Patents

Literature

78 results about "Sulfur dichloride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

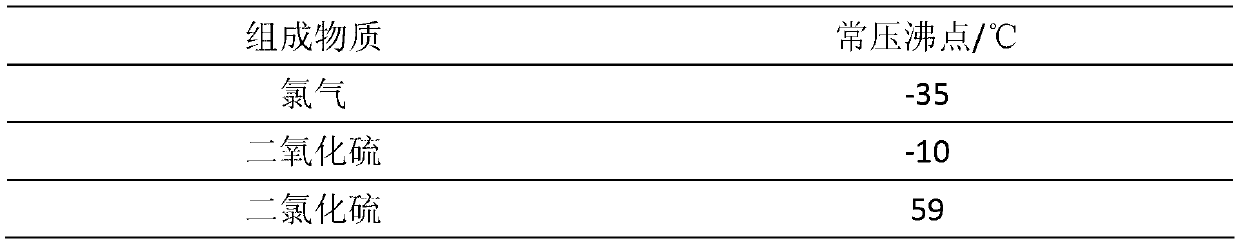

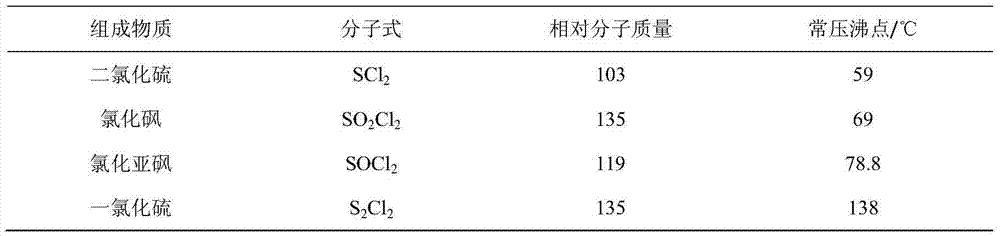

Sulfur dichloride is the chemical compound with the formula SCl₂. This cherry-red liquid is the simplest sulfur chloride and one of the most common. It is used as a precursor to organosulfur compounds.

