Patents

Literature

60 results about "Sulfur monochloride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

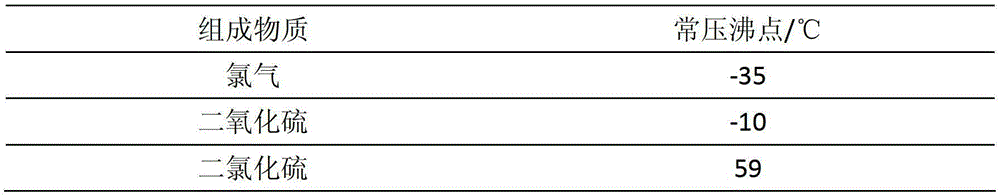

Disulfur dichloride is the chemical compound of sulfur and chlorine with the formula S 2 Cl 2. Some alternative names for this compound are sulfur monochloride (the name implied by its empirical formula, SCl), disulphur dichloride (British English Spelling) and sulphur monochloride (British English Spelling).

Separation and purification method of mixed waste gas containing chlorine and hydrogen chloride

InactiveCN1865127ARealize recycling of resourcesHigh recovery rateChlorine/hydrogen-chloride purificationPurification methodsGas phase

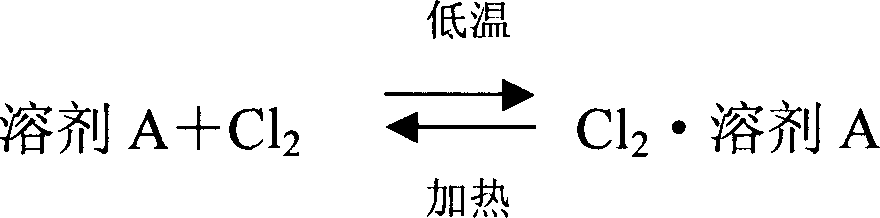

This invention relates to a method for separating and purifying mixing exhaust gas of chlorine and hydrochloride, comprising: absorb the chlorine in the mixing exhaust gas using solvent A to separate from gas phase hydrochloride, the chlorine can be obtained after solvent A desorption, the hydrochloride can be obtained by removing solvent A in the gas phage hydrochloride using solvent B, wherein: solvent A is one of benzene, silicon tetrachloride, nonyl hydride, sulfur monochloride, carbon tetrachloride and chlorosulfonic acid, and solvent B is one of cyclopentadiene and hexachlorobutadiene. By washing with concentrated hydrochloric acid to remove trace amount of organic compounds, and chemical washing to remove heavy metal elements, the hydrochloride is absorbed by water to make hydrochloric acid. This invention is characterized of efficient separation of chlorine and hydrochloride, high efficiency of separation, low cost, high-usage of resources, high purity of chlorine up to 99%, recycling use, and the purity of hydrochloride meets the requirement of producing industrial hydrochloride and hydrochloride regent .

Owner:ZHEJIANG WEIHUA CHEMICAL CO LTD

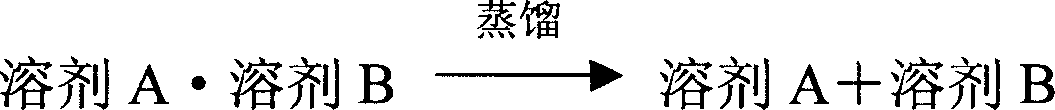

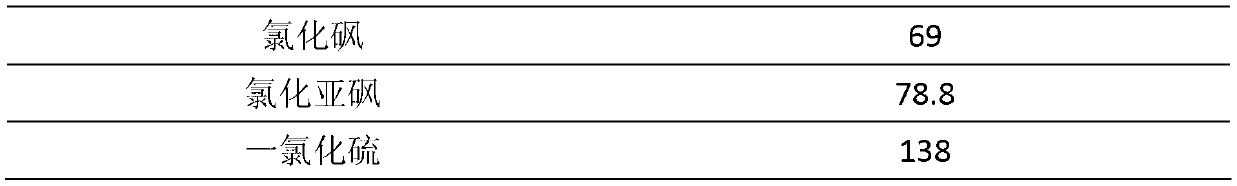

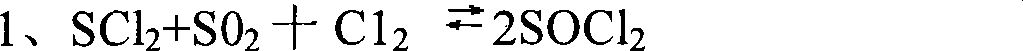

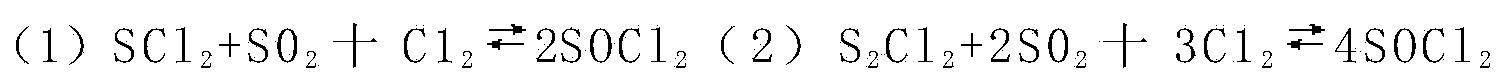

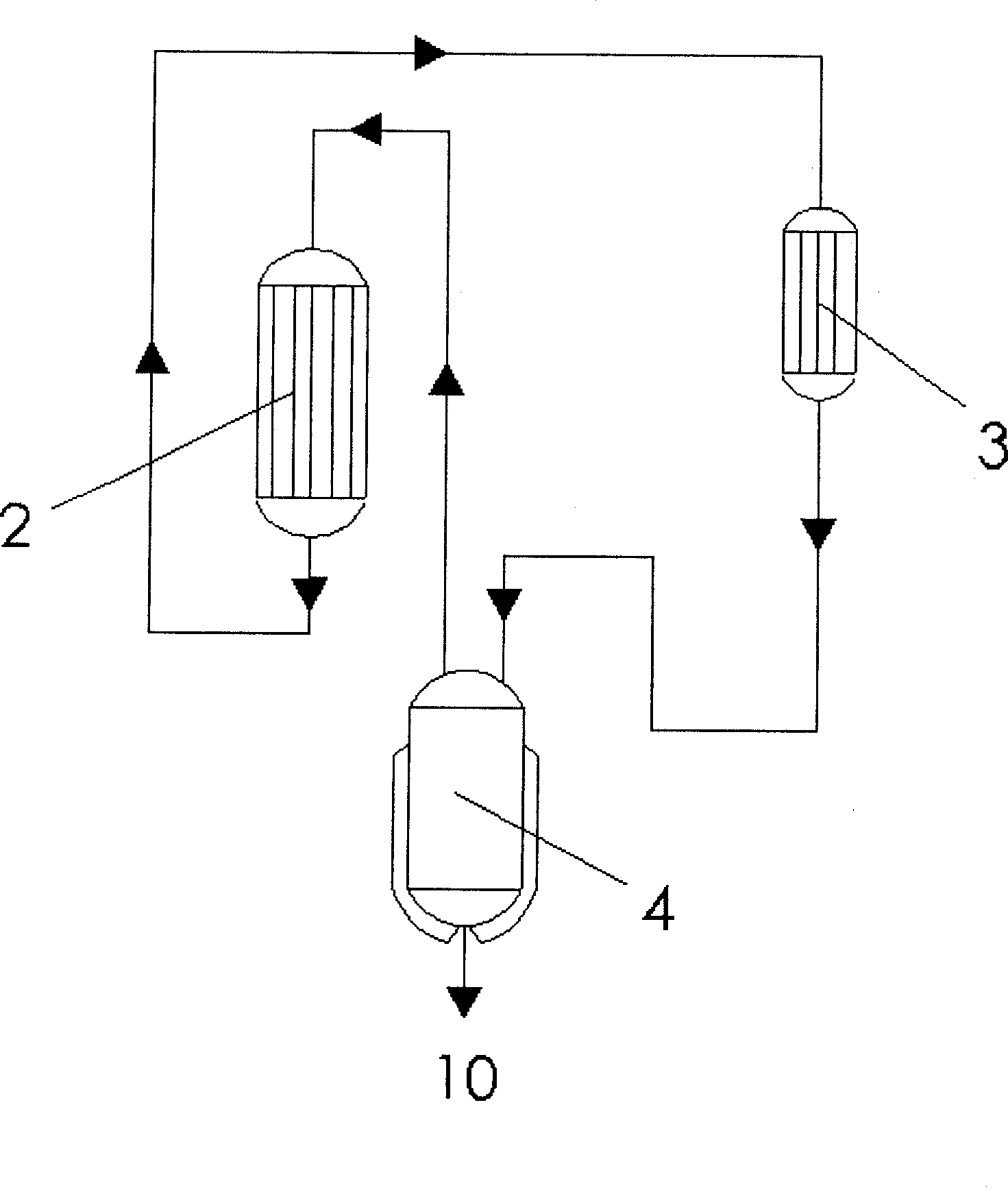

Gas phase circulation method in synthesis of thionyl chloride

ActiveCN101284653AEasy to scale up productionNo pollutionSulfur and halogen compoundsGas phaseDistillation

The invention relates to a method of gas phase in the synthesis of thionyl chloride, and particularly includes synthesizing sulfur dichloride by adding chlorine to sulfur monochloride, synthesizing crude thionyl chloride gas of light concentration by adding chlorine and sulfur dioxide, then subjecting the thionyl chloride gas to condensation, desaeration, purification, sulfuration and distillation to obtain the sulfur monochloride, and then rectifying the sulfur monochloride, thereby representing the method for all gases to enter the circulated use during the whole process.

