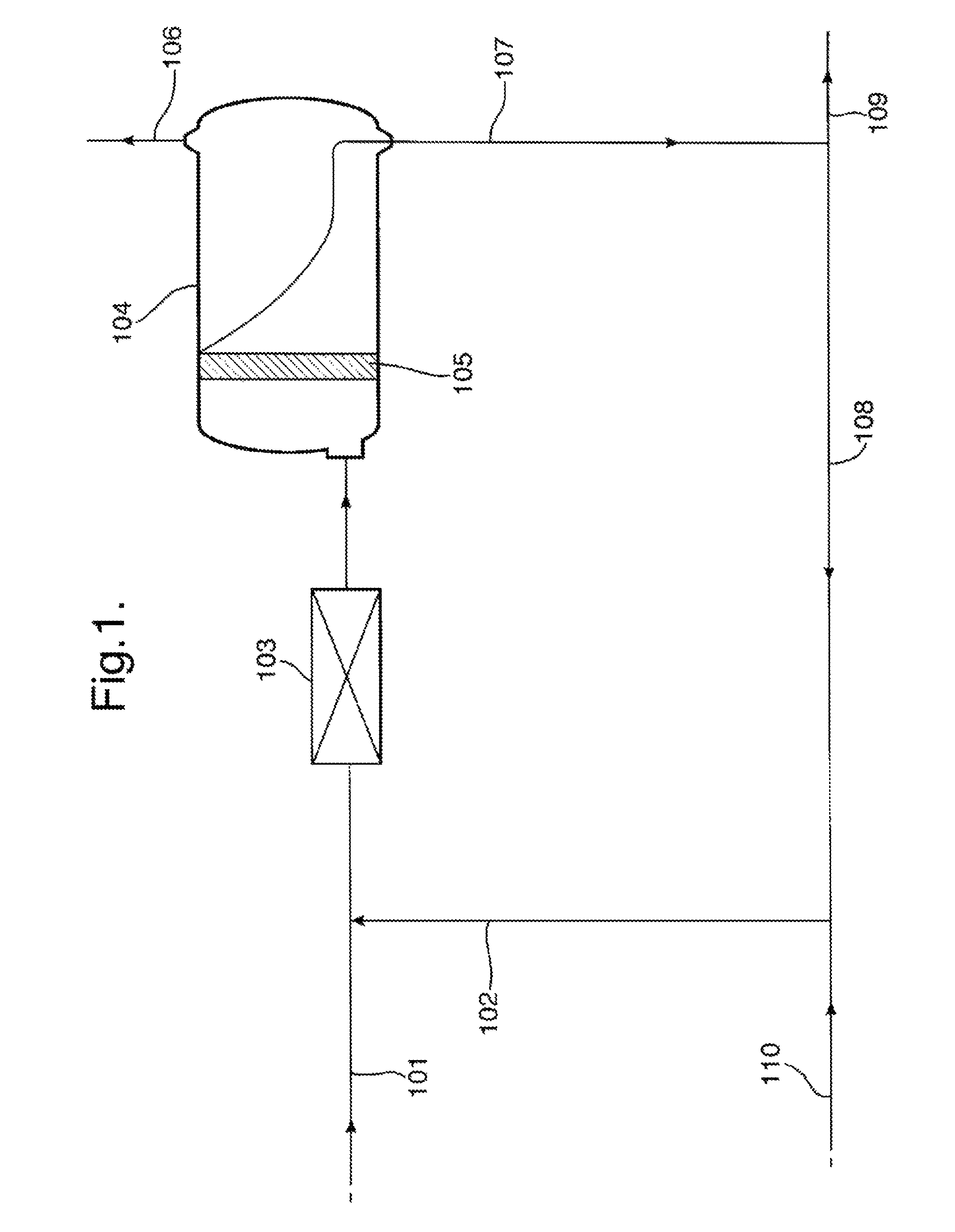

Process for preparing an organic hydroperoxide, industrial set-up therefore and process wherein such organic hydroperoxide is used in the preparation of an alkylene oxide

ActiveUS20070282146A1Good removal effectSlightly corrodedOxygen-containing compound preparationOrganic compound preparationGlass fiberOrganic reaction

A process for preparing an organic hydroperoxide, which process comprises: (a) oxidizing an organic compound to obtain an organic reaction product containing organic hydroperoxide; (b) mixing at least part of the organic reaction product of step (a) with a basic aqueous solution to obtain a mixture of basic aqueous solution and the organic reaction product; (c) separating the mixture of step (b) to obtain a separated organic phase containing organic hydroperoxide, and a separated aqueous phase; (d) mixing at least part of the separated organic phase of step (c) with water to obtain a mixture of an aqueous phase and the organic phase; and (e) separating the mixture of step (d) to obtain a separated organic phase containing organic hydroperoxide, and a separated aqueous phase; in which process the separation to a separated organic phase and a separated aqueous phase in step (e) is carried out with the help of a coalescer containing glass fibers.

