Preparation method of dialkoxyl xanthate polysulfide

A technology of dialkoxyxanthate and polysulfide, which is applied in the preparation of new rubber additives and the field of preparation of dialkoxyxanthate polysulfide, which can solve the problem of long synthesis process and high yield. And unstable quality, complex and cumbersome problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

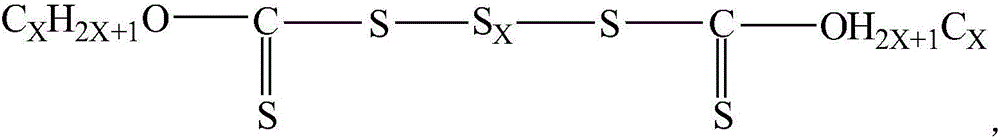

[0007] A dialkoxy xanthate polysulfide, the structural formula is as follows:

[0008]

[0009] Among them, the alkoxy group (C X h 2X+1 In O), X=1, 2, 3..., is normal alkoxy and / or iso-alkoxy.

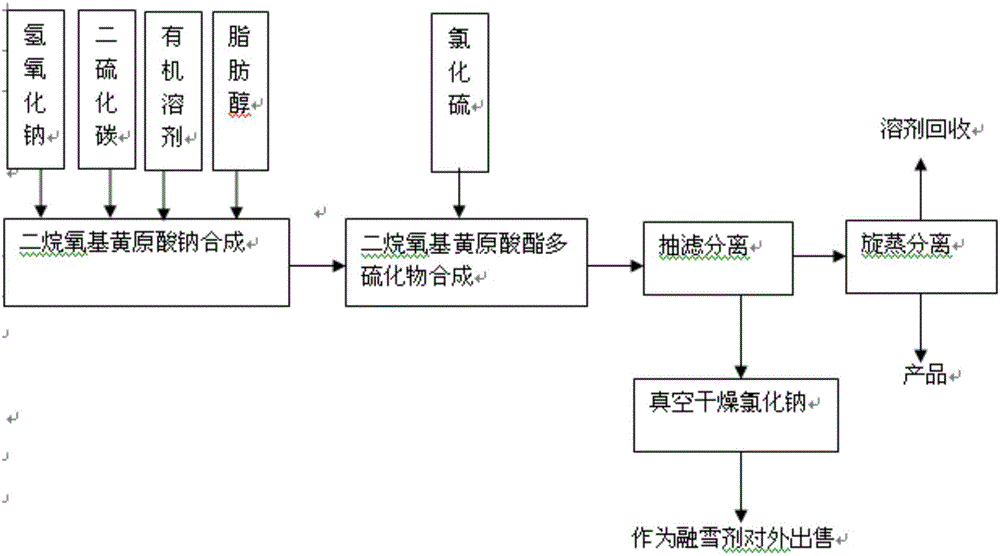

[0010] The preparation method of above-mentioned dialkoxy xanthate polysulfide comprises steps as follows:

[0011] (1) Add fatty alcohol and powdered sodium hydroxide to the organic solvent, stir at room temperature for 20-40 minutes, then slowly add carbon disulfide to the system, and obtain a mixture of sodium dialkoxydithioformate after the reaction is completed , fatty alcohol: carbon disulfide: sodium hydroxide: the molar ratio of organic solvent is (1.0~1.5):(1.0~1.5):1.0:(5.0~20.0);

[0012] (2) Slowly add sulfur chloride to the mixture of dialkoxy sodium dithioformate prepared in step (1), the mol ratio of the addition of sulfur chloride to carbon disulfide is: (0.5~1.0): (1.0~ 1.5), after the dropwise addition is completed, the obtained material is subjected to suctio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com