Owner:JIANGXI SELON INDAL

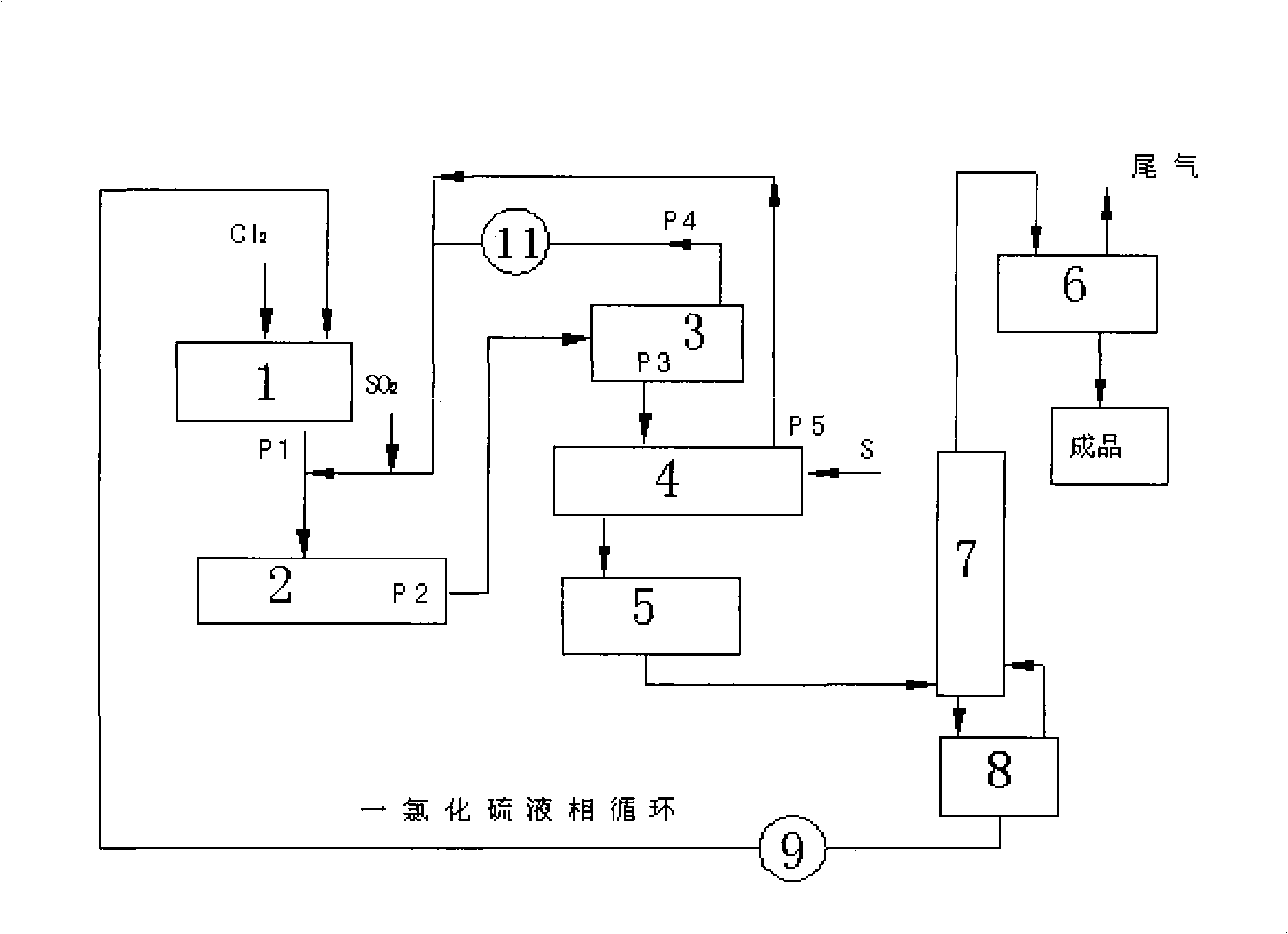

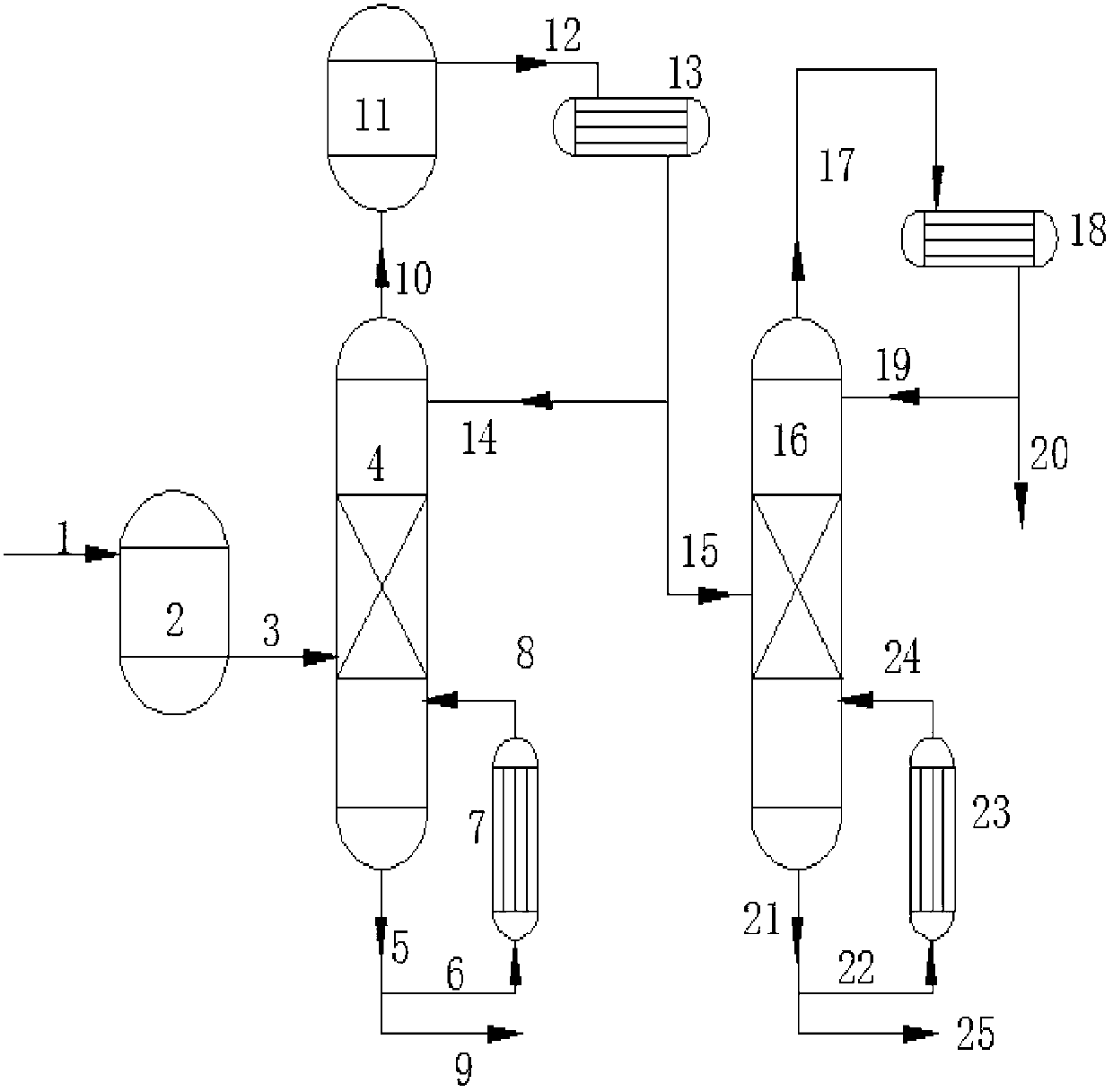

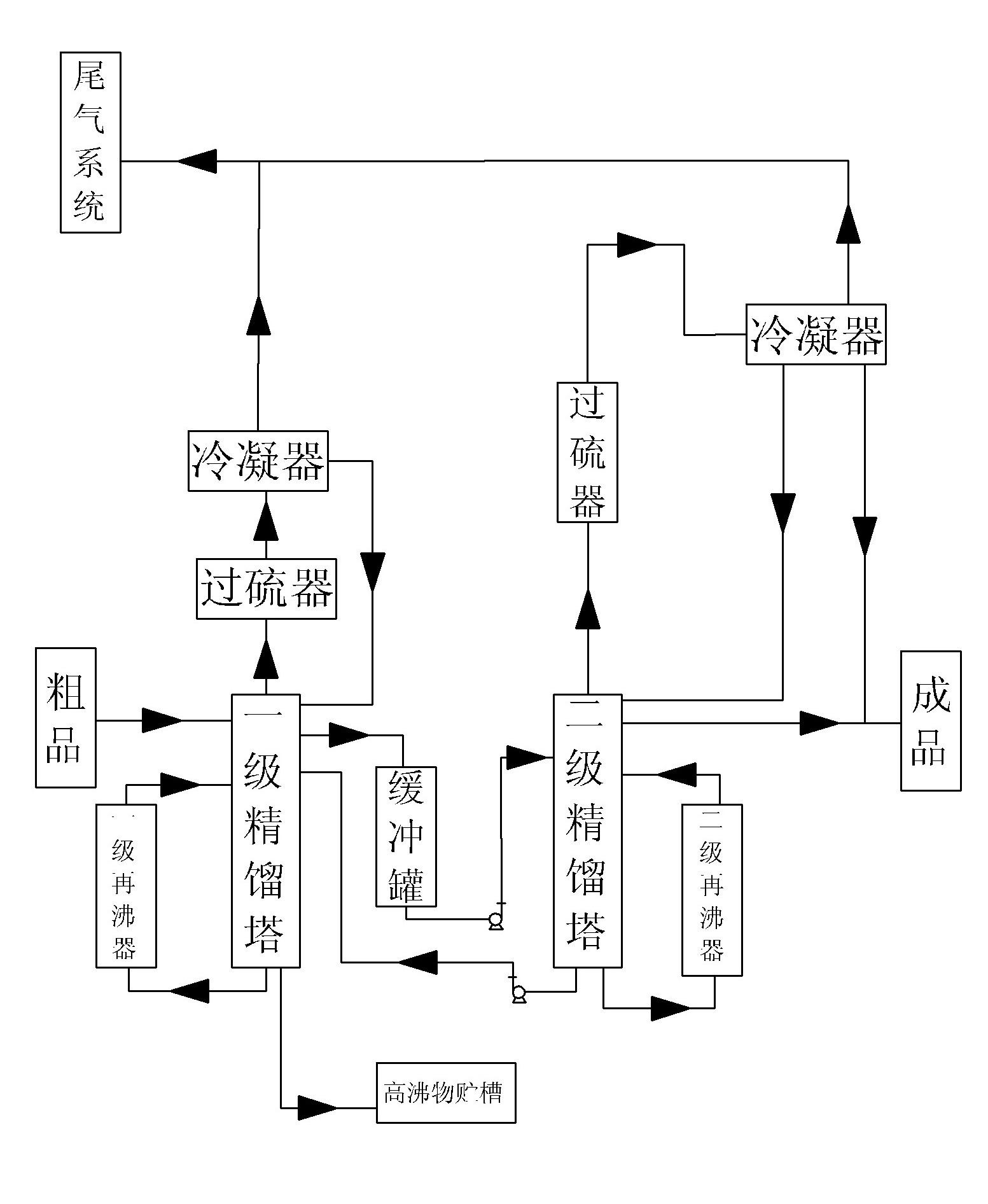

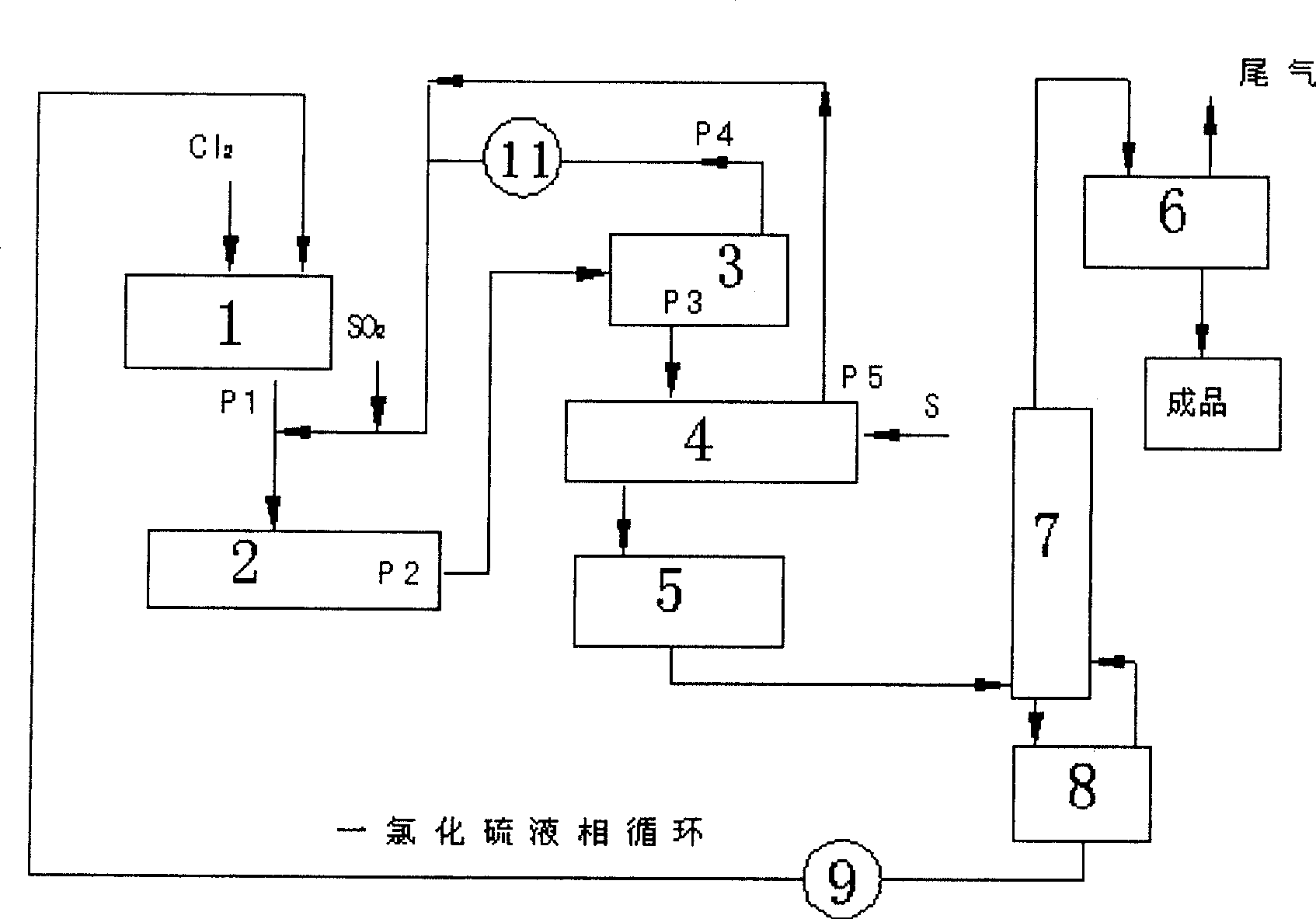

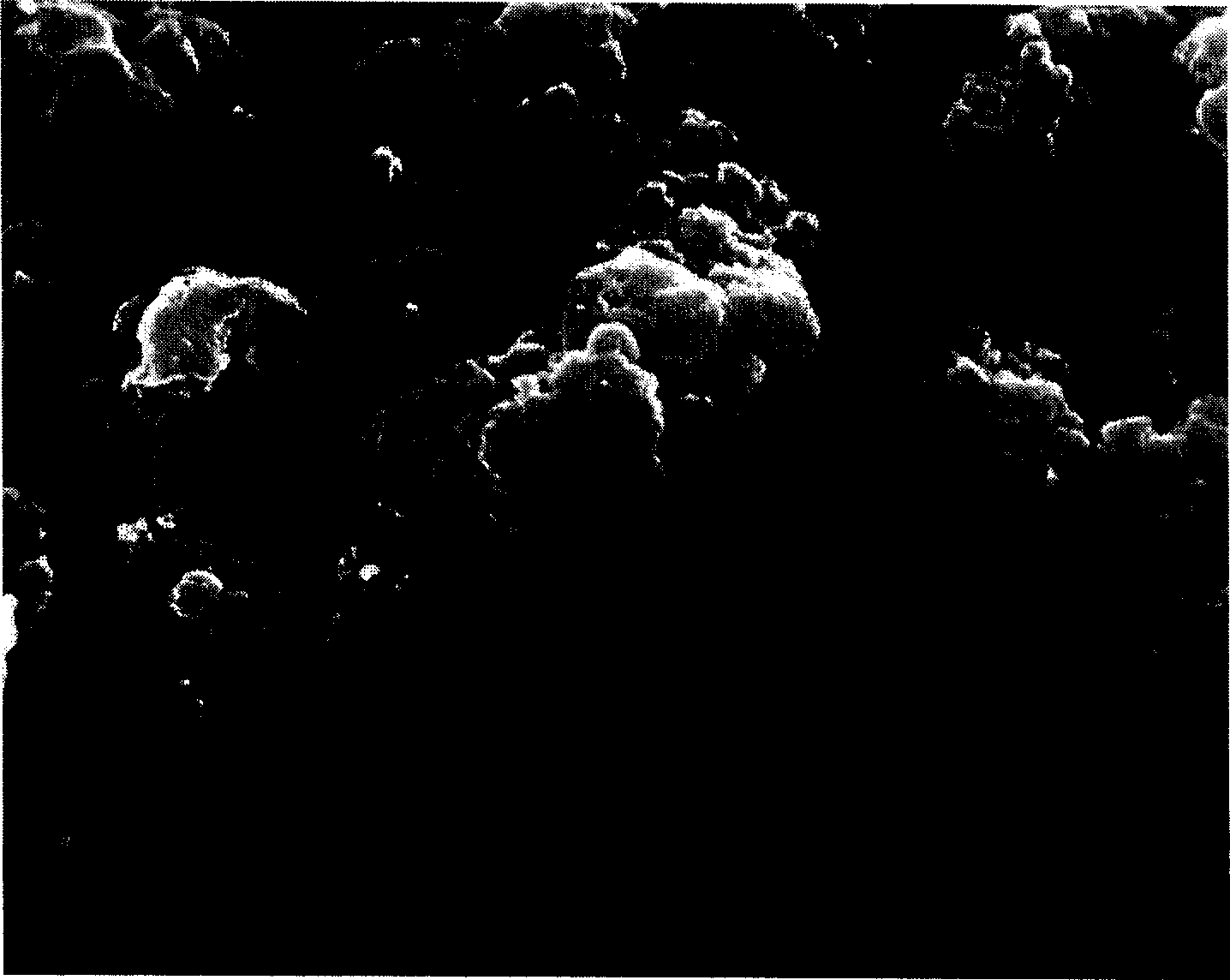

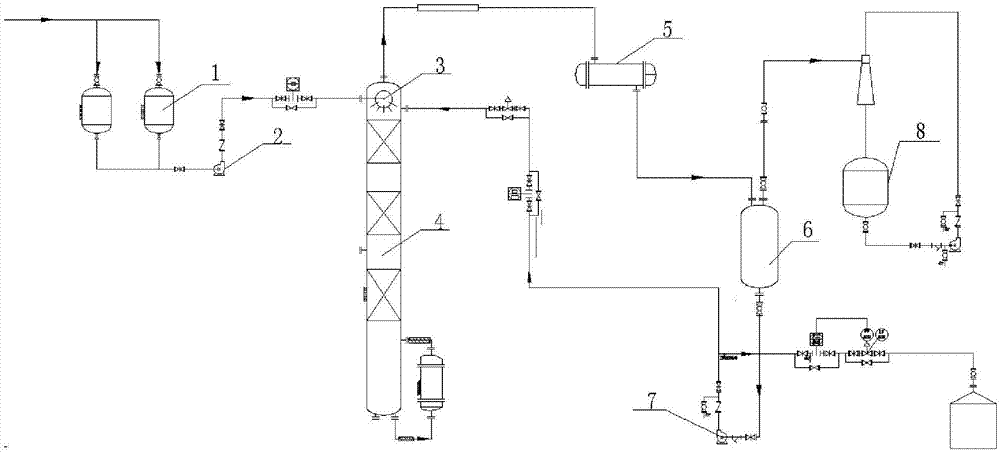

Continuous-pressure-changing rectification method and device for preparing medicine-level sulfoxide chloride

ActiveCN103130197AImprove continuityGuaranteed puritySulfur and halogen compoundsReaction rateDissolution

The invention relates to a continuous-pressure-changing rectification method and a device for preparing medicine-level sulfoxide chloride. With the adoption of the pressure-changing rectification method, an indirect sequence of carrying out heavy component removal and then carrying out light component removal is adopted as a rectification sequence, so that the decomposition of sulfoxide chloride at high temperature is reduced; sulfur is coarsely mixed with raw materials, sulfur is mixed with tower top gas of a heavy component removal tower, and a low-boiling-point substance, namely sulfur dichloride which is hard to remove, is fundamentally converted into a high-boiling-point substance, namely sulfur monochloride which is easy to remove, due to multistep sulfur adding; and a catalyst is added, so that the dissolution rate and reaction rate of the sulfur are accelerated. The heavy component removal tower is subjected to normal-pressure operation; and a light component removal tower is subjected to depressurized operation. The energy consumption of operation is reduced, and the decomposition reaction of the sulfoxide chloride hardly carries out under depressurized conditions, so that the probability that the color and luster of products are polluted by sulfur dichloride is greatly reduced, high-purity and colorless sulfoxide chloride products are produced from tower bottoms, and the content is over 99.9%.

