Patents

Literature

111 results about "Sulfur chloride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sulfur dichloride is the chemical compound with the formula SCl 2. This cherry-red liquid is the simplest sulfur chloride and one of the most common. It is used as a precursor to organosulfur compounds.

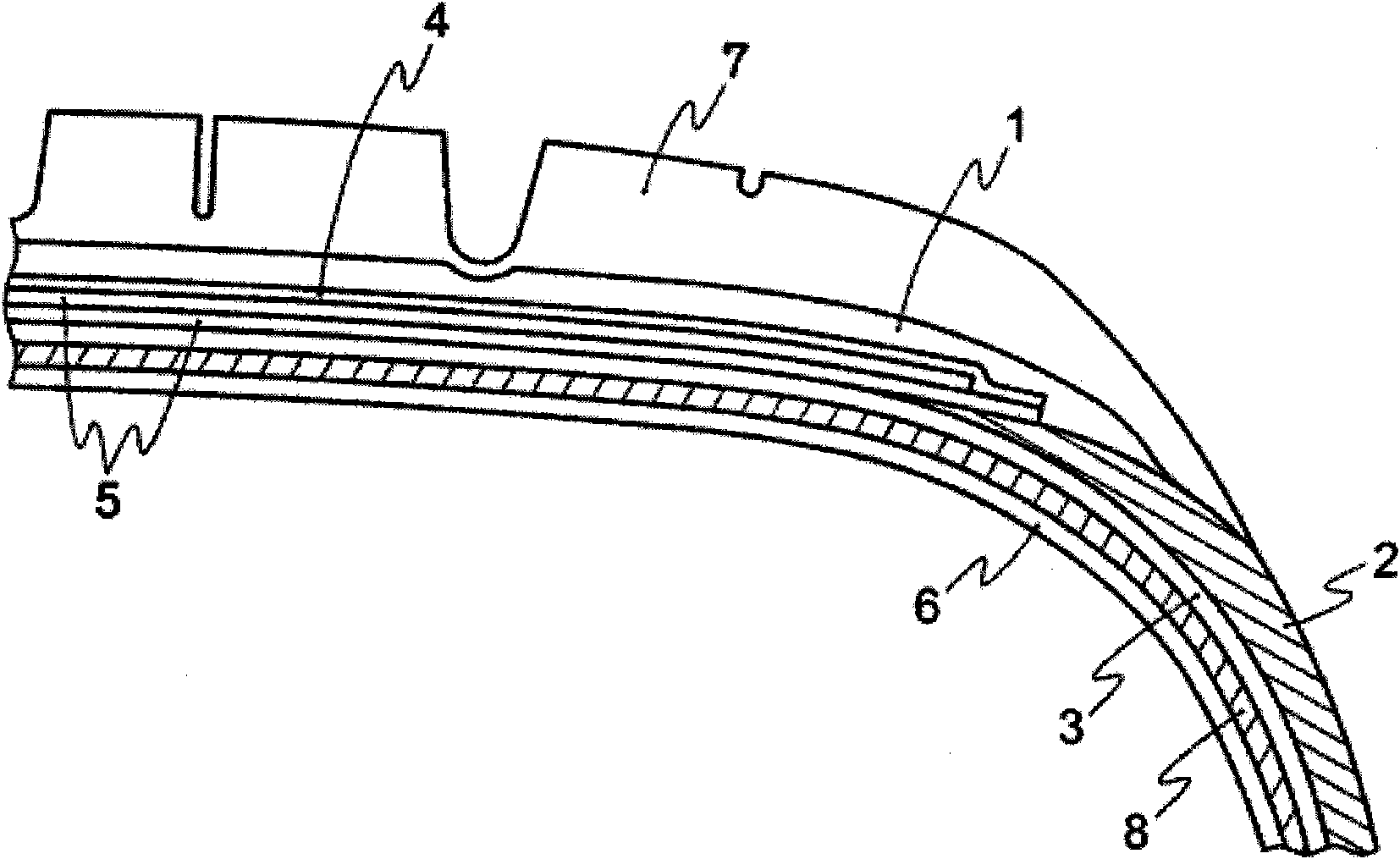

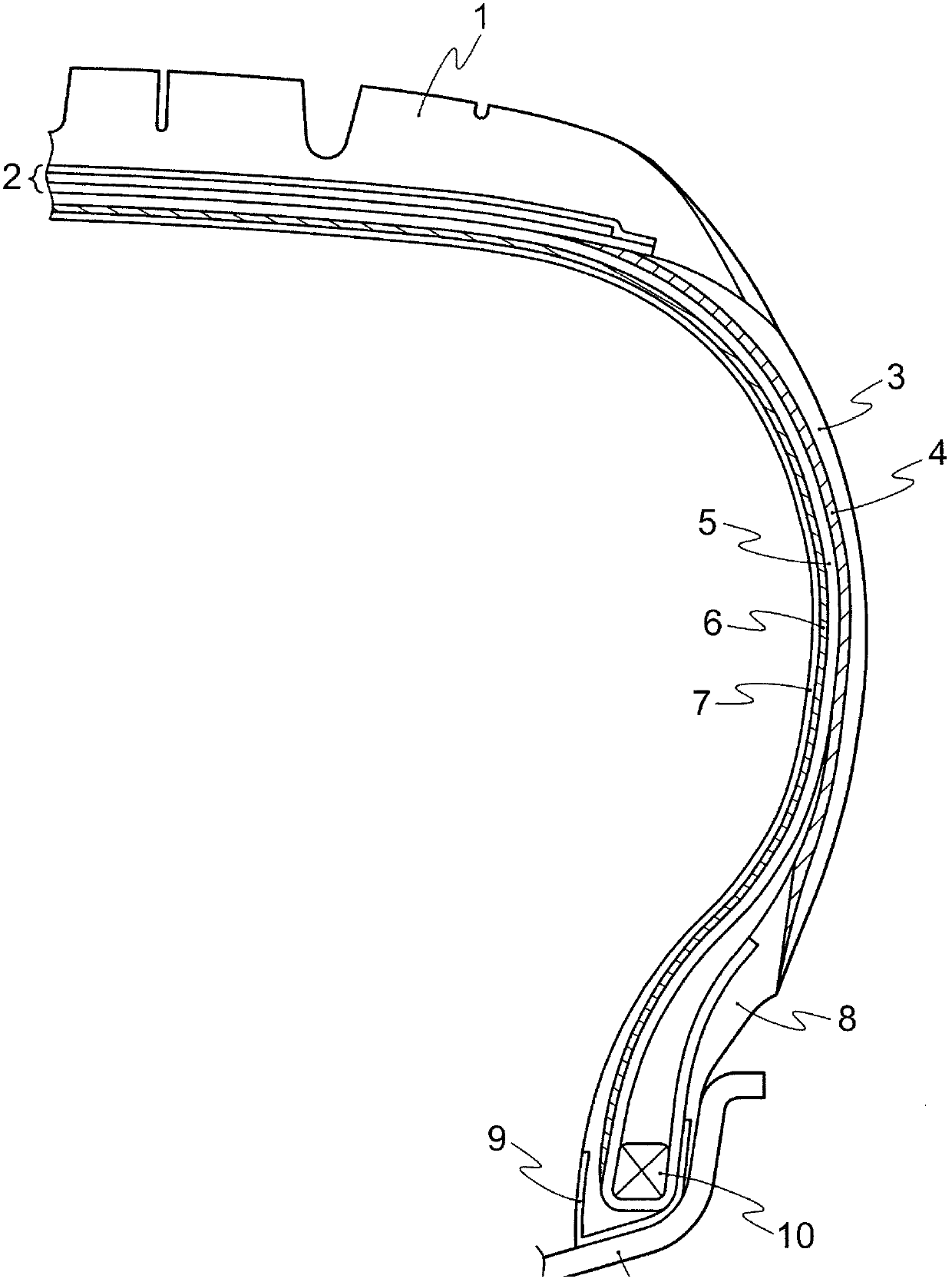

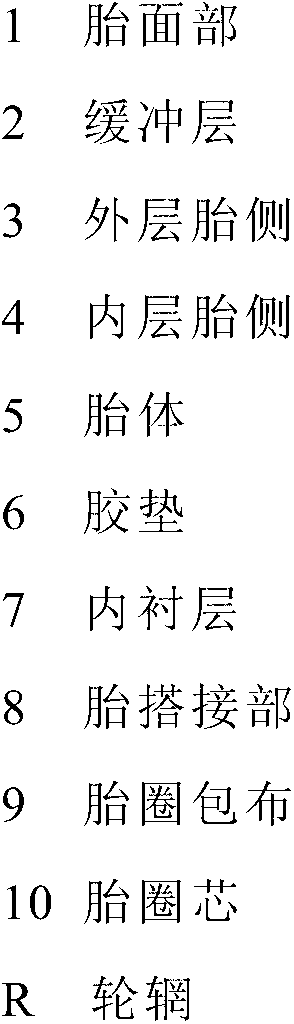

Rubber composition for tire

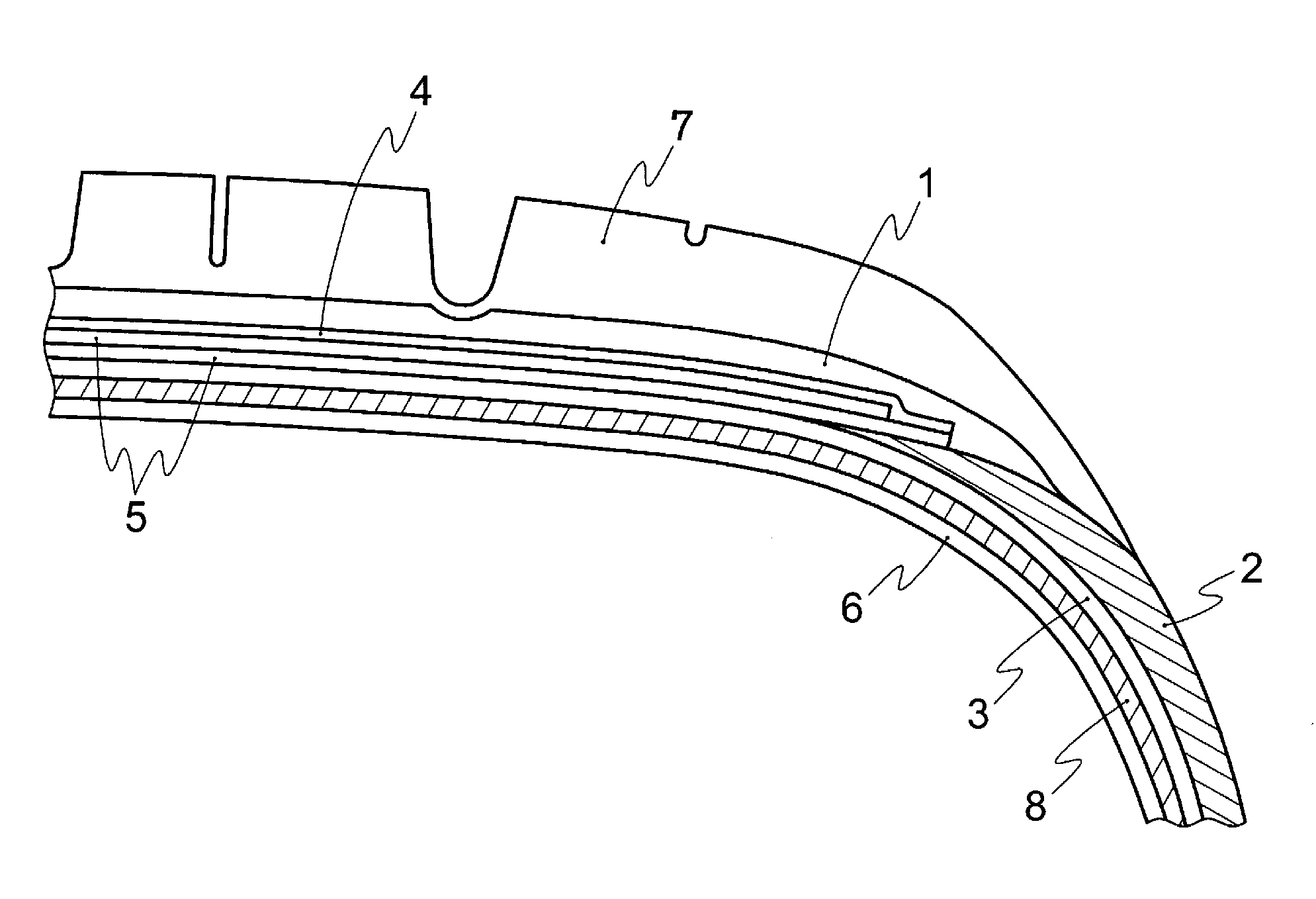

InactiveUS20100224299A1Good resistance stabilityImprove rolling resistanceSpecial tyresInflatable tyresVulcanizationPolymer science

