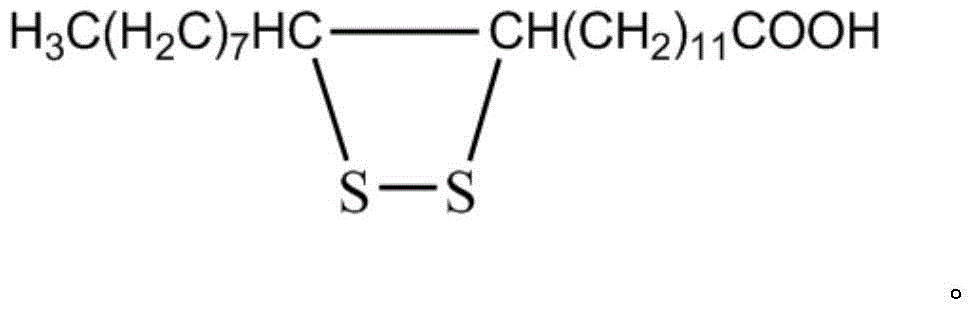

Sulfurized erucic acid as well as preparation method and application thereof

A technology of sulfurizing erucic acid and erucic acid, which is applied in organic chemistry, petroleum industry, additives, etc., can solve the problems of poor oil solubility, dark color, limited use field, etc., and achieve excellent anti-wear and anti-friction performance and light color. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

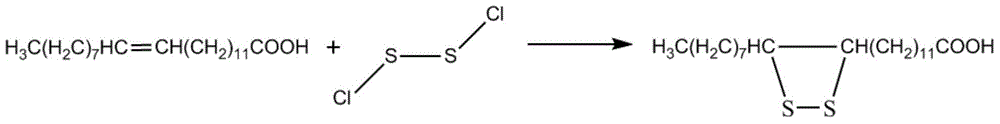

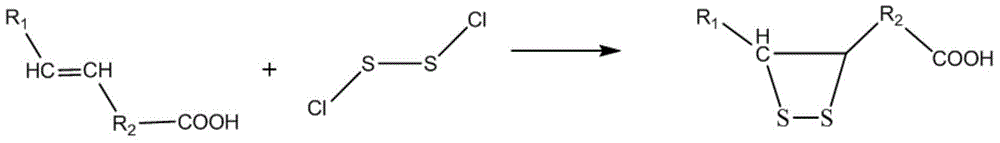

Method used

Image

Examples

Embodiment 1

[0035] In the first embodiment, the molar ratio of erucic acid: sulfur monochloride is 1:0.9.

[0036] Specific steps are as follows:

[0037] Step 1. Weigh erucic acid, pour it into a flask, and place the flask in a constant temperature water bath (the temperature is controlled at 15±1°C);

[0038] Step 2. Add sulfur monochloride dropwise through the separatory funnel, stir at 600 r / min, carry out low-temperature vulcanization, and react until there are no more bubbles at the catheter port where the sodium hydroxide solution (mass percentage concentration is 20%) is introduced. After generating, stop the reaction after reacting for 15 minutes;

[0039] Step 3, the product is fully washed with 5% sodium hydroxide solution, and the water layer is removed after standing for liquid separation;

[0040] Step 4, wash twice with distilled water;

[0041] Step 5, decompression distillation to obtain light yellow sulfurized erucic acid product 1#.

Embodiment 2

[0043] In the second embodiment, the molar ratio of erucic acid: sulfur monochloride is 1:1.

[0044] Specific steps are as follows:

[0045] Step 1. Weigh erucic acid, pour it into a flask, and place the flask in a constant temperature water bath (the temperature is controlled at 20±1°C);

[0046] Step 2. Add sulfur monochloride drop by drop through the separatory funnel, stir at 650 rpm, carry out low-temperature vulcanization, and react until there are no more bubbles at the conduit port where the sodium hydroxide solution (mass percentage concentration is 15%) is introduced. After generating, stop the reaction after reacting for 15 minutes;

[0047] Step 3, the product is fully washed with 10% sodium hydroxide solution, and the water layer is removed after standing for liquid separation;

[0048] Step 4, wash twice with distilled water;

[0049] Step 5, decompression distillation to obtain light yellow sulfurized erucic acid product 2#.

Embodiment 3

[0051] In Example 3, the molar ratio of erucic acid: sulfur monochloride is 1:2.

[0052] Specific steps are as follows:

[0053] Step 1. Weigh erucic acid, pour it into a flask, and place the flask in a constant temperature water bath (the temperature is controlled at 25±1°C);

[0054] Step 2: Add sulfur monochloride drop by drop through the separatory funnel, stir at 600 rpm, carry out low-temperature vulcanization, and react until there are no more bubbles at the conduit port where the sodium hydroxide solution (mass percentage concentration is 15%) is introduced After generating, stop the reaction after reacting for 15 minutes;

[0055] Step 3, the product is fully washed with 5% sodium hydroxide solution, and the water layer is removed after standing for liquid separation;

[0056] Step 4, wash twice with distilled water;

[0057] Step five, depressurization distillation obtains light yellow sulfurized erucic acid product 3#.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com