Owner:TIANJIN UNIV

Method for synthesizing thionyl chloride with crude product thionyl chloride as raw material

ActiveCN101412503AEasy to scale up productionReduce manufacturing costSulfur and halogen compoundsCyclic processSulfur monochloride

The invention relates to a method for synthesizing thionyl chloride which takes a crude thionyl chloride product as an initial point. The method is a totally closed circulating process comprising the following steps: other materials in the synthesized crude thionyl chloride product is used to react with sulfur so as to mainly produce a sulfur monochloride product; the other materials comprises sulfur monochloride, sulfur dichloride, thionyl chloride, a small amount of chlorine and sulfur dioxide; and then the sulfur monochloride product is used to synthesize thionyl chloride together with chlorine, sulfur dichloride, and a gas product from the condenser after thionyl chloride synthesis and the crude product purification process.

Owner:JIANGXI SELON INDAL

Method for preparing trichlorideacetyl chloride from mother liquor of chloroactic acid

InactiveCN1562941ARaw materials are easy to getReduce manufacturing costOrganic compound preparationCarboxylic compound preparationBoiling pointChloride

Mother liquor is refined by distilation at temp. of 140 deg.C to remove low boiling point matters, then under the function of sulfur monochloride, pumping in chlorine gas to proceed acyl-chlorization to abtain acetic chloride mixture. After rectifications, the mixture of monoacetic chloride and diacetic chloride is obtained. The mixture is then chloridized by pumping-in chlorine gas using catalyst of pyridine and assistant catalyst active carbon. After rectification the final product trichloro-acetic chloride is obtd. The advantages are: raw material is available easily, simple process, safety, high pureness and high yield.