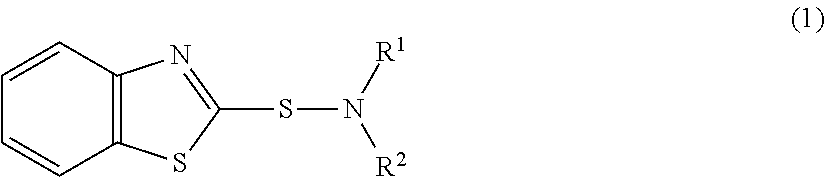

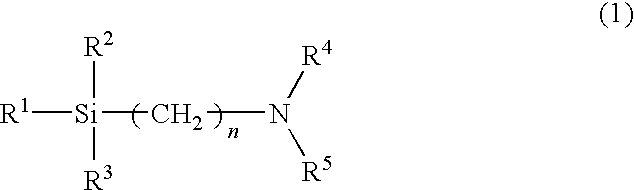

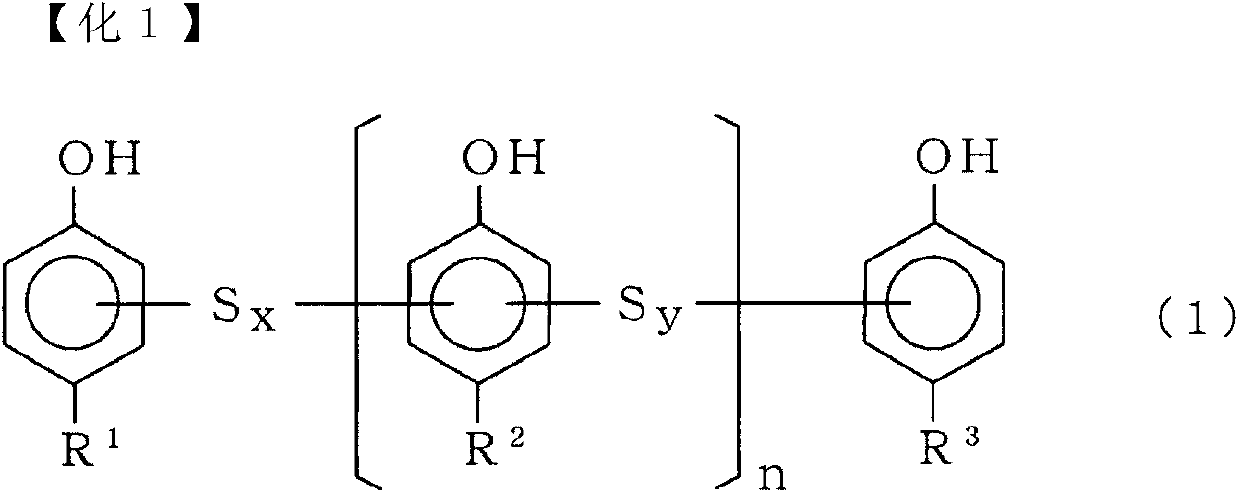

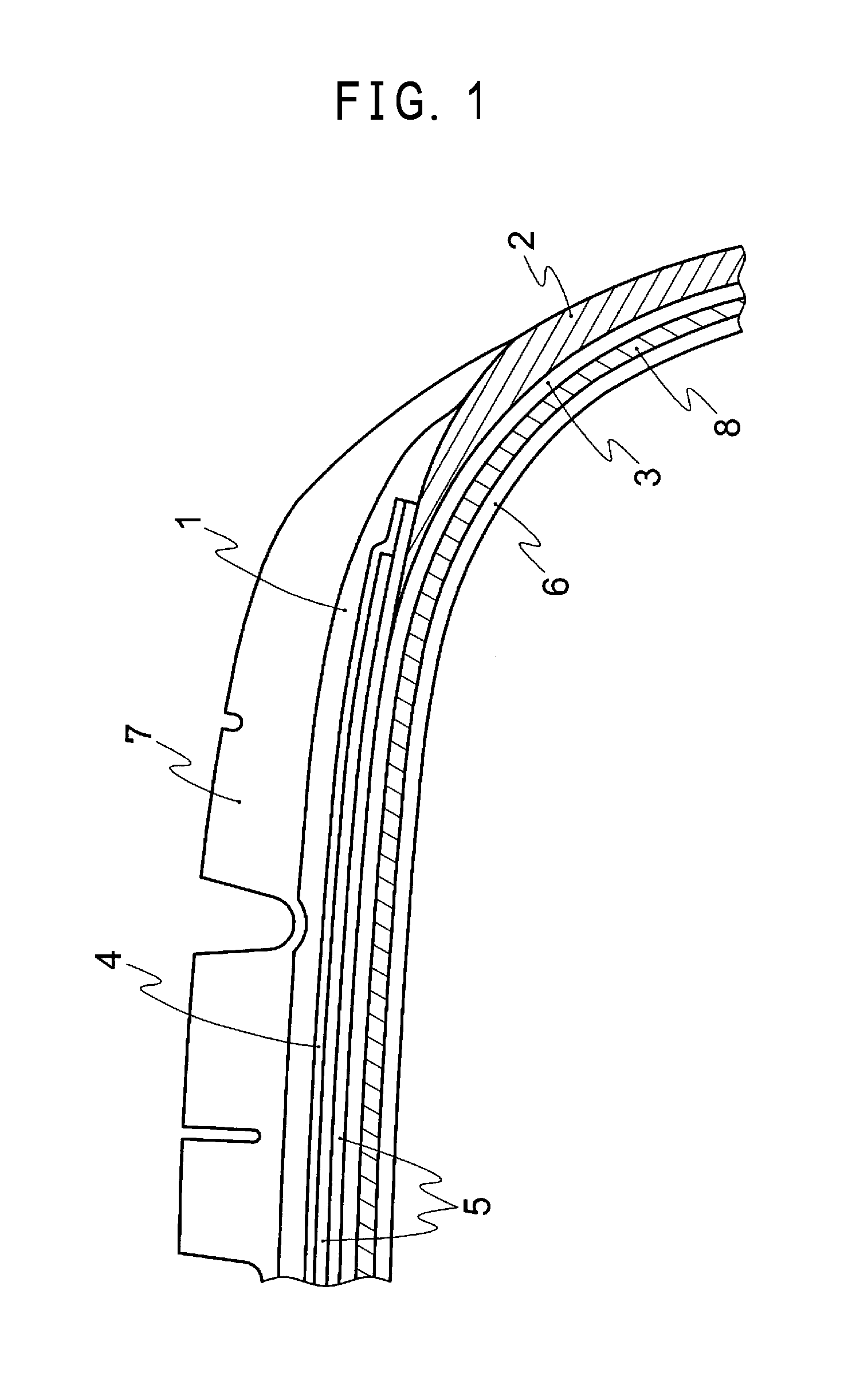

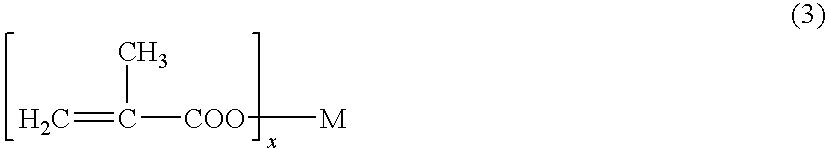

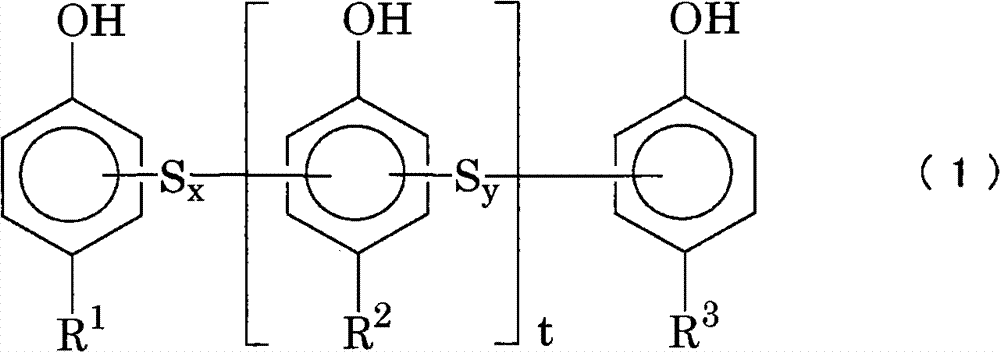

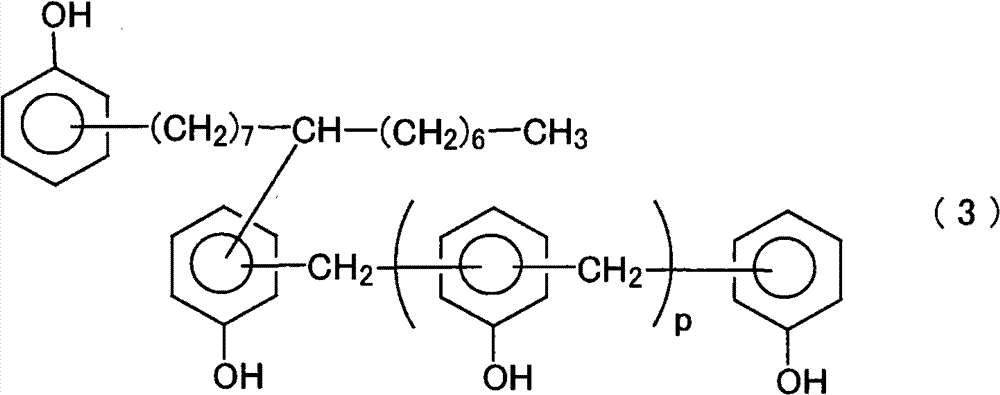

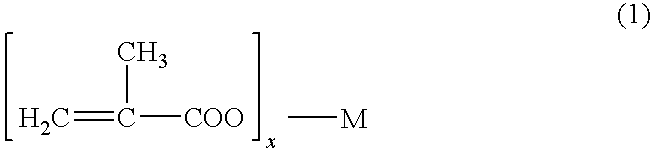

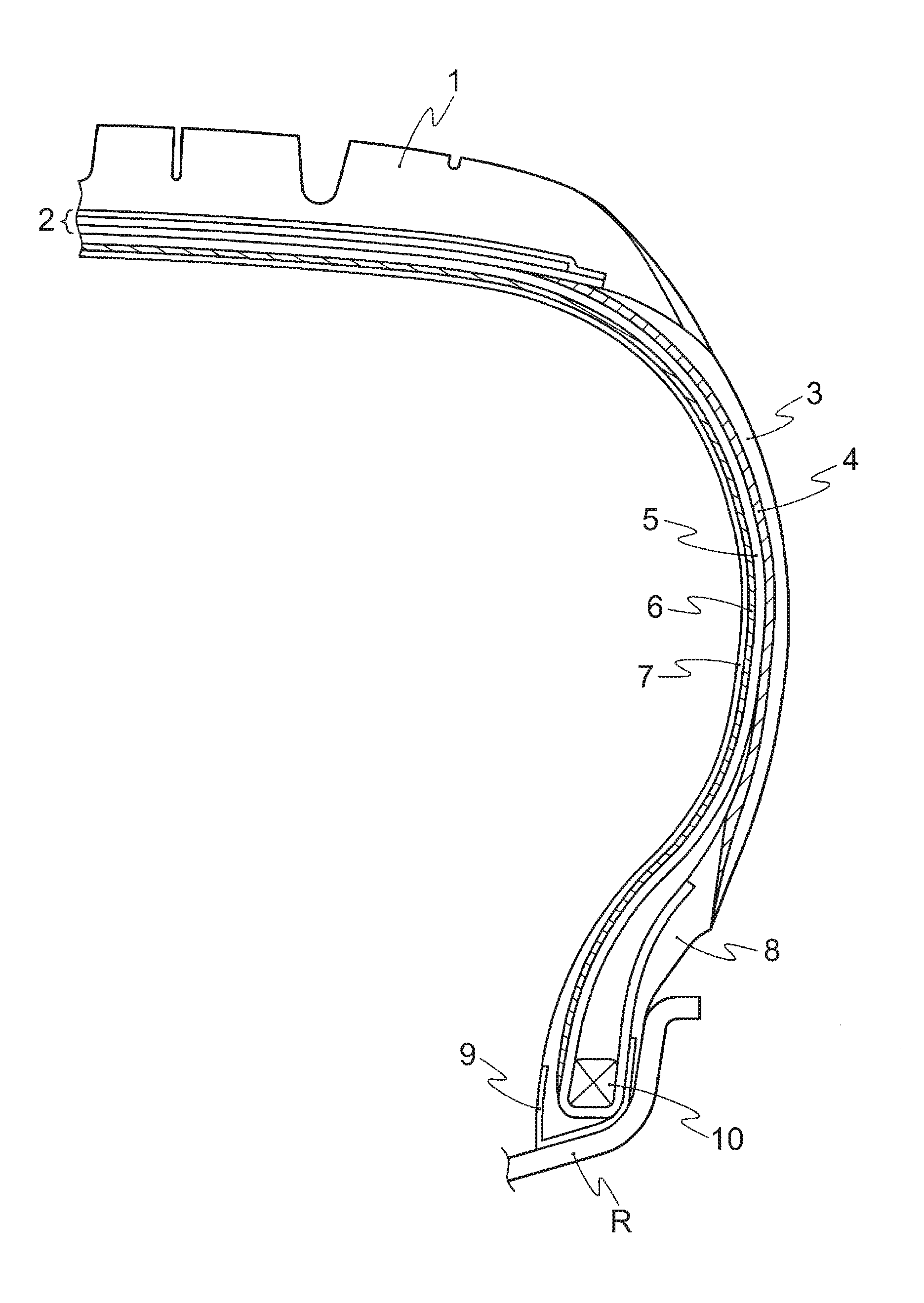

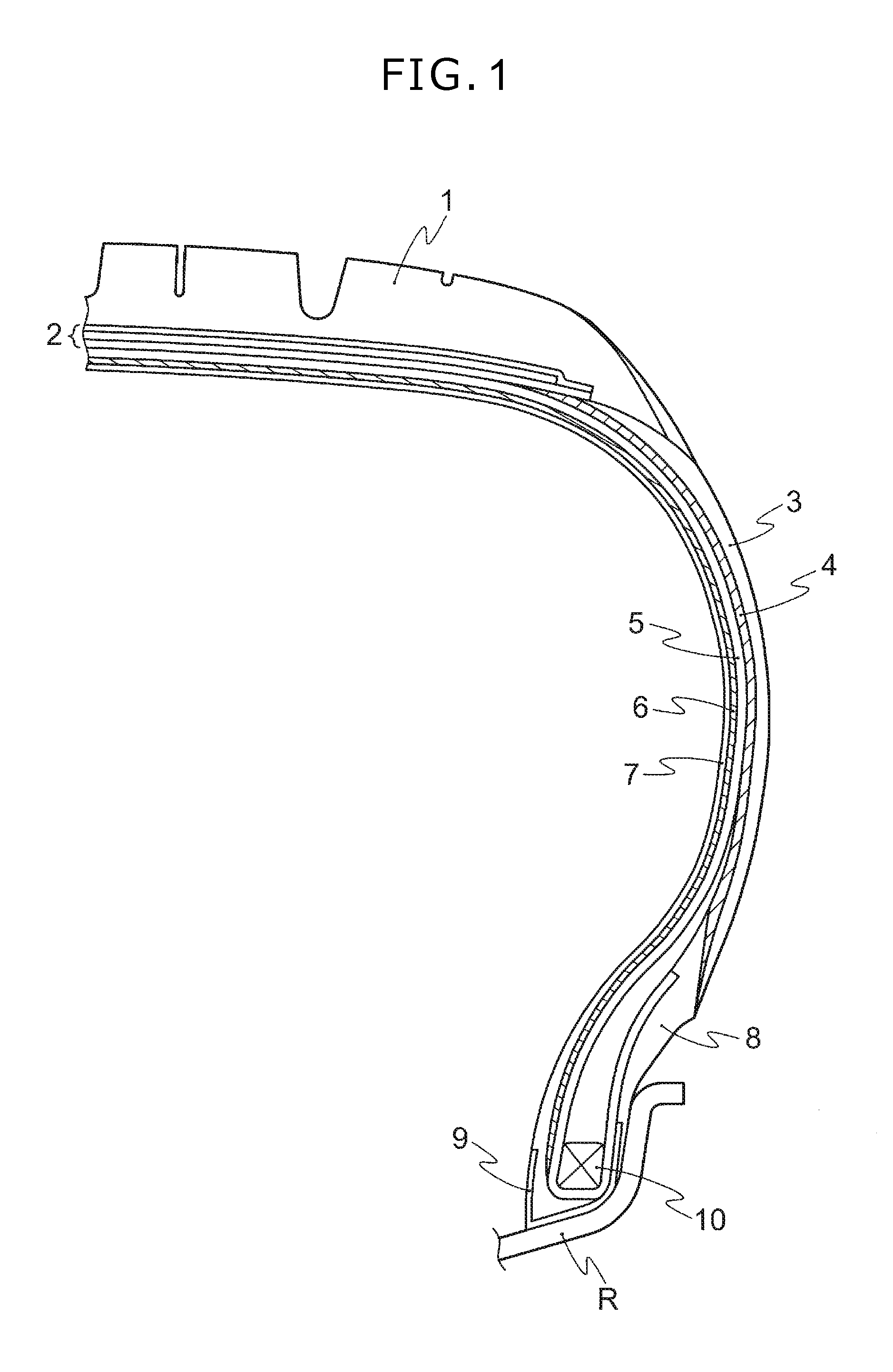

The present invention relates to a rubber composition for a sidewall, a clinch and an insulation comprising 20 to 60 parts by mass of filler, 1.0 to 4.0 parts by mass of sulfur and 0.1 to 10 parts by mass of at least one vulcanization accelerating aid selected from a group comprising a citraconimide compound, an organic thiosulfate compound, an alkylphenol-sulfur chloride condensate, a compound represented by the formula (2) and a metal salt of methacrylic acid represented by the formula (3), based on 100 parts by mass of a diene rubber component comprising 10 to 70% by mass of at least one diene rubber component (a) selected from a group comprising a solution polymerization-modified styrene-butadiene rubber, a tin-modified butadiene rubber and a butadiene rubber whose terminal is modified with a compound represented by the formula (1), and 20 to 80% by mass of a diene rubber component (b) other than the diene rubber component (a) for the purpose of improving rolling resistance and steering stability.

Owner:SUMITOMO RUBBER IND LTD

Rubber composition for tires, and pneumatic tire

InactiveUS20140102611A1Improve fuel economyImprove handling stabilitySpecial tyresInflatable tyresPolymer scienceAlkylphenol

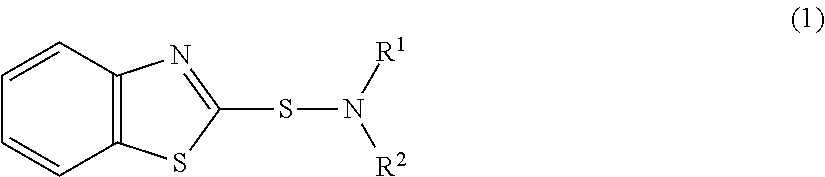

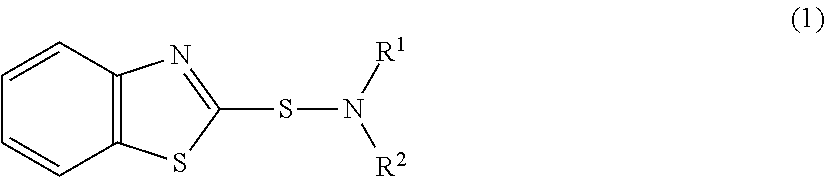

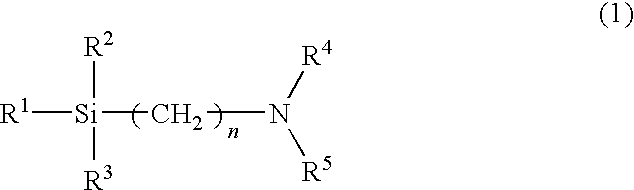

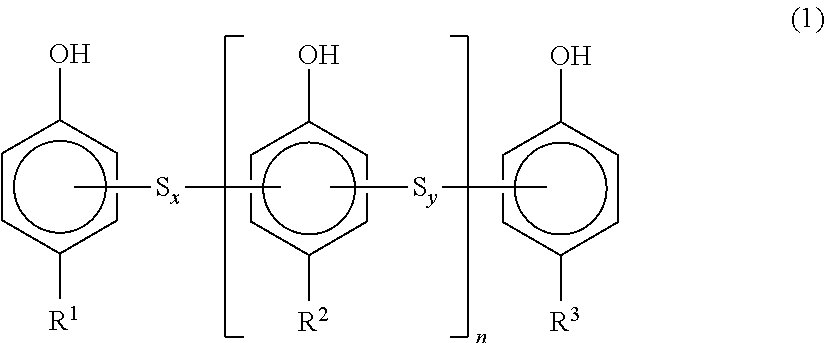

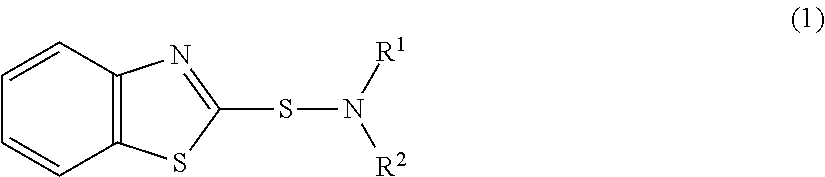

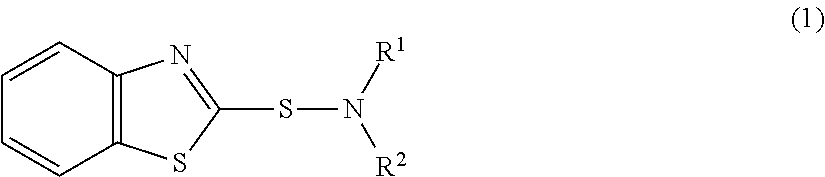

The invention relates to a rubber composition for a tire, containing an isoprene-based rubber and a compound represented by formula (1) below, wherein an amount of the isoprene-based rubber is at least 70% by mass; and an amount of the compound represented by formula (1) is 0.5-6 parts by mass per 100 parts by mass of the rubber component. The invention also relates to a rubber composition for a tire, containing an alkylphenol-sulfur chloride condensate and a compound represented by formula (1) below, wherein an amount of the alkylphenol-sulfur chloride condensate is 0.4-6 parts by mass, and an amount of the compound represented by formula (1) is 0.5-6 parts by mass, each per 100 parts by mass of a rubber component of the rubber composition:wherein R1 represents a C2-C16 alkyl group; and R2 represents a C3-C16 alkyl, benzothiazolyl-sulfide, or cycloalkyl group.