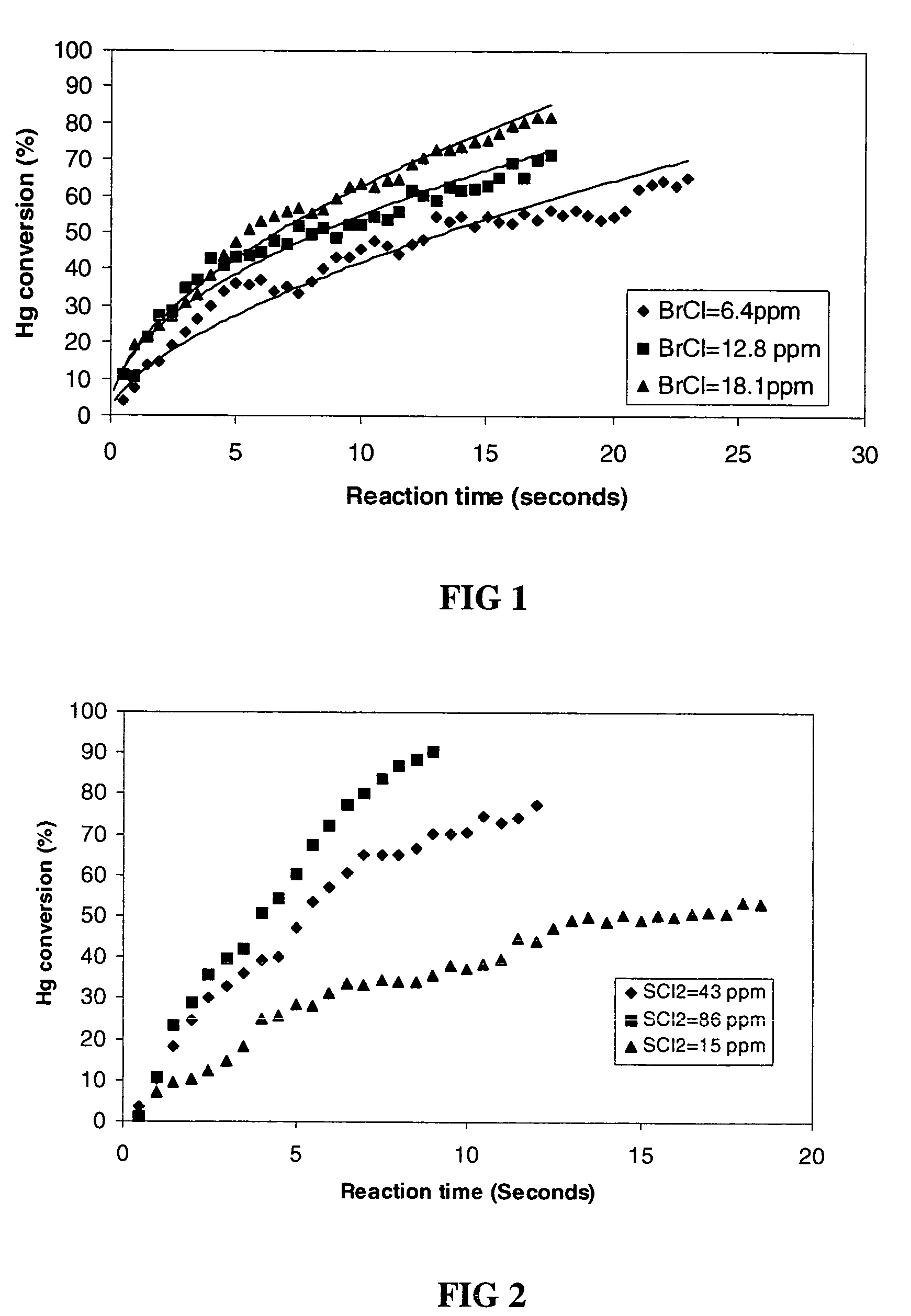

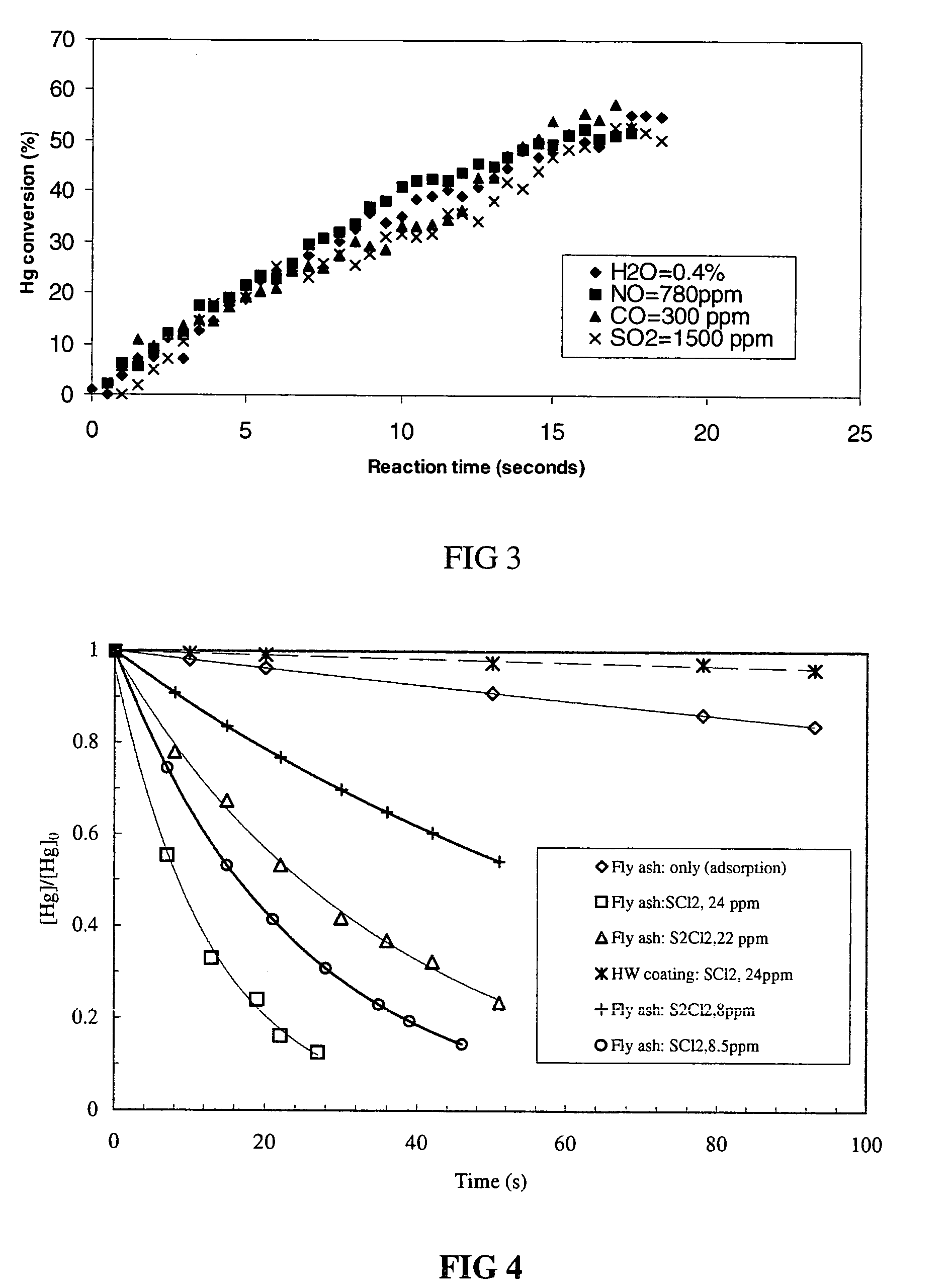

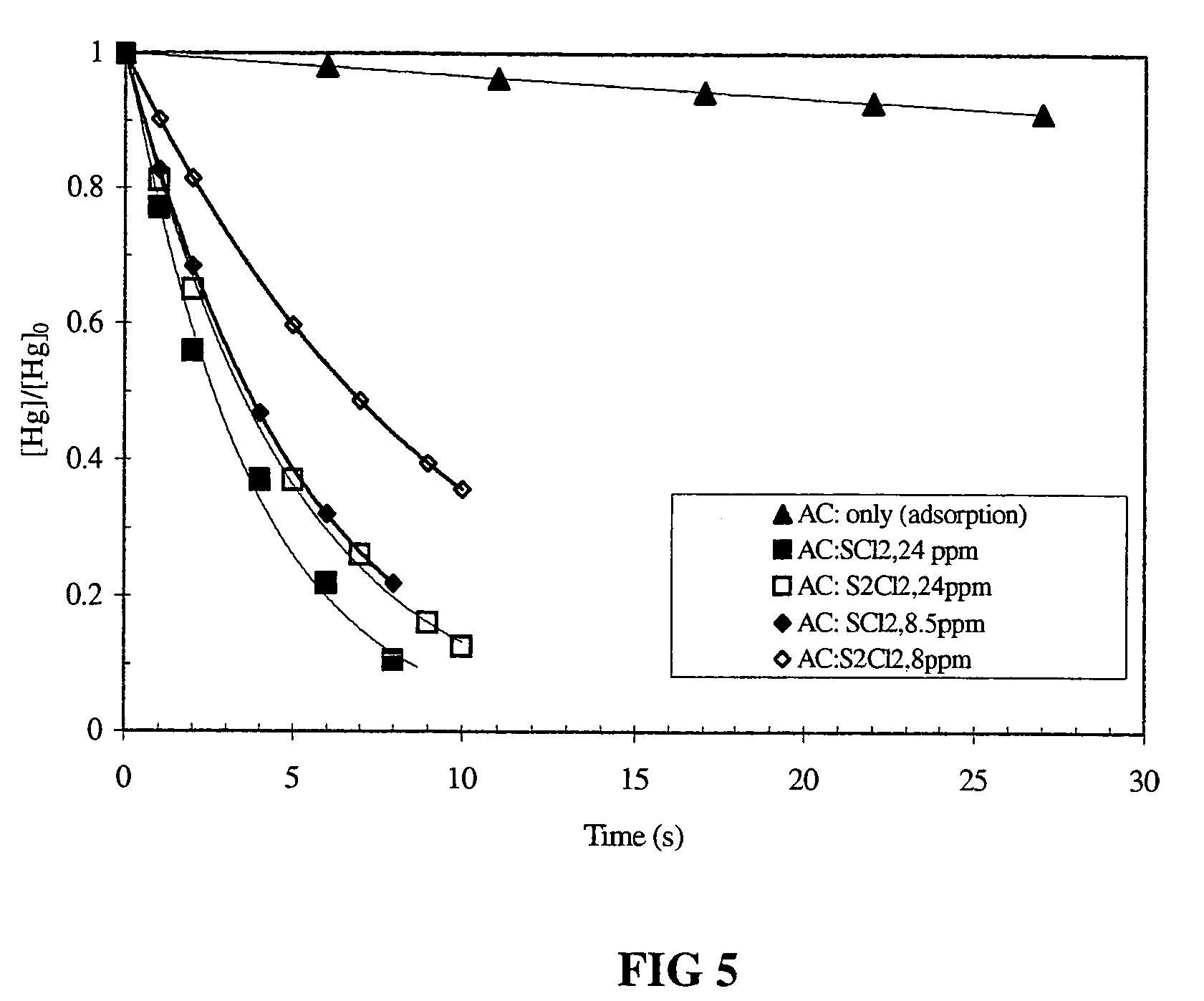