Owner:大庆市富杰化工有限公司

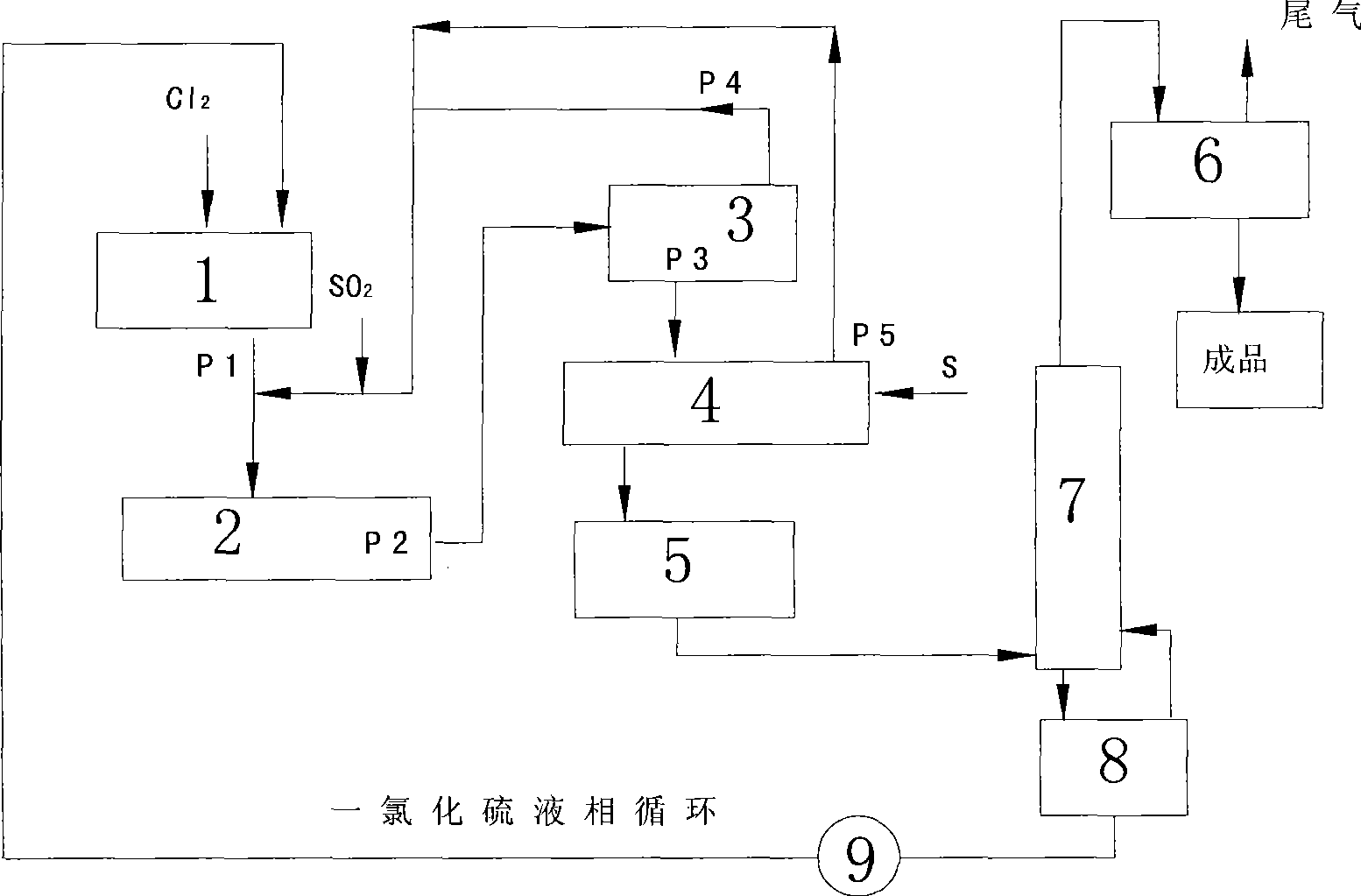

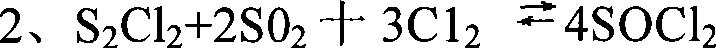

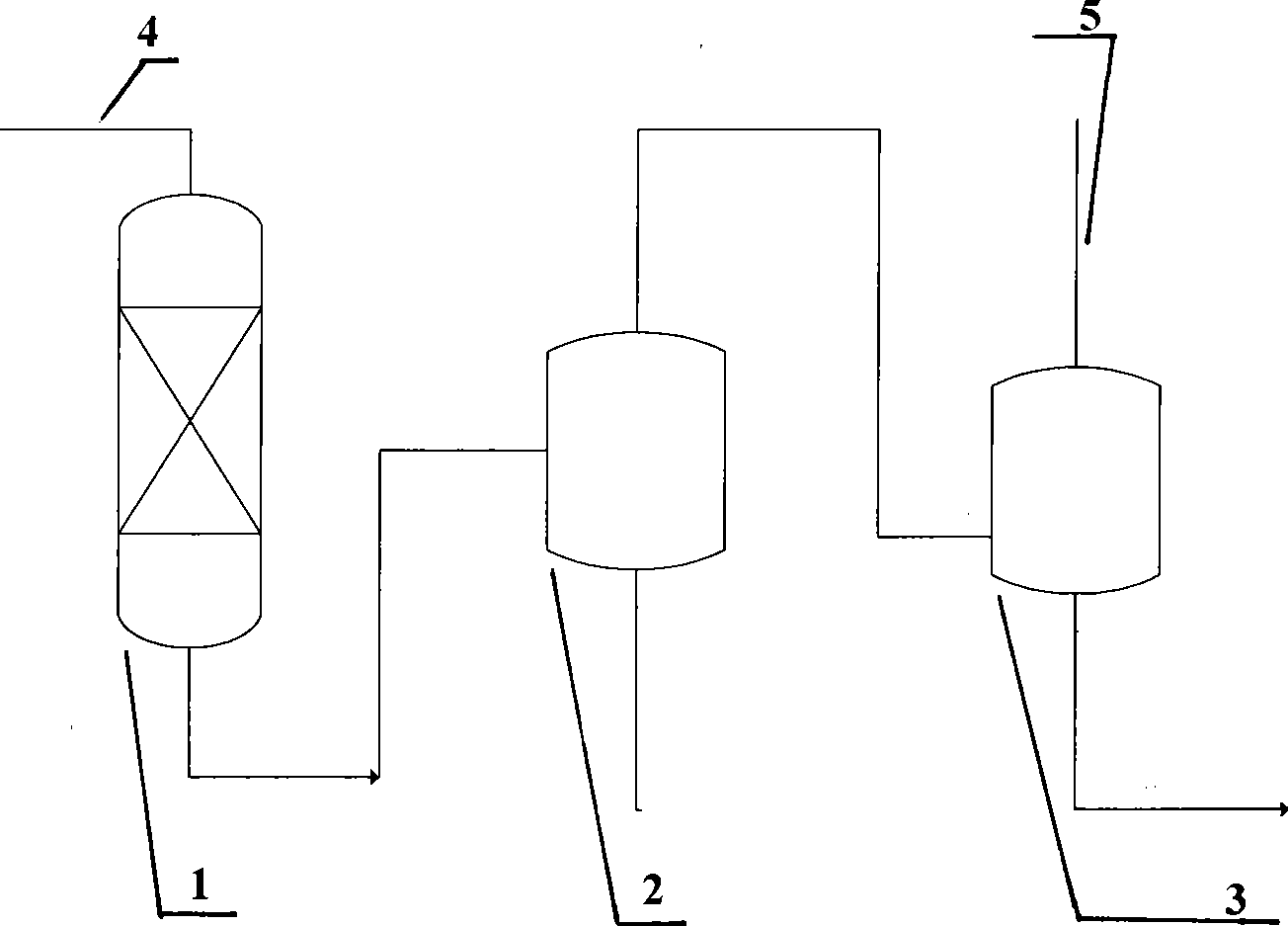

Method for rectifying thionyl chloride

InactiveCN101920938AIncrease production capacityRealize large-scale productionSulfur and halogen compoundsHigh energyEconomic benefits

The invention discloses a method for rectifying thionyl chloride. A two-stage continuous rectification process is adopted. The method comprises the following steps of: continuously feeding a crude product of the thionyl chloride into a first-stage rectification column, continuously extracting sulfur monochloride from a column bottom of the first-stage rectification column, and continuously extracting a semifinished product of the thionyl chloride from a lateral line; and continuously feeding the semifinished product of the thionyl chloride into a second-stage rectification column, continuously extracting a finished product of the thionyl chloride on a column top of the second-stage rectification column, and feeding a mixture on a column bottom into the first-stage rectification column. Overcuring devices are arranged between the first-stage rectification column and a condenser connected therewith and between the second-stage rectification column and a condenser connected therewith. The rectification method can realize continuous large-scale production, can maintain the relatively stable yield and quality of products and has high energy utilization rate, high degree of automation and easy control of operation. Compared with the conventional discontinuous rectification, the method for rectifying the thionyl chloride has the advantages of remarkable improvement of the production capability of a single device, large-scale production, guarantee of production safety, reduction of production cost, and good economic benefit.

Owner:CHINA PINGMEI SHENMA GRP KAIFENG DONGDA CHEM

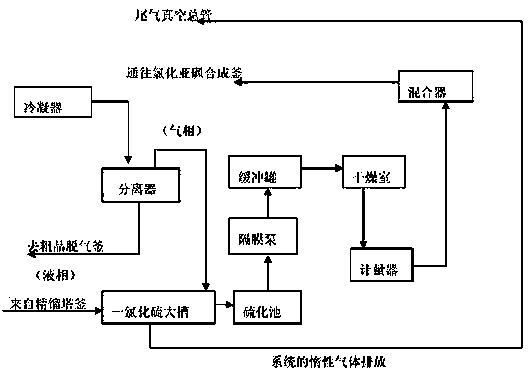

Pressure-relief discharge, absorption, treatment and recycling method in production process of thionyl chloride

ActiveCN104108686AImprove securityIncrease productivitySulfur and halogen compoundsBuffer tankSulfur monochloride

The invention relates to a pressure-relief discharge, absorption, treatment and recycling method in production process of thionyl chloride. During the synthesis process of thionyl chloride, due to the specificity of reaction process, the unbalanced reaction of single-phase gas excessive sulfoxide is inevitably generated to cause the pressure increase situations of the system. The method comprises the following steps: (1) accelerating the gas flow by properly discharging condensed non-condensable gas to a sulfur monochloride tank; (2) absorbing chlorine gas in the gas discharged into the tank by use of sulfur monochloride, and then vulcanizing to leave sulfur dioxide gas and tiny inert gas; (3) quantitatively discharging inert gas in the sulfur monochloride tank into tail gas and carrying out absorption treatment so as to prevent excessive inert gas from causing the pressure increase of the system; (4) delivering the remaining sulfur dioxide gas to a buffer tank and metering so as to flow in the system for recycling, so that the synthesis reaction can return to a steady state. By virtue of the method, the purposes of improving the safety and high-efficiency production of a synthesis device can be achieved.

Owner:JIANGXI SELON INDAL

Gas phase circulation method in synthesis of thionyl chloride

ActiveCN100480174CEasy to scale up productionNo pollutionSulfur and halogen compoundsGas phaseDistillation

The invention relates to a method of gas phase in the synthesis of thionyl chloride, and particularly includes synthesizing sulfur dichloride by adding chlorine to sulfur monochloride, synthesizing crude thionyl chloride gas of light concentration by adding chlorine and sulfur dioxide, then subjecting the thionyl chloride gas to condensation, desaeration, purification, sulfuration and distillation to obtain the sulfur monochloride, and then rectifying the sulfur monochloride, thereby representing the method for all gases to enter the circulated use during the whole process.

Owner:JIANGXI SELON INDAL

Preparation of 3-alkylthiophene

A process for preparing 3-alkylthiophenium includes such steps as addition reaction between 2-alkyl-1,3-butadiene and sulfur monochloride under action of catalyst, and high-temp condensation-ring forming reaction.

Owner:JIEXIN CHEM IND ZIBO CITY

Green synthesis technology of O,O-diethyl thiophosphoryl chloride

InactiveCN109369708AAvoid generatingReduce processing costsGroup 5/15 element organic compoundsChemical synthesisPollution

The invention provides a green synthesis technology of O,O-diethyl thiophosphoryl chloride and relates to the field of chemical synthesis. The green synthesis technology comprises the following steps:taking O,O-diethyl dithiophosphate to react with chlorine gas at low temperature, so as to obtain a crude product of the O,O-diethyl thiophosphoryl chloride; then transferring the crude product to react at high temperature; enabling the residual O,O-diethyl dithiophosphate to further completely react with the chlorine gas. Meanwhile, in a high-temperature reaction process, a polymeric compound isprevented from being generated when a compound catalyst is used and sulfur monochloride impurities are completely removed through reaction, so that a byproduct sulfur has a crystalline state and a product more easily separated and purified. Moreover, HCl and sulfur-containing odorous gas are pumped away through applying negative pressure and the tail gas is absorbed to prevent air pollution. In awhole reaction process, technological water does not need to be added, so that wastewater is not generated and the treatment cost of sulfur-containing and phosphorus-containing wastewater is reduced.The technology has the advantages of simplicity in operation, easiness for obtaining raw materials, moderate reaction conditions, small pollution and environment friendliness.