Owner:SHELL USA INC

Florfenicol synthesizing method

ActiveUS9951000B2Solve the real problemHigh yieldOrganic chemistryOrganic compound preparationKetoneHydrolysis

A method for synthesizing florfenicol comprises the steps of cyclization, selective reduction, fluorination, ring opening, deprotection, acylation, esterification with sulfonic acids, epimerization and hydrolysis. Florfenicol is prepared by successively purifying, selectively reducing, and epimerizing chiral (R)-amino ketones. This improves atom economy, reduces waste water pollution and accordingly reduces costs for treating waste water and pollution to the environment, thus lowering costs and simplifying the process. Furthermore, triethylamine hydrofluoride is used as a fluorinating reagent, resulting in improved safety, because of the use of liquid reaction conditions as compared to gaseous reaction conditions, and reduced corrosion to the reaction equipment.

Owner:MASTEAM BIO TECH

Spinel type nickel aluminate base metal ceramic inert electrode

The present invention relates to a spinelle type nickel aluminate base metal ceramic indifferent electrode for aluminium electrolysis. Said indifferent electrode component includes nickel aluminte base metal ceramics or nickel aluminate and nickel ferrite composite metal ceramics and copper-nickel series multicomponent alloy powder, and the above-mentioned materials and undergone the process of cold-press sintering or hot pressing method so as to obtain the indifferent anode with a certain size and thickness. The purity of said aluminium product is 99.6% Al.

Owner:NORTHEASTERN UNIV LIAONING

General efficient paint remover

InactiveCN100429283CSlightly corrodedLow toxicityChemical paints/ink removersChlorideSURFACTANT BLEND

Owner:BEIJING UNIV OF CHEM TECH

Ultrahigh-temperature-resistant low-viscosity low-corrosion emulsifier and emulsified acid system containing same

ActiveCN112552894AImprove temperature resistanceImprove stabilityDrilling compositionEpoxyHalohydrocarbon

Owner:SOUTHWEST PETROLEUM UNIV

Stripping solution and stripping method for copper-based palladium-nickel alloy coating stripping

The invention discloses deplating liquid and a deplating method for deplating a copper base palladium-nickel alloy plating layer. The deplating liquid is obtained by homogenizing 45-55 parts of bromide, 6-10 parts of oxidant, 0.3-0.6 part of corrosion inhibitor-benzotriazole and 40-60 parts of water; the pH value of the deplating liquid is less than 4; the bromide is one or a composition of two of hydrobromic acid and sodium bromide; and the oxidant is two or compositions of more than two of hydrogen peroxide water solution, manganese dioxide, sodium bromate and high sodium bromate. A bromination method is adopted to remove the palladium-nickel alloy plating layer on a copper matrix; the plating layer is deplated thoroughly and efficiently; the process is simple; the corrosion of the copper matrix is slight; the separation of the copper matrix and the palladium-nickel alloy plating layer in the plating part is realized, that is, the deplating of the copper base palladium-nickel alloy plating layer is realized; and after the deplating liquid is saturated, patalldium and nickel can be recovered therefrom.

Owner:JIANGSU UNIV OF TECH

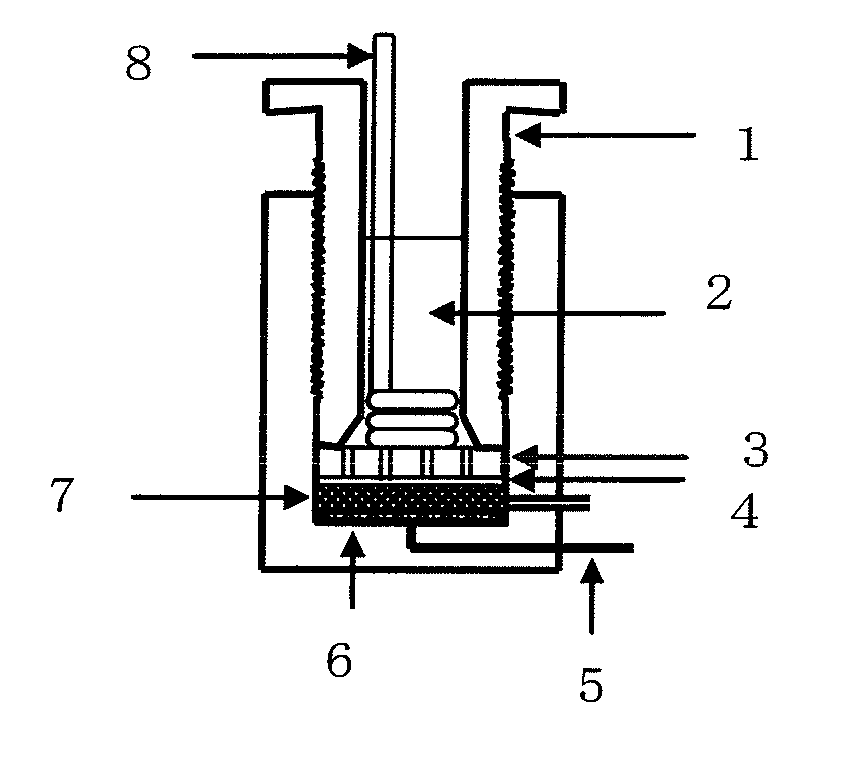

Movable sulfurization active carbon heating regenerator and regeneration

InactiveCN100372605CSimple structureReduce volumeOther chemical processesDispersed particle separationActivated carbonProduct gas

A movable heating apparatus for regenerating the used desulfurizing activated carbon is composed of a feeding segment consisting feeding cabin and gas locking valve, a transition segment with regenerating gas pumping-in inlet, a heating-regenerating segment with heat exchanger, a stage-one cooling segment, a stage-two cooling segment with heat exchanger, and an gas-in and material-discharging segment. Its regenerating process is also disclosed.