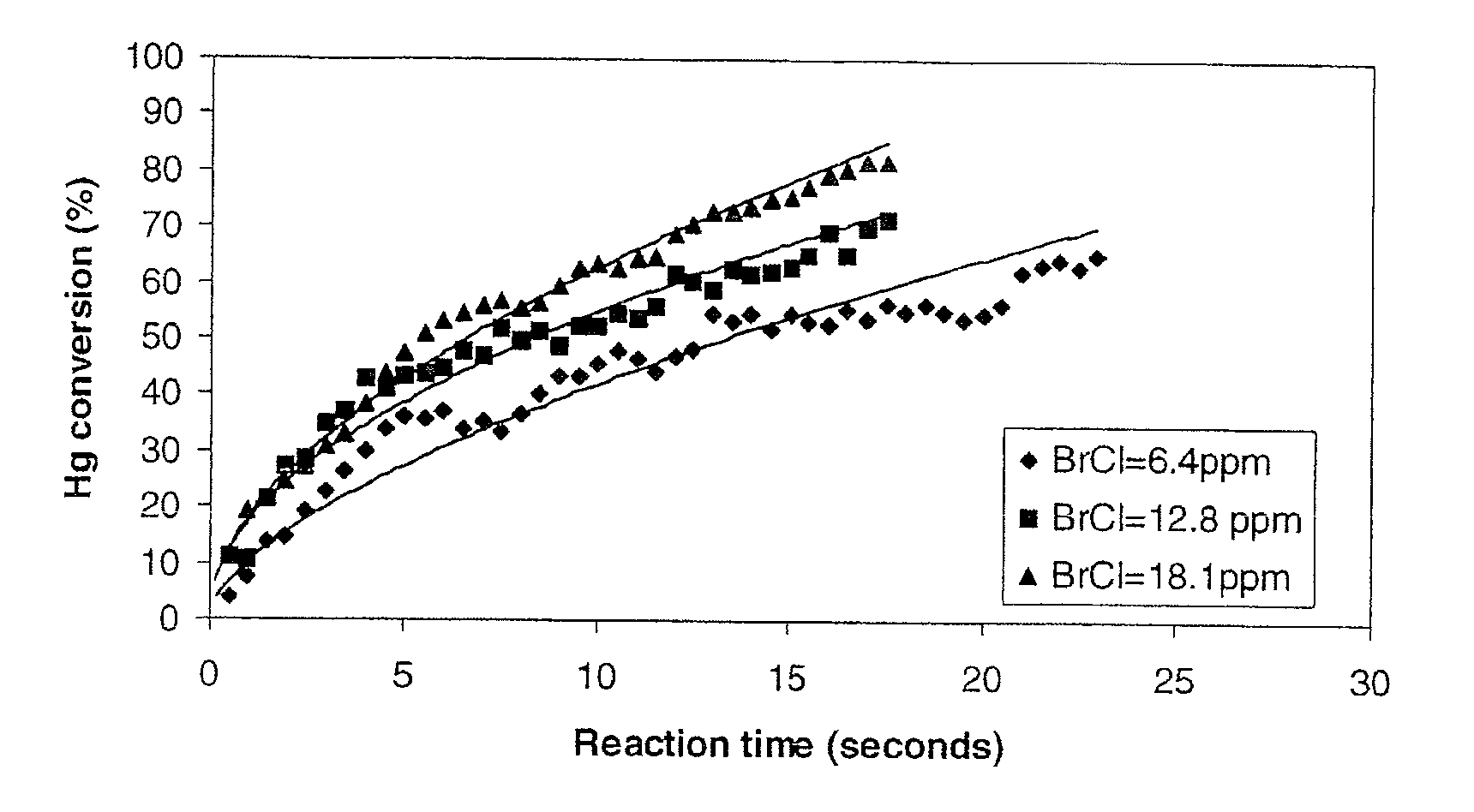

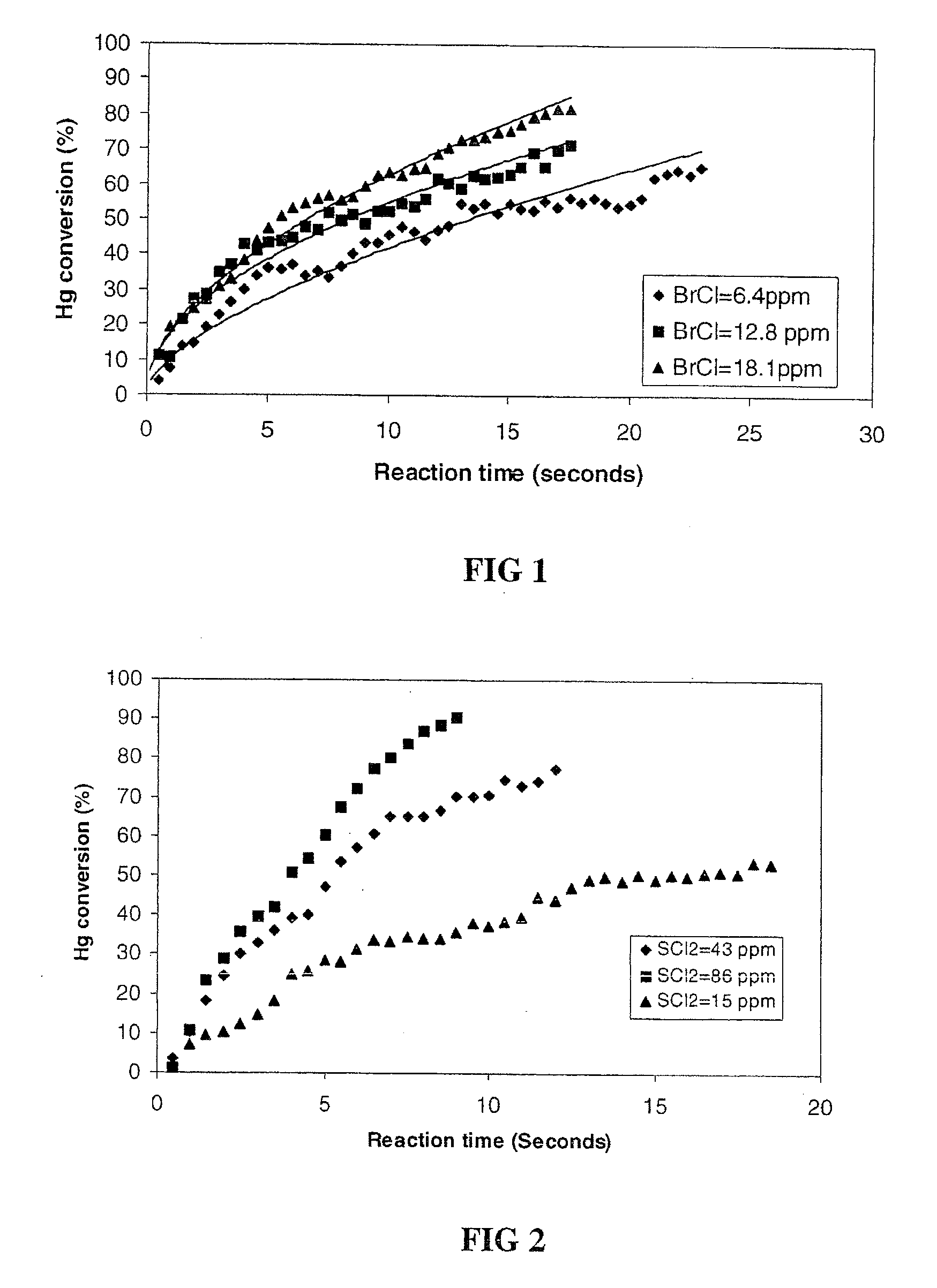

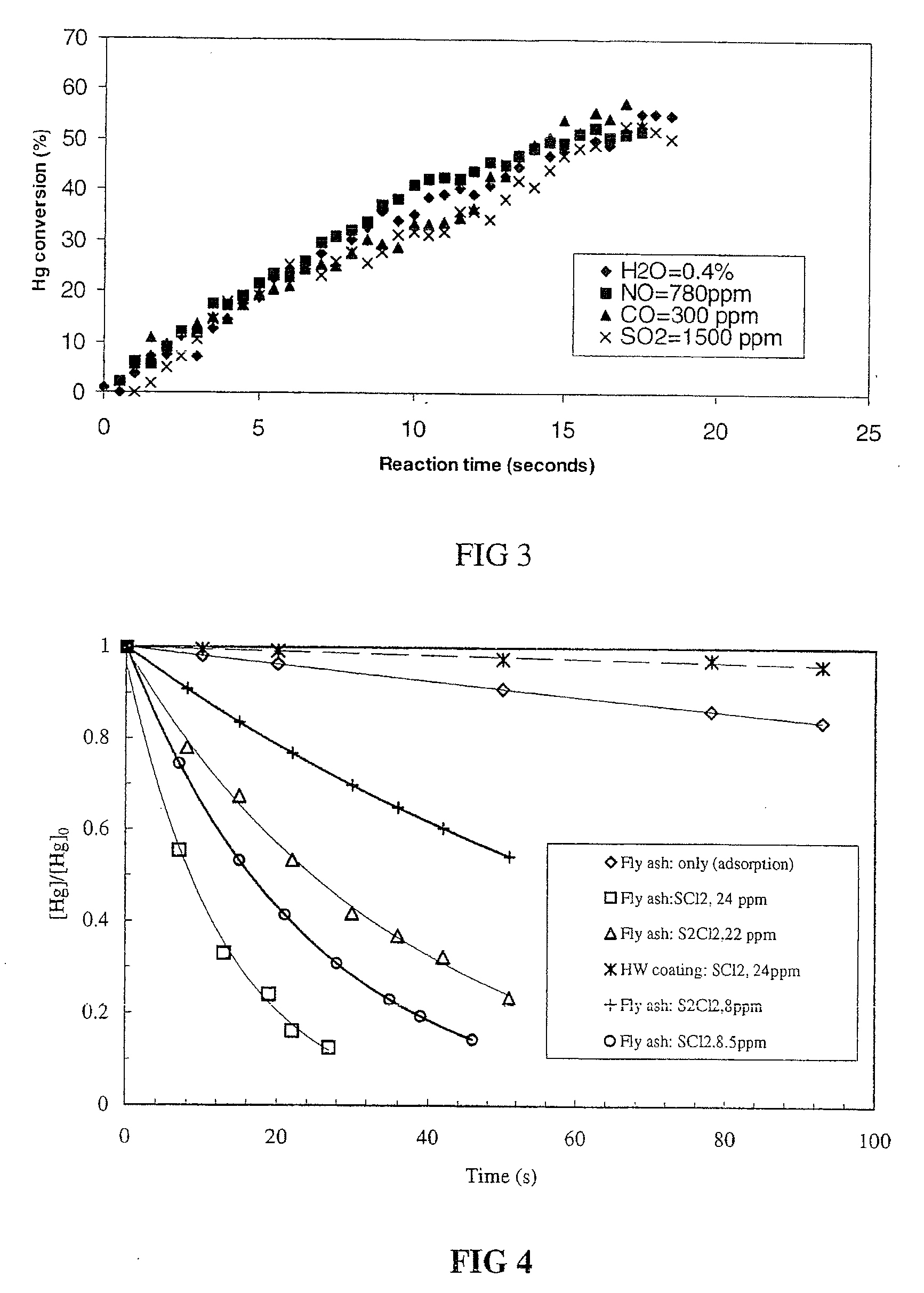

Method for scavenging mercury