Owner:CHONGQING HUAGE BIOCHEM

Antiwear rubber sole

InactiveCN104497367AExcellent bending resistanceExcellent and cold resistanceSolesSalicylic acidCarvacryl acetate

A disclosed antiwear rubber sole is prepared from the following raw materials in parts by weight: 10-20 parts of natural rubber, 6-12 parts of styrene-butadiene rubber, 5-10 parts of sulfur monochloride, 2-8 parts of trichlorofluoromethane, 8-16 parts of white carbon black, 6-13 parts of white oil, 8-12 parts of zinc carbonate, 6-12 parts of diantimony trioxide, 5-10 parts of salicylic acid, 5-10 parts of stearic acid, 3-7 parts of sulphur, 4-8 parts of an anti-ageing agent, 7-11 parts of high styrene, 4-8 parts of magnesium oxide, 7-14 parts of ethylene-vinylacetate copolymer, 8-14 parts of magnesium oxide, 4-8 parts of nanometer zinc oxide, and 3-6 parts of solid cumarone. The provided antiwear rubber sole is excellent in wet slippery resistance, fracture resistance and cold resistance, extremely good in oil resistance, relatively good in heat resistance and strong in adhesive force.

Owner:QINGDAO LAOXIANG TEA PROD

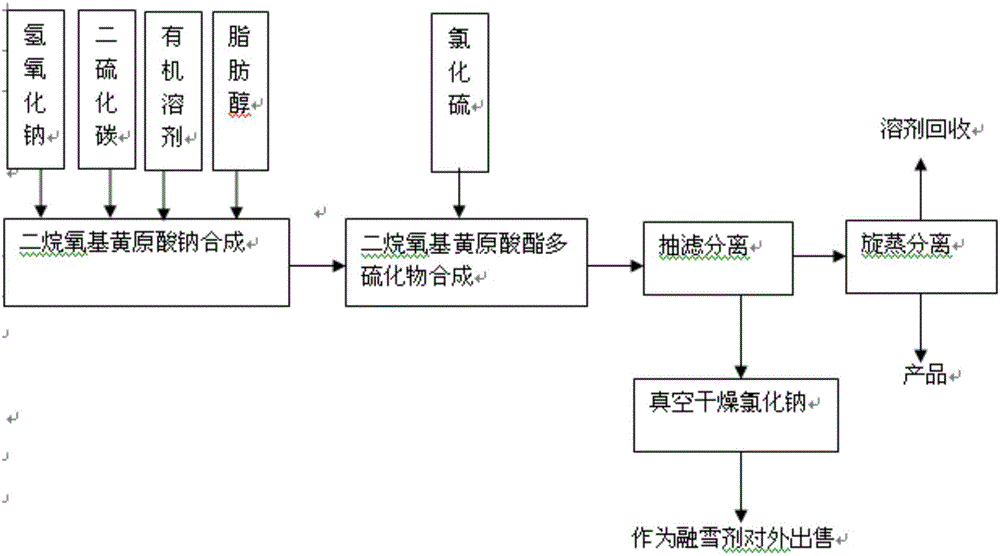

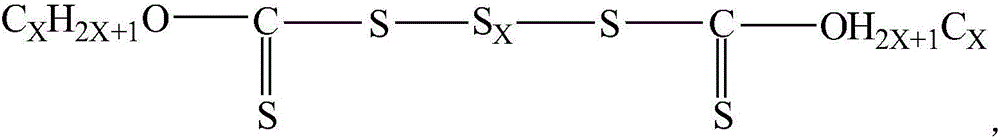

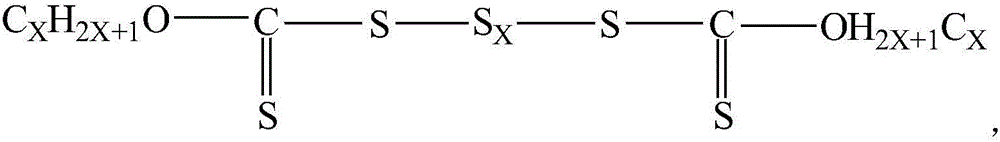

Preparation method of dialkoxyl xanthate polysulfide

Provided is a preparation method of dialkoxyl xanthate polysulfide. The preparation method comprises the steps that fatty alcohol, carbon disulfide and powdered sodium hydroxide synthesize sodium dimethyldithiocarbamate in an organic solvent, sulfur chloride (sulfur monochloride or sulfur dichloride) is dropwise added, and the dialkoxyl xanthate polysulfide is obtained through a reaction; after the reaction is completed, pumping filtration is conducted to separate out inorganic salt sodium chloride, inorganic salt sodium chloride is subjected to simple treatment to serve as a by-product for sale, liquid is subjected to rotary distillation separation to obtain the product, and the distilled organic solvent can be recycled. The preparation method is short in process, the product yield and quality are stable, and the production efficiency is high. The recovery technology of inorganic salt sodium chloride is simple, no other inorganic salt impurity is contained, the purity is high, and recycling is promoted.

Owner:SHANDONG YANGGU HUATAI CHEM

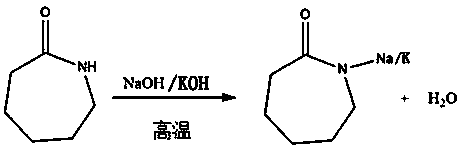

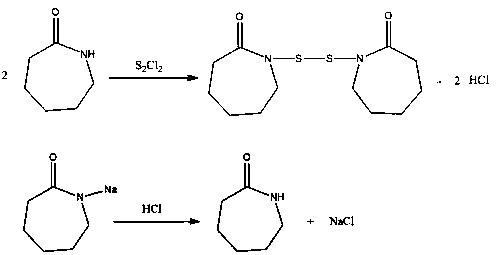

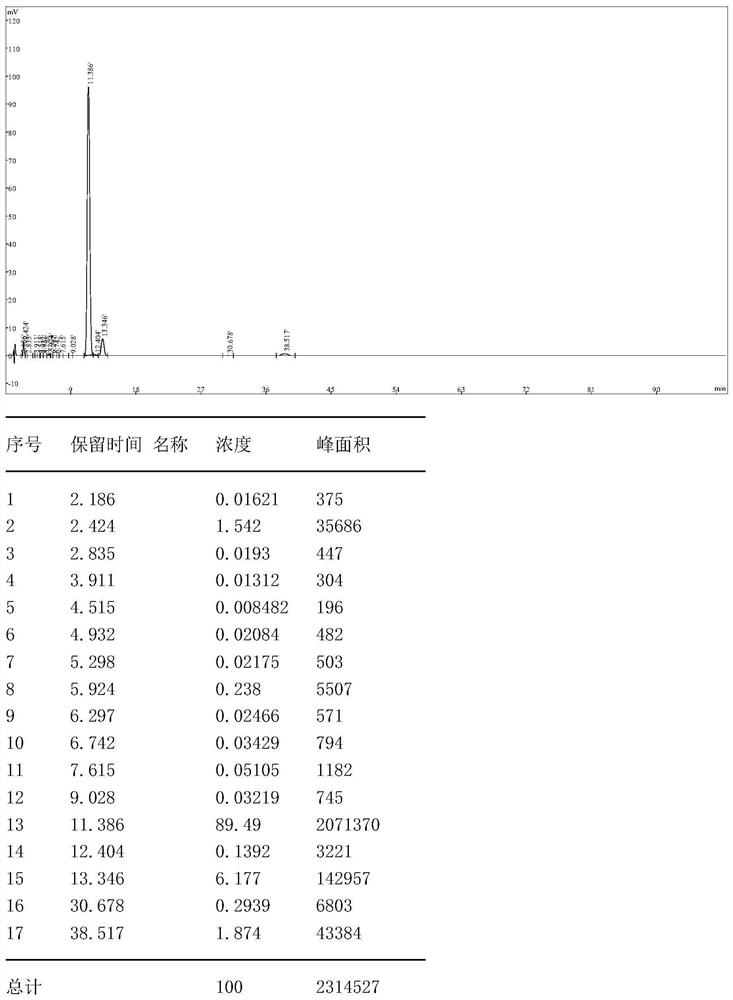

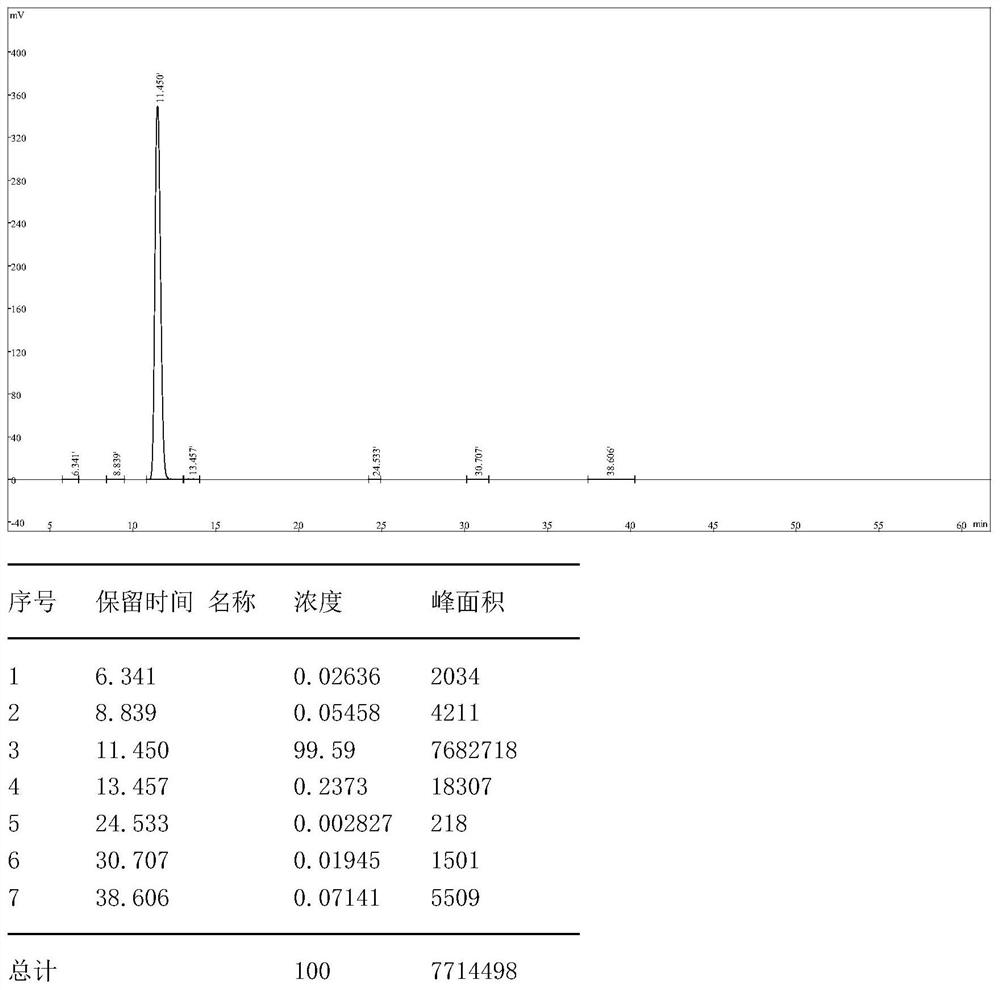

Synthetic method of 1,1'-dicaprolactam disulfide

ActiveCN110143922ASimple production processSimple post-processingOrganic chemistryInorganic saltsSulfur monochloride

The invention discloses a synthetic method of 1,1'-dicaprolactam disulfide. Caprolactam is used as an initiator, and sulfur monochloride and caprolactam inorganic salt are used as raw materials. Sulfur monochloride firstly reacts with caprolactam to form 1,1'-dicaprolactam disulfide and acid; caprolactam inorganic salt is continuously converted to caprolactam under the action of the acid formed bythe reaction; and caprolactam continuously reacts with sulfur monochloride to form 1,1'-dicaprolactam disulfide. According to the method, there is no need to add other types of acid-binding agents, and the raw material caprolactam can be synthesized by itself in the reaction process. The production technology is simple, has strong operationality and simple post-treatment, and has industrial application value. The product is white solid powder in the appearance, and the yield is 88% and above, the purity is 99% and above. The product meets the use requirements.