Owner:SUMITOMO RUBBER IND LTD

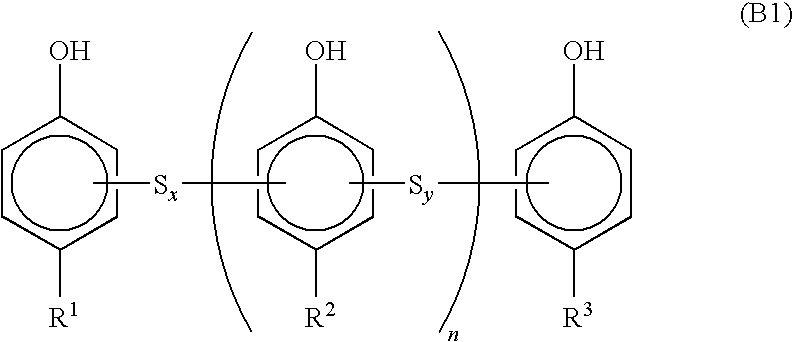

Rubber composition for tread and tire having tread comprising thereof

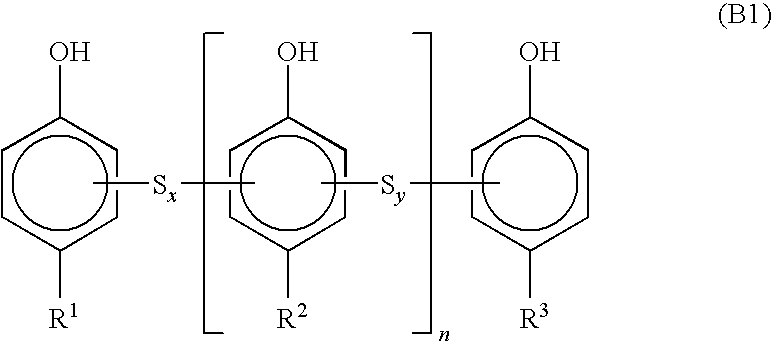

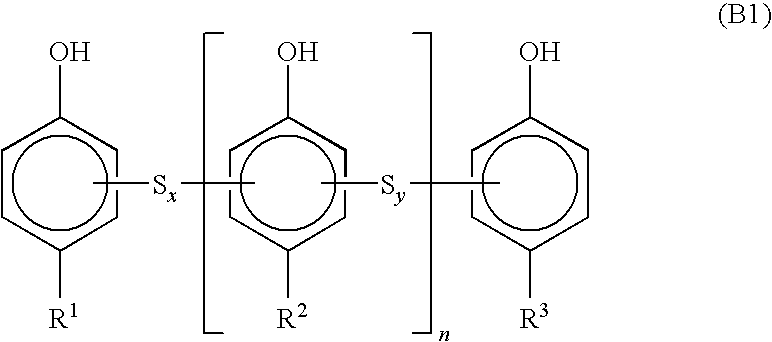

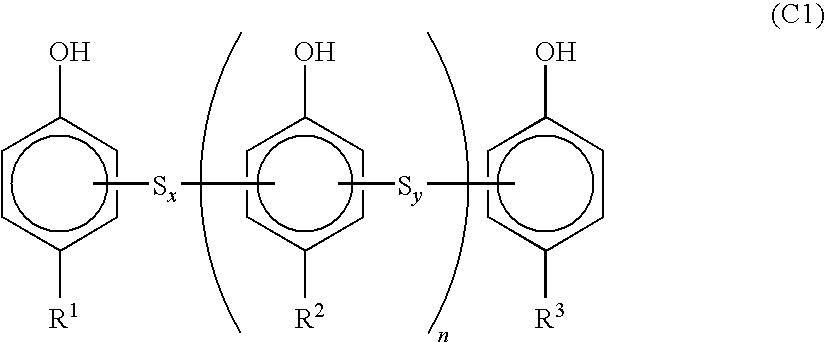

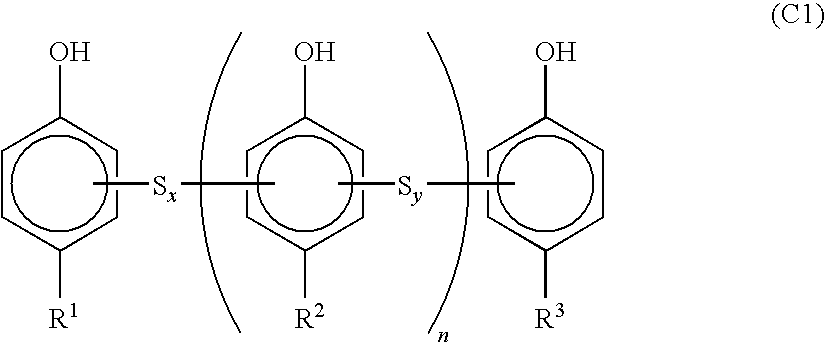

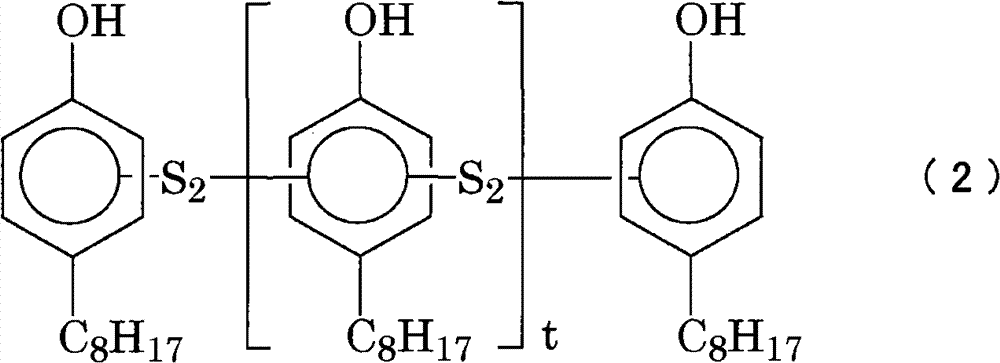

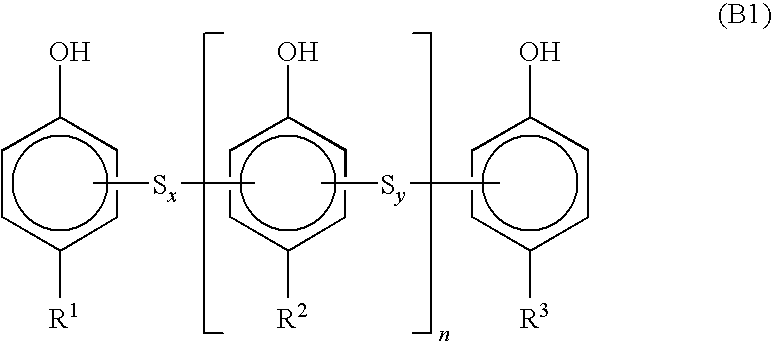

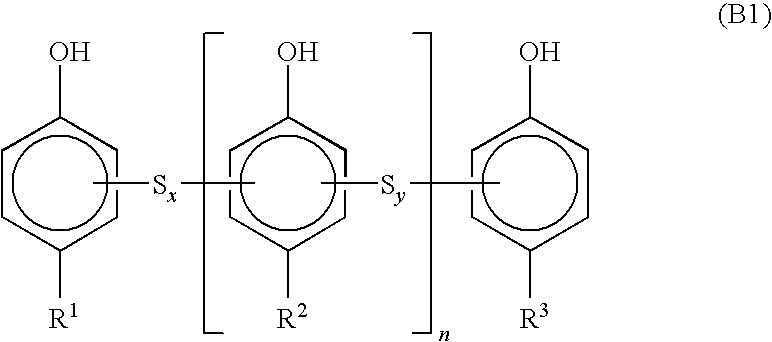

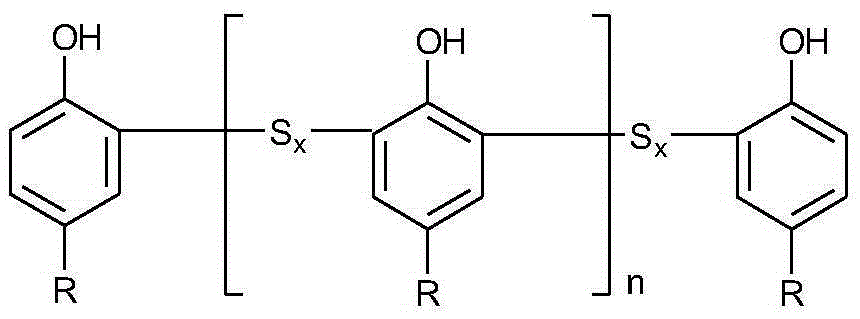

An object of the present invention is to satisfy both of the low heat build-up property and strength at break. The present invention provides a rubber composition for tread comprising 0.5 to 10 parts by mass of (B) an alkylphenol-sulfur chloride condensate indicated by the formula (B1):(wherein R1 to R3 are same or different, either is an alkyl group having 5 to 12 carbons; x and y are same or different, and either is an integer of 2 to 4; n is an integer of 0 to 10), 0.5 to 6 parts by mass of (C) sulfur, and 10 to 100 parts by mass of (D) silica, based on 100 parts by mass of the specific (A) rubber component comprising, and a tire having tread using thereof.

Owner:SUMITOMO RUBBER IND LTD

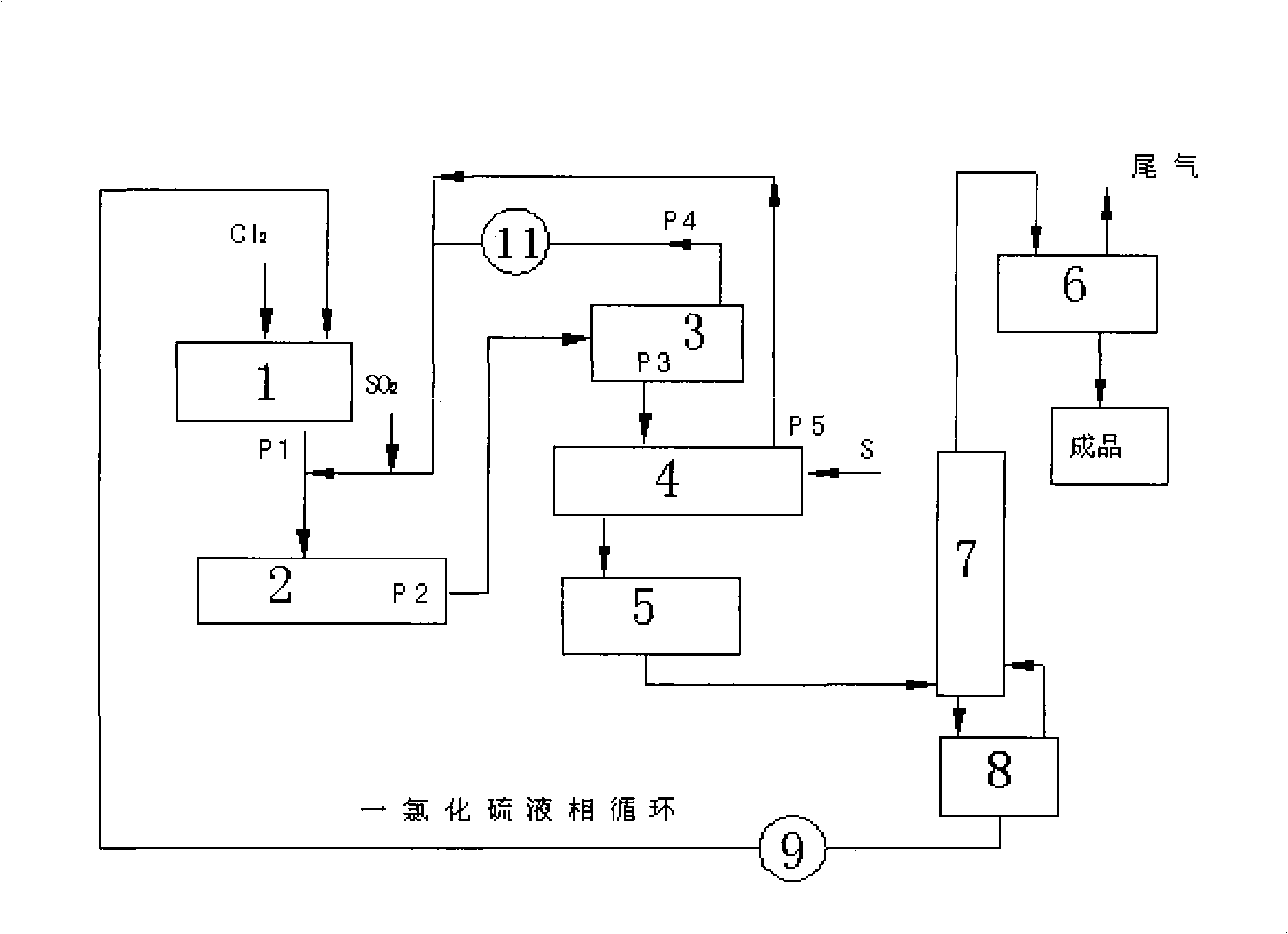

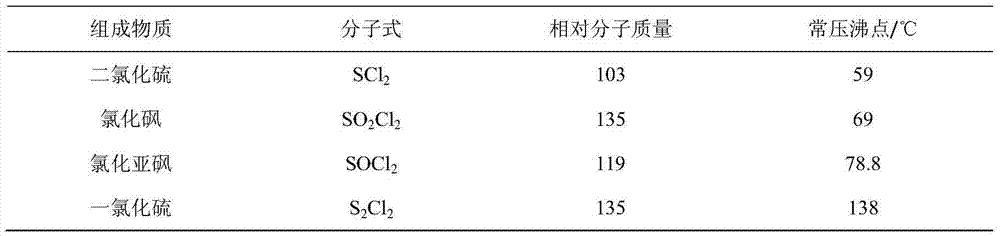

Gas phase circulation method in synthesis of thionyl chloride

ActiveCN101284653AEasy to scale up productionNo pollutionSulfur and halogen compoundsGas phaseDistillation

The invention relates to a method of gas phase in the synthesis of thionyl chloride, and particularly includes synthesizing sulfur dichloride by adding chlorine to sulfur monochloride, synthesizing crude thionyl chloride gas of light concentration by adding chlorine and sulfur dioxide, then subjecting the thionyl chloride gas to condensation, desaeration, purification, sulfuration and distillation to obtain the sulfur monochloride, and then rectifying the sulfur monochloride, thereby representing the method for all gases to enter the circulated use during the whole process.

Owner:JIANGXI SELON INDAL

Rubber composition for tire

InactiveCN101883818AIncrease resistanceImprove handling stabilityWithout separate inflatable insertsSpecial tyresRolling resistancePolymer science

The object is to improve rolling resistance properties and controllability / stability. Thus, disclosed is a rubber composition for a side-wall, a clinch or an insulation, which comprises: 100 parts by mass of a diene rubber component; 20 to 60 parts by mass of a filler, 1.0 to 4.0 parts by mass of sulfur, and 0.1 to 10 parts by mass of a vulcanization accelerator aid, wherein the diene rubber component comprises 10 to 70 mass% of at least one diene rubber component (a) selected from the group consisting of a solution-polymerization-modified styrene-butadiene rubber, a tin-modified butadiene rubber and a butadiene rubber modified with a compound represented by the formula (1) at its terminus and 20 to 80 mass% of a diene rubber component (b) that is different from the diene rubber component (a), and wherein the vulcanization accelerator aid is selected from the group consisting of a citraconimide compound, an organic thiosulfate compound, an alkyl phenol-sulfur chloride condensate, a compound represented by the formula (2) and a methacrylic acid metal salt represented by the formula (3).

Owner:SUMITOMO RUBBER IND LTD

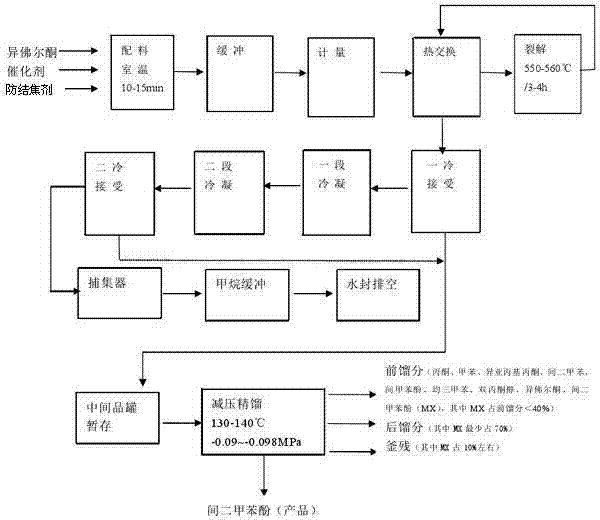

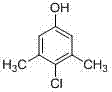

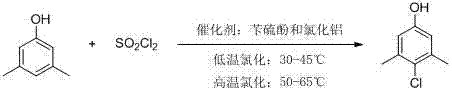

Preparation method of 3,5-dimethyl-4-chlorophenol

InactiveCN104326881AImprove conversion rateReduce generationOrganic chemistryOrganic compound preparationAluminium chlorideWater chlorination

The invention discloses a preparation method of 3,5-dimethyl-4-chlorophenol, which takes tetrachloroethylene as a solvent, benzyl thiophenol and aluminium chloride as cocatalysts, sulfuric chloride as a chloridizing agent, orientation chlorination is carried out through two phases of low-temperature chlorination and high-temperature chlorination, the mass ratio of tetrachloroethylene to MX is 0.5-4: 1; the mass ratio of the cocatalyst to MX is 2.5-6.5:1000; at low temperature chlorination phase, the mass ratio of sulfuric chloride dropping amount to MX is 0.9-1.2: 1; at high temperature chlorination phase, the mass ratio of sulfuric chloride dropping amount to MX is 0.1-0.2: 1; the temperature at the low temperature chlorination phase is controlled at 30-45 DEG C, chlorination is carried out for 4-6 hours; the temperature at high temperature chlorination phase is controlled at 50-65 DEG C, and chlorination is carried out for 1-2 hours, insulation reaction is carried out after the dropping process of sulfuric chloride is completed, tail gas is removed for 1-2 hours, and steps of water-washing layering, cooling and crystallizing, centrifuging and washing, and drying to obtain the product. According to the method, the conversion rate can reach more than 95%, finished product PCMX yield is increased, and the by-product can be effectively reduced.

Owner:RONGCHENG QINGMU CHEM MATERIALS

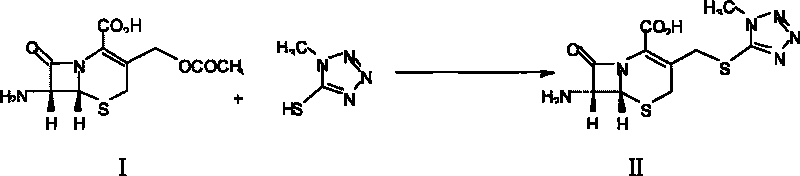

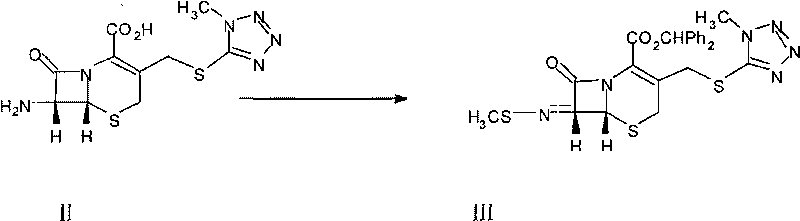

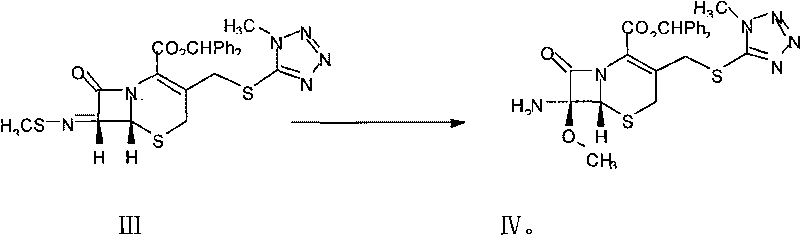

Synthetic method of 7-MAC intermediate

The invention discloses a synthetic method of a 7-MAC intermediate, which comprises the following steps: reacting 7-ACA as raw material with MMTZ to obtain 7-TMAC; enabling the 7-TMAC and methyl sulfur bromide to undergo imidization, and then, reacting the imidization product with diphenyl diazomethane to obtain the intermediate; and enabling the intermediate and a methoxylation reagent to undergo methoxylation reaction to obtain a finished product. In the synthetic method, the 7-ACA which can be obtained easily is used as original material to synthesize the 7-TMAC, thereby reducing the production cost. In the imidization reagent of the synthetic method, methyl sulfur chloride is replaced by the methyl sulfur bromide, thereby increasing the reaction activity, improving the yield, simplifying the operation and reducing the cost.

