Resin binding agent for a diamond wire saw and preparation method thereof

A diamond and bonding agent technology, applied in metal processing equipment, manufacturing tools, abrasives, etc., can solve the problems of low production speed, high cost, resin strength, resin and wire holding force can not meet the requirements of good cutting, etc. Low consumption and high cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

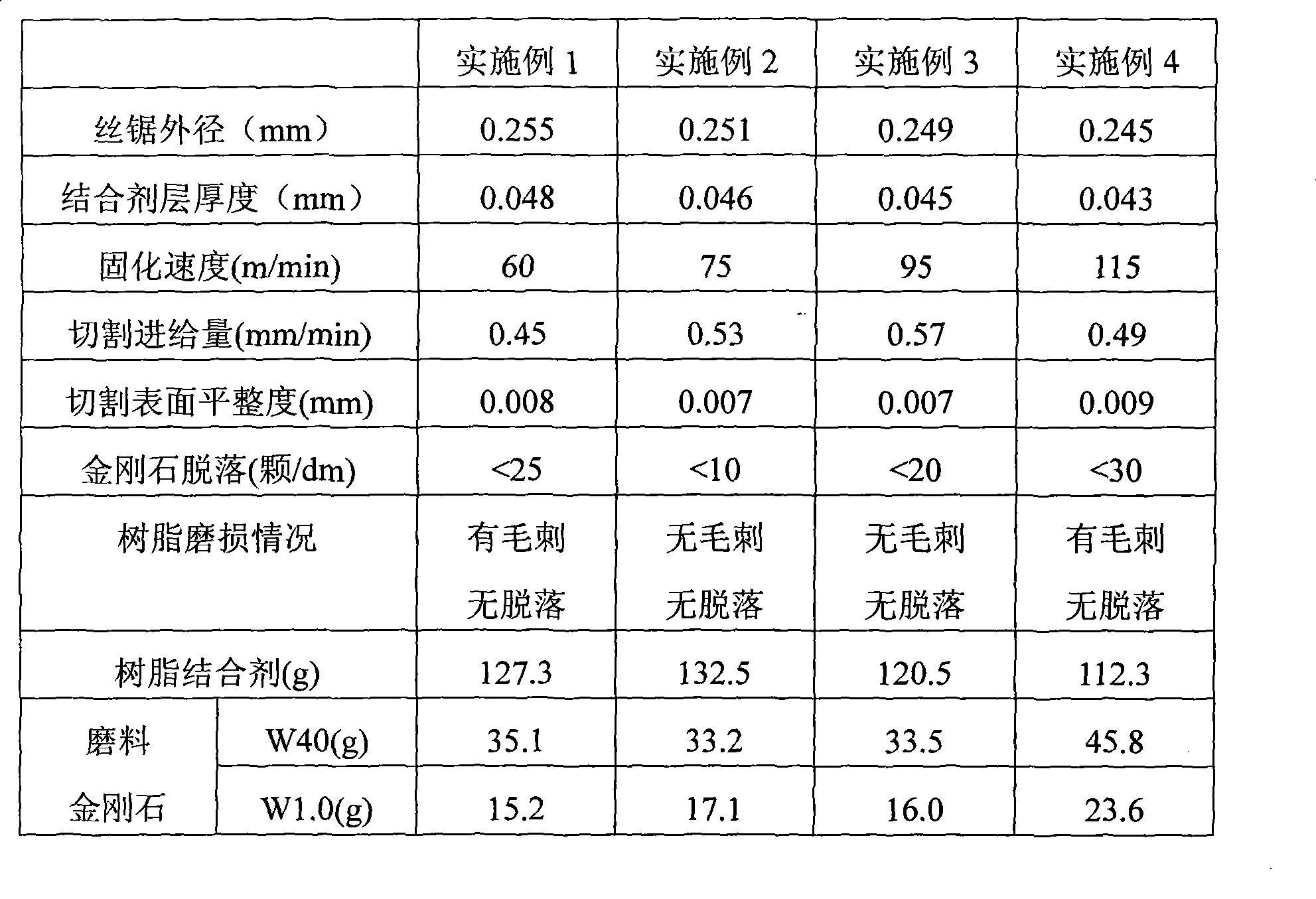

Embodiment 1

[0053]In parts by weight, the components and weight fraction ratio of the resin binder for diamond wire saw are: UV curable resin 40, solvent 25, inorganic filler 17, mixed whisker 10, accelerator 4.5, coupling agent 3.5. Wherein, the composition and weight fraction ratio of the inorganic filler are: 40% of aluminum oxide, 30% of silicon oxide, 10% of silicon carbide, 10% of cerium oxide, and 10% of chromium oxide. First, accurately weigh and mix the components of the mixed whiskers and inorganic fillers, grind them to ultrafine powder (0.5-5 microns), add the ultrafine powder to the UV curable resin in proportion, add a certain amount of solvent, Accelerator and coupling agent, obtain a kind of resin bonding agent for diamond wire saw.

[0054] Take 127.35g of this binder, 35.14g of W40 nickel-plated diamond powder, and 15.23g of W1.0 diamond powder, stir them evenly in a magnetic stirrer, and put them into the storage tank of the special coating device. On the special wire ...