Owner:SHANDONG YANGGU HUATAI CHEM

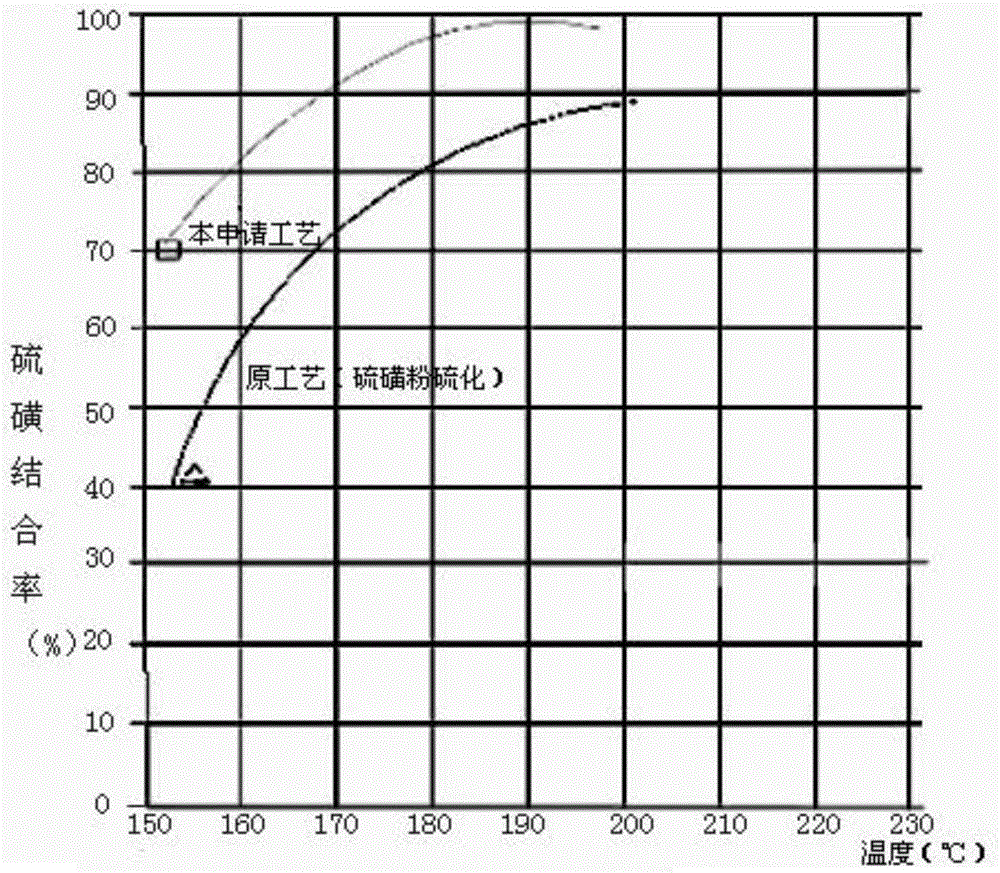

Reclaimed rubber activator sulfo synthetic method

InactiveCN104761581AReduce manufacturing costReduce dosageGroup 5/15 element organic compoundsPlastic recyclingPolymer scienceThermal insulation

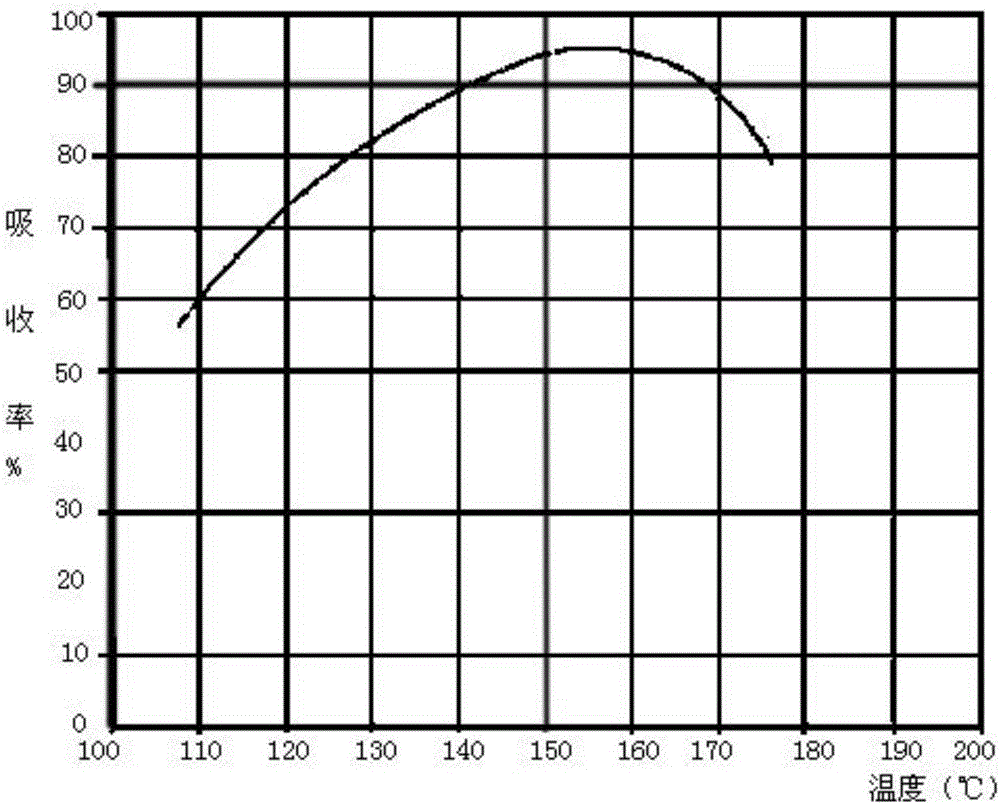

The present invention provides a reclaimed rubber activator sulfo synthetic method, and relates to reclaimed rubber additive production technical field, the reclaimed rubber activator sulfo synthetic method comprises the following steps: antioxidant mother liquor is melted, the melted antioxidant mother liquor is pumped into a reactor, each reactor is fed with 2.8 tons of the material; the antioxidant mother liquor is heated to 120 DEG C, and stirred and dewatered for 40 minutes, and the temperature is dropped to 80 DEG C; under stirring conditions, a certain quantity of sulfur monochloride is dropwise added, the temperature gradually rises to 140 to 145 DEG C for high temperature synthesis; after the material is fed, the material is stirred for 30 minutes, the reactor is heated to 120 DEG C, after 2 hours of thermal insulation, the reactor is heated to 140 DEG C, after 2 hours of thermal insulation, the material in the reactor is transferred into a finished product packaging kettle, and stirred and cooled to 85 DEG C, and the material is packed to obtain a finished product. The reclaimed rubber activator sulfo synthetic method has the advantages of simple process and easy control of the process conditions, and the synthesized reclaimed rubber activator has the characteristics of no smell, less dosage and good effect, and compared with the activator synthesized by a conventional method, the dosage can be reduced by more than 50%.

Owner:安徽金马橡胶助剂有限公司

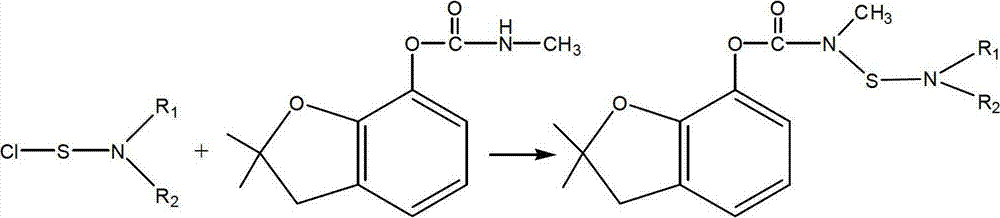

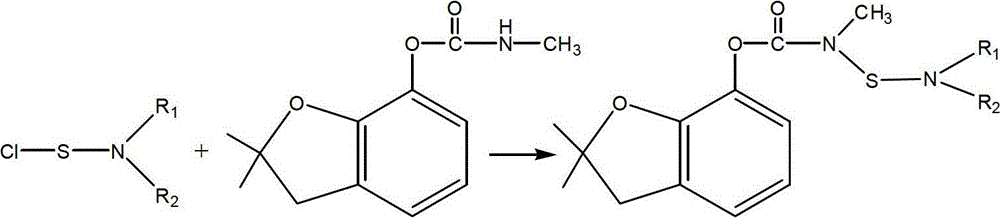

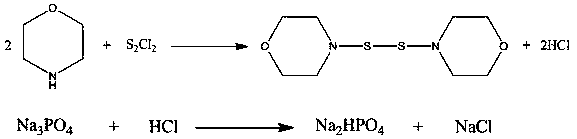

Preparation method for sulfur-containing carbofuran derivative with less than 0.1% of harmful impurity carbofuran

ActiveCN102786503ATroubleshoot incomplete responsesSolve the technical problem of high carbofuran contentOrganic chemistryCarbofuranEthane Dichloride

The invention discloses a preparation method for sulfur-containing carbofuran derivative with less than 0.1% of harmful impurity carbofuran. The preparation method comprises the following steps of: using di-n-butylamine or N-isopropyl-beta-alanine ethyl ester derivative and sulfur monochloride as raw materials to prepare into disulphide in the presence of an acid-binding agent triethylamine and an organic solvent 1, 2-dichloroethane; and then reacting with a chlorinating agent sulfuryl chloride to obtain nitrogen sulfur chlorine; and finally reacting with carbofuran under the effect of a cosolvent N-methyl-2-pyrrolidone or dimethylformamide so as to obtain the sulfur-containing carbofuran derivative with not less than 96% of quality percentage composition and less than 0.1% of main harmful impurity carbofuran. By adopting the preparation method, the problem that the carbofuran cannot be completely reacted during being reacted can be solved, the defects due to low content and low yield of sulfur-containing carbofuran derivatives such as benfuracarb and carbosulfan caused by a solid-liquid two-phase reaction can be avoided, the technical problem due to relatively high content of main harmful impurity carbofuran can be solved, and the content of the sulfur-containing carbofuran derivatives such as benfuracarb and carbosulfan can reach a value not less than 96%, and the yield is 97 to 98%, and the main harmful carbofuran in the product is less than or equal to 0.1%, so that the preparation method has a wide popularization and application prospect.

