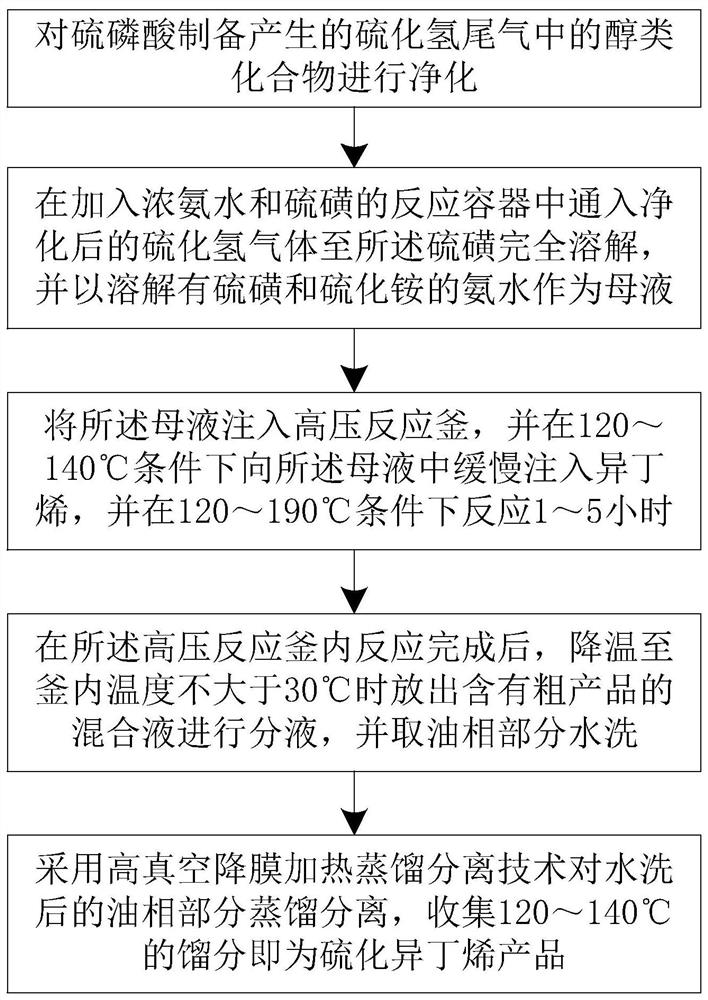

Method for preparing sulfurized isobutylene by combining hydrogen sulfide tail gas in sulfur-phosphoric acid production

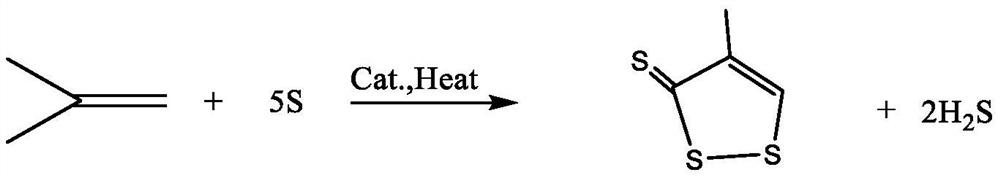

A technology for sulfided isobutylene and hydrogen sulfide, applied in hydrogen sulfide, chemical instruments and methods, sulfur compounds, etc., can solve the problems of light color, low odor, and poor economic benefits of hydrogen sulfide gas.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

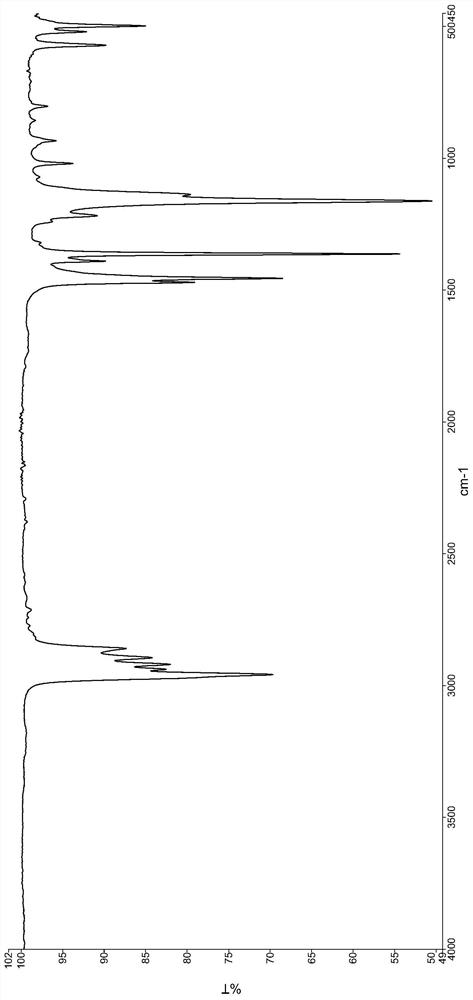

Examples

Embodiment 1

[0073] In 200L stainless steel atmospheric pressure kettle, drop into 37.5Kg flake sulfur, ammoniacal liquor (mass content 24%) 100Kg, while stirring, use gas mass flowmeter to measure the input amount of hydrogen sulfide, until the hydrogen sulfide of feeding 9.5Kg, Stirring was continued for 1 h to obtain a clear mother liquor.

[0074] Take the above mother liquor, inject it into a 250L autoclave purged with nitrogen, close the autoclave, raise the temperature to 130°C, feed 52Kg of isobutene within 1 hour, keep the reaction temperature at 130°C, and the maximum pressure in the autoclave is 4.3Mpa. After adding isobutene, the reaction was continued for 2 hours, and then the temperature was naturally lowered to 30°C. Subsequently, open the vent of the autoclave, and release the liquid containing the crude product after there is no pressure in the autoclave. The total weight of the liquid is 197Kg. Get the organic phase (heavy 92.7Kg) in the above liquid, and the water phas...

Embodiment 2

[0080] Drop into 34.9Kg flake sulfur in 200L stainless steel atmospheric pressure kettle, the mother liquor 104.3Kg of ammoniacal liquor (mass content 24%) 6.25Kg and reclaim, while stirring, feed the hydrogen sulfide of 8.15Kg (measurement mode is with embodiment 1) , and continued to stir for 1h to obtain a clear mother liquor.

[0081] Take the above mother liquor and 22.25Kg of recovered light and heavy fractions, inject them into a 250L autoclave after purging with nitrogen, close the body of the autoclave, raise the temperature to 135°C, feed 40Kg of isobutylene within 1 hour, raise the temperature to 145°C and moisturize the reaction. The highest pressure is 3.9Mpa. After adding isobutene, the reaction was continued for 3 hours, then the heating was stopped, and cooling heat transfer oil was introduced into the coil until the temperature in the kettle reached 30°C. Subsequently, open the vent of the autoclave, and release the liquid containing the crude product after t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com