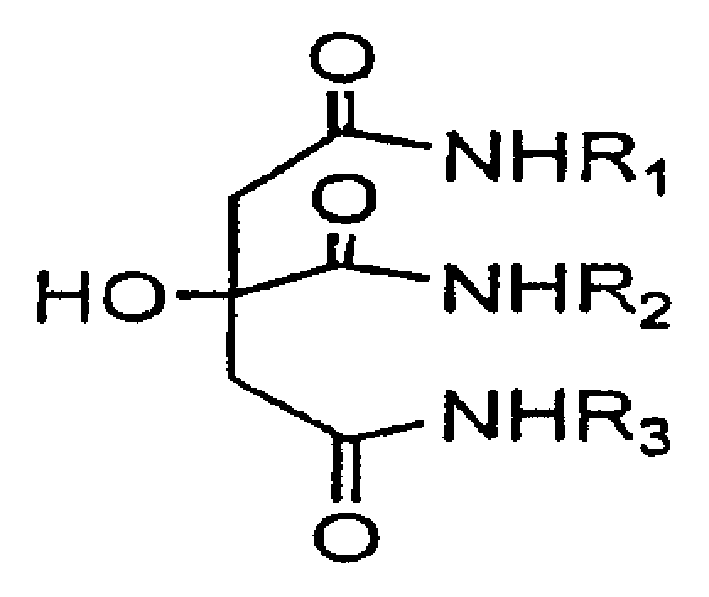

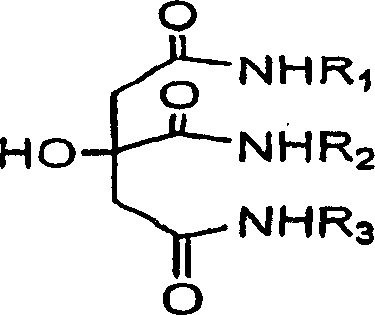

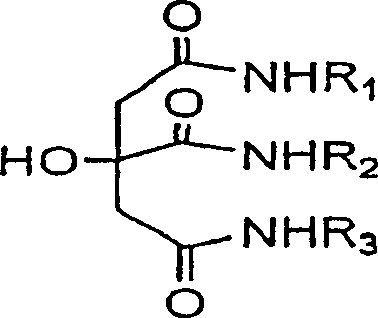

Citric trialkyl amide surfactant

A technology of surfactant and alkyl amide, which is applied in the direction of surface active detergent composition, carboxylic acid amide preparation, surface pretreatment, etc., can solve the problems such as unsuitability, and achieve environmental friendliness, low odor, and excellent wettability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] N,N',N"-tri-n-propyl citric amide was prepared by reacting n-propylamine with triethyl citrate. To a round bottom flask was added triethyl citrate (30.245 g; 1 g equivalent), n Propylamine (19.427 g, 3.16 g equivalents) and methanol (40 mL). The clear pale yellow solution was stirred at room temperature for 3 days before the methanol was removed by disk evaporation at 50° C. The resulting yellow liquid was vacuumed at 70° C. Drying gave a sticky white solid. The crude solid was triturated with diethyl ether, collected by filtration and dried in vacuo to give a slightly odorous white powder (19.19 g; 55% yield).

Embodiment 2

[0061] N,N',N"-tri-n-butyl citric acid amide was prepared by reacting n-butylamine with triethyl citrate. To a round bottom flask was added triethyl citrate (31.485 g; 0.1140 mol, 1 g eq) and methanol (40 mL). To this solution was slowly poured n-butylamine (24.999 g, 3.00 g eq). Before the methanol was removed by disk evaporation at 60° C., the clear pale yellow solution was stirred at room temperature for 3 The resulting crude sticky solid was triturated with diethyl ether, collected by filtration and dried in vacuo to give a white powder with a slight amine odor (23.95 g; 58% yield).

Embodiment 3

[0063] N,N',N"-triisobutyl citric acid amide was prepared by reacting isobutylamine with triethyl citrate. To a round bottom flask was added triethyl citrate (30.001 g; 1 g equivalent), Isobutylamine (24.034 g; 3.03 g equivalents) and methanol (40 mL). The clear pale yellow solution was stirred at room temperature for 2 days, then additional isobutylamine (3.06 g equivalents) was added. After stirring overnight, wet The methanol was removed in vacuo and the solid was triturated with diethyl ether, collected by filtration and dried in vacuo to give a white powder with no detectable odor (31.09 g; 80.3% yield).

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com