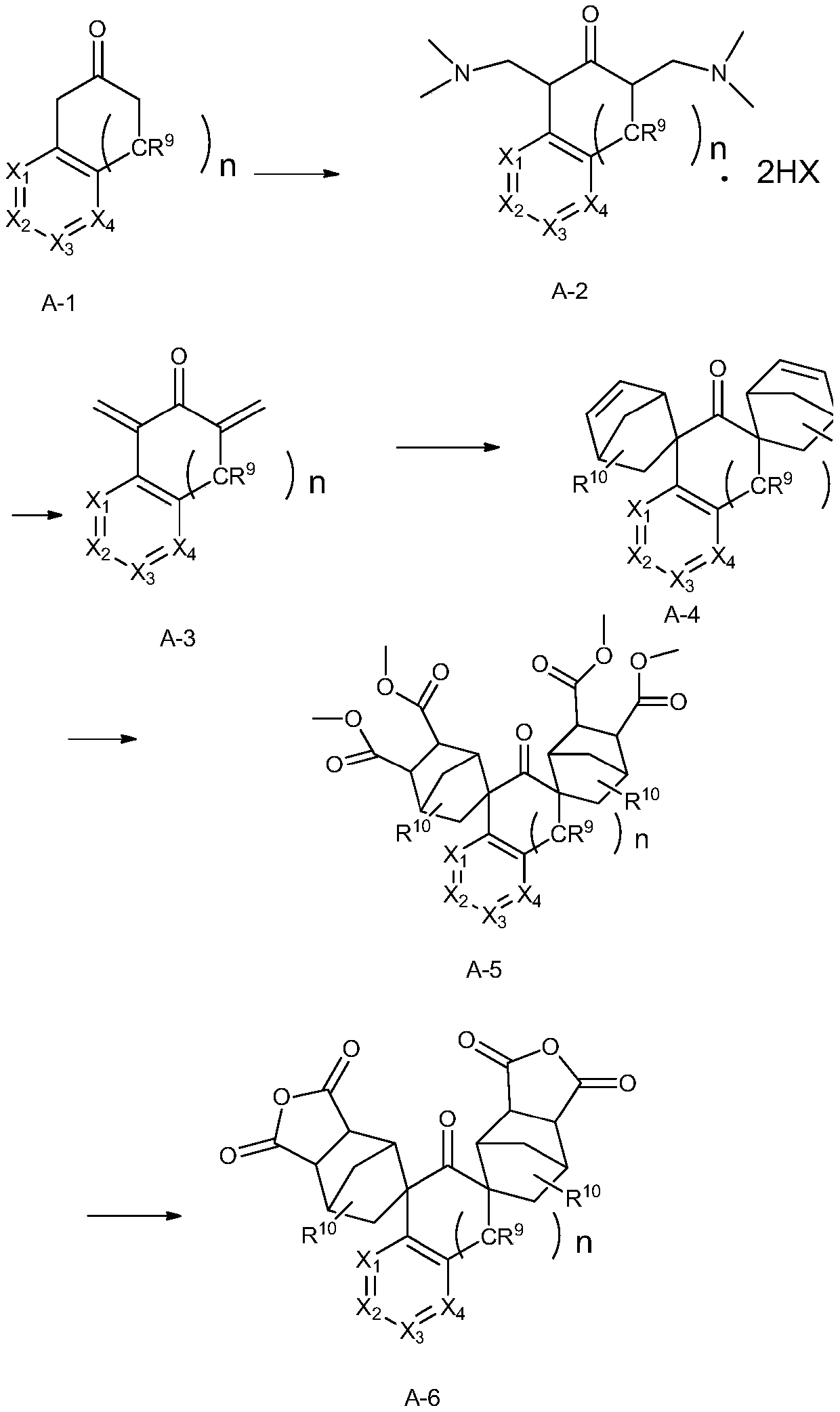

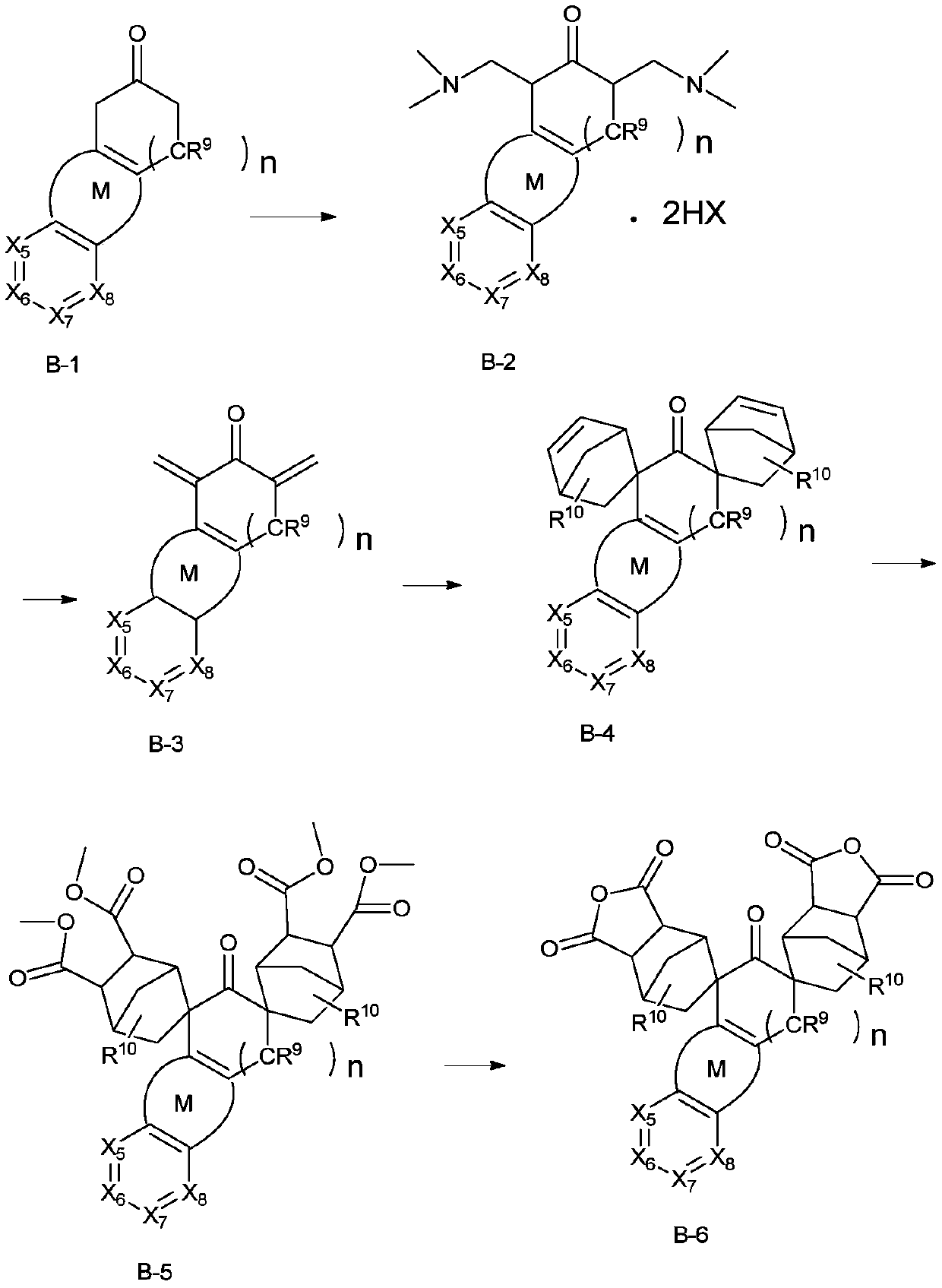

Diacid anhydride compound, and preparation method and application thereof

A technology of compound and dianhydride, which is applied in the field of dianhydride compound and its preparation, can solve the problems of poor light transmittance, limit the development of PI film, affect the light transmittance of PI film, etc., achieve good optical properties and overcome the effect of deep color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