Owner:史鱼海

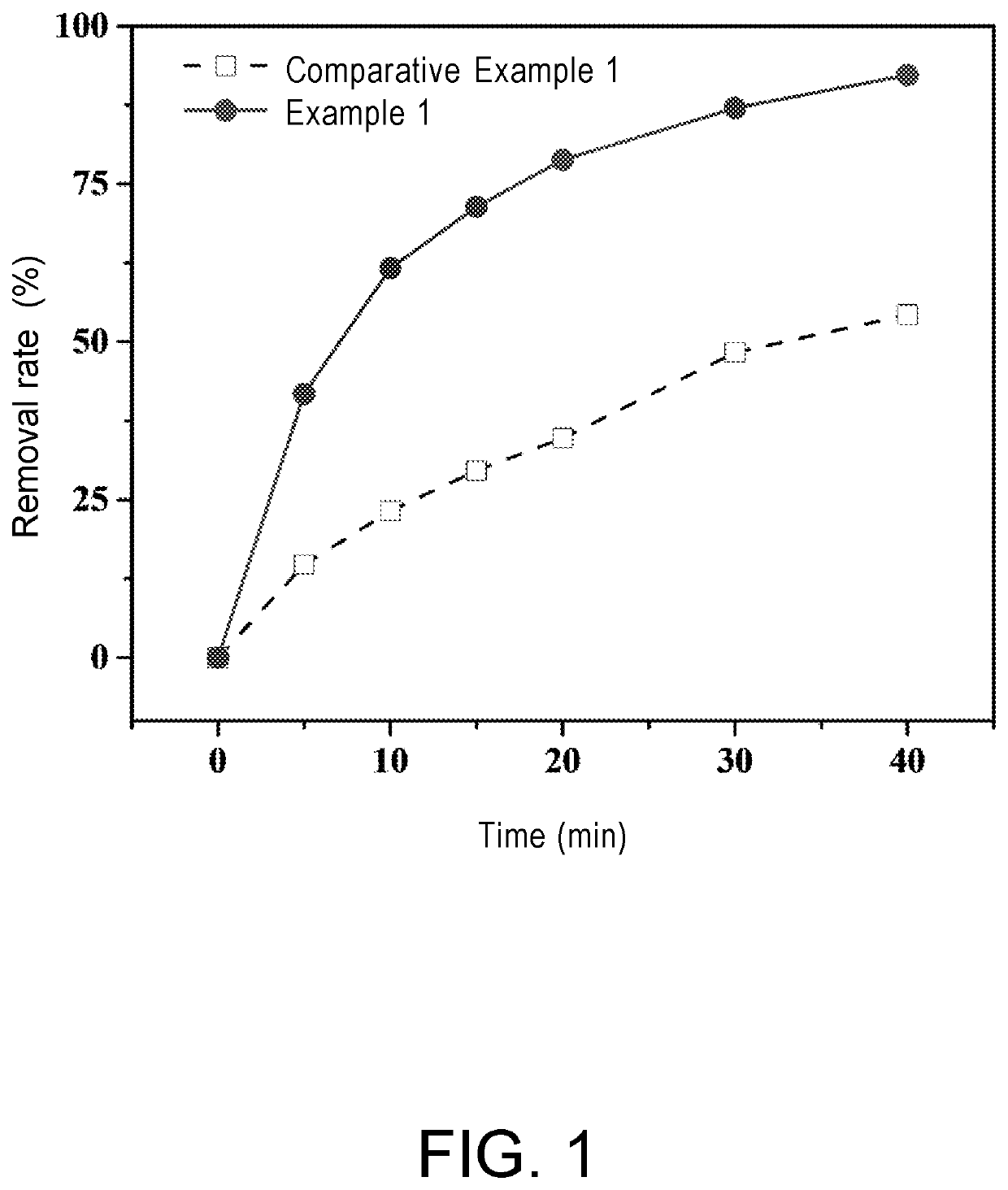

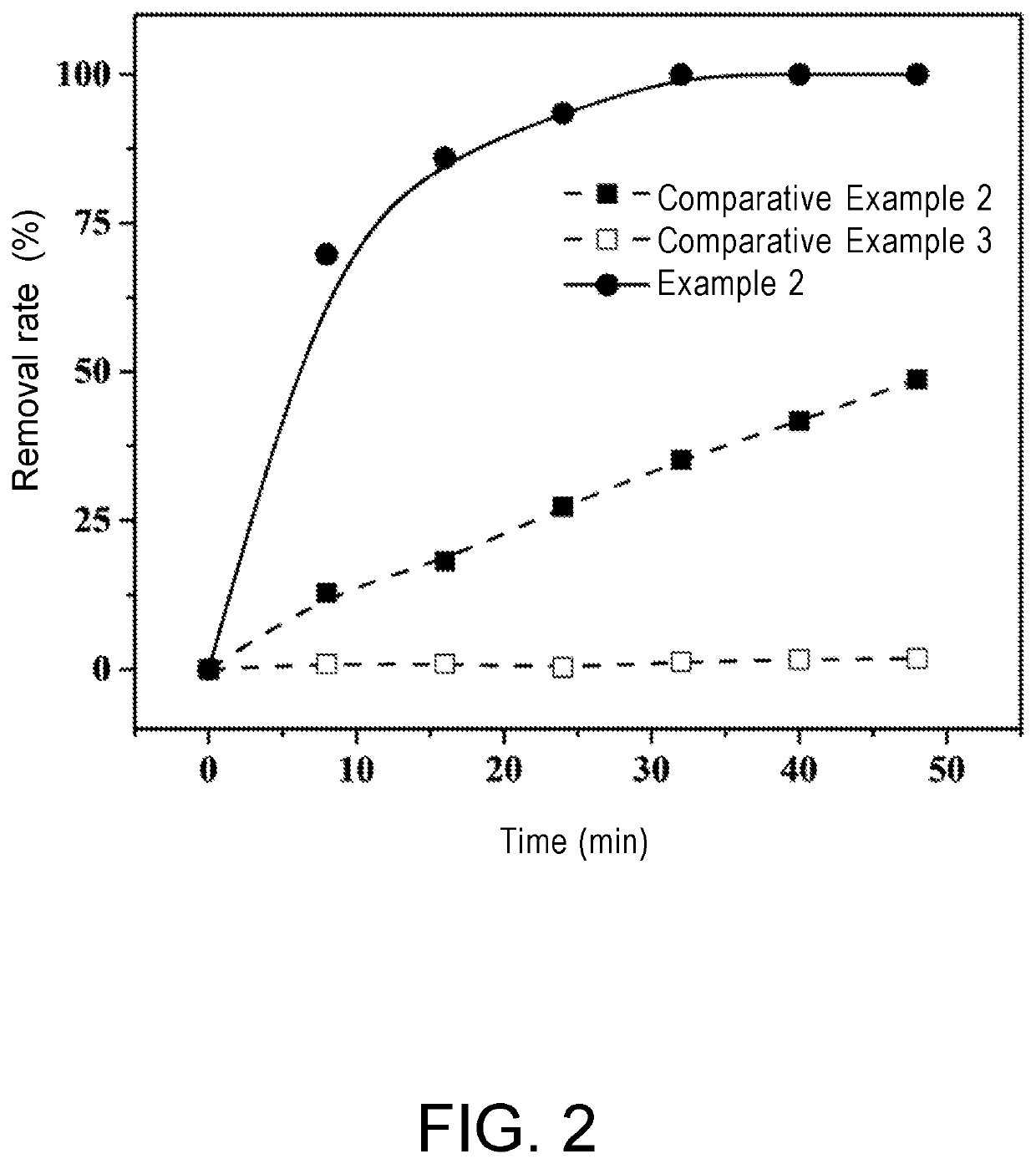

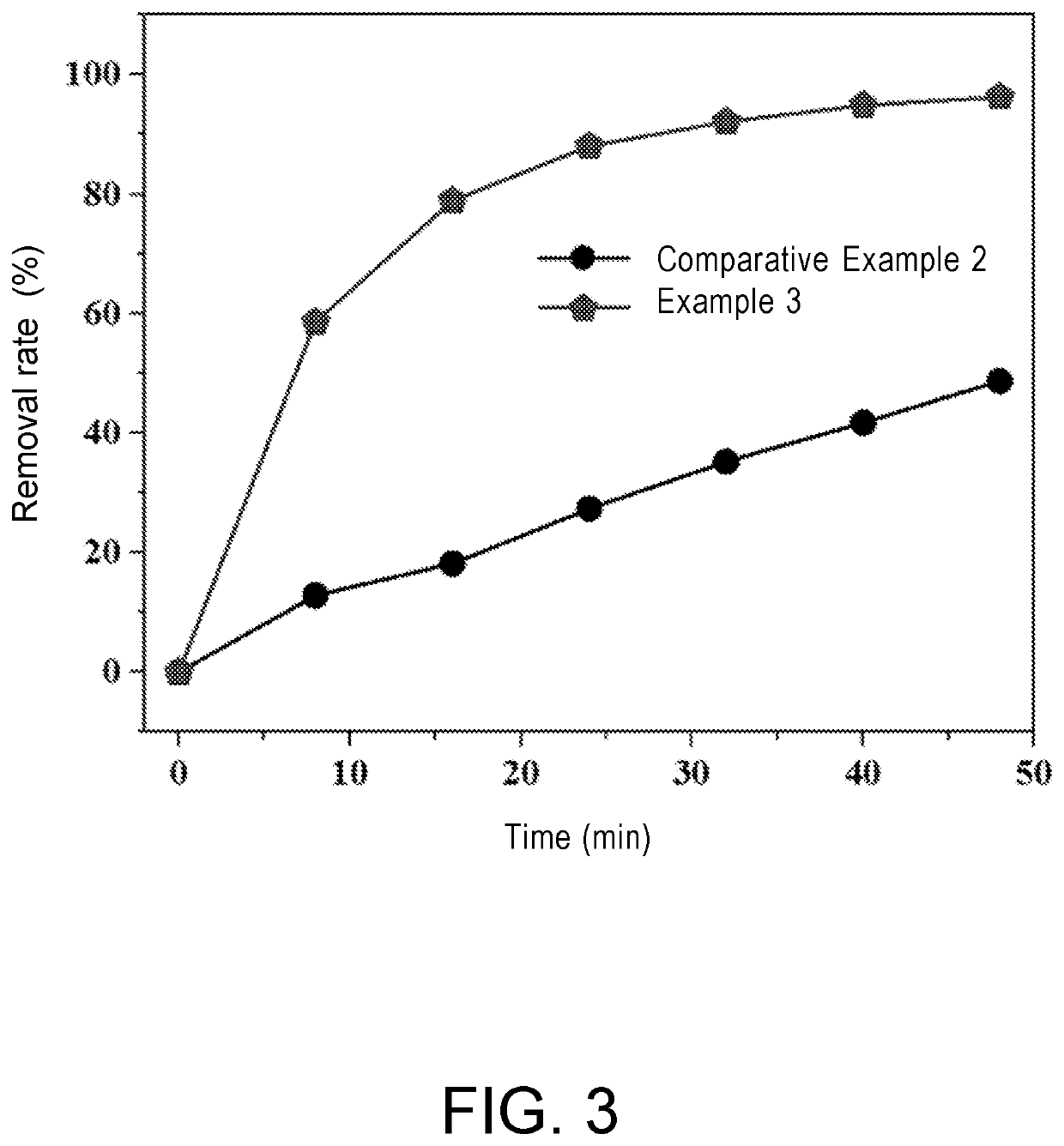

Method for recovering groundwater polluted by organic phenols

ActiveUS20210198131A1Simple processEasy to operateWater treatment compoundsWater contaminantsEnvironmental engineeringManganese oxide

The disclosure is a method for recovering groundwater contaminated with organic phenols. The method includes the step of injecting a remediation agent into the groundwater extracted from the stratum to be rehabilitated or ex-situ extracted, followed by the step of injecting manganese-based oxidant. By adding a suitable proportion of soluble silicon to the water to be treated as a remediation agent, the efficiency of manganese-based oxidant in the treatment of phenolic pollutants is enhanced based on interface properties and stability of various manganese oxides