Owner:CANGZHOU SENARY CHEM SCI TEC

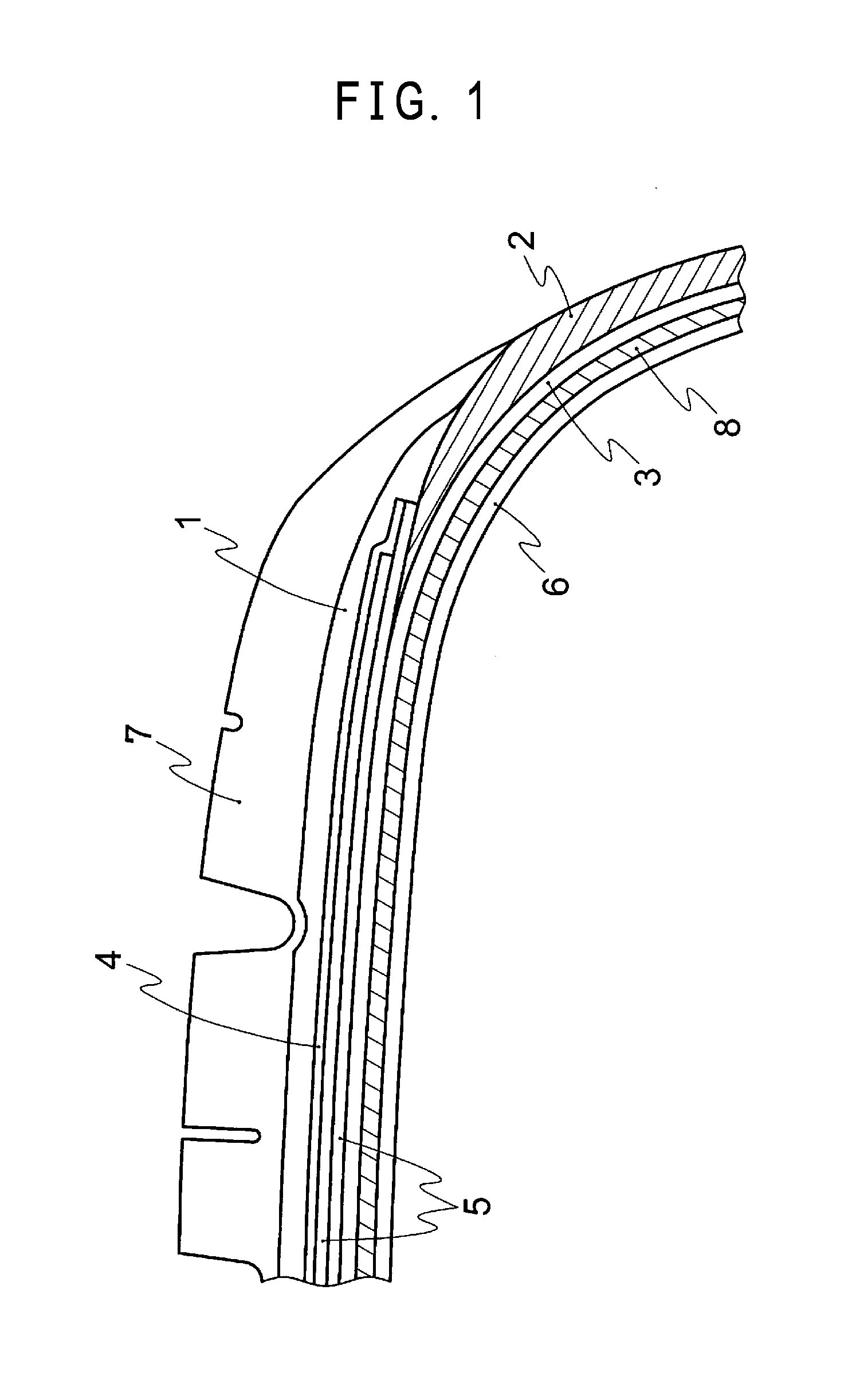

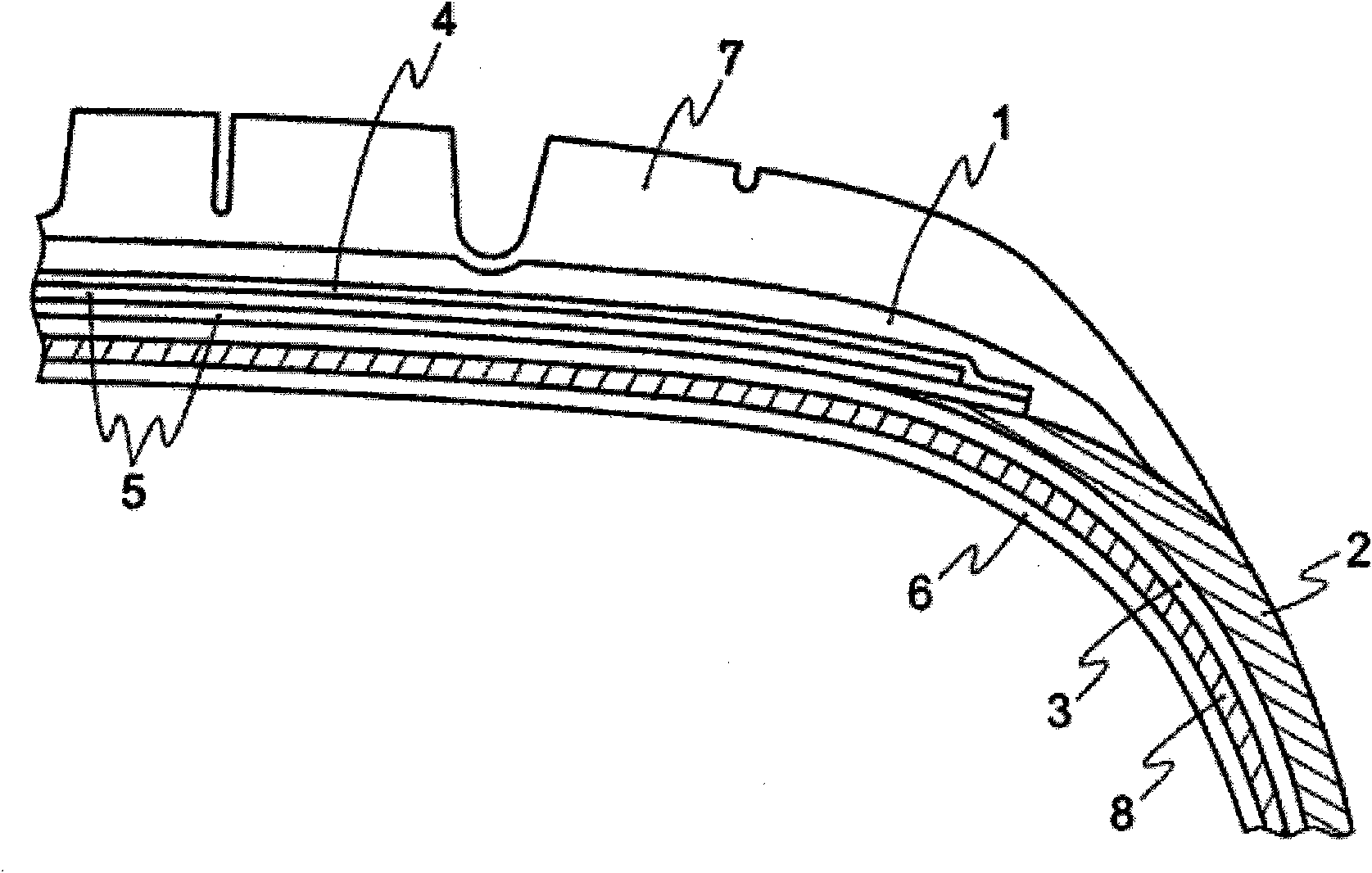

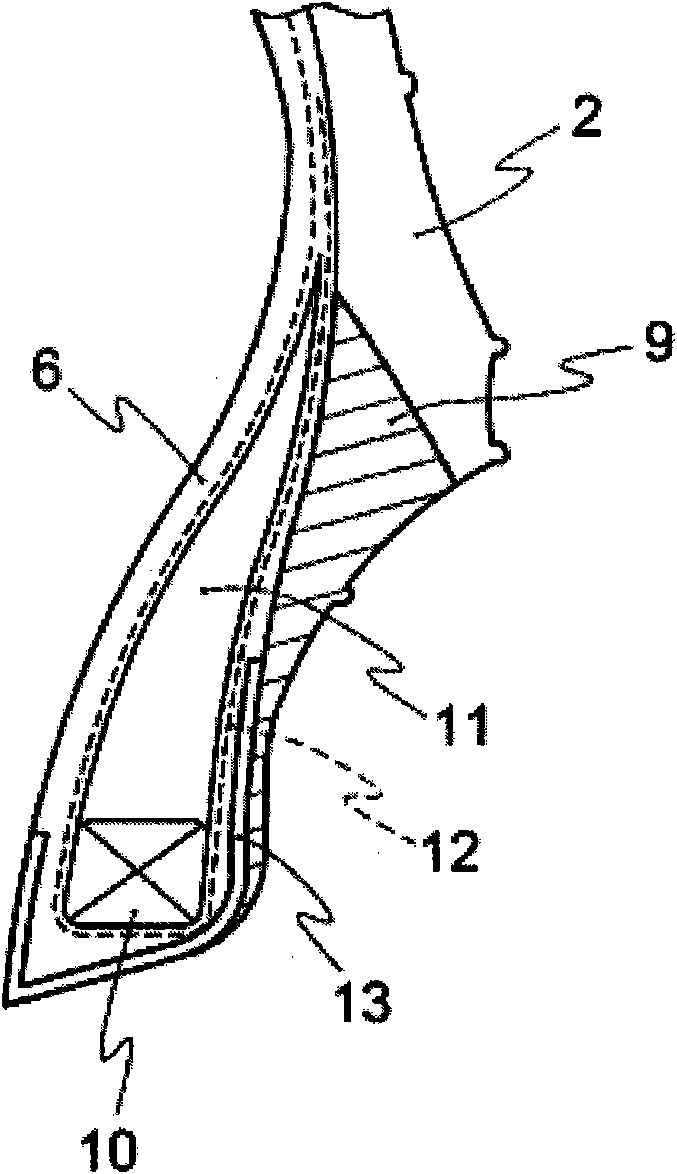

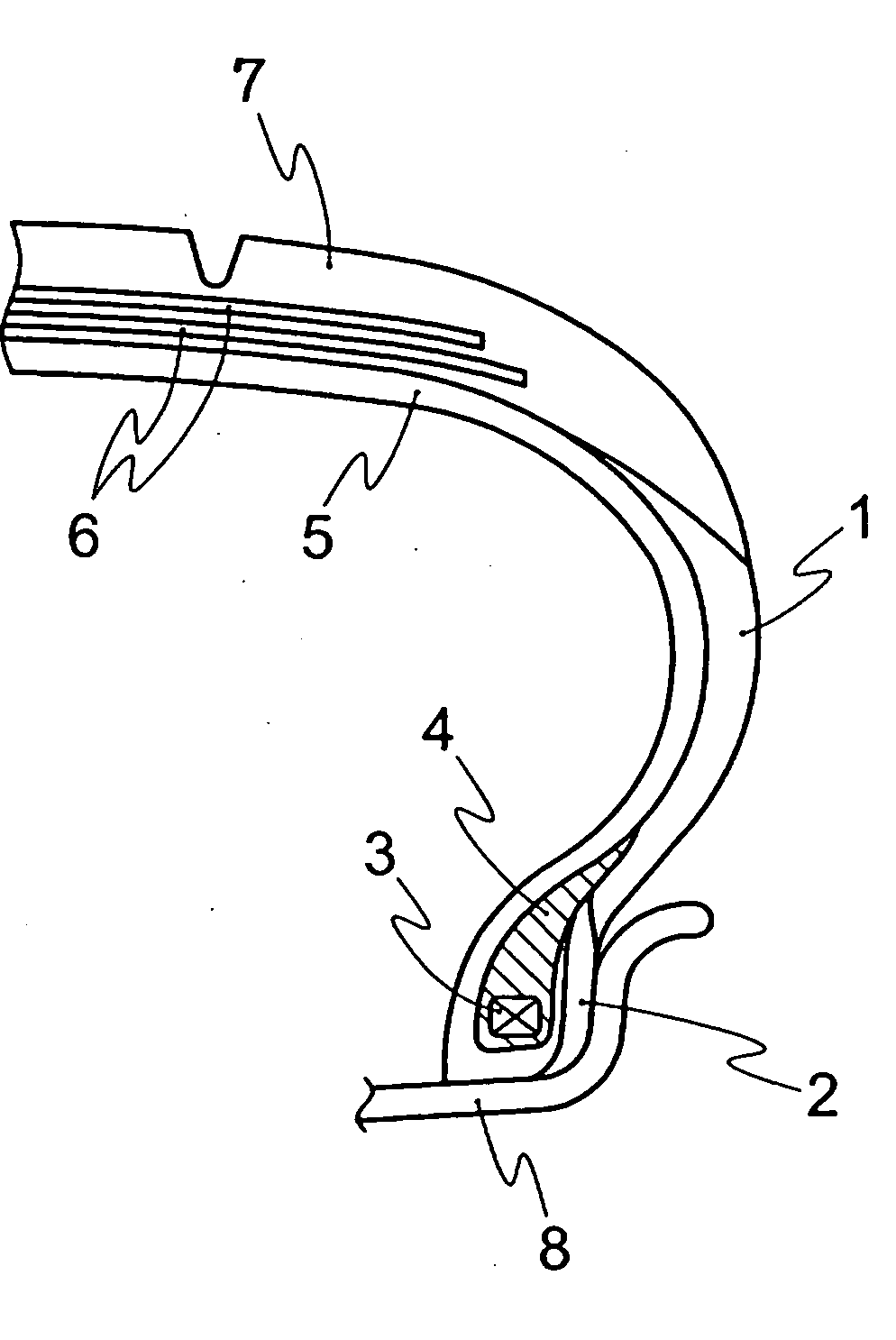

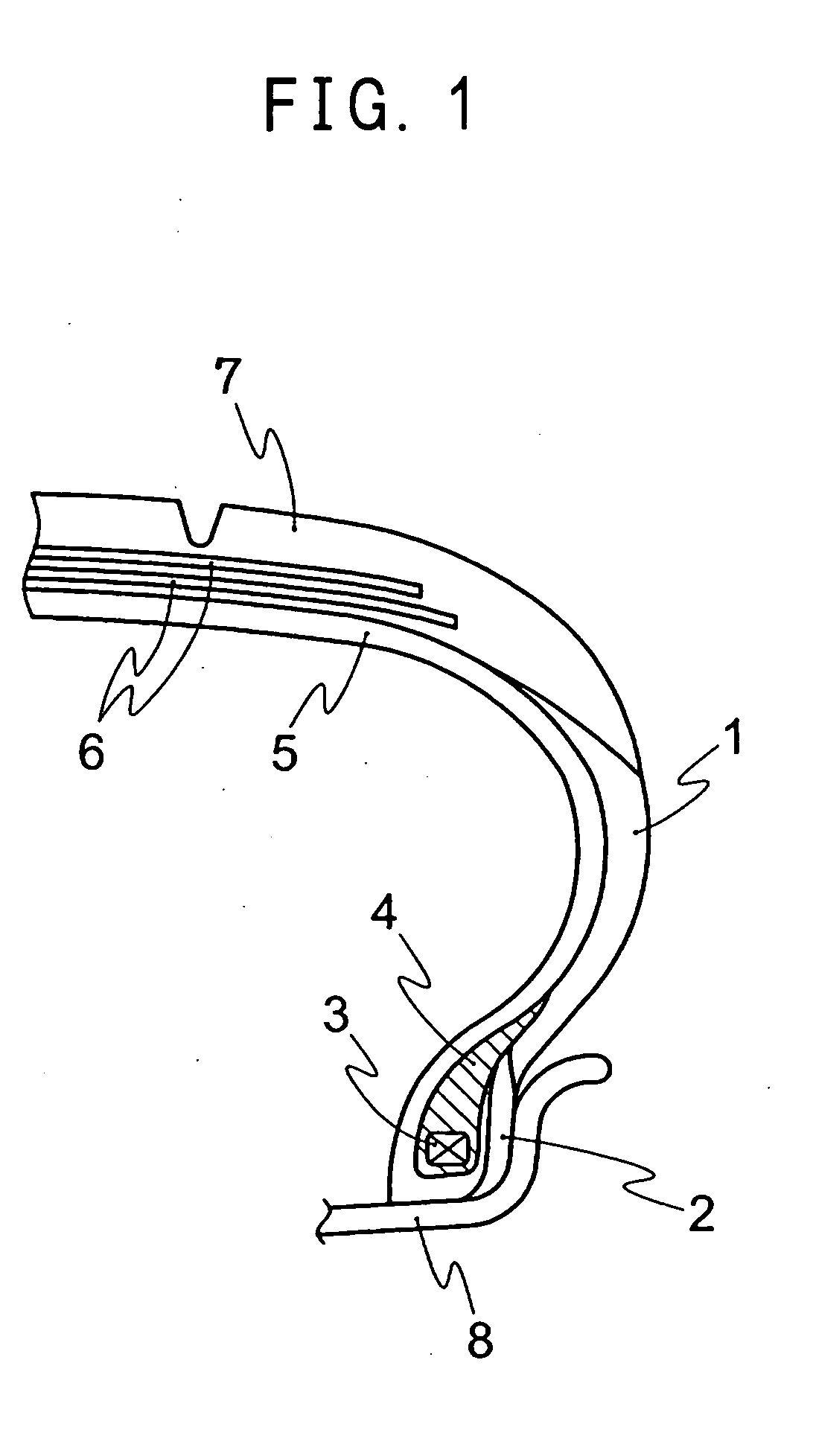

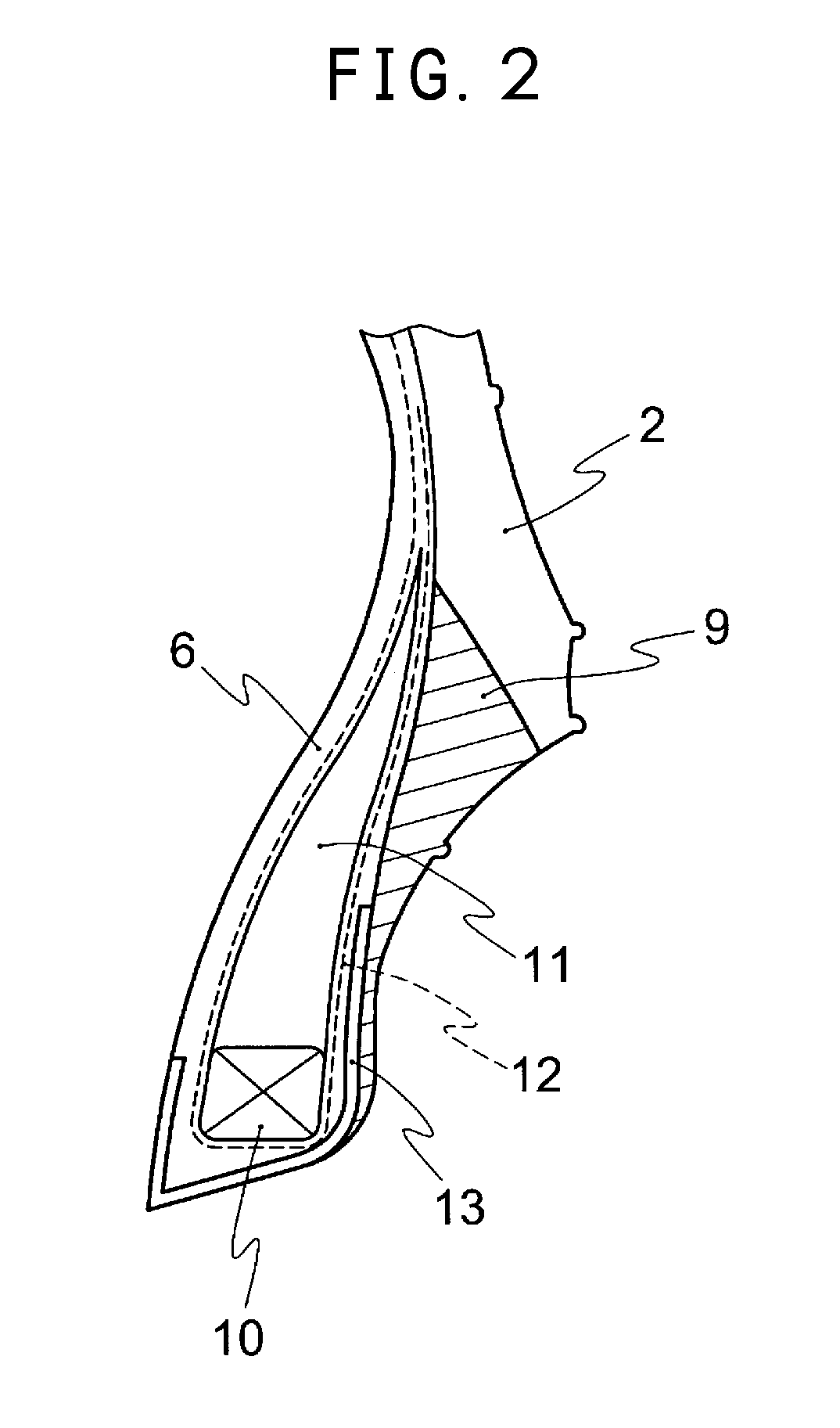

Rubber Composition for Bead Apex and Tire Having Bead Apex Prepared Using Same

InactiveUS20090151844A1Good extrusion processing performanceImprove rigidityLayered productsSpecial tyresRolling resistanceVulcanization

There is provided a rubber composition for a bead apex which can enhance extrusion processability by optimizing a rate of vulcanization during a vulcanization process, and can improve rigidity, steering stability and a low fuel consumption property, a tire having a bead apex prepared by using the rubber composition for a bead apex and being capable of enhancing steering stability and reducing rolling resistance and a tire for a sports utility vehicle (SUV) having further enhanced durability. The rubber composition for a bead apex comprises a diene rubber, a phenol resin and / or a modified phenol resin, sulfur, hexamethylenetetramine, a vulcanization accelerator, and at least one kind of vulcanization acceleration auxiliary selected from the group consisting of a citraconimide compound, a condensate of alkyl phenol and sulfur chloride, an organic thiosulfate compound and a compound represented by the general formula: R1—S—S-A-S—S—R2.

