Movable sulfurization active carbon heating regenerator and regeneration

A regeneration equipment, heating regeneration technology, applied in separation methods, filter regeneration, chemical instruments and methods, etc., can solve the problems of burning out regeneration equipment safety hazards, heavy operation and maintenance workload, reducing regeneration efficiency, etc., to achieve heating heat source. Flexibility, high heat utilization efficiency and high regeneration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

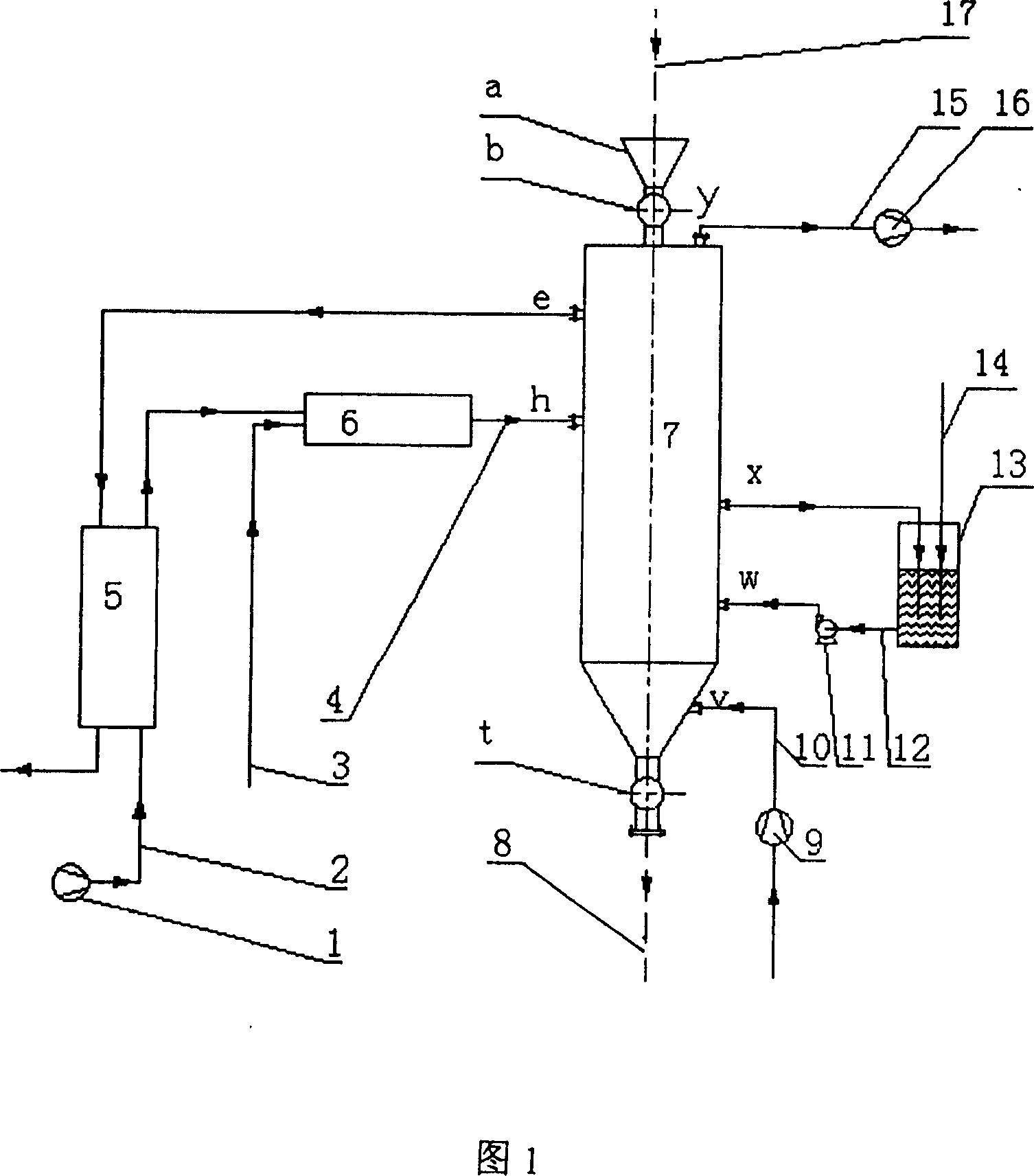

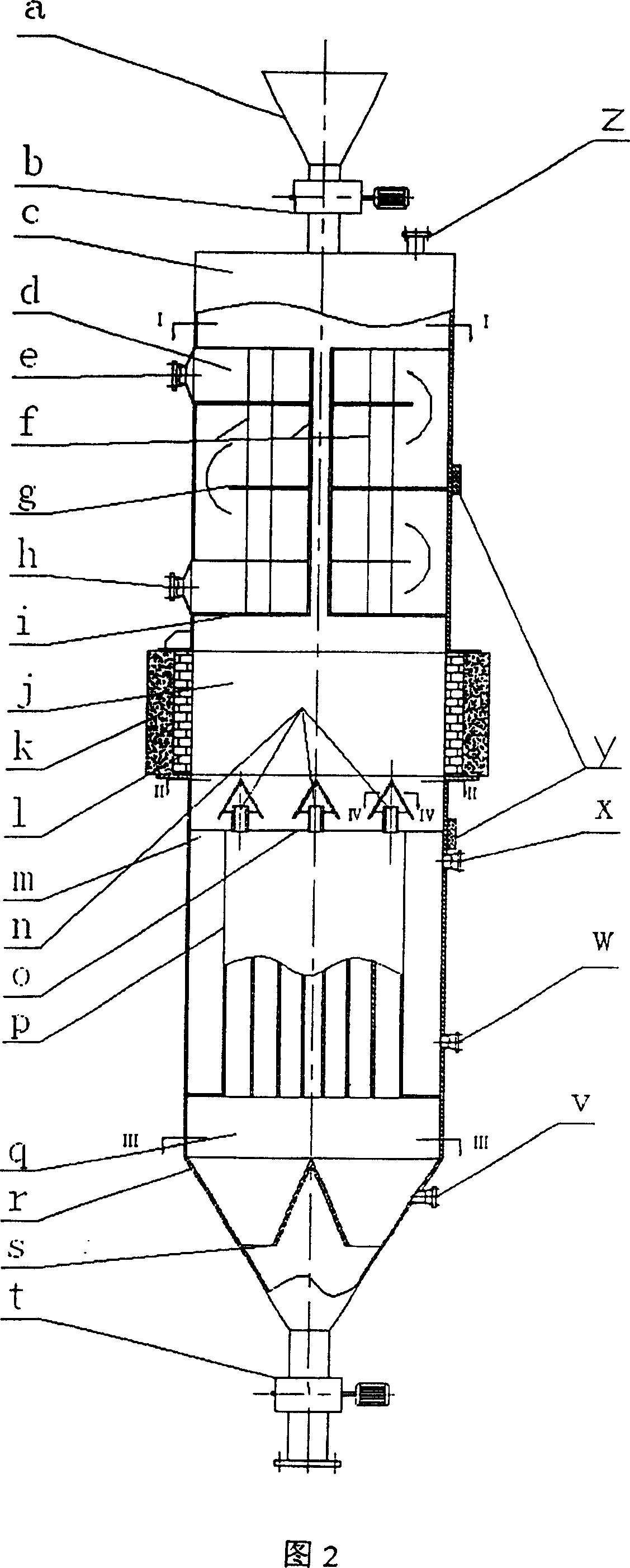

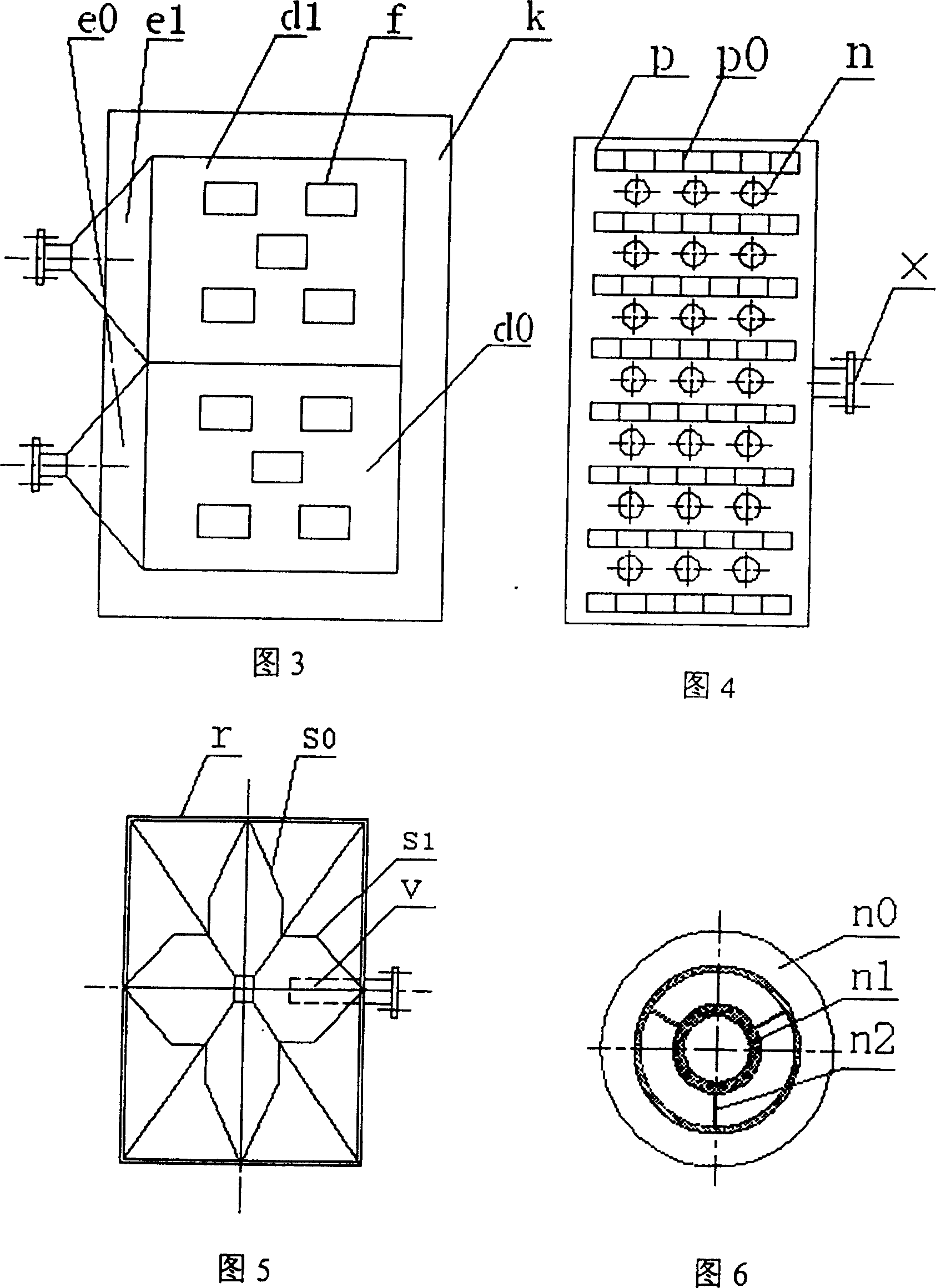

[0048] It can be clearly seen from Fig. 1 that the moving bed desulfurization activated carbon regeneration method designed by the present invention is composed of the following equipment: air blower 1, air preheater 5, hot blast stove 6, regeneration equipment 7, inert gas blower 9, water pump 11, water tank 13 and regenerative gas extraction induced draft fan 16 to form. The air preheater 5 is a tube-and-tube heat exchanger, and the material can be Corten steel or NI steel with good acid dew point corrosion resistance. The outer wall of the heat exchange tube is welded with spiral fins to enhance heat exchange, and the heat exchange surface is painted for corrosion protection. According to the fuel form (solid, liquid or gas), select different hot blast stoves 6 for use. The regenerative gas extraction induced draft fan 16 is selected from a temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com