Alkynolalkoxy compound modified siloxanesurfactant and preparation method thereof

A technology of surfactant and compound, applied in the field of siloxane surfactant and its preparation, can solve the problems of leather surface effect, reduce dynamic surface tension, large dynamic surface tension gap, etc., and achieve good environmental and economic benefits , Improve foam problem, good compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

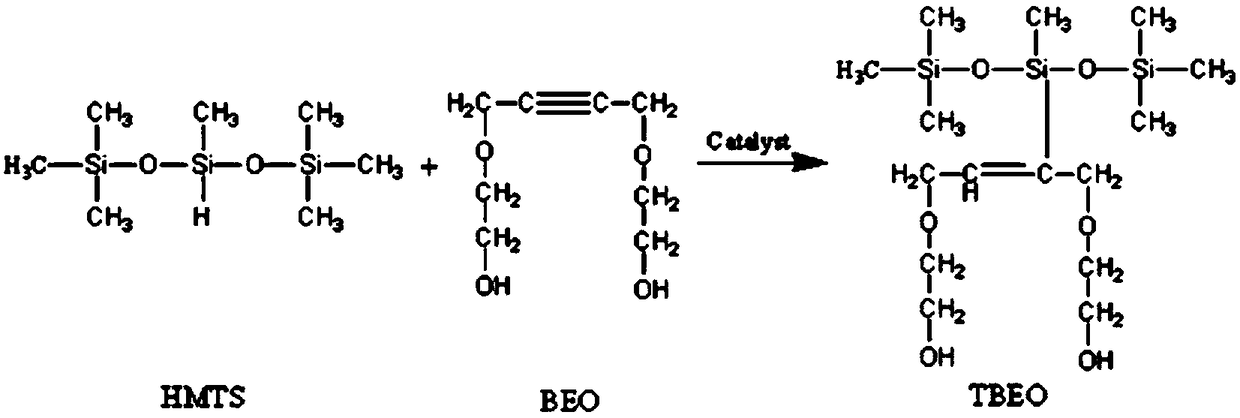

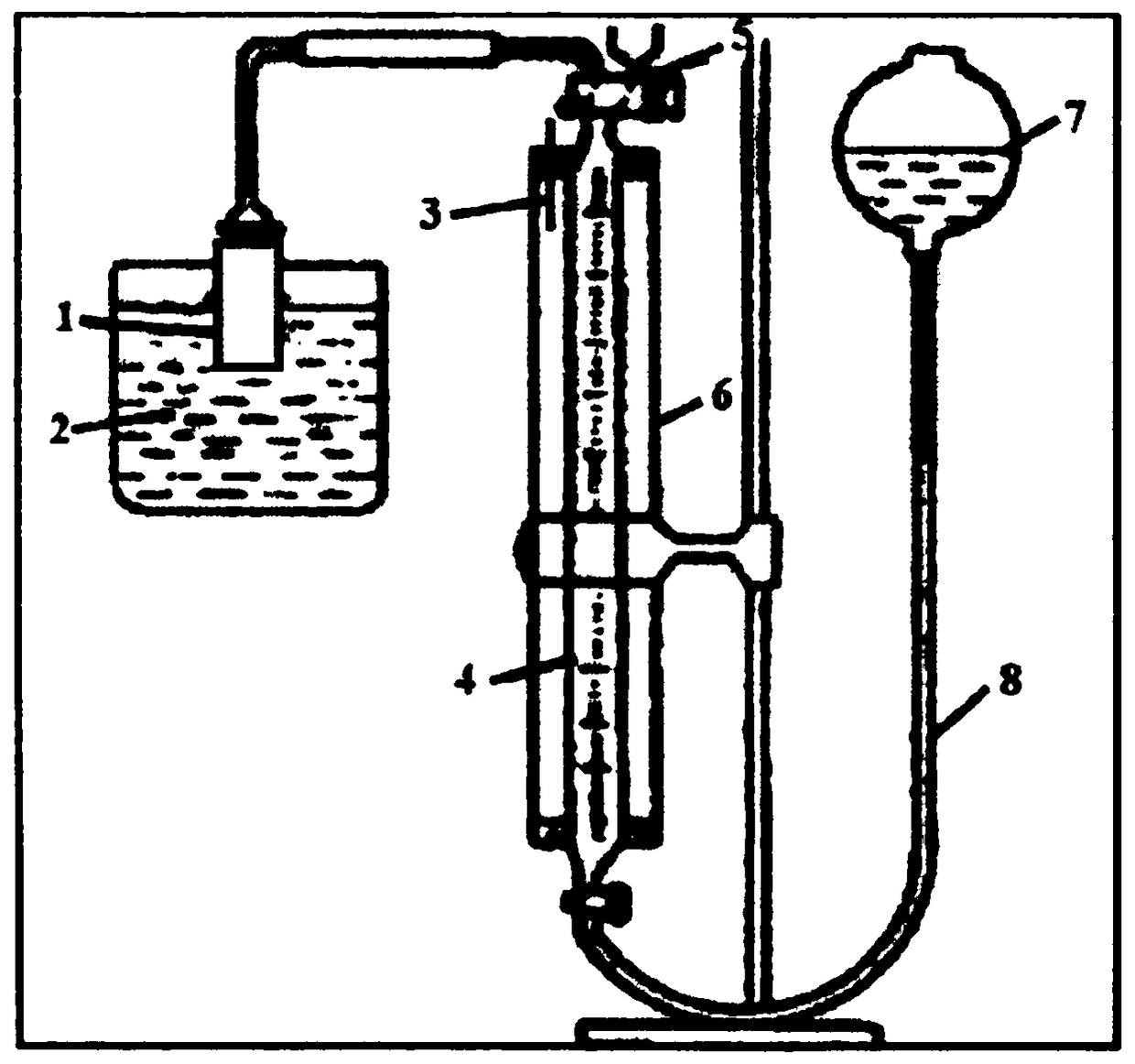

[0036] The preparation process of the siloxane surfactant modified by the acetylenic alcohol alkoxy compound is as follows figure 1 Shown, the reaction raw materials 1,1,1,3,5,5,5--heptamethyltrisiloxane (HMTS) and butynediol ethoxy ether (BEO), through the hydrosilylation reaction method synthesis.

[0037] The specific operation is: feed the raw materials HMTS (Runhe Silicone) and BEO (Wuhan Aoke Special Chemicals) at a molar ratio of 1.13:1, and the catalyst H 2 PtC1 6 According to 100ppm (the amount is based on the mass of Pt / the total mass of acetylenic alcohol alkoxy compound and hydrogen-containing siloxane), the reaction inhibitor sodium carboxylate is added to a 250mL four-port container equipped with a mechanical stirring device, a condensing reflux device and a thermometer. In the round-bottomed flask, wherein the addition of the reaction inhibitor accounts for 0.05% of the total reactant mass percentage, then vacuumizes, and the vacuum degree is at 500mmHg, and t...

Embodiment 2