Owner:SUMITOMO RUBBER IND LTD

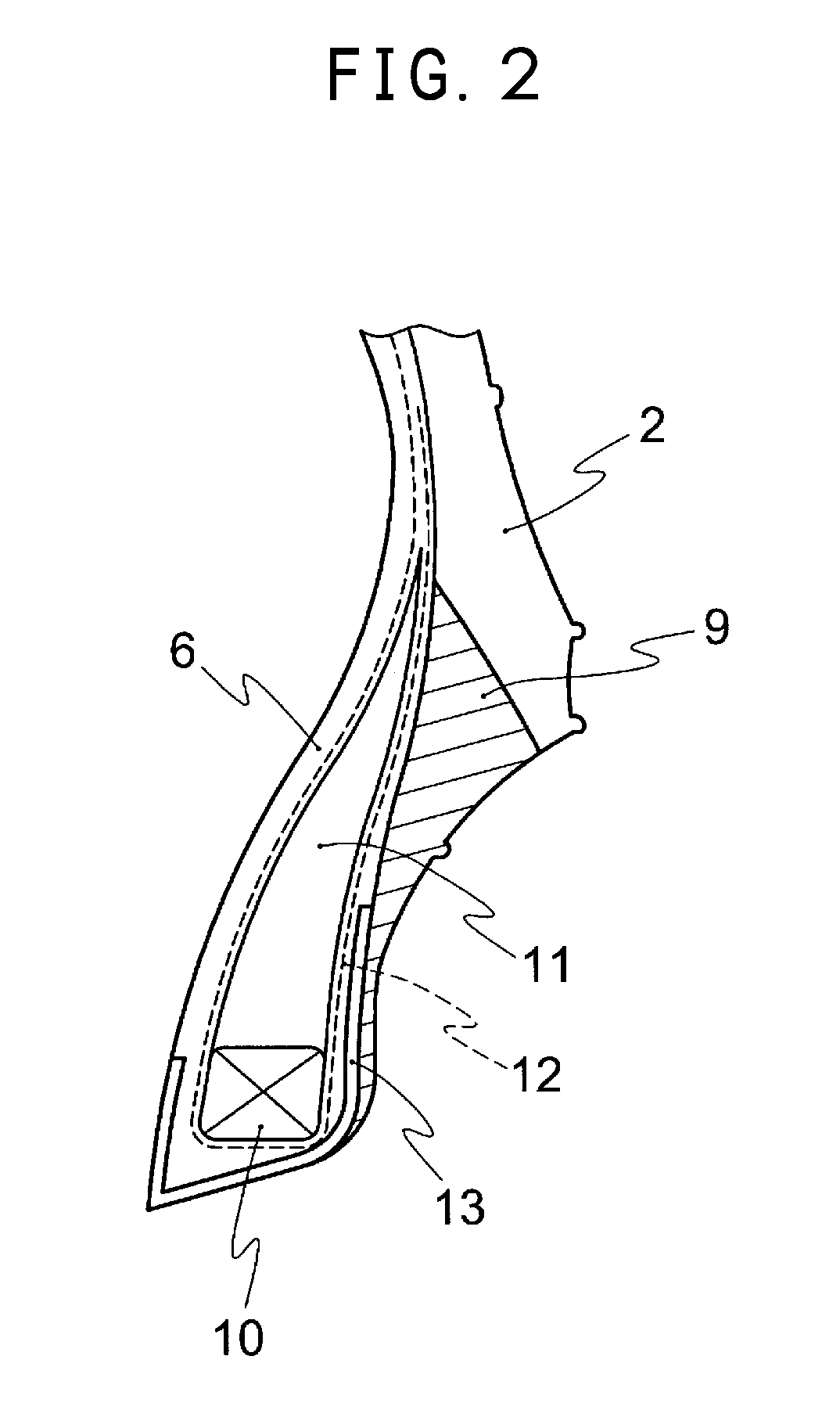

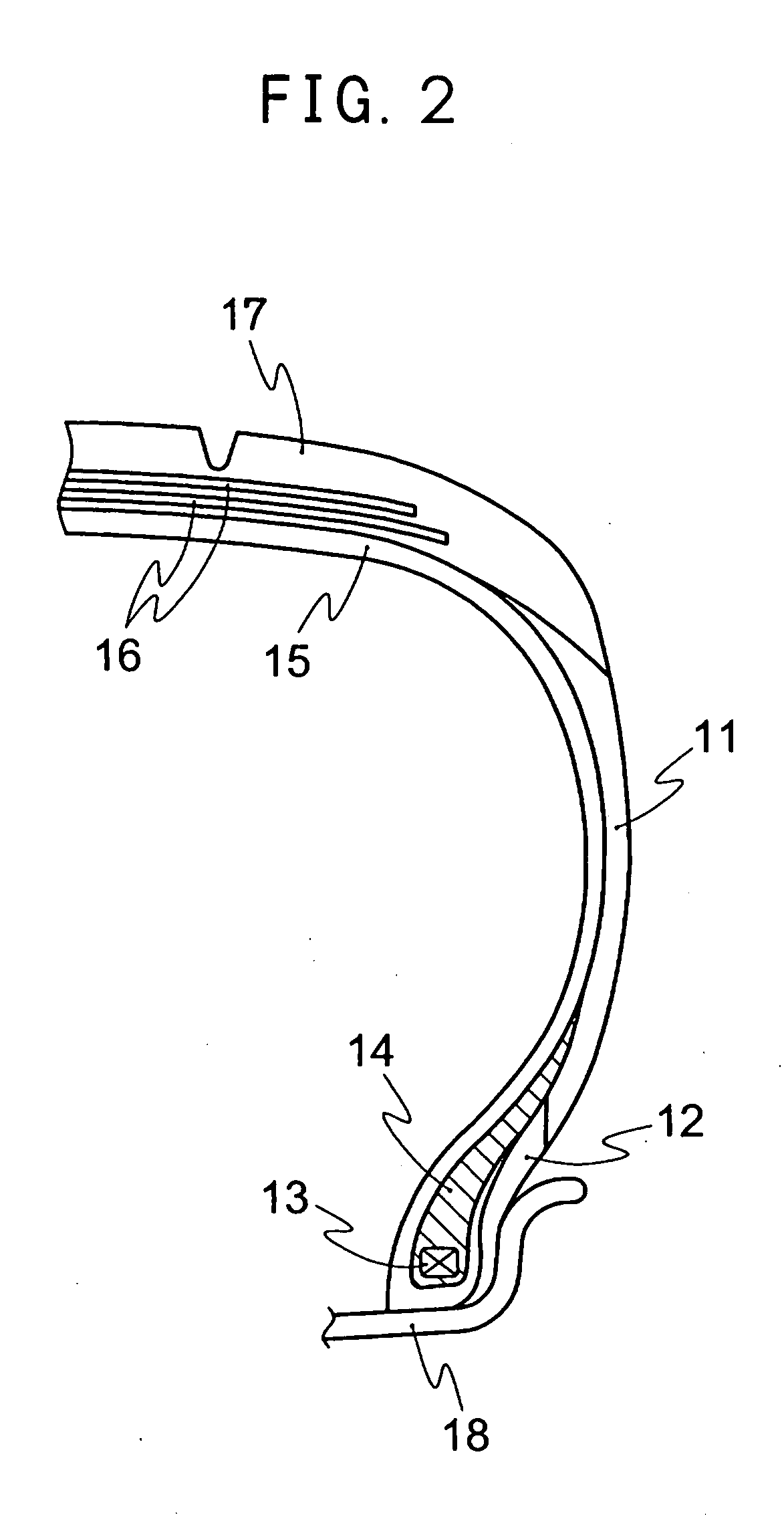

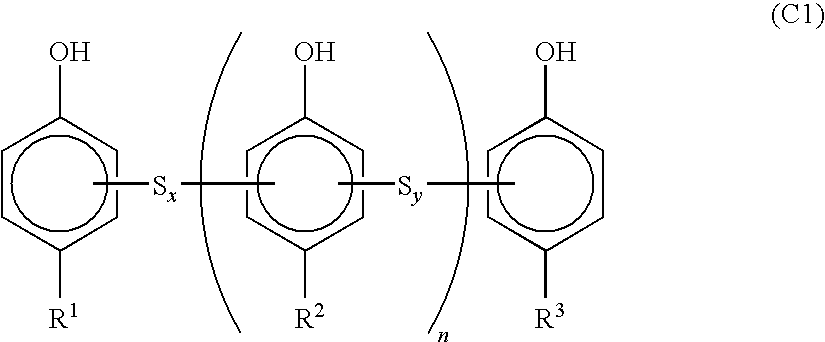

Rubber composition for inner liner and tire having inner liner comprising thereof

InactiveUS20100249278A1Superior in low heat build-up propertyIncreased durabilityOther chemical processesSpecial tyresPolymer scienceAlkylphenol

The present invention provides a rubber composition for an inner liner including 21 to 50 parts by weight of (B) carbon black and / or silica and 0.25 to 6 parts by weight of (C) an alkylphenol-sulfur chloride condensate indicated by the formula (C1):(Wherein R1 to R3 are same or different and either is an alkyl group having 5 to 12 carbons; x and y are same or different and either is an integer of 2 to 4; and n is an integer of 0 to 10.), wherein whole sulfur content is 0.3 to 1.5 parts by weight, based on 100 parts by weight of (A) a rubber component including 60 to 100% by weight of a butyl rubber for the purpose of keeping air permeation resistance and improving low heat build-up property and durability.

Owner:SUMITOMO RUBBER IND LTD

Preparation method of polymerization chlorination zinc iron sulfate flocculating agent

ActiveCN103771572ALow costLarge flocs settle quicklyWater/sewage treatment by flocculation/precipitationIron sulfateChemical oxygen demand

The invention discloses a polymerization chlorination zinc iron sulfate flocculating agent. The polymerization chlorination zinc iron sulfate flocculating agent is prepared from ferrous sulfate septihydrate, technical hydrochloric acid, water glass and zinc sulfate used as main raw materials and is low in cost, high in sedimentation speed and good in effect. Fe is oxidized by using sodium chlorate in a hydrochloric acid environment through accurate metering and design of a dosing method of an oxidizing agent. A preparation technology is simple, and the unit preparation cost of the flocculating agent is lower than that of a commercially available product. The content of an active ingredient, namely the full iron in the flocculating agent is relatively high; the flocculating agent does not contain potential harmful elements; and a beneficial element zinc is used as a complex, and polysilicic acid serving as a stabilizing agent and a coagulant agent participates in a preparation and flocculation reaction process. Experiments prove that the flocculating agent can be used for effectively treating feedwater and wastewater and has a very strong removal effect on turbidity, chemical oxygen demand (COD), total phosphorous (TP), total nitrogen (TN) and algae and chlorophyll a in alga wastewater.

Owner:深圳市佳耀生态环保科技有限公司

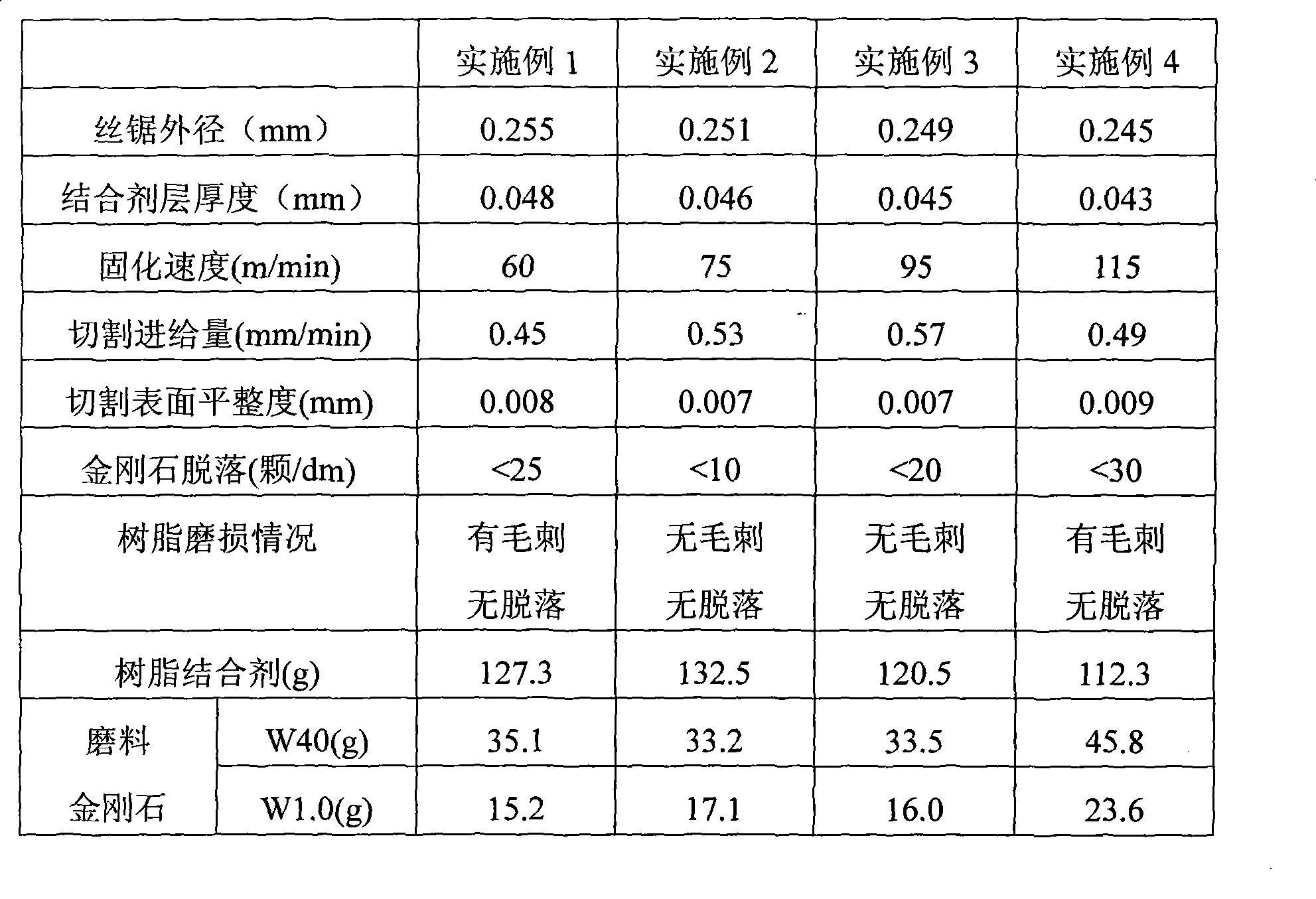

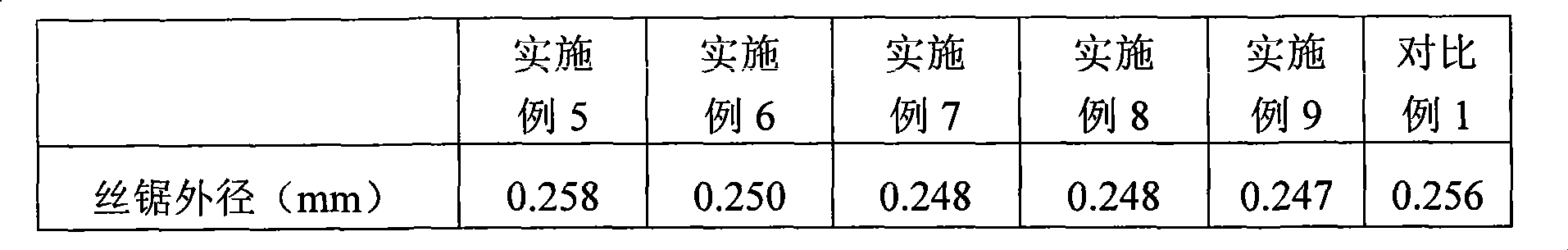

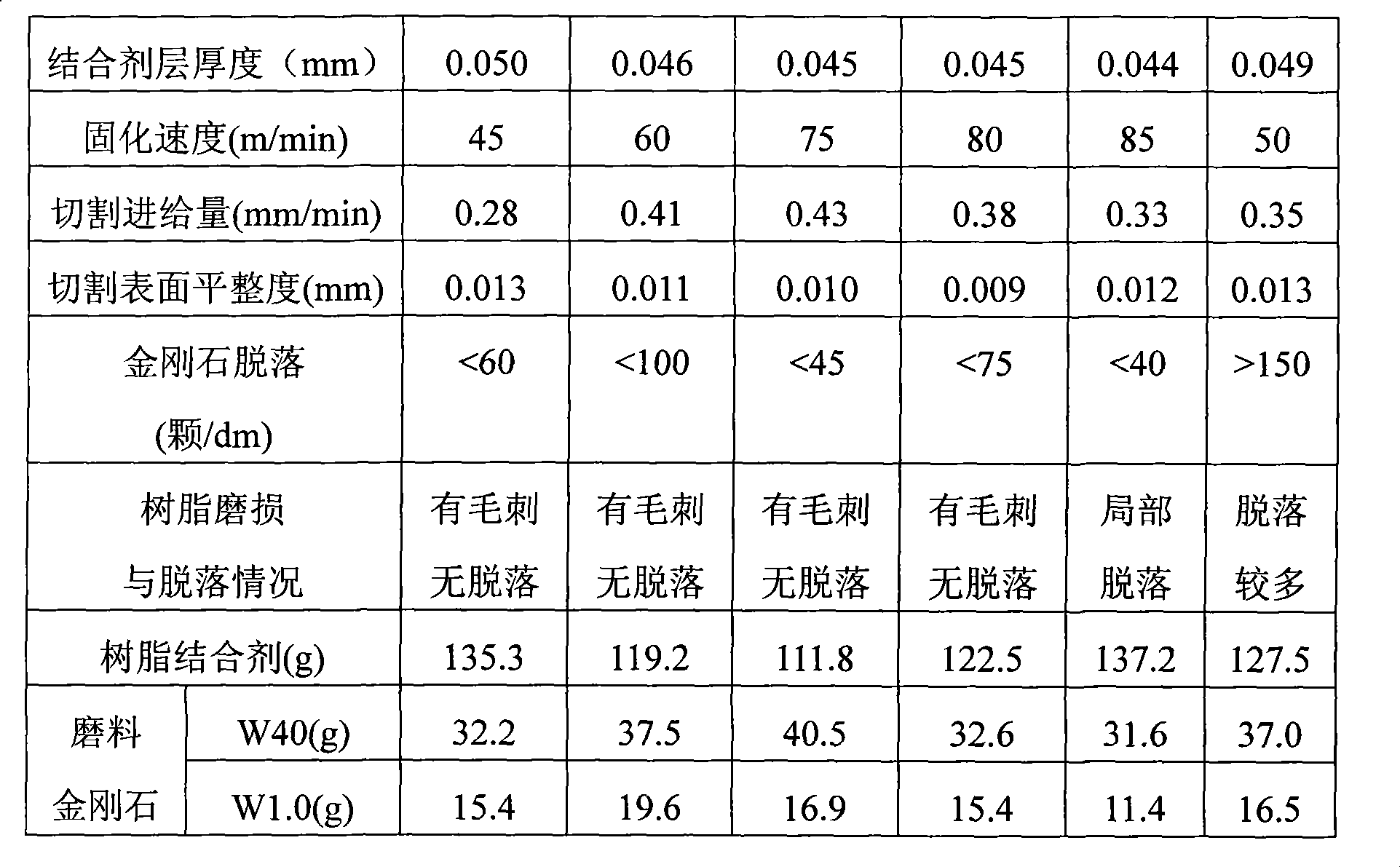

Resin binding agent for a diamond wire saw and preparation method thereof

InactiveCN101445587AReduce energy consumptionNo pollution in the processAbrasion apparatusVinyl etherPhosphate

The invention relates to a resin binding agent for a diamond wire saw and a preparation method thereof. The resin binding agent comprises the following components by the weight proportion: 30 to 90 portions of UV cured resin, 1 to 30 portions of solvents, 1 to 30 portions of inorganic fillers, 0.5 to 20 portions of mixed crystal whiskers, 0.5 to 10 portions of accelerating agents and 0.5 to 10 portions of coupling agents. The adopted resin is positive ion cured UV resin; a photoinitiator is selected from chloride diphenyl iodine salt or sulfur chloride triphenyl salt; and a prepolymer is selected from an activated epoxy compound or a polyalcohol mixture. The solvent is an activated monomer solvent; one or more of acrylic acid monomers or vinyl ethers with the simple function or the multifunction are adopted; the mixed crystal whisker is a silicon-contained crystal whisker and a polytetrafluoroethylene crystal whisker mixture; the accelerating agent is selected from a compound containing 1 to aziridine or ethylene phosphate, a vulcanization type chain transfer agent, and one or more of thiobarbituric acid ester different kwai or dodecyl mercaptan; and the coupling agent is a silane coupling agent. The invention has the advantages of low energy consumption, no pollution and high cutting efficiency.

