Method for producing wetting agent

A production method and wetting agent technology, applied in chemical instruments and methods, preparation of organic compounds, coatings, etc., can solve problems such as foaming, low surface tension, and high surface tension, and achieve low surface tension and low dynamic surface Tonicity, water solubility improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

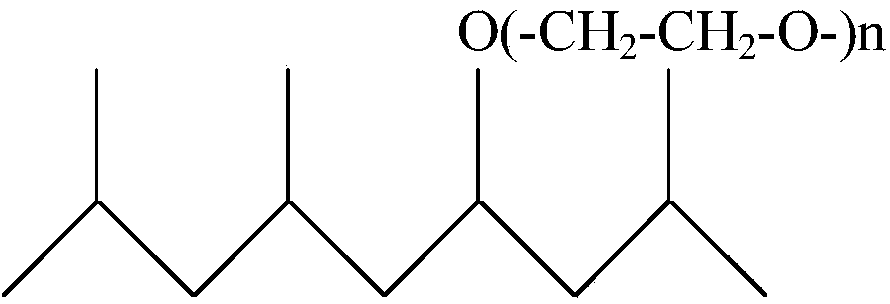

Image

Examples

Embodiment 1

[0022] A production method of a wetting agent, characterized in that: comprising the steps of:

[0023] Step 1. Add organic solvent A, basic catalyst M, and methyl isobutyl ketone into the reaction kettle, and react for 2 hours at a temperature of 35°C to obtain a reaction liquid, which is processed by high vacuum distillation process , to obtain 2,6,8-trimethyl-6-hydroxyl-4 nonanone; the preferred potassium hydroxide of the basic catalyst M, the added mass is 0.3% of the mass of methyl isobutyl ketone; the preferred organic solvent A is benzene; high vacuum The rectification process conditions are that the degree of vacuum is 10 Pa and the temperature is 65°C.

[0024] Step 2: 2,6,8-trimethyl-6-hydroxy-4-nonanone is dehydrated for 0.5 hours, and then catalyst N is added for catalytic hydrogenation reaction to generate 2,4,8-trimethyl-4-nonanone Alcohol, the 2,4,8-trimethyl-4-nonanol is filtered; the reaction conditions for catalytic hydrogenation are: temperature 60°C, react...

Embodiment 2

[0027] A production method of a wetting agent, characterized in that: comprising the steps of:

[0028] Step 1. Add organic solvent A, basic catalyst M, and methyl isobutyl ketone into the reaction kettle, and react for 0.5 hours at a temperature of 60° C. to obtain a reaction solution, which is processed by high vacuum rectification process , to obtain 2,6,8-trimethyl-6-hydroxyl-4 nonanone; basic catalyst M is preferably a mixture of potassium hydroxide and sodium hydroxide, and the added quality is 0.3% of the quality of methyl isobutyl ketone; organic solvent A Benzene is preferred; the high vacuum rectification process conditions are as follows: a vacuum degree of 50 Pa and a temperature of 115°C.

[0029] Step 2: 2,6,8-trimethyl-6-hydroxy-4-nonanone is dehydrated for 2 hours, and then catalyst N is added to carry out catalytic hydrogenation reaction to generate 2,4,8-trimethyl-4-nonanone Alcohol, the 2,4,8-trimethyl-4-nonanol is filtered; the reaction conditions for cata...

Embodiment 3

[0032] A production method of a wetting agent, characterized in that: comprising the steps of:

[0033] Step 1. Add organic solvent A, basic catalyst M, and methyl isobutyl ketone into the reaction kettle, and react for 1 hour at a temperature of 53° C. to obtain a reaction liquid, which is processed by high vacuum distillation process , to obtain 2,6,8-trimethyl-6-hydroxyl-4 nonanone; basic catalyst M is preferably triethylamine, and the added mass is 0.2% of the mass of methyl isobutyl ketone; organic solvent A is preferably 1,2- Dichloroethane; high vacuum rectification process conditions are, the vacuum degree is 45Pa, and the temperature is 91°C.

[0034]Step 2: 2,6,8-trimethyl-6-hydroxy-4-nonanone is dehydrated for 1 hour, and then catalyst N is added to carry out catalytic hydrogenation reaction to generate 2,4,8-trimethyl-4-nonanone Alcohol, the 2,4,8-trimethyl-4-nonanol is filtered; the reaction conditions for catalytic hydrogenation are: temperature 45°C, reaction t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com