[0039] The raw materials HMTS (Runhe Silicone) and BEO (Wuhan Aoke Specialty Chemicals) were fed in a molar ratio of 1.13:1, and the catalyst H 2 PtC1 6 According to 50ppm (the amount is based on the total mass of Pt mass / alkynol alkoxy compound and hydrogen-containing siloxane), accounting for 0.05% reaction inhibitor sodium carboxylate in the mass percentage of the total reaction substances, add a mechanical stirring device , 250mL four-neck round-bottomed flask with a condensing reflux device and a thermometer, vacuumize, and the vacuum degree is at 700mmHg, and then under stirring conditions, after heating and reacting in an oil bath for 3.5 hours, the temperature is finally cooled and discharged to obtain the product acetylenic alcohol alkoxy compound Modified silicone surfactant (TBEO). It is measured that the hydrosilylation conversion rate is 85%, and the color is transparent and watery white.

Embodiment 3

[0041] The raw materials HMTS (Runhe Silicone) and BEO (Wuhan Aoke Specialty Chemicals) were fed in a molar ratio of 1.13:1, and the catalyst H 2 PtC1 6According to 200ppm (the amount is based on the total mass of Pt mass / alkynol alkoxy compound and hydrogen-containing siloxane), accounting for 0.05% reaction inhibitor sodium carboxylate in the mass percentage of the total reaction substance, add a mechanical stirring device , a 250mL four-necked round-bottomed flask with a condensing reflux device and a thermometer, vacuumize, and the vacuum degree is at 500mmHg, and then under stirring conditions, after heating and reacting in an oil bath for 3.5 hours, the temperature is finally cooled and discharged to obtain the product acetylenic alcohol alkoxy compound . The tested silicon hydrogen conversion rate is 88%. Color yellow.

[0042] In terms of silicon hydrogen conversion rate, increasing the amount of catalyst did not improve the conversion rate, and the color deepened. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com