Owner:湖南海利常德农药化工有限公司

Method for continuous production of sulphur chlorination isobutene

InactiveCN101462989ASimple processReduce process stepsOrganic chemistryOrganic compound preparationSulfur monochlorideMethanol

The invention relates to a method for producing sulfur chloride isobutene continuously. Firstly, MTBE is cracked into isobutene and methanol substance under the action of acid catalyst; the reaction pressure is 0.1-1.0MPa, the temperature is 120-185 DEG C, and the feeding weight airspeed of the raw material MTBE is 1-10h<-1>; the generated isobutene is separated in a distilling tower to obtain isobutene mixture containing a little bit methanol by the separation; the operation pressure is 0.2-1.0Pa, and the reflux ratio is 0.3-3.0; the isobutene mixture enters into a sulfuration reactor to react with sulfur monochloride to generate the sulfur chloride isobutene at the temperature of 20-50 DEG C; the isobutene feeding volume airspeed is 0.5-5h<-1>; the feeding weight ratio of the isobutene and the sulfur monochloride is 1:0.8-1.2; and the technical steps are carried out continuously. The invention has simple technical process, saves the technical steps and ensures that the reaction is carried out continuously; and a product has light color, good quality and high yield.

Owner:陆晓

Preparation method for sulfur-containing carbofuran derivative with less than 0.1% of harmful impurity carbofuran

ActiveCN102786503BTroubleshoot incomplete responsesSolve the technical problem of high carbofuran contentOrganic chemistryCarbofuranEthane Dichloride

The invention discloses a preparation method for sulfur-containing carbofuran derivative with less than 0.1% of harmful impurity carbofuran. The preparation method comprises the following steps of: using di-n-butylamine or N-isopropyl-beta-alanine ethyl ester derivative and sulfur monochloride as raw materials to prepare into disulphide in the presence of an acid-binding agent triethylamine and an organic solvent 1, 2-dichloroethane; and then reacting with a chlorinating agent sulfuryl chloride to obtain nitrogen sulfur chlorine; and finally reacting with carbofuran under the effect of a cosolvent N-methyl-2-pyrrolidone or dimethylformamide so as to obtain the sulfur-containing carbofuran derivative with not less than 96% of quality percentage composition and less than 0.1% of main harmful impurity carbofuran. By adopting the preparation method, the problem that the carbofuran cannot be completely reacted during being reacted can be solved, the defects due to low content and low yield of sulfur-containing carbofuran derivatives such as benfuracarb and carbosulfan caused by a solid-liquid two-phase reaction can be avoided, the technical problem due to relatively high content of main harmful impurity carbofuran can be solved, and the content of the sulfur-containing carbofuran derivatives such as benfuracarb and carbosulfan can reach a value not less than 96%, and the yield is 97 to 98%, and the main harmful carbofuran in the product is less than or equal to 0.1%, so that the preparation method has a wide popularization and application prospect.

Owner:湖南海利常德农药化工有限公司

Process for preparing polyanilinechloride

The present invention relates to a preparation method of chloropolyaniline, and is characterized by that the polyailine and sulfur monochloride are heated and returned under the action of lewis acid catalysis in the polar aprotic solvent so as to obtain the invented chloropolyaniline. Every 6 carbon atoms of the chloropolyaniline contain 2-3 chlorine atoms, and its yield rate is up to 93-97%, it can be used as precursor raw material of positive material of lithium secondary cell.

Owner:NO 63971 TROOPS PLA

Continuous-pressure-changing rectification method and device for preparing medicine-level sulfoxide chloride

ActiveCN103130197BImprove continuityGuaranteed puritySulfur and halogen compoundsPtru catalystReaction rate

The invention relates to a continuous-pressure-changing rectification method and a device for preparing medicine-level sulfoxide chloride. With the adoption of the pressure-changing rectification method, an indirect sequence of carrying out heavy component removal and then carrying out light component removal is adopted as a rectification sequence, so that the decomposition of sulfoxide chloride at high temperature is reduced; sulfur is coarsely mixed with raw materials, sulfur is mixed with tower top gas of a heavy component removal tower, and a low-boiling-point substance, namely sulfur dichloride which is hard to remove, is fundamentally converted into a high-boiling-point substance, namely sulfur monochloride which is easy to remove, due to multistep sulfur adding; and a catalyst is added, so that the dissolution rate and reaction rate of the sulfur are accelerated. The heavy component removal tower is subjected to normal-pressure operation; and a light component removal tower is subjected to depressurized operation. The energy consumption of operation is reduced, and the decomposition reaction of the sulfoxide chloride hardly carries out under depressurized conditions, so that the probability that the color and luster of products are polluted by sulfur dichloride is greatly reduced, high-purity and colorless sulfoxide chloride products are produced from tower bottoms, and the content is over 99.9%.

Owner:TIANJIN UNIV

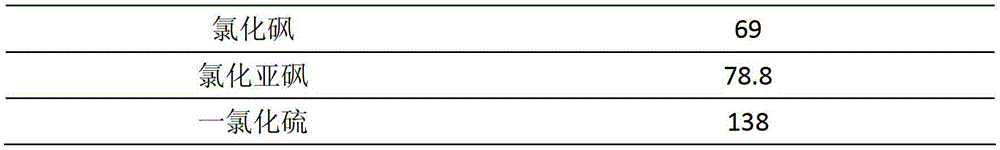

Method for synthesizing 4,4'-dithiodimorpholine

The invention discloses a method for synthesizing 4,4'-dithiodimorpholine. Sulfur monochloride and morpholine are used as raw materials, anhydrous trisodium phosphate is used as an acid binding agent,the sulfur monochloride and morpholine are reacted to produce 4,4'-dithiodimorpholine and hydrochloric acid, and the anhydrous trisodium phosphate can react with the hydrochloric acid generated in the reaction to avoid the hydrochloric acid with from reacting morpholine and the morpholine from losing the reactivity. The acid binding agent anhydrous trisodium phosphate is added in the method of the invention, so the dosage of the raw material morpholine is reduced, and the production cost is saved; and the product and impurities can be separated by washing with water after the reaction is finished, so the method has the advantages of simple production, high operability, simplicity in post-treatment and industrial application values. The appearance of the obtained product is a white needlecrystal, the yield is 90% or above, the purity is 98% or above, and use requirements are met.

Owner:SHANDONG YANGGU HUATAI CHEM +1

Rubber material filled with kaolinite

A rubber material filled with kaolinite comprises the following raw materials in parts by weight: 4-9 parts of zinc oxide, 3-5 parts of sulfur monochloride, 4-7 parts of an antiager RD, 10-18 parts of nitrile rubber, 15-22 parts of isoprene rubber, 4-6 parts of wood fibers, 1-4 parts of ammonium phosphate, 1-3 parts of sulfur, 6-11 parts of simethicone, 4-7 parts of calcium carbonate, 1-5 parts graphite powder, 7-11 parts of spraying carbon black, 6-8 parts of magnesium oxide, 1-3 parts of a dispersing agent, 7-10 parts of epoxy octyl stearate, and 15-20 parts of kaolinite. The rubber material has the benefits that kaolinite is used as a filler, so that the strength and the toughness of rubber are well improved, and the rubber material is good in corrosion resistance.

Owner:QINGDAO QIYUAN ZHENDONG ELECTRIC

Synthesis method of bis(di-n-butylamine) disulfide

ActiveCN111138330AReduce heat release rateAvoid the defects of severe exothermic reactionOrganic chemistryCombinatorial chemistrySulfur monochloride

The invention discloses a synthesis method of bis(di-n-butylamine) disulfide. The synthesis method comprises the following steps: (1) respectively introducing an organic solution of di-n-butylamine and an organic solution of sulfur monochloride into a first reactor containing a reaction channel, mixing to initiate a reaction, and carrying out a partial reaction in the reaction channel of the firstreactor to obtain a reaction mixed solution; and (2) continuously introducing the reaction mixed solution into a second reactor containing a reaction channel, introducing a sodium hydroxide solutioninto the second reactor, and fully reacting to obtain bis(di-n-butylamine) disulfide. The continuous synthesis method improves the yield of bis(di-n-butylamine) disulfide, reduces the generation of byproducts, reduces the feeding amount of sulfur monochloride and sodium hydroxide, can greatly slow down the reaction heat release speed, and has the advantages of simple process flow, high productionefficiency, low cost, high safety and the like.

Owner:湖南海利常德农药化工有限公司

Preparation method of carbofuran derivatives

The invention discloses a preparation method of carbofuran derivatives. The preparation method of the carbofuran derivatives comprises the following steps: (1) taking amine derivatives and sulfur monochloride as raw materials, adding a first acid-binding agent and a reaction solvent and performing sulfuration reaction to obtain a first intermediate disulfide, wherein the first acid-binding agent is triethylamine and the reaction solvent is chloroform or dichloromethane; (2) performing chlorination reaction on the first intermediate disulfide and chlorine which serve as raw materials to obtain a second intermediate nitrogen and sulfur chloride; (3) taking the second intermediate nitrogen and sulfur chloride and carbofuran as raw materials, adding a second acid-binding agent and performing condensation reaction to obtain the carbofuran derivatives. The preparation method has the advantages that the process is simple, and the product is low in toxicity, high in purity and high in yield.

