Method for preparing strength plate from waste soft plastic bottles and waste packaging boards

A technology of soft plastic and packaging cardboard, which is applied in the field of preparing strength boards from waste soft plastic bottles and waste packaging cardboard, can solve problems such as poor performance, and achieve the effects of improved processing and surface improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

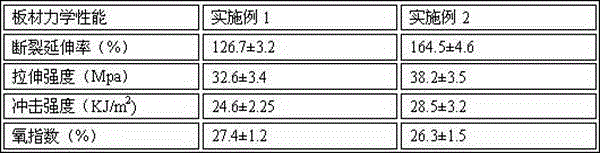

Examples

Embodiment 1

[0022] A method for preparing a strength board by utilizing waste soft plastic bottles and waste packaging cardboard, which is carried out according to the following process:

[0023] (1) Sorting and pretreatment of waste soft plastic bottles: Sorting waste soft plastic bottles from waste plastic bottles, removing the plastic film coverings on the bottle caps and bottles, and putting the cleaned bottles into Soak in a weak acid aqueous solution for 8 hours, then take it out and wash it until neutral, dry it fully, put it into a crusher for crushing, take it out, put it into a high-speed mixer with a small amount of linear low-density polyethylene and internal slip agent monoglyceride, and mix it at a high speed at 50°C Drop into extruder after 5 minutes and melt and extrude pelletizing at 160-180° C. to obtain masterbatch A, for subsequent use;

[0024] Among them, the selected waste soft plastic bottle is a mixture of polyethylene bottle and polypropylene bottle, and the mass...

Embodiment 2

[0031] A method for preparing a high-strength biomass plate with good flame retardancy, the process is:

[0032] A method for preparing a strength board by utilizing waste soft plastic bottles and waste packaging cardboard, which is carried out according to the following process:

[0033] (1) Sorting and pretreatment of waste soft plastic bottles: Sorting waste soft plastic bottles from waste plastic bottles, removing the plastic film coverings on the bottle caps and bottles, and putting the cleaned bottles into Soak in a weak acid aqueous solution for 10 hours, then take it out and wash it until neutral, dry it fully, put it into a crusher for crushing, take it out, put it into a high-speed mixer with a small amount of linear low-density polyethylene and internal slip agent monoglyceride, and mix it at a high speed at 50°C Drop into extruder after 5 minutes and melt and extrude pelletizing at 160-180° C. to obtain masterbatch A, for subsequent use;

[0034] Among them, the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com