Differential pressure thermal coupling rectification method and equipment for sulfoxide chloride

A differential pressure thermal coupling, thionyl chloride technology, applied in the fields of sulfur and halogen compounds, fractionation, chemical industry, etc., can solve the problems of high energy consumption, non-compliance with energy saving and emission reduction, and achieve energy saving and conveying equipment saving. and corresponding pipelines to achieve the effect of continuous production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

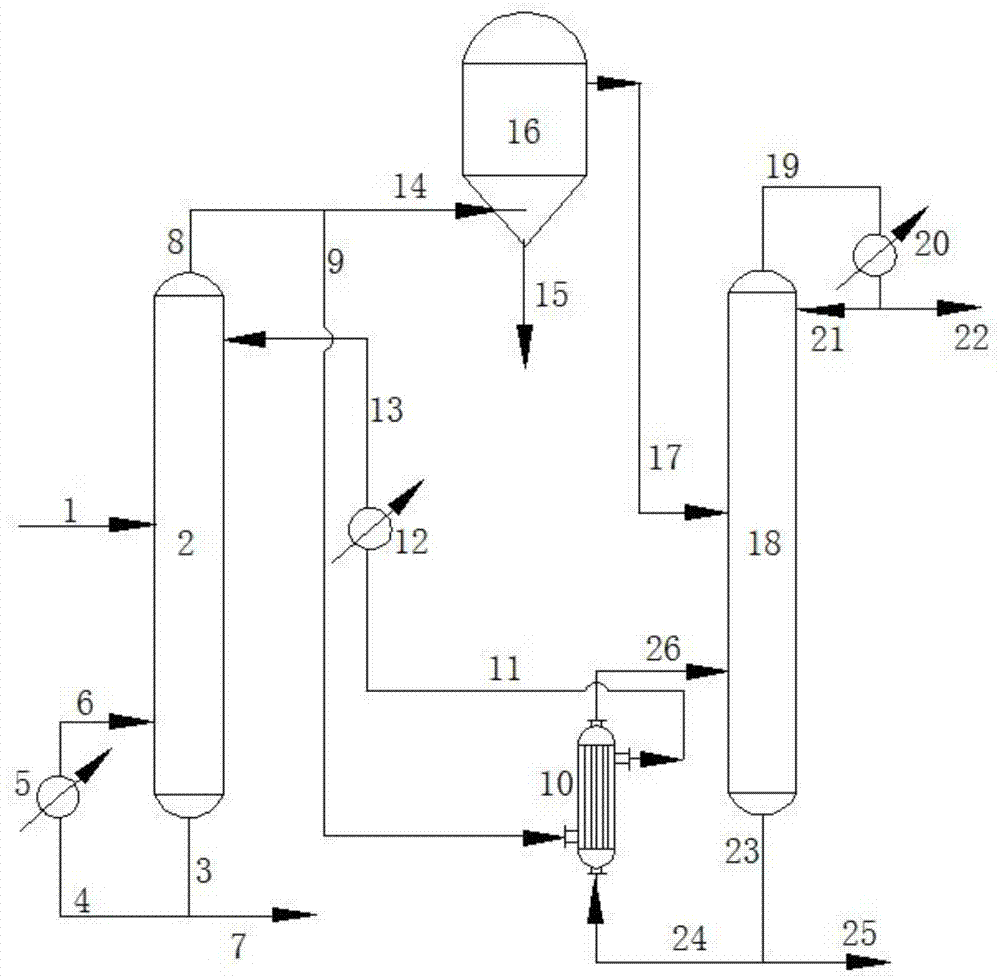

[0023] The technology and equipment provided by the present invention will be further explained below in conjunction with the drawings:

[0024] The main equipment involved in the present invention includes: a heavy-removing tower (2) with a reboiler (5) at the bottom, a light-removing tower (18) with a condenser (20) at the top of the tower, a heavy-removing tower (2) and A condensation reboiler (10), an auxiliary condenser (12) and a conversion reactor (16) are arranged between the light tower (18), and the vapor phase material at the top of the deweighting tower (2) is extracted into two parts: One part is connected to the heating medium inlet of the condensing reboiler (10), the heating medium outlet is connected to the auxiliary condenser (12), and then returned to the top of the de-weighting tower (2), and the liquid-phase material outlet at the bottom of the de-lighting tower is connected To the heating medium inlet of the condensing reboiler (10), the heating medium outle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com