Owner:RGT UNIV OF CALIFORNIA

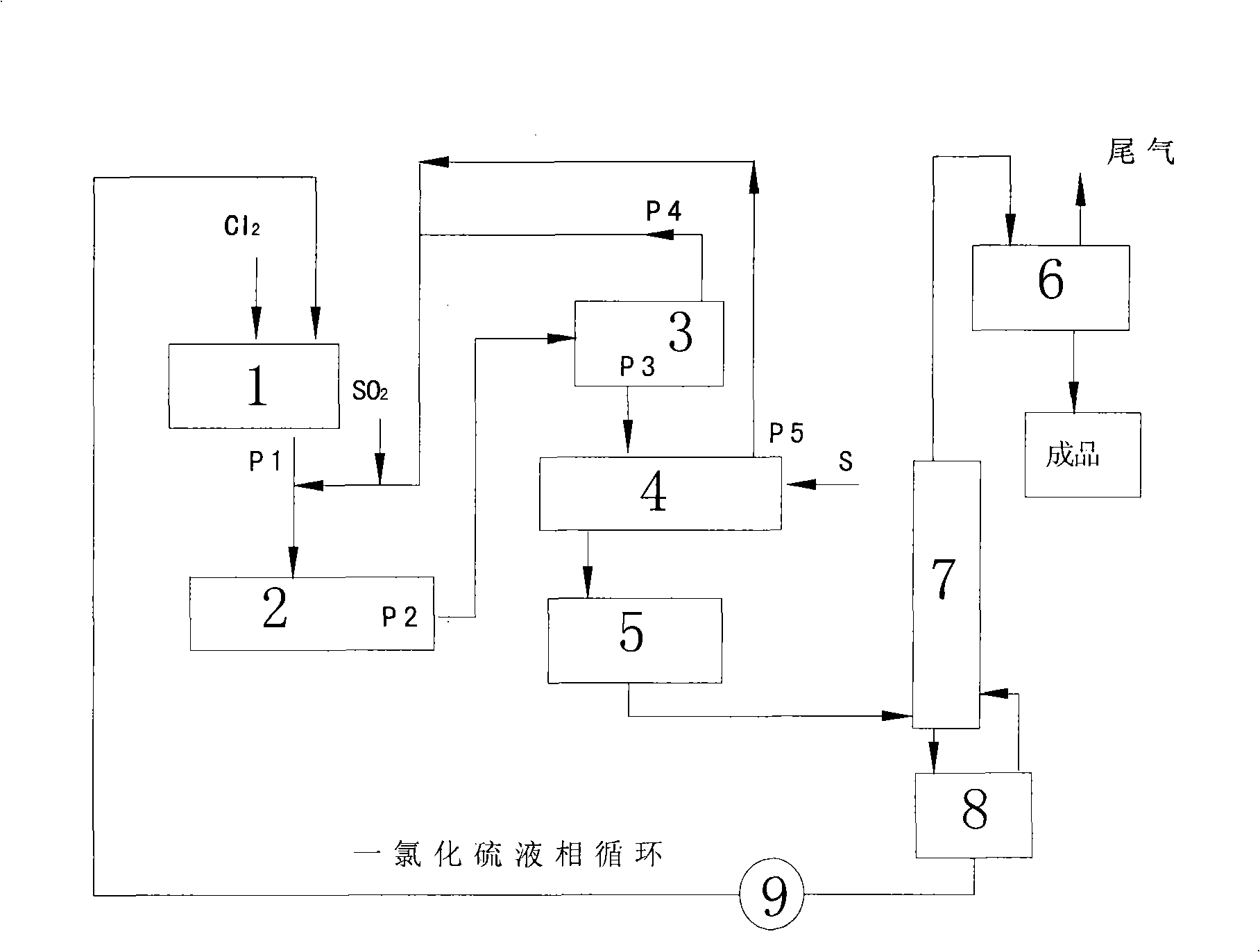

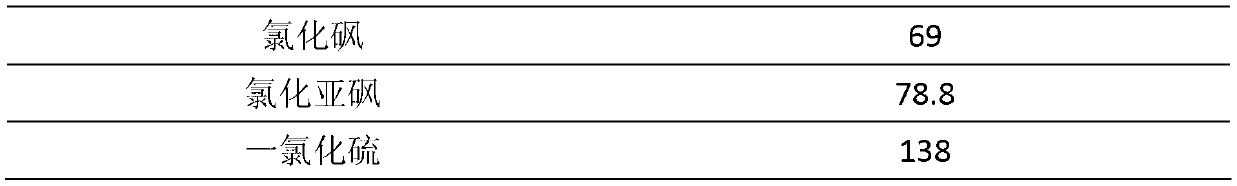

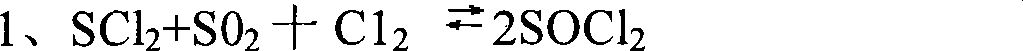