in the regulating and recovering process. The method for recovering groundwater contaminated with organic phenols provided by the disclosure has a simple process and is convenient to operate, the adopted chemicals are inexpensive and easy to obtain, cause little corrosion to the injection equipment, and has a wide range of applications in practice. The adopted oxidant will not produce halogenated toxic by-products during the treatment process.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

A method for stripping the nickel-phosphorus coating on the surface of a workpiece

The invention discloses a method for deplating a nickel-phosphorus coating on the workpiece surface, characterized by preparing a deplating liquid and putting the workpiece in the deplating liquid to deplate. According to the invention, the method guarantees that after deplating nickel-phosphorus coatings in various proportions on copper alloy or aluminium alloy base materials, the surface of the base material is slightly etched and the fineness is not influenced, and the method is suitable for all copper alloy and aluminium alloy and solves the problems of low quality and low efficiency of deplating high-phosphorus nickel-phosphorus coatings on copper alloy or aluminium alloy, and corrosion to the base materials in the prior art; in addition, compared with common nickel-phosphorus coatings, the method disclosed herein can achieve a total amount of deplated coatings which is more than 10 times that obtained by traditional method, thus the efficiency is greatly raised.

Owner:SICHUAN HUAFENG ENTERPRISE GRP

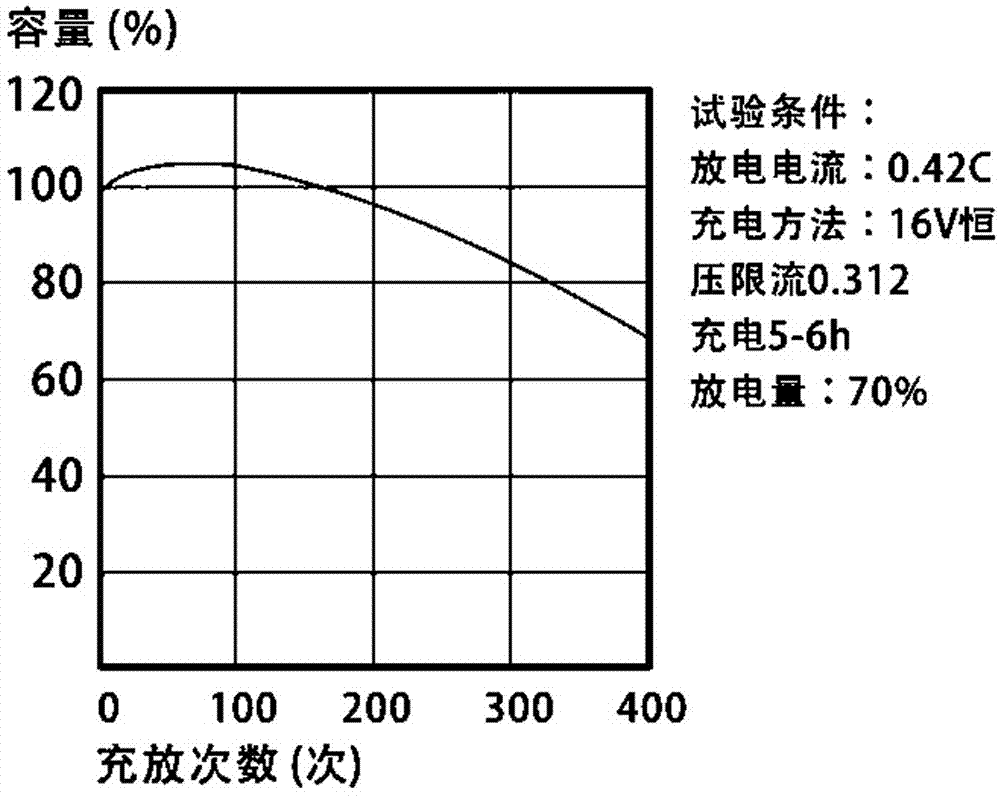

Novel silicate electrolyte storage battery

ActiveCN102122729BWill not polluteIncrease oxygen contentLead-acid accumulatorsSilanesSilicon dioxide