Owner:NANJING NORMAL UNIVERSITY

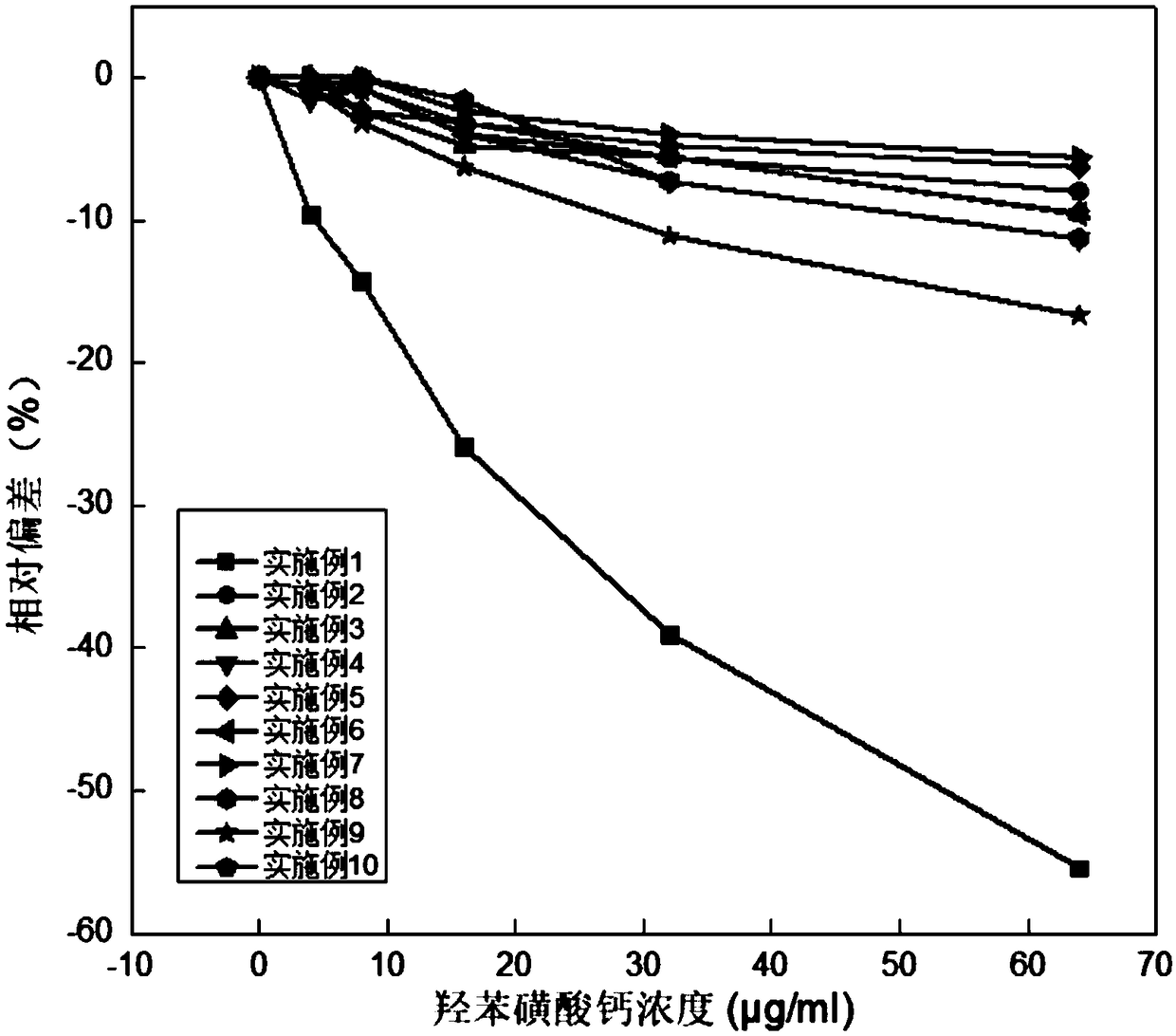

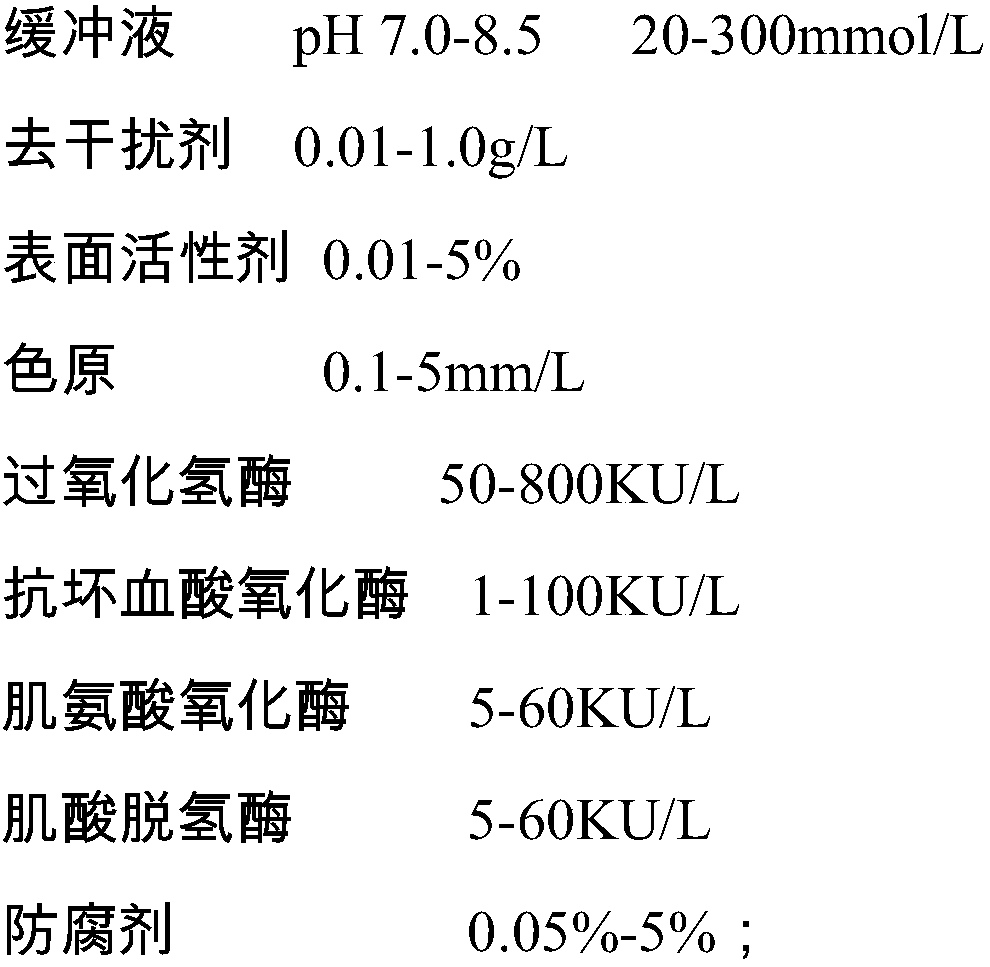

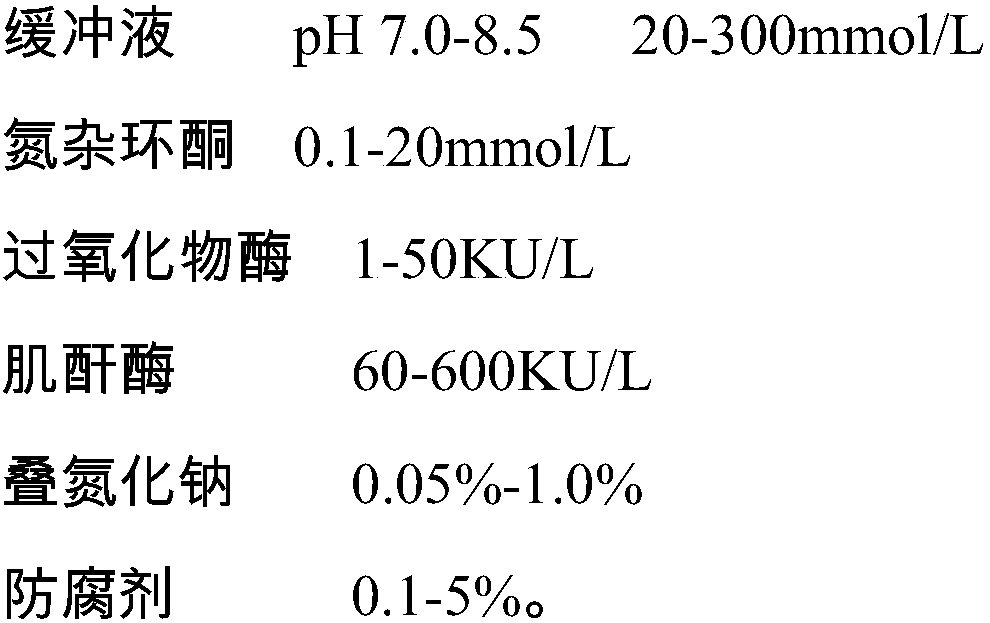

Composition for eliminating interference of calcium dobesilate medicine on creatininase-method detection

ActiveCN108627654ASolve the problem of serious negative interferenceDisease diagnosisBiological testingHigh concentrationCreatininase

The invention relates to a composition for eliminating the interference of a calcium dobesilate medicine on creatininase-method detection. The composition comprises an R1 reagent, an R2 reagent and ahigh molecular oxidant, wherein the high molecular oxidant is one or more of high molecular peroxy acid, high molecular selenium oxide, high molecular sulfur chloride ether, N-substituted imide, water-soluble tetrazole and a Dess-Martin oxidant. The high molecular oxidant in the composition disclosed by the invention can react with the calcium dobesilate in a sample to be detected, the calcium dobesilate loses the effect of interfering enzyme-method creatinine detection and the accuracy of sarcosine-oxidase-method detection is improved, so that the problem of serious negative interference, caused by high-concentration calcium dobesilate in blood of a patient, on an enzyme-method creatinine project detection result when the patient orally takes the calcium dobesilate medicine is solved.

Owner:WUHAN HANHAI NEW ENZYMES BIOLOGICAL TECH CO LTD

Sulfur-containing phenol formaldehyde resin and preparation method thereof

The invention provides sulfur-containing phenol formaldehyde resin and a preparation method thereof. Resin can be subjected to a reaction by taking phenol containing different substituent groups as raw materials and also can have the different sulfur contents. The molecular structure of the sulfur-containing phenol formaldehyde resin not only contains sulfur, but also contains a structure of the phenol formaldehyde resin. Sulfur can serve as a sulphur donor to achieve the crosslinking effect (such as a sulfurization reaction) and also can react with metal substances; the phenol formaldehyde resin can achieve the effects of bonding, reinforcing, insulating, high temperature resisting, corrosion resisting and the like, and therefore the phenol formaldehyde resin can be applied to the fields of rubber, plastic, paint, adhesives, printing ink, synthetic fibers, anti-corrosive and high-temperature-resisting materials, semiconductor materials and the like. The preparation method of the sulfur-containing phenol formaldehyde resin comprises the steps that phenol or alkylphenol is utilized to react with sulphur chloride to prepare a phenol or alkylphenol sulfide monomer or oligomer, the phenol or alkylphenol sulfide monomer or oligomer reacts with phenol or alkylphenol and formaldehyde under the acidic condition, and then the sulfur-containing phenol formaldehyde resin is prepared.

Owner:BEIJING RED AVENUE INNOVA

Method for recovery and purification of sulfoxide chloride in acyl chloride production

InactiveCN102992276AEfficient recyclingHigh recovery rateSulfur and halogen compoundsActivated carbonThree level

The invention relates to a method for recovery and purification of sulfoxide chloride in acyl chloride production, which comprises the following steps of: implementing primary purification by a distilling way; converting sulfur dichloride which is difficult to separate into sulfur chloride which is easy to remove by sulfur powder; and adsorbing other colored components by active carbon; and obtaining pure sulfoxide chloride which reaches three-level color degree. The method disclosed by the invention can effectively recover the sulfoxide chloride, and is high in recovery rate, good in quality, safe in process and easy in control; the purified sulfoxide chloride can reach 98.5% in purity and three-level color degree in color.

Owner:YANTAI TAYHO ADVANCED MATERIALS CO LTD +1

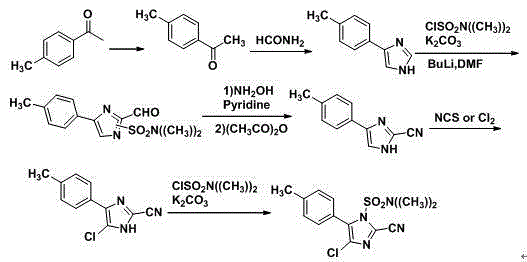

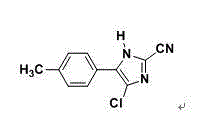

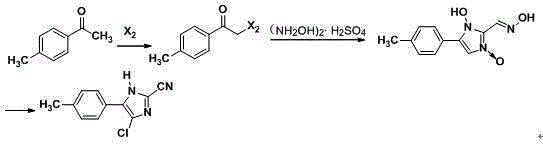

Synthetic method for 2-cyano-4-chloro-5-(4-methylphenyl)imidazole

The invention relates to a synthetic method for 2-cyano-4-chloro-5-(4-methylphenyl)imidazole. The synthetic method comprises the following steps: (1) by taking p-methylacetophenone as a raw material, carrying out a halogenating reaction under a light condition to obtain a compound I; (2) dissolving the obtained compound I in a solvent, stirring the mixture to react at a certain temperature, and performing cooling and suction-filtering to obtain a compound II; (3) dissolving the obtained compound II in a solvent and carrying out a reaction with glyoxal and hydroxylamine sulphate at a certain temperature to obtain a compound III; and (4) dissolving the obtained compound III in a solvent, carrying out a reaction with sulfoxide chloride in an ice bath in a manner of raising the temperature to room temperature and keeping the temperature for the reaction, dropwise adding sulfur chloride, and after reaction, washing the product to obtain a compound IV which is 2-cyano-4-chloro-5-(4-methylphenyl)imidazole. The synthetic method is good in atom economy, simple and convenient in process operation and high in product yield and industrial application value.

Owner:RUDONG ZHONGYI CHEM

Rubber composition for tire insulations and tire using same

ActiveCN103140549AExcellent low fuel consumption performanceIncreased durabilitySpecial tyresPneumatic tyre reinforcementsPolymer scienceEmulsion

For the purpose of improving rolling resistance and durability, the present invention provides a rubber composition for insulation of a tire comprising 0.2 to 4 parts by mass of (B) an alkylphenol-sulfur chloride condensate, and 20 to 59 parts by mass of (C) carbon black having a BET specific surface area of 25 to 50 m 2 / g based on 100 parts by mass of (A) a rubber component comprising 30 to 85% by mass of (a1) a natural rubber and / or an isoprene rubber, 0 to 70% by mass of (a2) at least one styrene butadiene rubber selected from the group consisting of an emulsion-polymerized styrene butadiene rubber, a solution-polymerized styrene butadiene rubber and a modified styrene butadiene rubber, and 0 to 60% by mass of (a3) a butadiene rubber, and a tire having insulation prepared from the rubber composition.

Owner:SUMITOMO RUBBER IND LTD

Rubber composition for tire

InactiveUS8383711B2Increase resistanceImprove stabilitySpecial tyresInflatable tyresRolling resistancePolymer science

The present invention relates to a rubber composition for a sidewall, a clinch and an insulation comprising 20 to 60 parts by mass of filler, 1.0 to 4.0 parts by mass of sulfur and 0.1 to 10 parts by mass of at least one vulcanization accelerating aid selected from a group comprising a citraconimide compound, an organic thiosulfate compound, an alkylphenol-sulfur chloride condensate, a compound represented by the formula (2) and a metal salt of methacrylic acid represented by the formula (3), based on 100 parts by mass of a diene rubber component comprising 10 to 70% by mass of at least one diene rubber component (a) selected from a group comprising a solution polymerization-modified styrene-butadiene rubber, a tin-modified butadiene rubber and a butadiene rubber whose terminal is modified with a compound represented by the formula (1), and 20 to 80% by mass of a diene rubber component (b) other than the diene rubber component (a) for the purpose of improving rolling resistance and steering stability.

Owner:SUMITOMO RUBBER IND LTD

Rubber composition for bead apex and pneumatic tire

InactiveCN102731855AImprove handling stabilityReduced handling stabilitySpecial tyresRolling resistance optimizationTire beadAlkylphenol

Owner:SUMITOMO RUBBER IND LTD

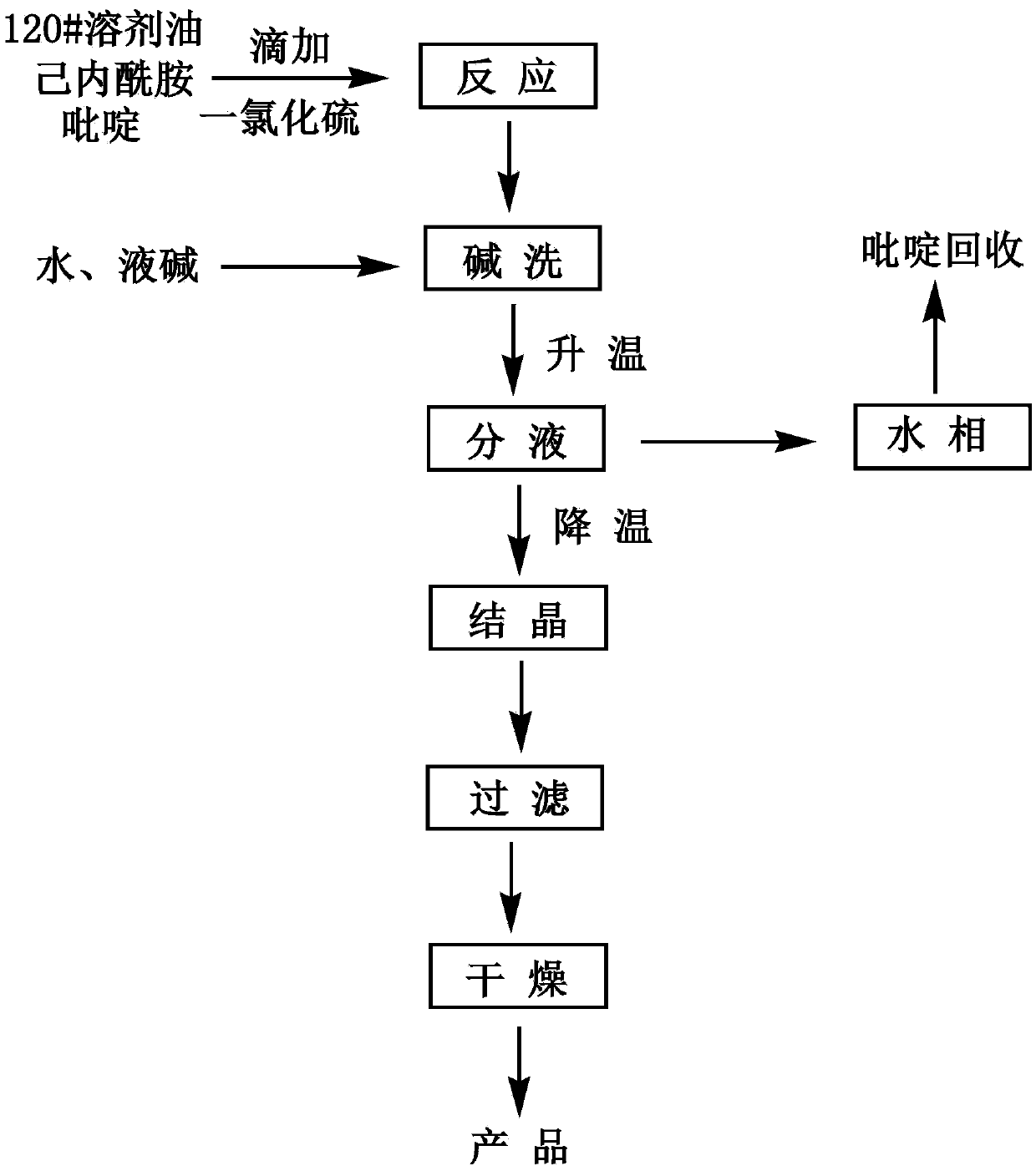

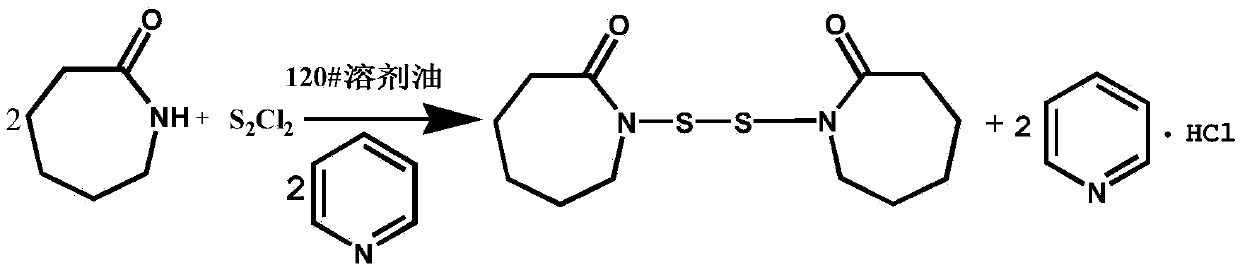

Synthetic method of vulcanizing agent 1,1-caprolactam disulfide

The invention relates to a synthetic method of a vulcanizing agent 1,1-caprolactam disulfide. The method comprises the following steps: adding solvent naphtha, caprolactam and pyridine in a reaction vessel in order, dropwise adding sulfur chloride at controlled temperature, and reacting to prepare a mixture; and neutralizing the mixture to a neutral state by adding water containing soda, heating and separating water to remove the water phase, cooling to crystallize, filtering, and drying to obtain a finished product. The method employs the 120# solvent naphtha as the solvent to achieve less volatilization of solvent in the production process; by heating water separation, the washing frequency is reduced, so as to reduce the wastewater discharge and greatly reduce the pollution to the environment. By using the solvent and the synthetic process, the product is crystallized by cooling, has improved quality of more than 98%, and increased yield of above 85%, and initial melting point of higher than 125 DEG C.

