Multilayered composite high-strength barrier film prepared by utilizing recovered waste plastics

A multi-layer composite, waste plastic technology, applied in layered products, synthetic resin layered products, chemical instruments and methods, etc., can solve problems such as poor performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

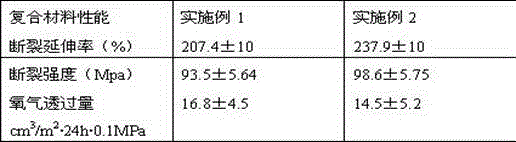

Embodiment 1

[0025] A multi-layer composite high-strength barrier film prepared by recycling waste plastics is composed of three layers, including an outer strength film layer, a middle layer connecting film layer and an inner layer barrier film layer.

[0026] The main raw materials of the strength film layer of the outer layer include recycled PET recycled materials, recycled PE recycled materials, nano-calcium silicate particles treated with silane coupling agents, PE-g-maleic anhydride, and recycled PET modifiers. Among them, recycled PET recycled materials accounted for 46% of the total raw material mass ratio, recycled PE regeneration accounted for 30% of the total raw material mass ratio, nano calcium silicate particles treated with silane coupling agent accounted for 19% of the total raw material mass ratio, PE-g -Maleic anhydride accounts for 3% of the total raw material mass ratio, and recycled PET modifier accounts for 2% of the total raw material mass ratio.

[0027] The prepar...

Embodiment 2

[0043] The main raw materials of the strength film layer of the outer layer include recycled PET recycled materials, recycled PE recycled materials, nano-calcium silicate particles treated with silane coupling agents, PE-g-maleic anhydride, and recycled PET modifiers. Among them, recycled PET recycled materials accounted for 55% of the total raw material mass, recycled PE accounted for 26% of the total raw material mass, silane coupling agent-treated nano-calcium silicate particles accounted for 14% of the total raw material mass, PE-g -Maleic anhydride accounts for 3.2% of the total raw material mass ratio, and recycled PET modifier accounts for 1.8% of the total raw material mass ratio.

[0044] The preparation method of the nano-calcium silicate particles treated with the silane coupling agent is as follows: a small amount of ethanol-dispersed silane coupling agent and nano-calcium silicate particles are put into a high-speed mixer and stirred at a high speed for 10-20 min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com