Ultrahigh-temperature-resistant low-viscosity low-corrosion emulsifier and emulsified acid system containing same

A low-viscosity, ultra-high-temperature technology, applied in the field of emulsified acid systems, can solve the problems of easily damaged structures and loss of use significance, and achieve the effects of reducing the rate of acid-rock reaction, excellent temperature resistance, and low friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

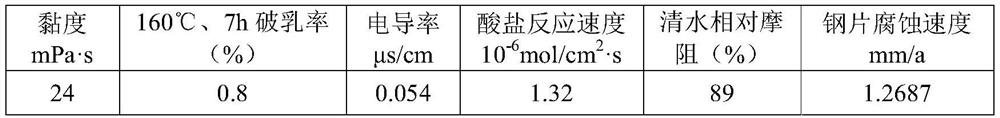

Embodiment 1

[0036] An emulsified acid system resistant to ultra-high temperature, low viscosity and low corrosion, comprising the following components in parts by weight:

[0037] 4 parts of viscoelastic surfactant with 3 hydrophobic tail chains prepared from docosenoic acid acyl propyl dimethyl tertiary amine and halogenated compound, 4 parts of sorbitan fatty acid ester polyoxyethylene ether, 2 parts of corrosion inhibitor (Mannich base synthesized from ethylenediamine, acetophenone and formaldehyde), 2 parts of iron ion stabilizer (sodium erythorbate), 30 parts of hydrochloric acid, and the balance is diesel oil.

[0038] Wherein, the preparation method of the halogenated compound is as follows: drip epichlorohydrin into the ethanol solution of N,N-dimethylpropylenediamine, react at room temperature for 10 hours, then remove the solvent and perform solid-liquid separation to obtain A compound with 3 halogenated head groups; the molar ratio of N,N-dimethylpropylenediamine to epichlorohy...

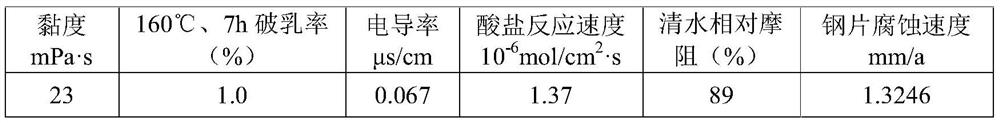

Embodiment 2

[0043] An emulsified acid system resistant to ultra-high temperature, low viscosity and low corrosion, comprising the following components in parts by weight:

[0044] 4 parts of viscoelastic surfactant with 2 hydrophobic tail chains prepared from docosenoic acid acyl propyl dimethyl tertiary amine and halogenated compound, 4 parts of sorbitan fatty acid ester polyoxyethylene ether, 2 parts of corrosion inhibitor (Mannich base synthesized from ethylenediamine, acetophenone and formaldehyde), 2 parts of iron ion stabilizer (sodium erythorbate), 30 parts of hydrochloric acid, and the balance is diesel oil.

[0045] Wherein, the preparation method of the halogenated compound is as follows: drip epichlorohydrin into the organic solution of butanolamine, react at room temperature for 10 hours, then remove the solvent and perform solid-liquid separation to obtain the compound having two halogenated head groups. Compound; the molar ratio of butanolamine to epichlorohydrin is 1:2.

...

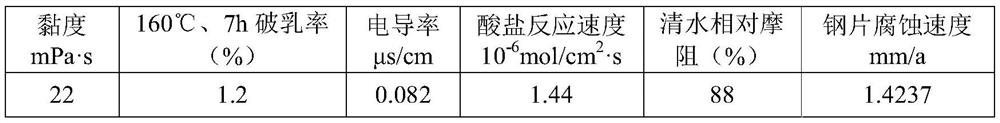

Embodiment 3

[0050] An emulsified acid system resistant to ultra-high temperature, low viscosity and low corrosion, comprising the following components in parts by weight:

[0051] 4 parts of viscoelastic surfactant with 1 hydrophobic tail chain prepared from docosenoic acid acyl propyl dimethyl tertiary amine and halogenated compound (1-chlorobutane), 4 parts of sorbitan fatty acid ester 4 parts of polyoxyethylene ether, 2 parts of corrosion inhibitor (Mannich base synthesized by ethylenediamine, acetophenone and formaldehyde), 2 parts of iron ion stabilizer (sodium erythorbate), 30 parts of hydrochloric acid, and the balance is diesel fuel.

[0052] The preparation process is as follows: add emulsifier and corrosion inhibitor to diesel oil, add iron ion stabilizer to acid solution, put the oil phase in a high-speed disperser at a speed of 2800r / min for ten minutes, and at the same time use peristaltic The pump drips the acid solution into the oil phase at a rate of 6mL / min to obtain an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com