The invention discloses a novel silicate electrolyte storage battery. The novel silicate electrolyte storage battery comprises a cathode, an anode, an isolation layer and electrolyte; and the electrolyte consists of sulfuric acid, ammonium phosphate, silicon dioxide, ammonium persulfate, sodium sulfate, potassium sulfate, polyacrylamide, a dispersing agent, a stabilizing agent and a catalyst, and the balance of deionized water, wherein the catalyst is one of basic salt, silane and silicone oil. The storage battery is environmentally-friendly, and has high performance and wide application prospect.

Owner:李海明

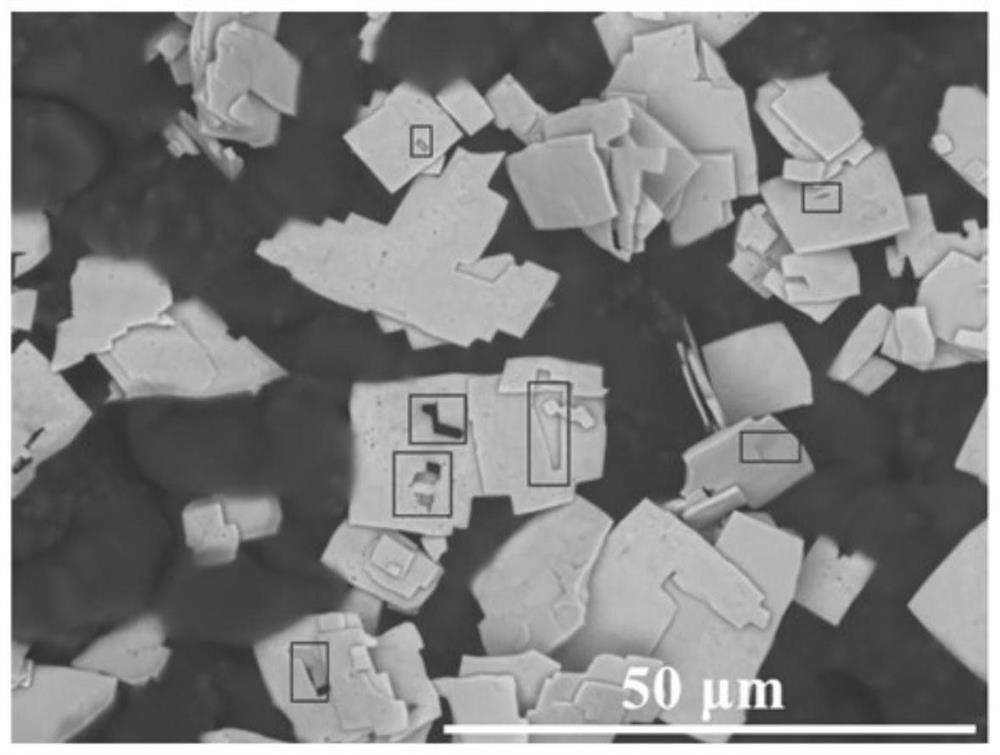

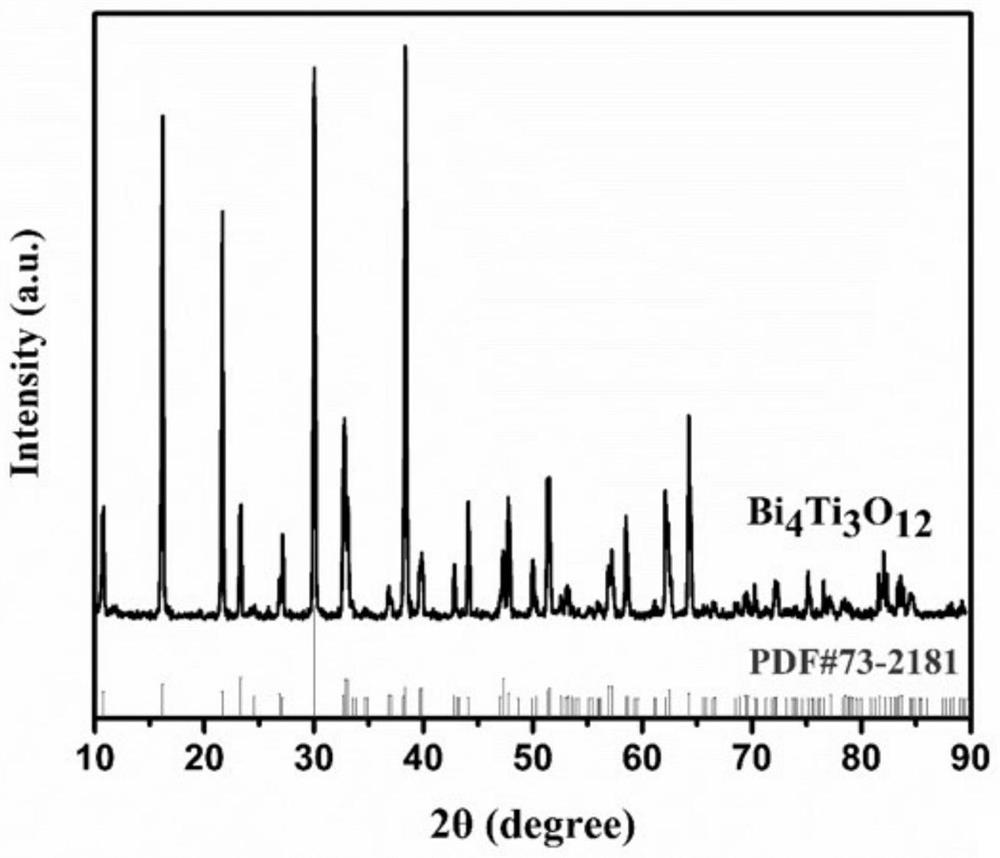

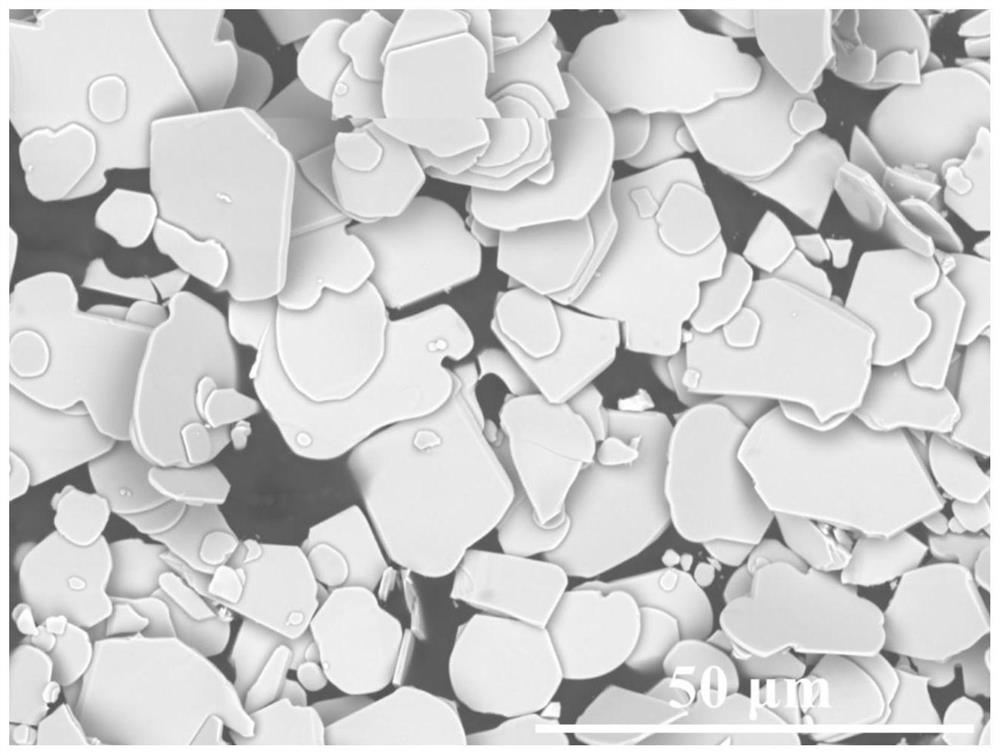

A method for improving the quality and yield of flaky barium titanate template

ActiveCN111072064BImprove qualityIncrease productionAlkaline earth titanatesBarium titanateEngineering