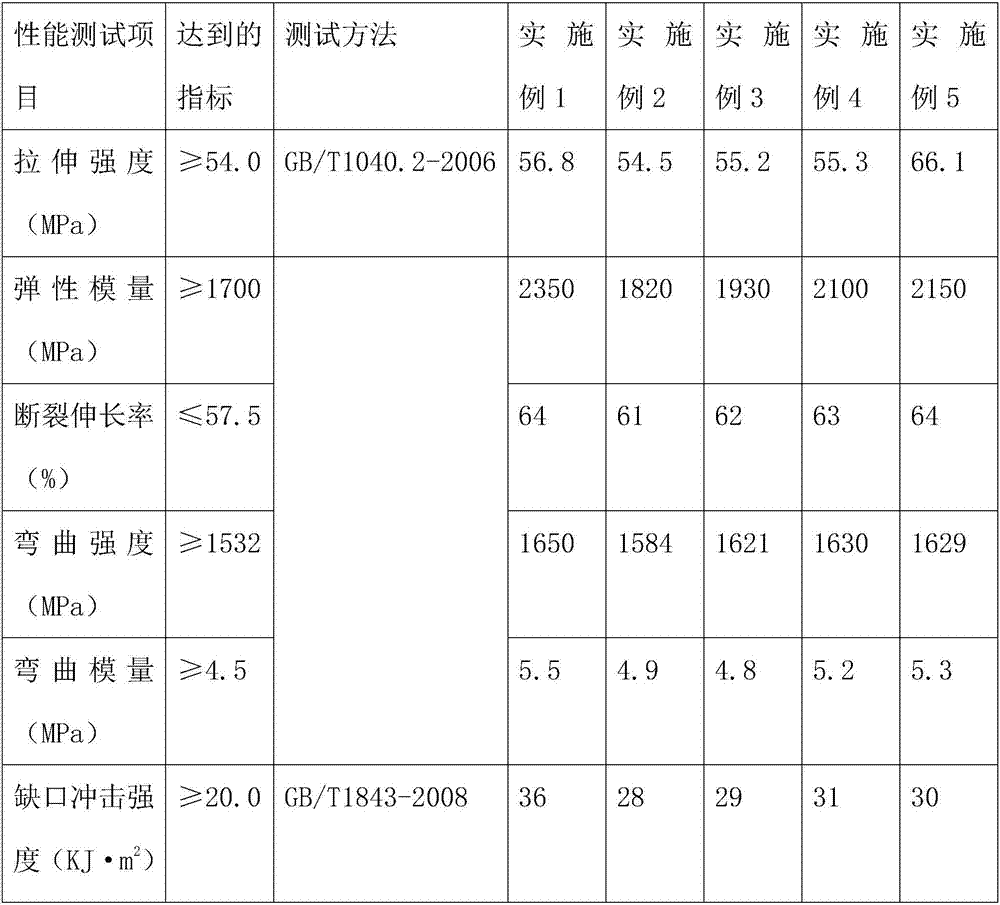

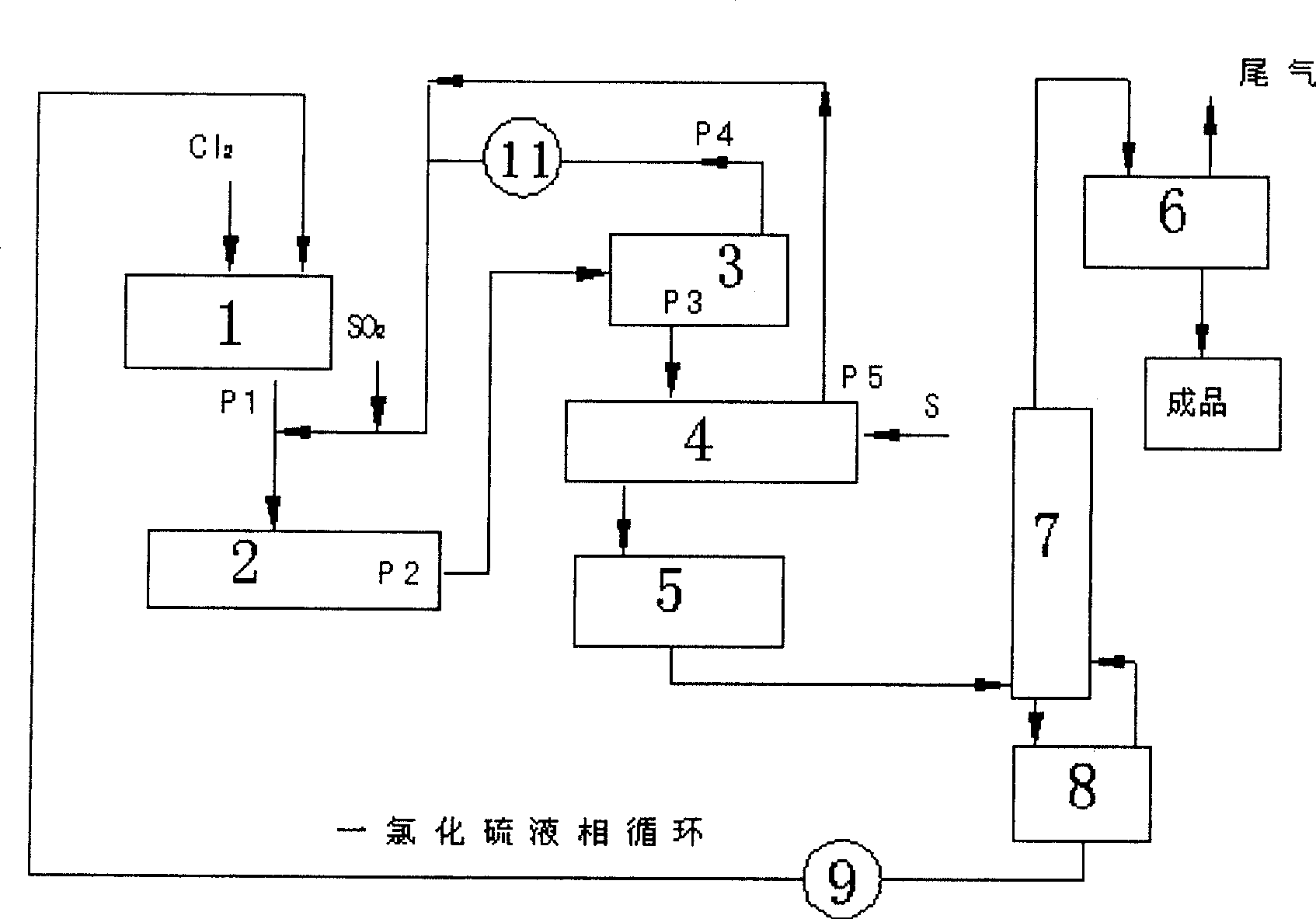

Liquid phase circulation method in synthesis of thionyl chloride

ActiveCN101284652AEasy to scale up productionGuaranteed uptimeSulfur and halogen compoundsSulfur dichlorideLiquid phase