Owner:湖南海利常德农药化工有限公司

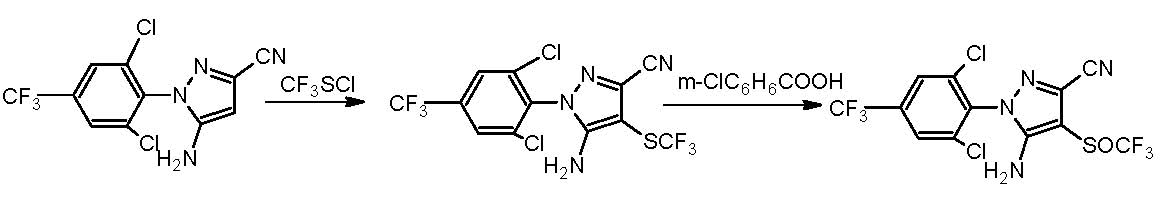

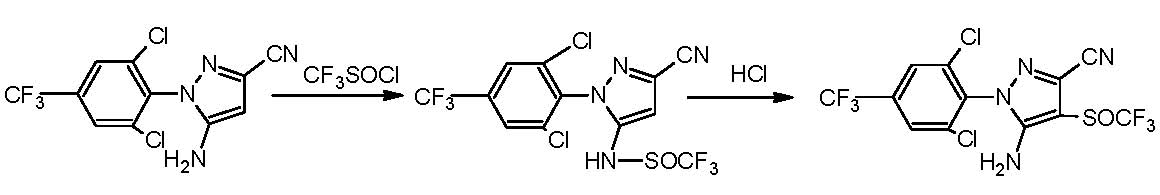

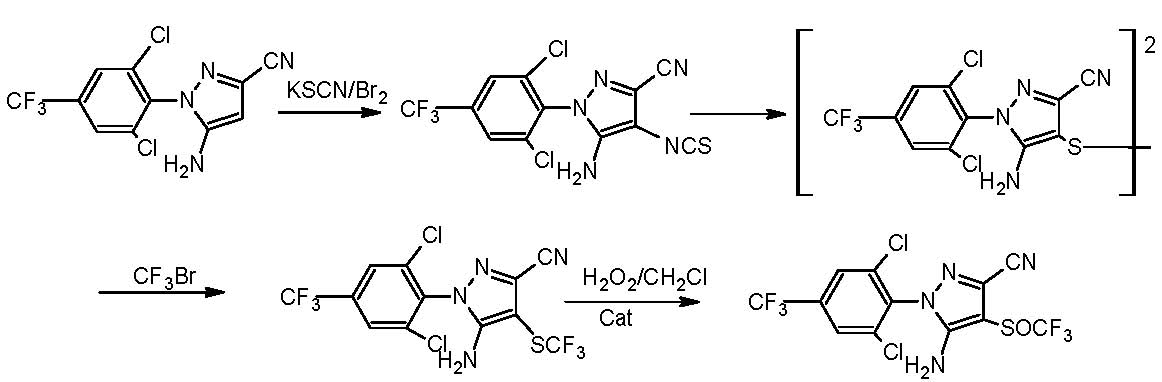

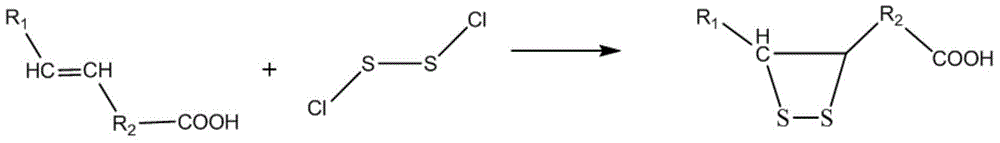

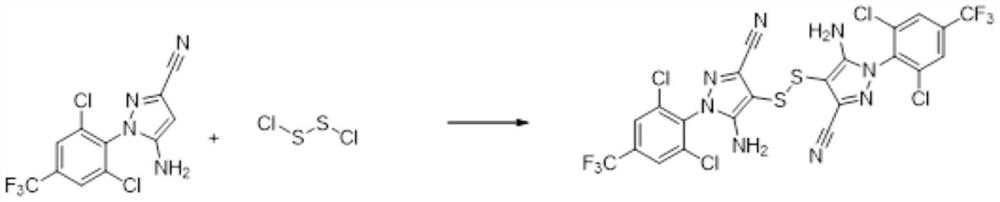

Synthesizing method for fipronil intermediates

The invention relates to a synthesizing method for fipronil intermediates. The synthesizing method for the fipronil intermediates effectively solves problems of low production yield in preparation of the fipronil intermediates, complicated operation, low purity and difficulty in industrialized production. The method includes steps of adding 5-amino-3-cyano-1-(2, 6-dichloro-4-trifluoromethyl phenyl) pyrazole into a polar solvent at first and blending the 5-amino-3-cyano-1-(2,6-dichloro-4-trifluoromethyl phenyl) pyrazole evenly, heating the 5-amino-3-cyano-1-(2,6-dichloro-4-trifluoromethyl phenyl) pyrazole to 30-70 DEG C under 0.3-0.6 atmosphere, distilling one sixth of the polar solvent, and then cooling the 5-amino-3-cyano-1-(2, 6-dichloro-4-trifluoromethyl phenyl) pyrazole to 20 DEG C, quickly adding sulfur monochloride to react for half an hour under the conditions of 35-40 DEG C and negative pressure of -0.095--0.01MPa, obtaining a mixture which is standing for half an hour under the conditions of 35-50 DEG C and one atmosphere so as to remove hydrogen chloride, adding an amine regulator to regulate a PH value as 7, cooling the mixture to < / =5 DEG C, filtering to obtain a filtered object which is washed by water, and drying to obtain 5-amino-1-(2,6-dichloro-4-trifluoromethyl phenyl)-3-cyano pyrazole-4-base double sulfur. The synthesizing method for the fipronil intermediates is prepared by simple process and operated under mild reaction conditions, high in production yield and purity, low in production cost, easy to produce in an industrialized manner and capable of serving as the intermediate to effectively prepare fipronil.

Owner:HENAN UNIV OF CHINESE MEDICINE

Insulating resin having good electromagnetic shielding effect

InactiveCN107501939ALow costImprove electromagnetic shielding performanceMagnetic/electric field screeningGlass fiberChlorobenzene

The invention discloses an insulating resin having a good electromagnetic shielding effect. The insulating resin consists of the following components in parts by weight: 8 parts of polysiloxane, 0.5 part of sulfur monochloride, 4 parts of chlorosulfonic acid, 7 parts of diphenol propane, 3 parts of aluminium trichloride, 6 parts of chlorobenzene, 2 parts of polyamide-imide, 1 part of tributyl citrate, 1 part of glass fibers, 43 parts of an anhydride curing agent and 1 part of a latent accelerator. The insulating resin provided by the invention has low costs, has a good electromagnetic shielding effect and good properties.

Owner:吴丹

Synthetic process for sulfurized calcium alkyl phenolate clearing agent

InactiveCN106367160ASolve the unsafe problem of high temperature spontaneous combustionMeet industry requirementsAdditivesSpontaneous combustionHydrogen sulfide poisoning

The invention provides a synthetic process for a sulfurized calcium alkyl phenolate clearing agent. The synthetic process comprises the following steps: adding dodecylphenol into a three-neck bottle with a stirring function, mounting a condenser tube and an absorption bottle and adding sulfur monochloride into the three-neck bottle for sulfuration so as to obtain sulfurized alkyl phenate; pouring sulfurized alkyl phenate into a neutralization kettle, adding base oil and an aqueous solution of calcium chloride and adding calcium oxide for a neutralization reaction; after completion of neutralization, adding the solvent glycol, stearic acid and calcium oxide, introducing CO2 and carrying out carbonation once; after completion of carbonation, adding calcium oxide into the neutralization kettle, introducing CO2 and continuing carbonation twice to three times; and carrying out pressure-reduced distillation and filtering so as to obtain the product sulfurized calcium alkyl phenolate. The synthetic process has the advantages that the process is simple and rational, can prevent the unsafe factor of spontaneous combustion of sulfur dust at high temperature and the accident of hydrogen sulfide poisoning caused by leakage of hydrogen sulfide, overcomes the problem of emission of exhaust gas and waste water in the process of sulfuration of alkylphenol, and enables by-products to be recycled.

Owner:朝阳中联化工有限公司

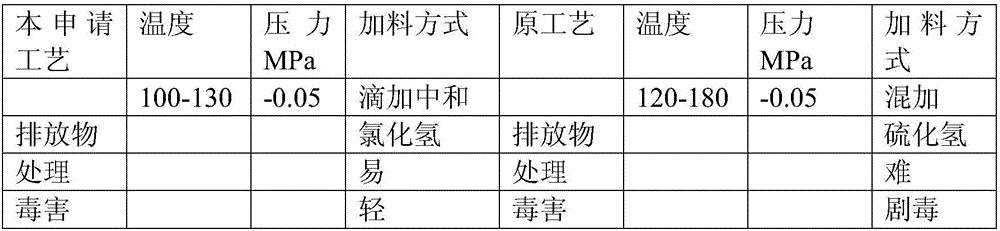

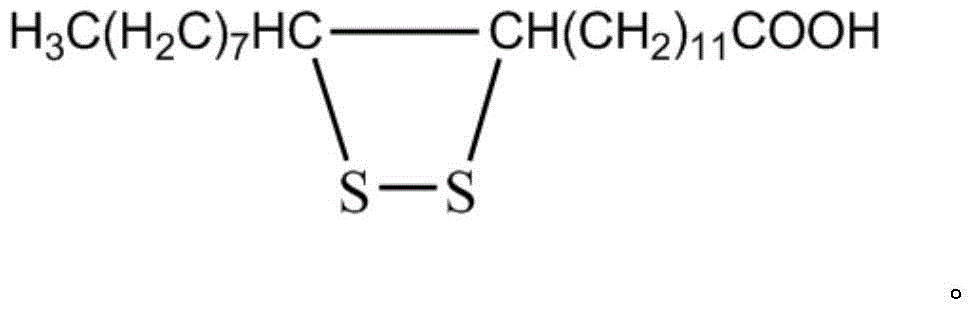

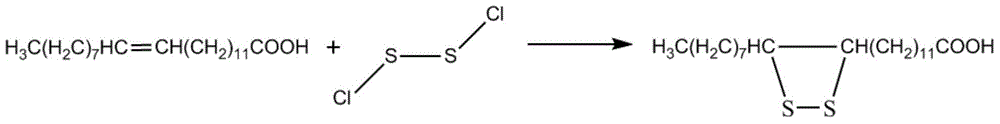

Sulfurized erucic acid as well as preparation method and application thereof

InactiveCN104016965AOvercome dark colorOvercoming the flaws of poor performanceOrganic chemistryAdditivesSolubilityChemical structure

The invention provides sulfurized erucic acid as well as a preparation method and application thereof. Sulfurized erucic acid has a chemical structure formula as shown in the specification and is prepared by performing low-temperature sulfurization reaction on sulfur monochloride and erucic acid in the presence of protection gas. Sulfurized erucic acid provided by the invention is light in color and excellent in anti-wear and anti-friction performances, and has excellent oil solubility in whether protection synthetic oil of base oil I or protection synthetic oil of base oil II or above.

Owner:东昊石油集团有限公司

Preparation method of 5-amino-3-cyano-1-(2,6-dichloro-4-trifluoromethylphenyl) pyrazole disulfide

The invention discloses a preparation method of 5-amino-3-cyano-1-(2, 6-dichloro-4-trifluoromethylphenyl)pyrazole disulphide, and belongs to the technical field of medicines. The preparation method comprises the steps of dissolving 5-amino-3-cyano-1-(2,6-dichloro-4-trifluoromethylphenyl)pyrazole in a mixed solvent, reducing the temperature, dropwise adding sulfur monochloride, increasing the temperature, conducting heat preservation for a halogenation reaction in a mixed solvent to generate 5-amino-3-cyano-1-(2,6-dichloro-4-trifluoromethylphenyl)pyrazole disulfide; conducting first separation and purificationon the reaction liquid of the halogenation reaction, recycling the mixed solvent, and leaving a residue; performing secondary separation and purification on the residue to obtain a crude product; and subjecting the crude product to third separation and purification to obtain a 5-amino-3-cyano-1-(2, 6-dichloro-4-trifluoromethylphenyl)pyrazole disulfide refined product. Operation is simplified, the generation efficiency is improved, the adverse effect of the characteristics of high polarity and easy water absorption of acetonitrile on the reaction is avoided, and the operation difficulty is reduced.

Owner:台州达辰药业有限公司

Preparation method of dicaprolactam disulfide

ActiveCN110156691AEasy to operateShorten the timeOrganic chemistryReaction temperatureProcess safety

The invention discloses a preparation method of dicaprolactam disulfide. The method comprises adding sulfur monochloride only one time at a low temperature, and then raising the temperature to a reaction temperature according to a heating rate of 1-3 DEG C / min to carry out a reaction to obtain dicaprolactam disulfide. The method replaces slow dropping by directly inputting sulfur monochloride, shortens the time required for the synthesis process, and at the same time makes the operation of operators be relatively simple; and the pollution is small, the energy is saved and the environment is protected, the production cost is reduced, the process safety hidden dangers are reduced, and the product yield is high, so that the method adapts to national green chemical policy requirements.

Owner:SHANDONG YANGGU HUATAI CHEM

Method for optimizing production process of thionyl chloride

ActiveCN107954400AImprove disposal capacityReduce usageThionyl chlorideFractionating columnSulfur monochloride

The invention relates to a method for optimizing a production process of thionyl chloride and belongs to the technical field of chemical engineering. Liquid sulfur in a liquid sulfur tank is metered by a metering pump and then pumped into an atomizing device in a distillation column; a crude thionyl chloride product is mixed with the liquid sulfur at the top of the distillation column; sulfur dichloride in the crude thionyl chloride product and the liquid sulfur are subjected to a reaction, a heavy component, namely, sulfur monochloride, is produced and withdrawn from the bottom of the distillation column, remaining crude thionyl chloride product is condensed by a condenser and enters a return tank, a part of liquid phase in the return tank is pumped into the distillation column by a reflux pump to be recycled, and the remaining liquid-phase material is recovered from the return tank. By means of the method, automatic sulfur addition is realized, time and labor cost are saved, and thedecoloration effect is better.

Owner:SHANDONG KAISHENG NEW MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com