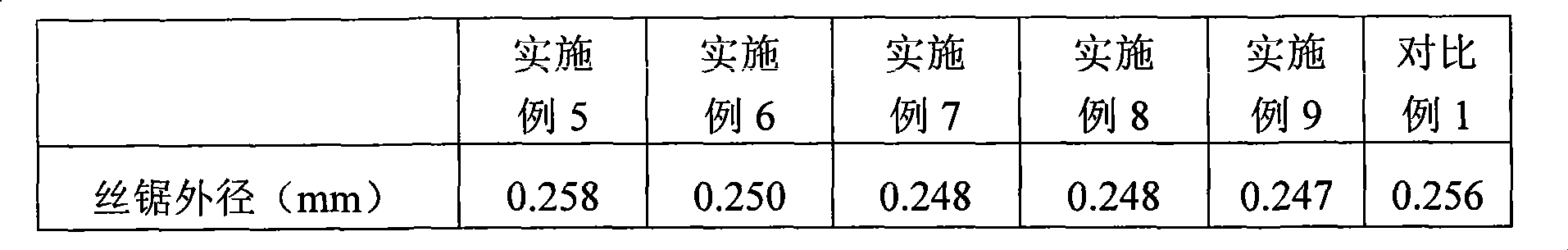

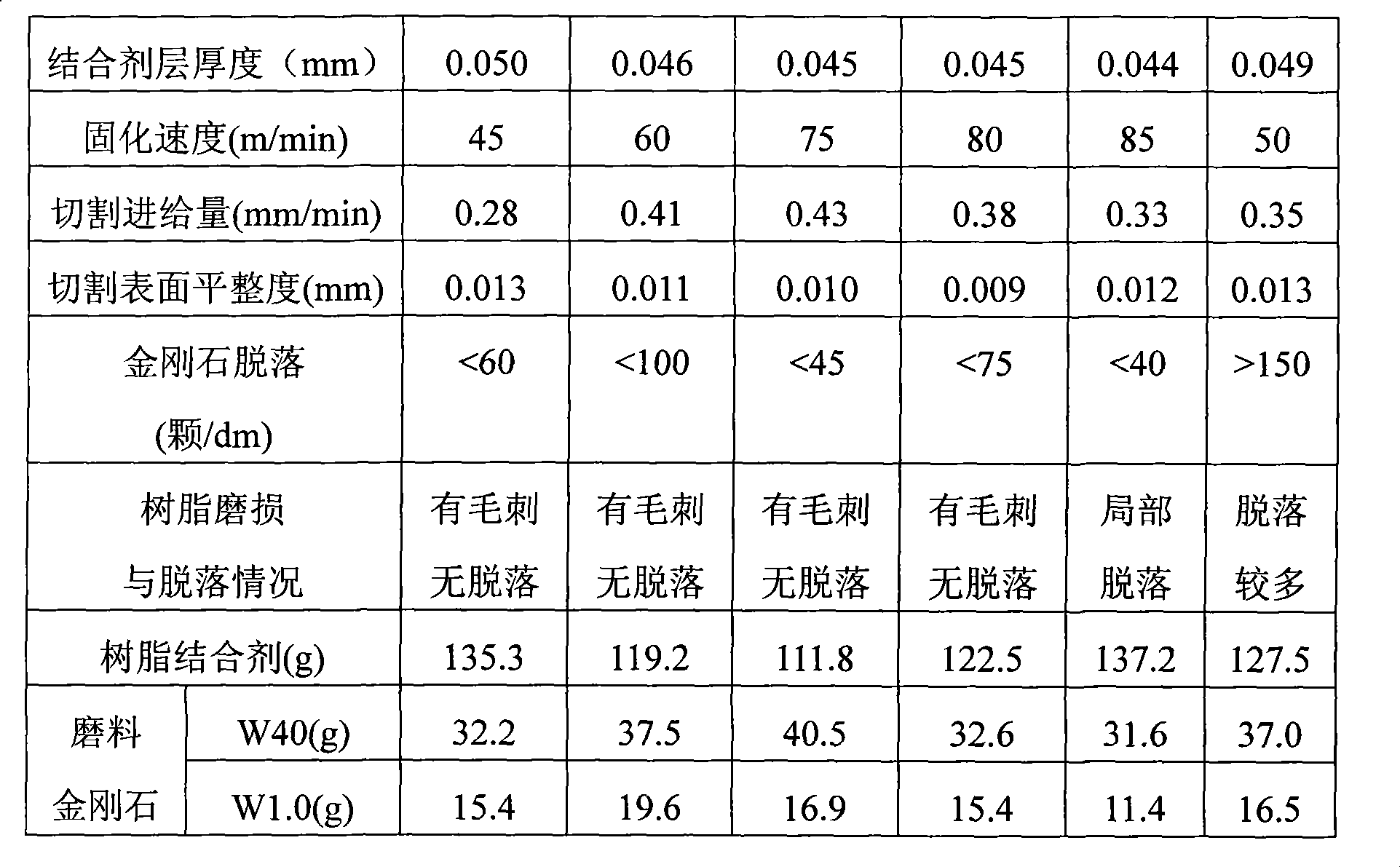

Embodiment 2

[0057] In parts by weight, the components and weight ratios of the resin binder for diamond wire saws are: 50 UV curable resins, 20 solvents, 20 inorganic fillers, 5 mixed whiskers, 3 accelerators, and 2 coupling agents. Wherein, the composition and weight fraction ratio of the inorganic filler are: 30% of aluminum oxide, 25% of silicon oxide, 15% of silicon carbide, 15% of cerium oxide, and 15% of chromium oxide.

[0058] The preparation method of the binder is the same as that of the wire saw in Example 1. The resin is selected from Taiwan EVERWIDE brand epoxy UV curable resin, and other materials are selected from the same example 1. The amount of resin binder and diamond used in the preparation of the wire saw is shown in Table 2.

Embodiment 3

[0060] In parts by weight, the components and weight fraction ratio of the resin binder for diamond wire saw are: UV curable resin 65, solvent 14, inorganic filler 15, mixed whiskers 3.5, accelerator 1.5, coupling agent 1. Wherein, the composition and weight fraction ratio of the inorganic filler are: 35% aluminum oxide, 35% silicon oxide, 15% silicon carbide, and 15% cerium oxide.

[0061] The preparation method of the binder and the preparation method of the wire saw are the same as in Example 1, and the selection of materials is the same as in Example 1. The amount of resin bond and diamond used in the preparation of the wire saw is shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com