Owner:SHANDONG YANGGU HUATAI CHEM

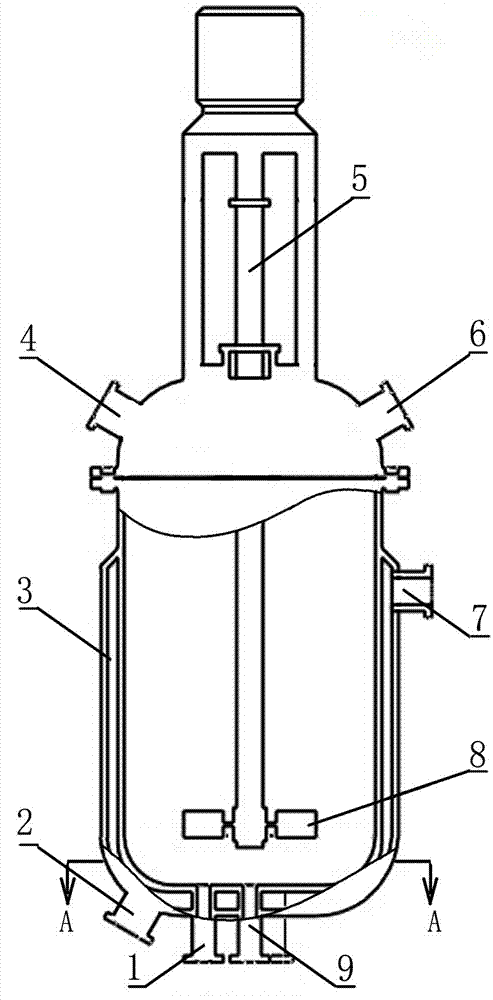

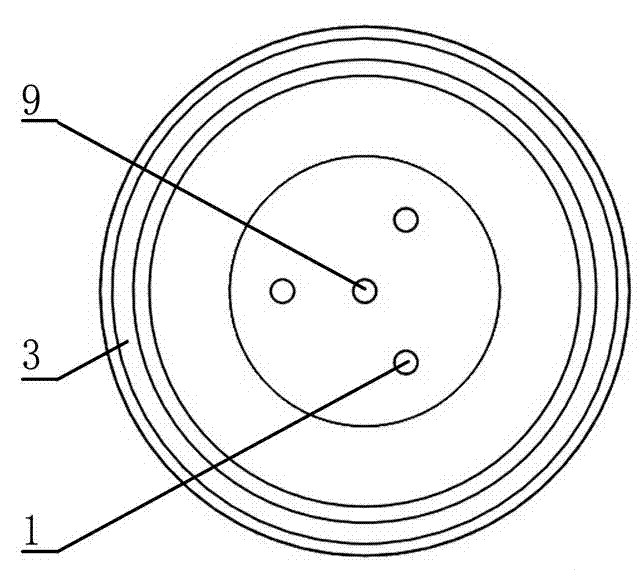

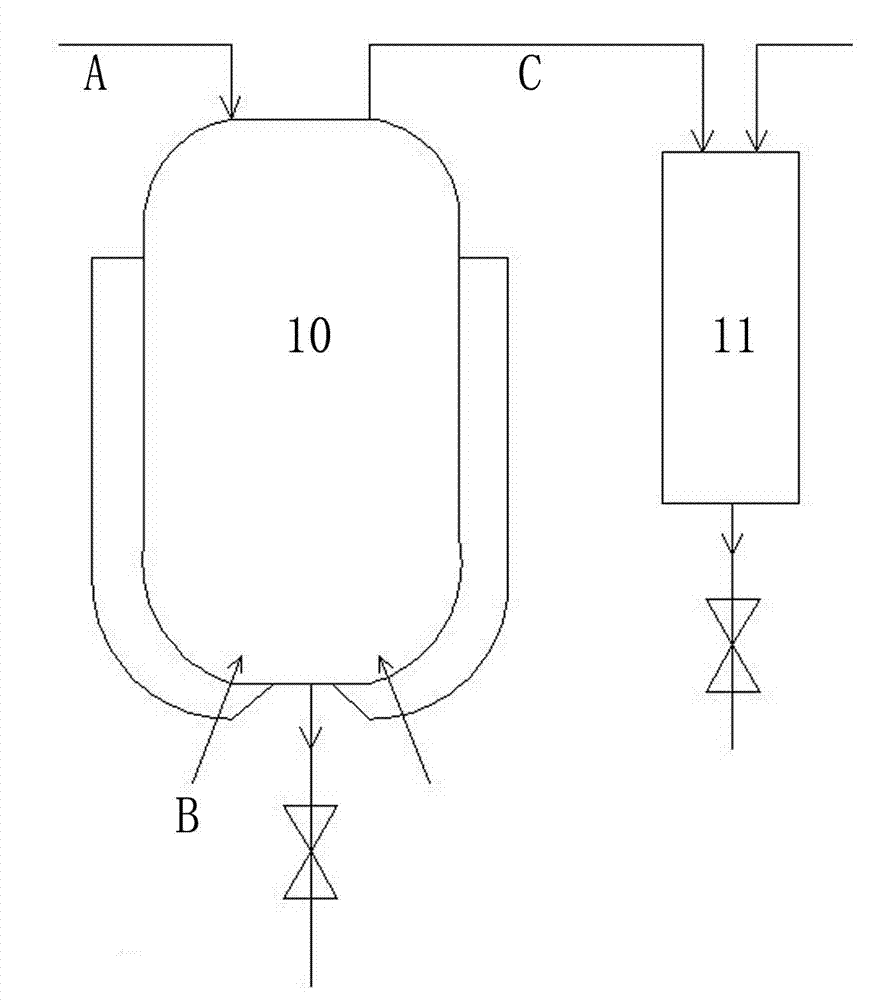

Sulfur chlorinated isobutylene production equipment and method

InactiveCN102949976ALess quantitySmooth responseOrganic chemistryChemical/physical/physico-chemical stationary reactorsGas liquid reactionWater chlorination

The invention provides sulfur chlorinated isobutylene production equipment, comprising an enamel gas liquid reaction kettle and a falling film absorption tower. According to the technical main points, the enamel gas liquid reaction kettle comprises an upper sealing head, a kettle body and a stirring shaft; a stirring blade is arranged on the stirring shaft; a jacket is arranged outside the kettle body; a cooling liquid inlet and a liquid outlet are arranged on the jacket; the upper sealing head is connected with the kettle body together; a feeding opening and an air exhaust opening are arranged at the upper part of the kettle body; the air exhaust opening is communicated with the falling film absorption tower; a discharging opening is arranged at the center of the bottom of the kettle body; an air inlet pipe is arranged at the bottom of the kettle body; and three to five air inlet pipes are uniformly and coaxially distributed on the rim of the discharging opening. The sulfur chlorinated isobutylene production equipment provided by the invention has the advantages that single sulfur chloride and isobutylene can be subjected to multipoint reaction, so that the reaction process tends to be stable, the reaction temperature is easy to control, side product amount can be reduced, the reaction time is shortened, the yield can be improved, and the production cost can be reduced; the isobutylene has sufficient reaction time, so that the raw materials can be prevented from being wasted; and the defects that the enamel has low toughness, is easy to break and the like can be overcome without arranging an individual air exhaust annular pipe, so that the occurrence of the safe accident can be avoided.

Owner:SHENYANG GUANGDA CHEM

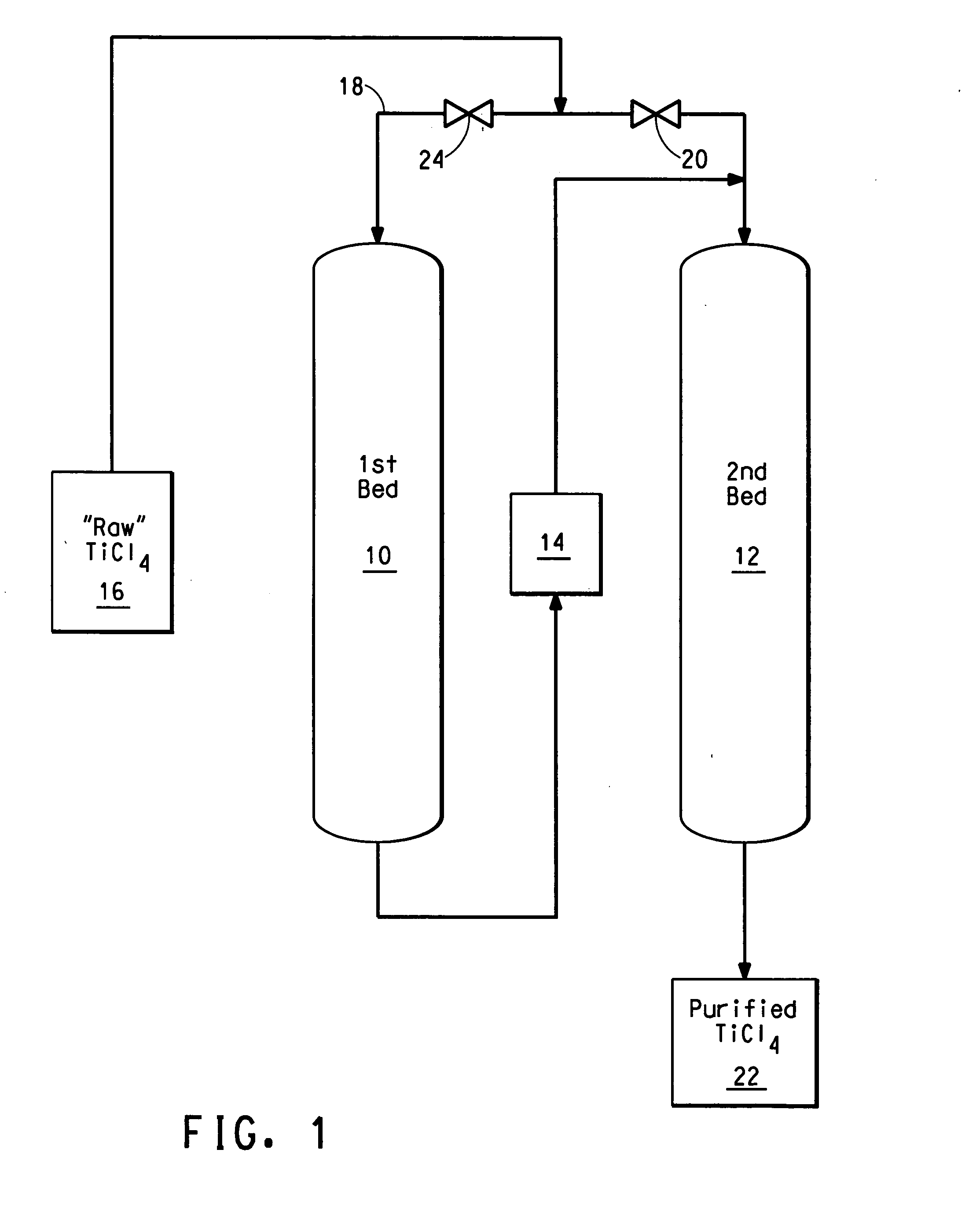

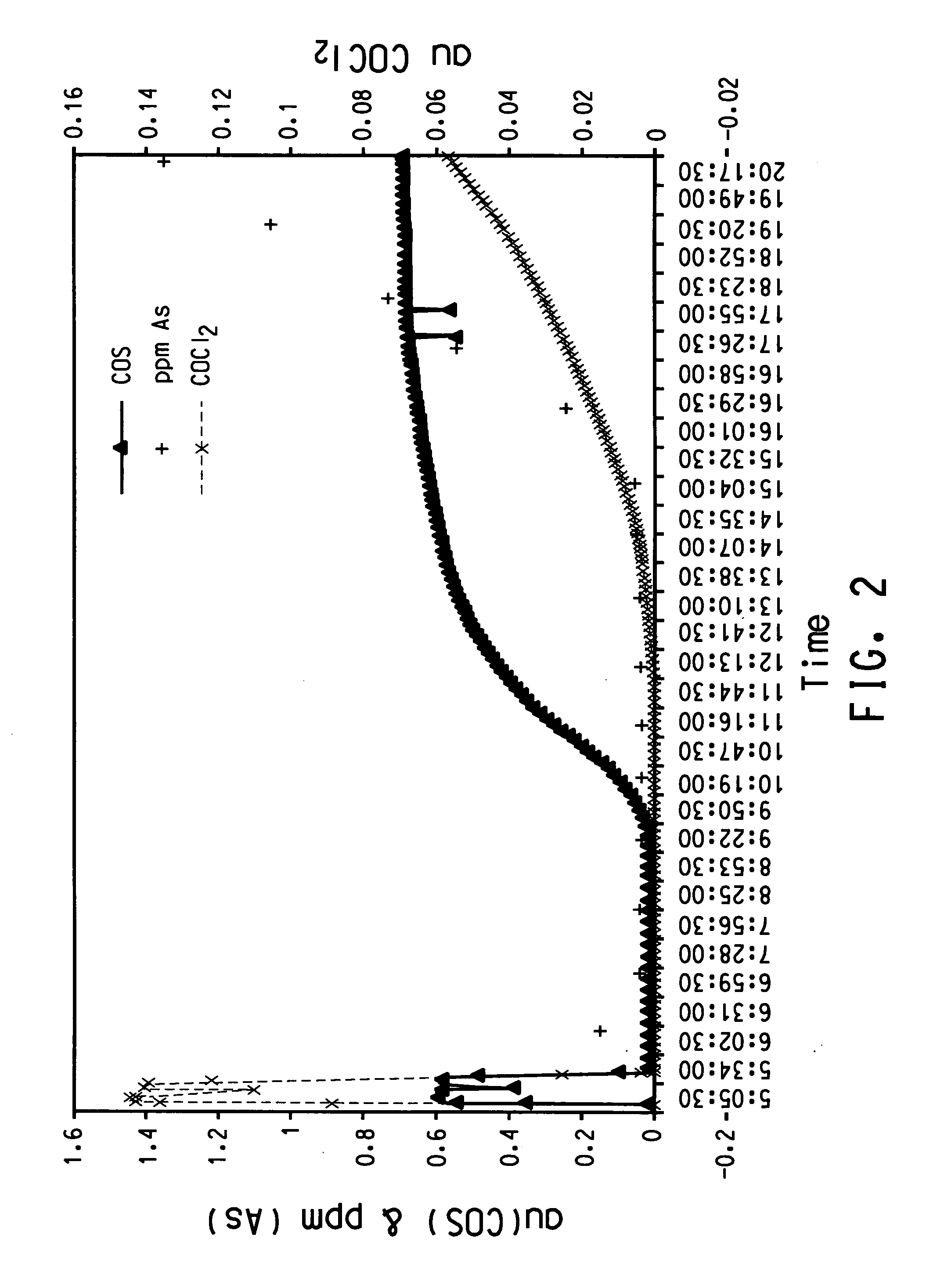

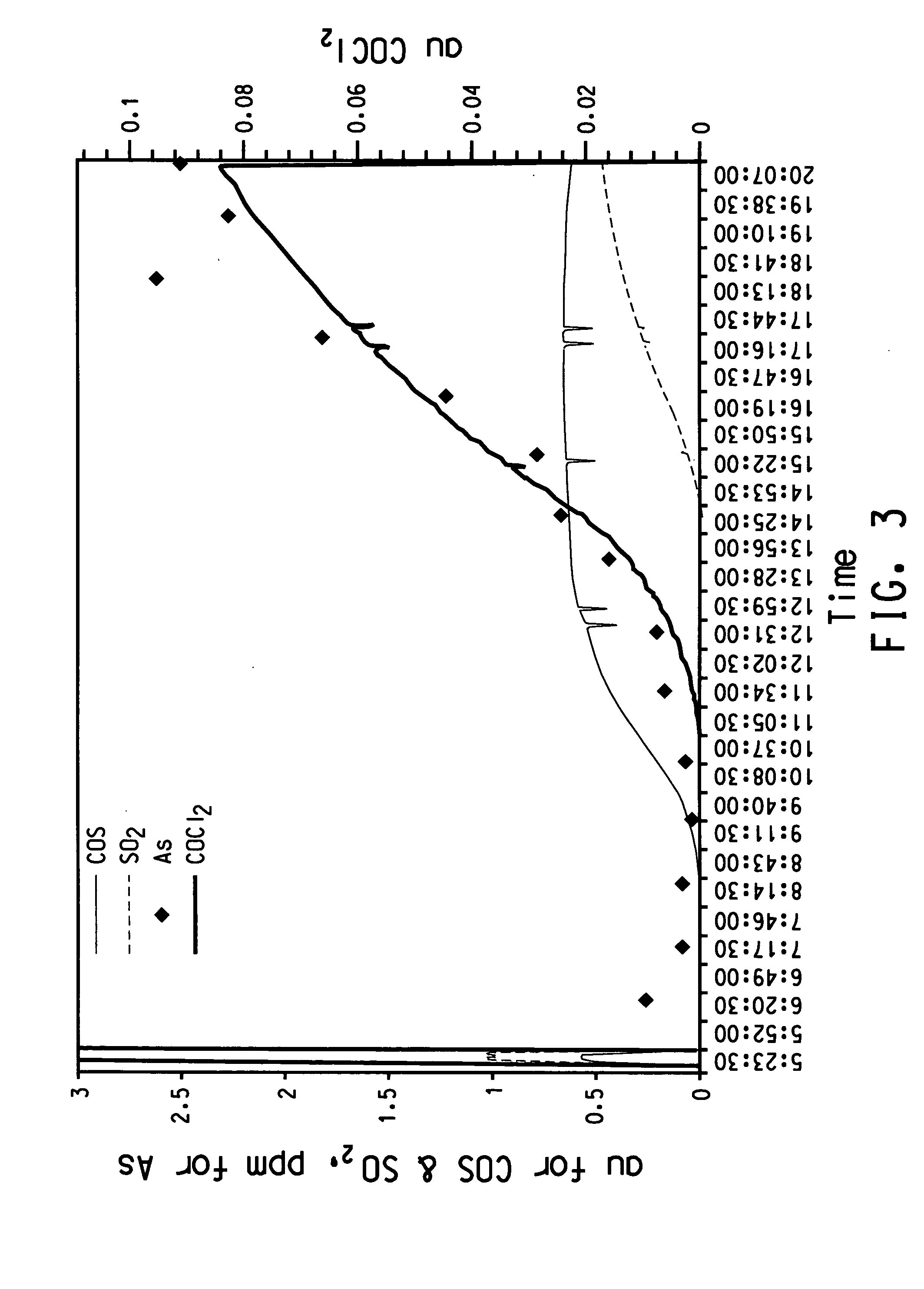

Process for purifying titanium chloride-containing feedstock

InactiveUS20060228292A1Easy to handleClose monitoringSolid sorbent liquid separationTitanium tetrachlorideTitanium chlorideCarbonyl sulfide

The disclosure is directed to a process for purifying a titanium chloride-containing feedstock using an activated carbon bed, comprising: (a) providing the titanium chloride-containing feedstock comprising an impurity, such as arsenic, and at least one tracker species selected from the group consisting of phosgene, carbonyl sulfide, sulfur dioxide, carbon disulfide, thionyl chloride, sulfur chloride, SO2Cl2, carbon dioxide, and hydrochloric acid and combinations thereof; (b) feeding the titanium chloride-containing feedstock to the activated carbon bed; (c) contacting the titanium chloride-containing feedstock with the activated carbon by flowing the feedstock through the activated carbon bed to remove at least a portion of both the tracker species and the impurity from the feedstock to form a treated product; (d) continuing the flow of the titanium chloride-containing feedstock at least until the tracker species is detected in the treated product; and (e) regenerating the activated carbon bed.