Owner:SHAANXI COAL & CHEM TECH INST

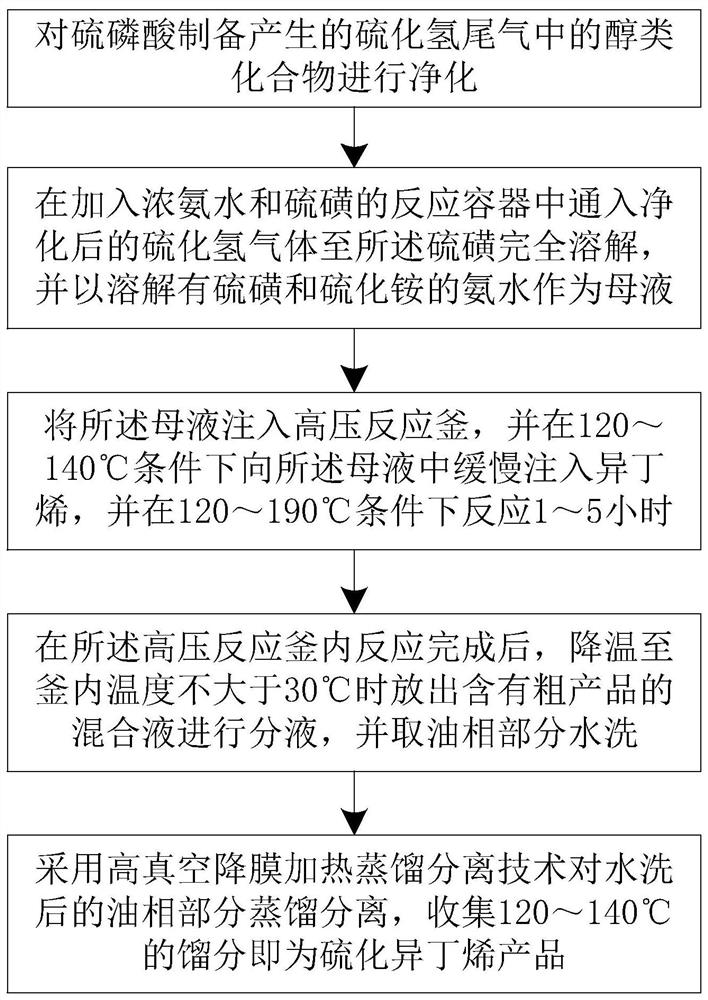

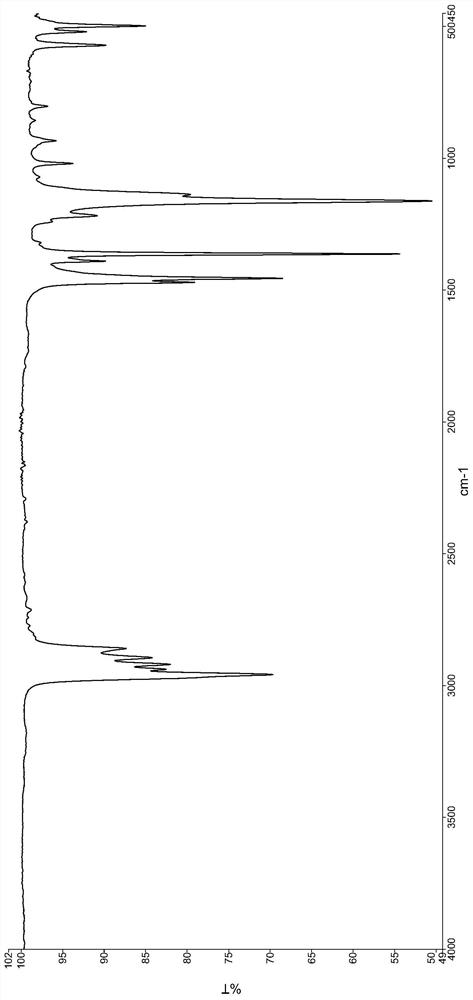

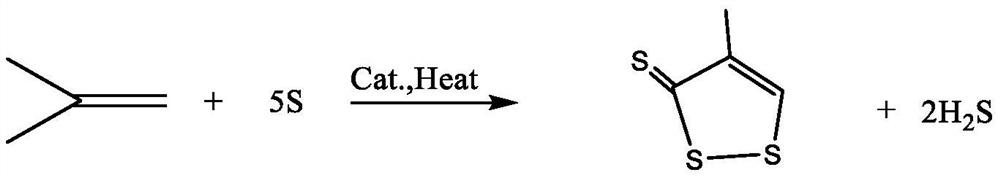

Method for preparing sulfurized isobutylene by combining hydrogen sulfide tail gas in sulfur-phosphoric acid production

PendingCN113387924AHigh process conversion rateIncrease productivityOrganic chemistryHydrogen sulfidesO-Phosphoric AcidDistillation

The invention discloses a method for preparing sulfurized isobutylene by combining hydrogen sulfide tail gas in sulfur-phosphoric acid production . The method comprises the following steps: purifying the hydrogen sulfide tail gas; introducing hydrogen sulfide gas into a reaction container added with concentrated ammonia water and sulfur sulfur is completely dissolved to serve as mother liquor, and wherein the molar ratio of ammonia to sulfur to hydrogen sulfide is 1: (0.8-1.2): (0.15-0.30); injecting isobutene into the mother liquor at the temperature of 120-140 DEG C, and carrying out reaction for 1-5 hours at the temperature of 120-190 DEG C, wherein the molar ratio of isobutene to hydrogen sulfide is 1: 0.3 to 1: 0.48; after the reaction is finished, cooling to not higher than 30 DEG C, separating liquid, taking an oil phase part, and washing with water; and carrying out high vacuum falling film heating distillation separation on the washed oil phase part, and collecting a fraction at 120-140 DEG C to obtain the product. According to the technical scheme, safe recovery of hydrogen sulfide is achieved, much less wastewater is generated, the process conversion rate and the comprehensive yield are high, the production efficiency is high, the product character and performance are high, and the technological process is simple.

Owner:XINXIANG RICHFUL LUBE ADDITIVE CO LTD

Process for preparing an organic hydroperoxide, industrial set-up therefore and process wherein such organic hydroperoxide is used in the preparation of an alkylene oxide

ActiveUS7863493B2Good removal effectSlightly corrodedOxygen-containing compound preparationOrganic compound preparationGlass fiberOrganic reaction

A process for preparing an organic hydroperoxide, which process comprises:(a) oxidizing an organic compound to obtain an organic reaction product containing organic hydroperoxide;(b) mixing at least part of the organic reaction product of step (a) with a basic aqueous solution to obtain a mixture of basic aqueous solution and the organic reaction product;(c) separating the mixture of step (b) to obtain a separated organic phase containing organic hydroperoxide, and a separated aqueous phase;(d) mixing at least part of the separated organic phase of step (c) with water to obtain a mixture of an aqueous phase and the organic phase; and(e) separating the mixture of step (d) to obtain a separated organic phase containing organic hydroperoxide, and a separated aqueous phase; in which process the separation to a separated organic phase and a separated aqueous phase in step(e) is carried out with the help of a coalescer containing glass fibers.

Owner:SHELL USA INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com