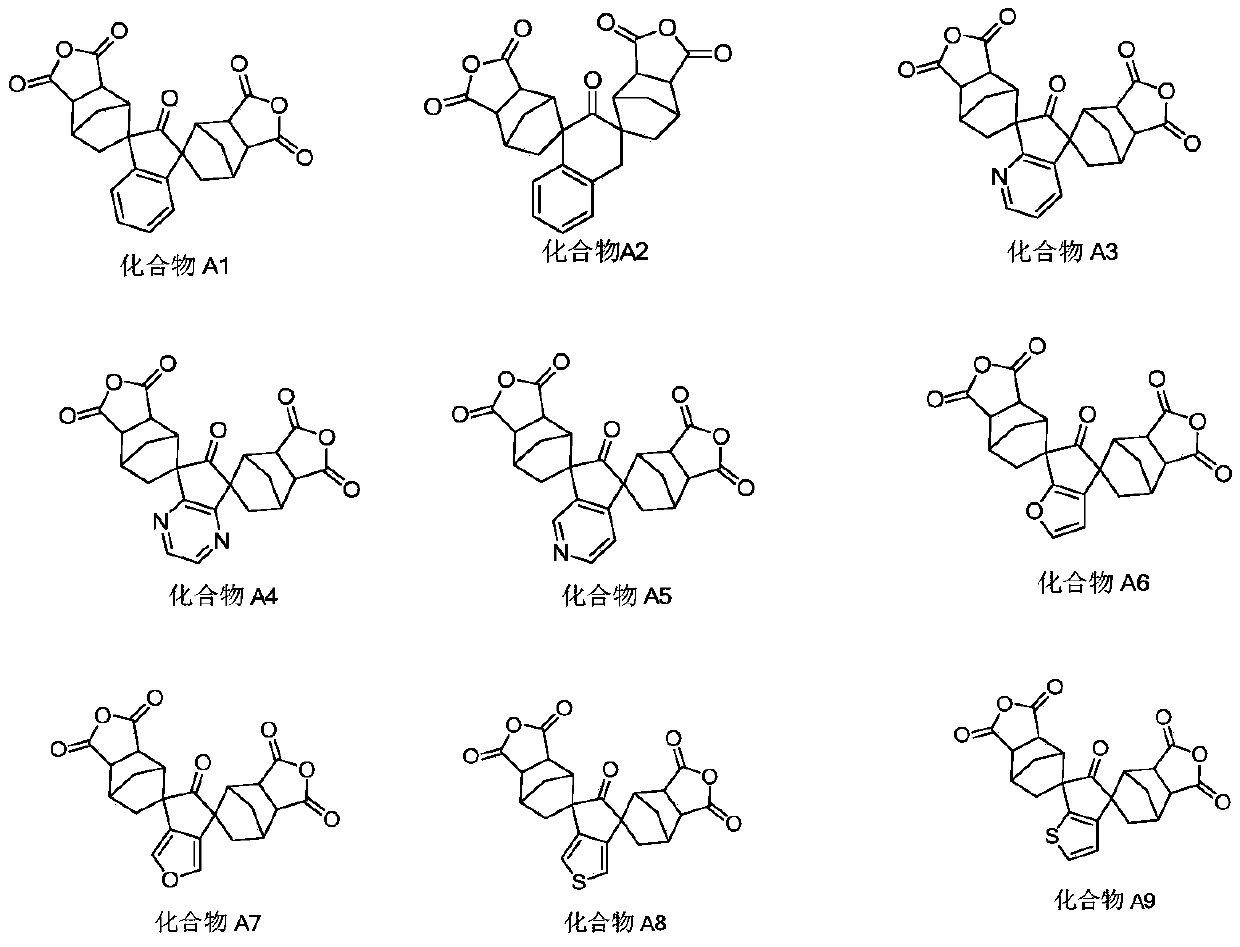

Embodiment 1

[0118] Exhaust the reaction vessel with nitrogen in advance, add 126.53g N,N-dimethylacetamide (DMAc, remove water with molecular sieve 24h in advance) after 30min, and then add 10.01g (50mmol) 4,4'-diaminobis Phenyl ether (ODA) was loaded and dissolved in DMAc, stirred at 25°C until completely dissolved; then 21.62g (50mmol) dianhydride compound A1 was gradually added, stirred until completely dissolved, and kept for 24h to obtain 20wt% polyamide Amino acid solution.

[0119] After the reaction is over, add acetic anhydride and isoquinoline in equimolar amounts of carboxylic acid groups, add DMAc that has been dehydrated, and adjust to a solution of 15 to 18 wt%; the obtained polyimide acid solution is coated on a glass substrate After pre-drying, transfer to the needle plate, and then transfer to the oven, heat treatment at 150 ° C / 250 ° C / 300 ° C / 350 ° C for 30 minutes, and carry out thermal imidization, so as to obtain a polyester with a thickness of about 25 μm. im...

Embodiment 2

[0121] Exhaust the reaction vessel with nitrogen in advance, add 129.34g N,N-dimethylacetamide (DMAc, remove water with molecular sieve 24h in advance) after 30min, and then add 10.01g (50mmol) 4,4'-diaminobis Phenyl ether (ODA) was charged and dissolved in DMAc, stirred at 25°C until completely dissolved; then 22.32g (50mmol) of dianhydride compound A2 was gradually added, stirred until completely dissolved and then kept for 24 hours to obtain 20wt% polyimide Amino acid solution.

[0122] Then, in the same manner as in Example 1, a 25 μm thick polyimide film was prepared.

Embodiment 3

[0124] Exhaust the reaction vessel with nitrogen in advance, add 136.54g N,N-dimethylacetamide (DMAc, remove water with molecular sieve 24h in advance) after 30min, then add 10.01g (50mmol) 4,4'-diaminobis Phenyl ether (ODA) was loaded and dissolved in DMAc, stirred at 25°C until completely dissolved; then 24.12g (50mmol) of dianhydride compound B1 was gradually added, stirred until completely dissolved, and kept for 24h to obtain 20wt% polyamide Amino acid solution.

[0125] Then, in the same manner as in Example 1, a 25 μm thick polyimide film was prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com