Owner:EI DU PONT DE NEMOURS & CO

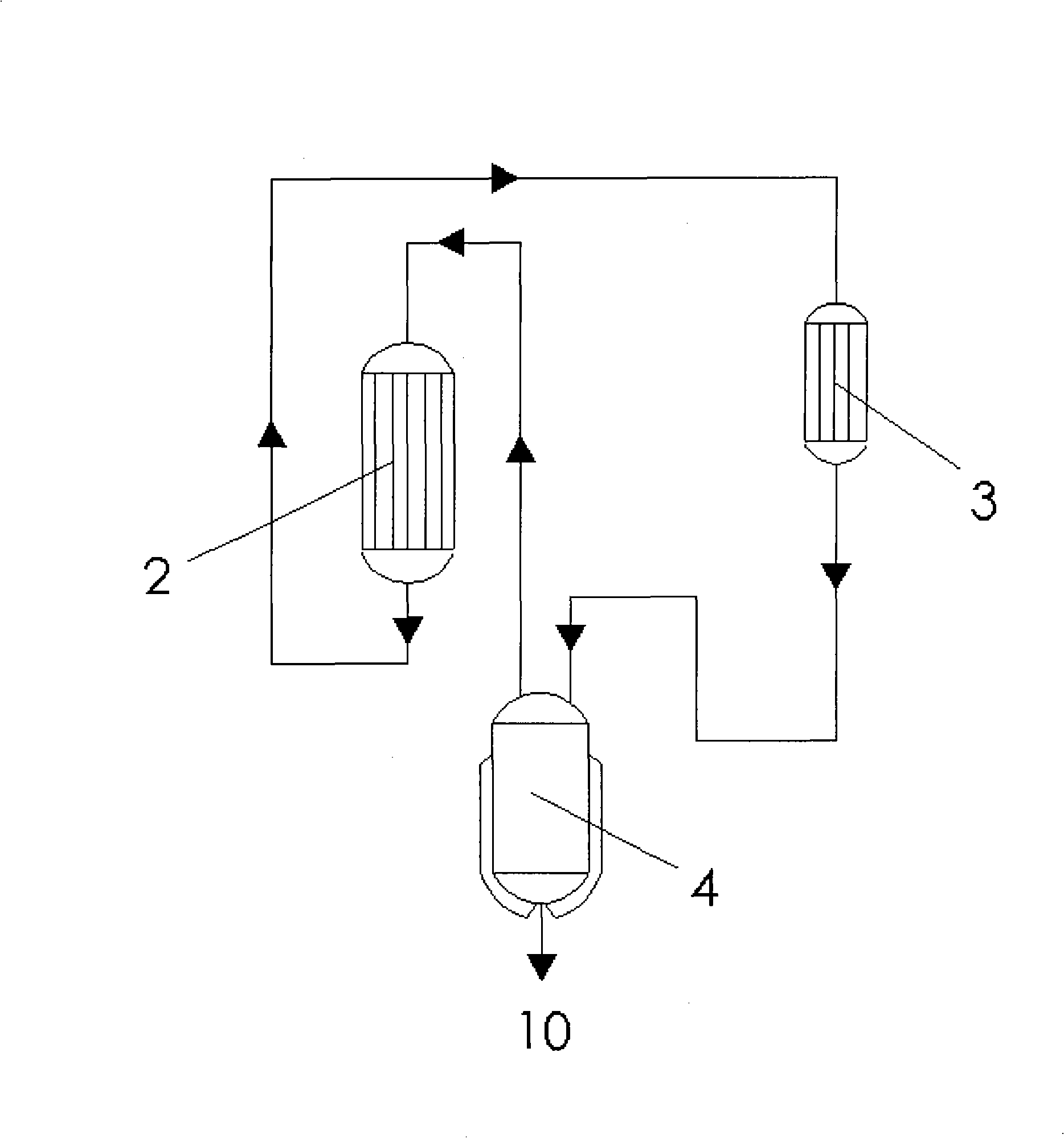

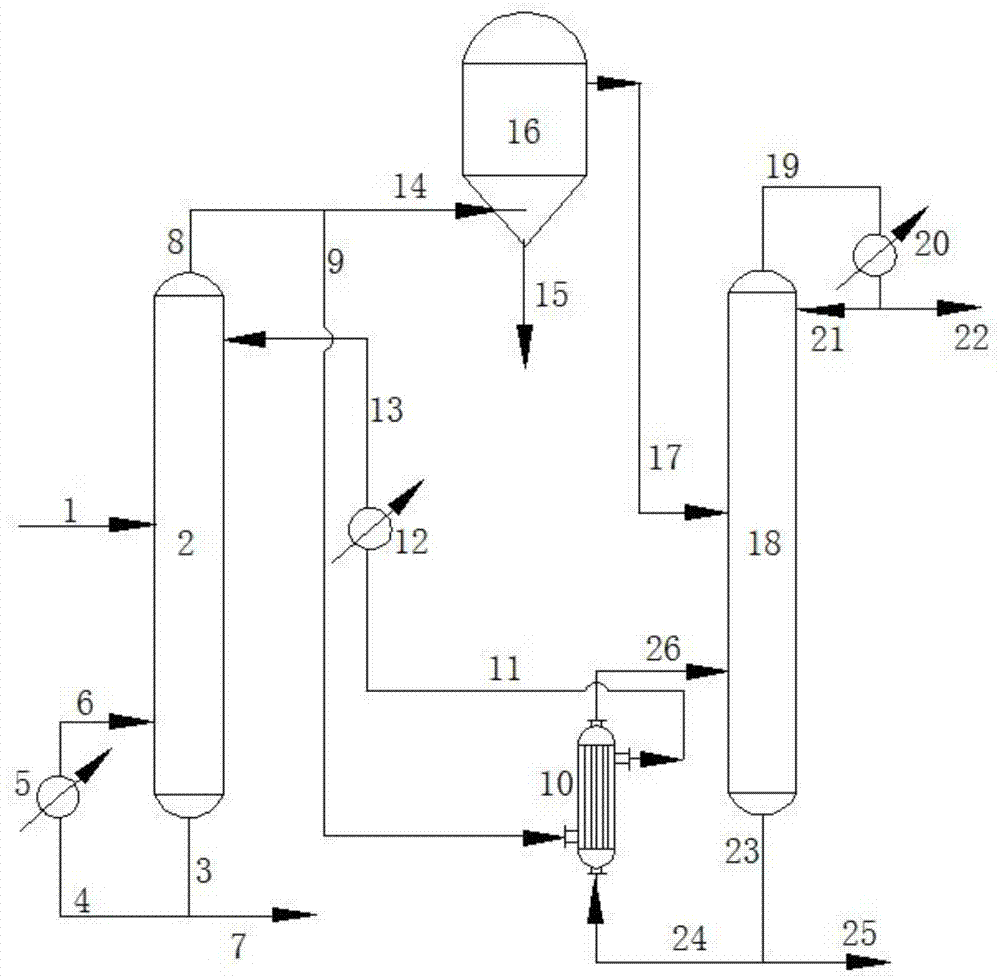

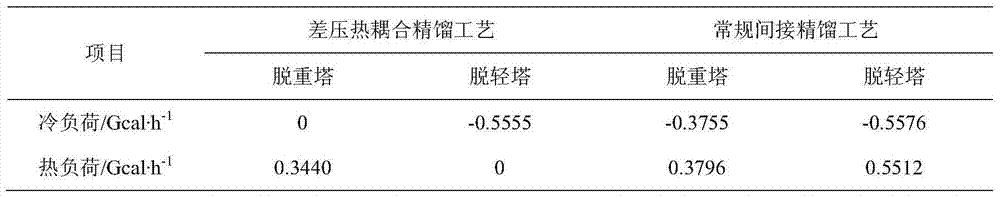

Differential pressure thermal coupling rectification method and equipment for sulfoxide chloride

ActiveCN103933751AReduce energy consumptionSolve problems affecting production scheduleChemical industrySulfur and halogen compoundsReboilerDifferential pressure

The invention relates to a differential pressure thermal coupling rectification method and equipment for sulfoxide chloride. According to the equipment, a heavy component removing tower of a re-boiler is arranged at the bottom of a tower and a light component removing tower of a condenser is arranged at the top of the tower; a condensation re-boiler, an auxiliary condenser and a conversion reactor are arranged between the heavy component removing tower and the light component removing tower. An extract of a vapor-phase material at the top of the heavy component removing tower is divided into two parts, wherein one part is connected with a heating medium inlet of the condensation re-boiler, a heating medium outlet is connected with the auxiliary condenser and then returns back to the top of the heavy component removing tower, a liquid-phase material outlet at the bottom of the light component removing tower is connected with a heated medium inlet of the condensation re-boiler, and then a heated medium outlet returns back to the bottom of the light component removing tower; the other part is connected with the conversion reactor to carry out a reaction of converting sulfur dichloride to sulfur chloride, and a reacted material vapor phase enters the light component removing tower. The differential pressure thermal coupling is used for coupling heat at the top of the heavy component removing tower and heat at the bottom of the light component removing tower and the energy consumption is saved. The difficulty of blocking a pipeline by sulfur is overcome. A practical example shows that a differential pressure thermal coupling rectification process can save energy by more than 50% compared with a conventional process.

Owner:SHANDONG KAISHENG NEW MATERIALS

Rubber composition for cap tread and tire having cap tread comprising the same

InactiveUS20100036019A1Low fracture strengthLow heat build-up propertySpecial tyresPolymer scienceAlkylphenol

A rubber composition for cap tread satisfying both of low heat build-up property and fracture strength and a tire having cap tread using the same are provided. A rubber composition for cap tread including 0.5 to 10 parts by mass of an alkylphenol-sulfur chloride condensate (B) indicated by the formula (B1):(wherein R1 to R3 are same or different, either is an alkyl group having 5 to 12 carbons; x and y are same or different, and either is an integer of 2 to 4; n is an integer of 0 to 10.), 0 to 0.45 parts by mass of sulfur (C), and 10 to 100 parts by mass of silica (D), based on 100 parts by mass of a specific rubber component (A).

Owner:SUMITOMO RUBBER IND LTD

Rubber composition for tread and tire having tread comprising the rubber composition

An object of the present invention is to satisfy both of the low heat build-up property and strength at break. The present invention provides a rubber composition for tread comprising 0.5 to 10 parts by mass of (B) an alkylphenol-sulfur chloride condensate indicated by the formula (B1):(wherein R1 to R3 are same or different, either is an alkyl group having 5 to 12 carbons; x and y are same or different, and either is an integer of 2 to 4; n is an integer of 0 to 10), 0.5 to 6 parts by mass of (C) sulfur, and 10 to 100 parts by mass of (D) silica, based on 100 parts by mass of the specific (A) rubber component comprising, and a tire having tread using thereof.

Owner:SUMITOMO RUBBER IND LTD

Rubber composition for insulation of tire and tire using same

InactiveUS20130137807A1Increased durabilityImprove rolling resistanceSpecial tyresPneumatic tyre reinforcementsPolymer scienceRolling resistance

For the purpose of improving rolling resistance and durability, the present invention provides a rubber composition for insulation of a tire comprising 0.2 to 4 parts by mass of (B) an alkylphenol-sulfur chloride condensate, and 20 to 59 parts by mass of (C) carbon black having a BET specific surface area of 25 to 50 m2 / g based on 100 parts by mass of (A) a rubber component comprising 30 to 85% by mass of (a1) a natural rubber and / or an isoprene rubber, 0 to 70% by mass of (a2) at least one styrene butadiene rubber selected from the group consisting of an emulsion-polymerized styrene butadiene rubber, a solution-polymerized styrene butadiene rubber and a modified styrene butadiene rubber, and 0 to 60% by mass of (a3) a butadiene rubber, and a tire having insulation prepared from the rubber composition.

Owner:SUMITOMO RUBBER IND LTD

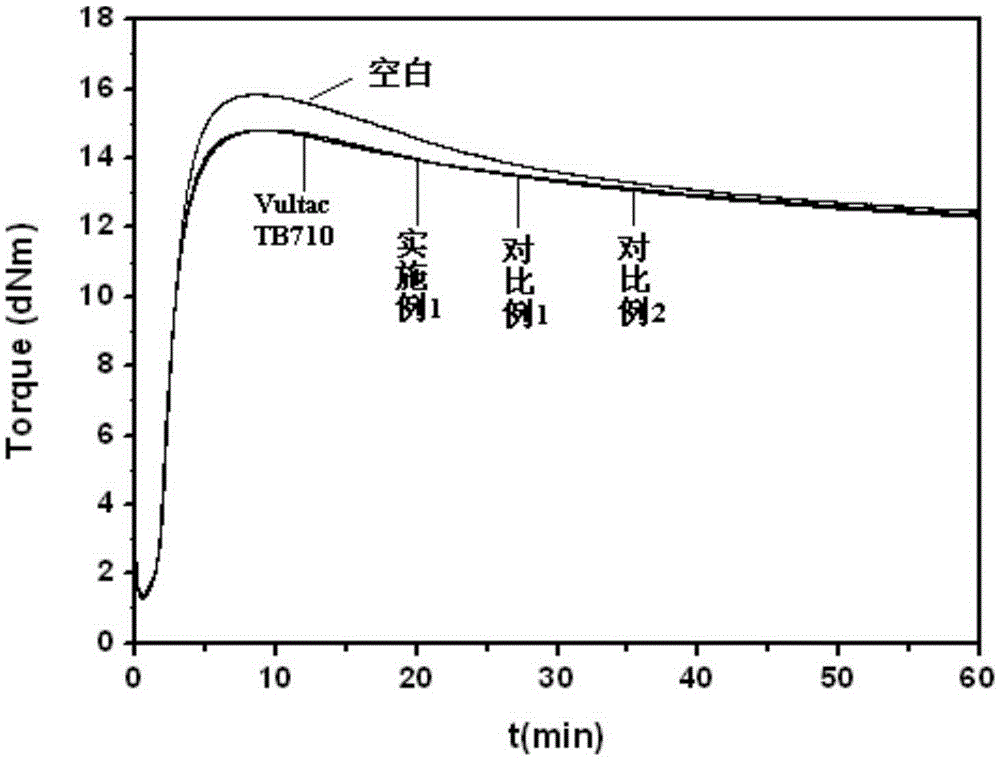

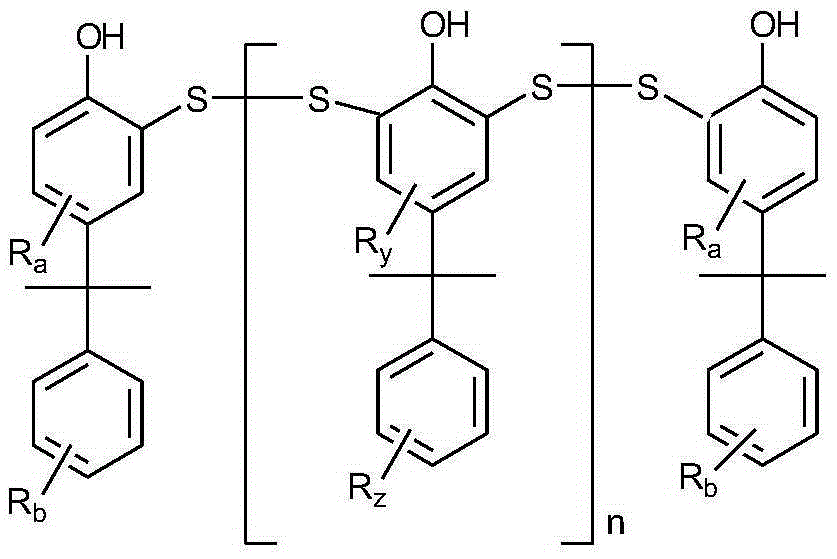

Alkylphenol sulfide and preparation method and application thereof

ActiveCN106565570ASimple preparation processEasy to industrializeHydropoly/poly sulfide preparationSulfide preparationRubber materialPolymer science

The invention relates to alkylphenol sulfide. The alkylphenol sulfide is obtained by reacting alkylphenol with sulfur chloride. When the alkylphenol sulfide serves as a sulfur donor to be used for rubber materials, the aging characteristic of rubber can be improved obviously. The structure of the alkylphenol sulfide is shown as formula (1): (please see the specification for the formula).

Owner:BEIJING RED AVENUE INNOVA

Method for synthesizing a variety of thiophenols by one-step method

The invention relates to a method for synthesizing a variety of thiophenols by a one-step method, belonging to the technical field of chemistry / chemical engineering. 2,4 - di-tert-butyl phenol acts with sulfur chloride in a solvent to be synthesized to the thiophenols. The method is characterized by comprising the following steps: in a petroleum ether solvent, firstly dissolving out a thiophenol, filtering, evaporating a filter liquor, removing the petroleum ether solvent, and then recrystallizing to obtain the mixture of other thiophenols. With simple operation and low cost, the method adopting the petroleum ether solvent has no toxic and side effect, safety, environment protection and easy industrial production.

Owner:淄博市新材料研究所

Rubber composition for tires, and pneumatic tire

InactiveUS8865803B2Improve economyEasy to processOrganic chemistrySpecial tyresPolymer scienceAlkylphenol

The invention relates to a rubber composition for a tire, containing an isoprene-based rubber and a compound represented by formula (1) below, wherein an amount of the isoprene-based rubber is at least 70% by mass; and an amount of the compound represented by formula (1) is 0.5-6 parts by mass per 100 parts by mass of the rubber component. The invention also relates to a rubber composition for a tire, containing an alkylphenol-sulfur chloride condensate and a compound represented by formula (1) below, wherein an amount of the alkylphenol-sulfur chloride condensate is 0.4-6 parts by mass, and an amount of the compound represented by formula (1) is 0.5-6 parts by mass, each per 100 parts by mass of a rubber component of the rubber composition:wherein R1 represents a C2-C16 alkyl group; and R2 represents a C3-C16 alkyl, benzothiazolyl-sulfide, or cycloalkyl group.

Owner:SUMITOMO RUBBER IND LTD

High and low temperature-resistant asphalt added with hexadecanol modifier and preparation method thereof

InactiveCN107828221AShort processing timeEase of mass productionBuilding insulationsGlycerolTemperature resistance

The invention discloses a high and low temperature resistant asphalt added with cetyl alcohol modifier and a processing method thereof. The high and low temperature resistant asphalt is made of base asphalt, styrene-butadiene rubber, powdered sulfur chloride, montmorillonite, linolenic acid, glycerin aqueous solution, and cetyl alcohol. First, the base asphalt is heated, and then linolenic acid and powdered chlorine are added. Sulfur, styrene-butadiene rubber, montmorillonite, and asphalt are modified, and then through a high-speed grinding process, after the dispersion is uniform, glycerin aqueous solution and cetyl alcohol modifier are added to further modify its stability. Finally, the product can be obtained after cooling down and developing in the later stage. The prepared modified asphalt product is not prone to delamination, and the processing flow is short, so it has a good application prospect.

Owner:莫春妹

Method for producing rubber vulcanization agent 4,4'-disulfuration dimorpholine

The invention discloses a method for producing rubber vulcanizing agent 4, 4'-dimorpholinyl disulfide, which belongs to the chemical technical field. The method comprises the following steps: prime city naphtha is added in a reaction kettle; sodium hydroxide fine powder is added to the solvent gradually under stirring condition; drewamine is added to the solvent; sulfur chloride is dripped within three to four hours at a temperature between 20 and 60 DEG C; after the mixture reacts for half an hour, the stirring is stopped; the mixture is kept stand for delamination; the sodium chloride deposited in the lower layer is discharged out; materials in the kettle are added with small amount of water to wash the materials, and are filtered to reclaim the solvent; the solvent is subjected to centrifuge-dripping to obtain a white crystal product; and the product is dried to obtain rubber vulcanizing agent 4, 4'-dimorpholinyl disulfide. The method can improve the yield and quality of the product, and reduce waste water discharge. The product has a melting point higher than 122 DEG C and ash content less than 0.5 percent.

Owner:SANMENXIA XIAWEI CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com