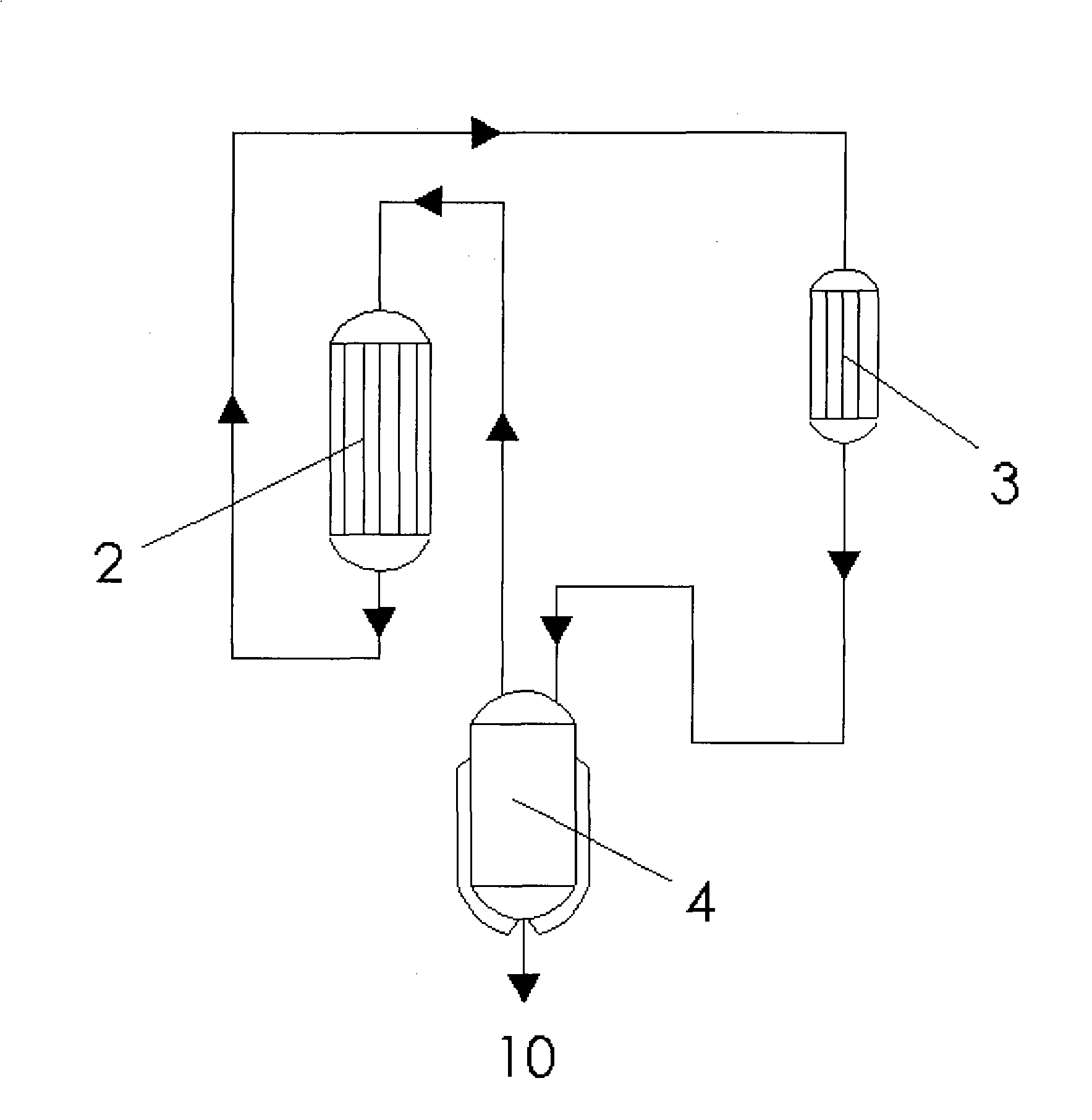

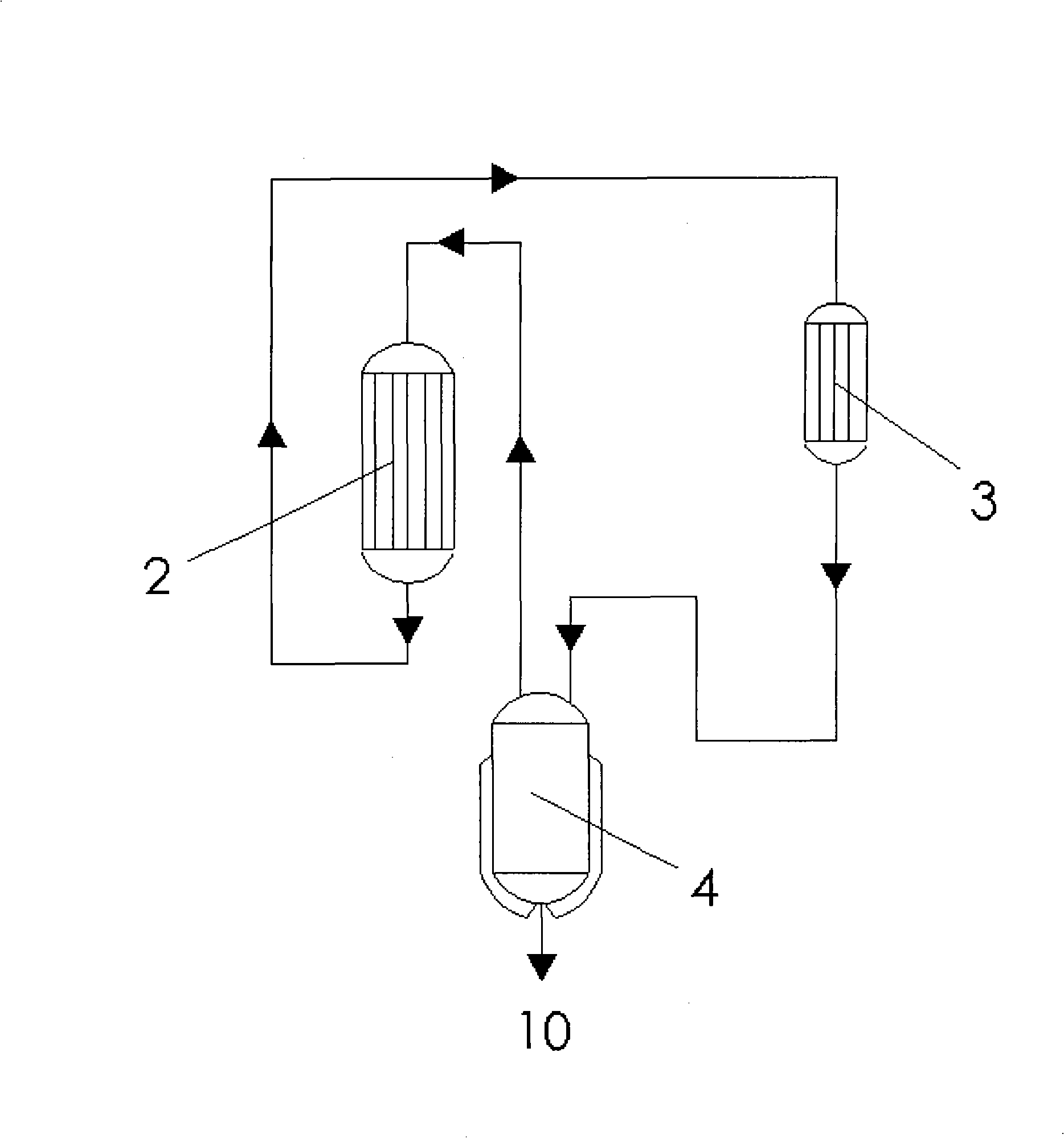

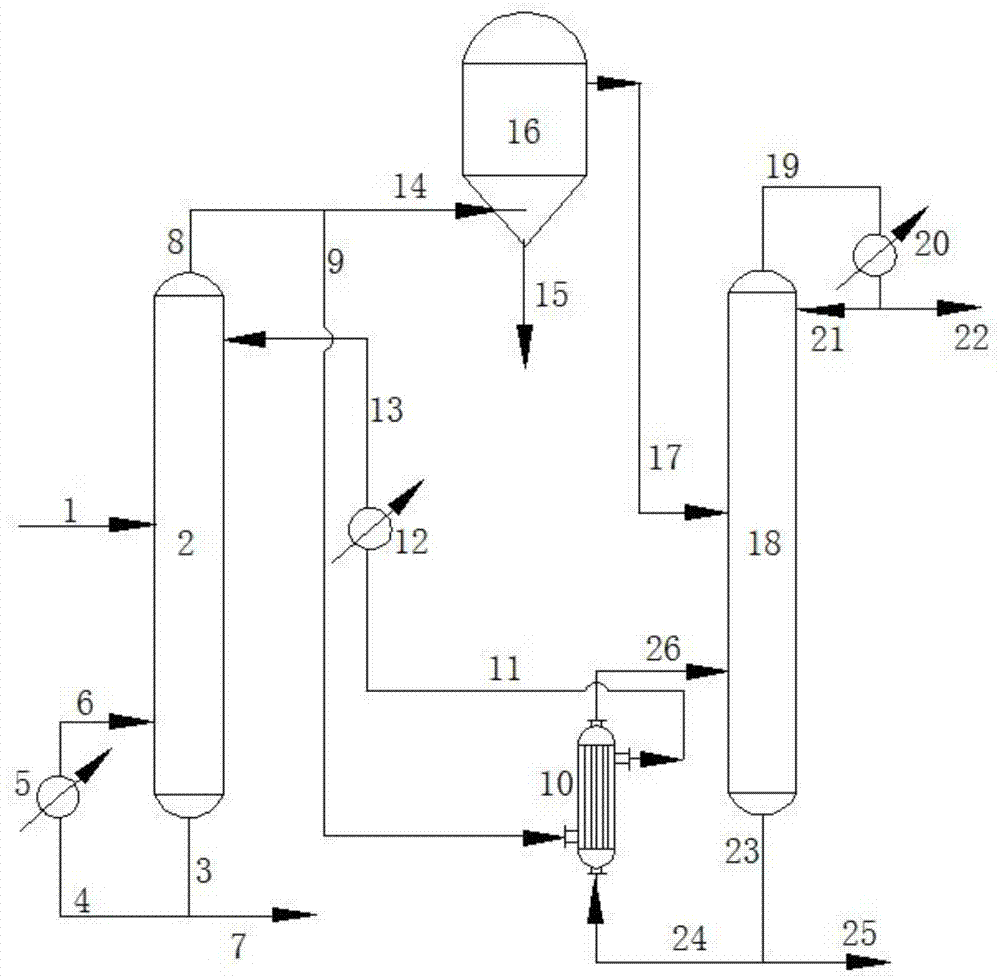

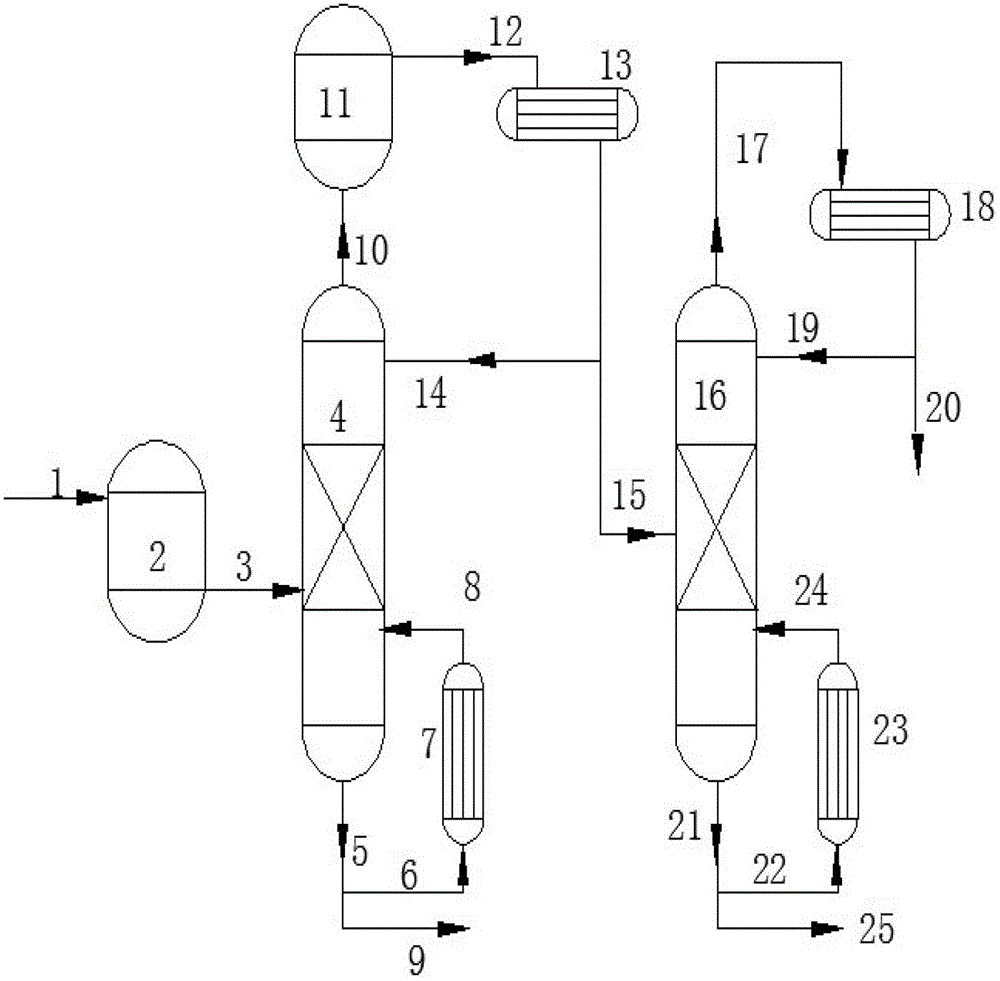

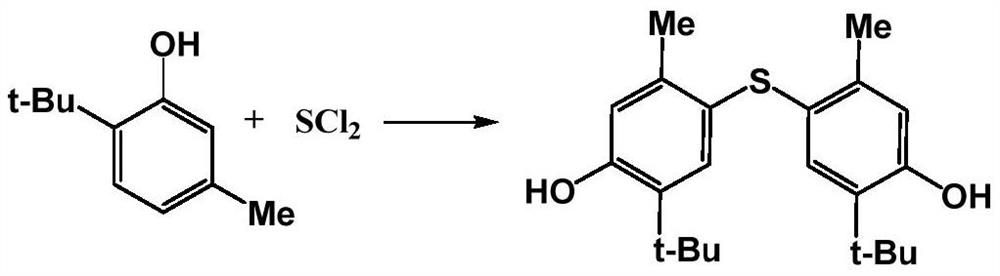

The invention relates to a liquid phase circulation method for synthesizing thionyl chloride. Specifically, the method comprises a process that the condensate of a crude product of the thionyl chloride and the purified mixed liquid of the crude product of the thionyl chloride in a degassing device are vulcanized and distilled, and then the distilled tower bottom residual liquid is again pumped to the sulfur dichloride for synthesis, thereby forming the fully-closed and full-circulation method for synthesizing the thionyl chloride.

Owner:JIANGXI SELON INDAL

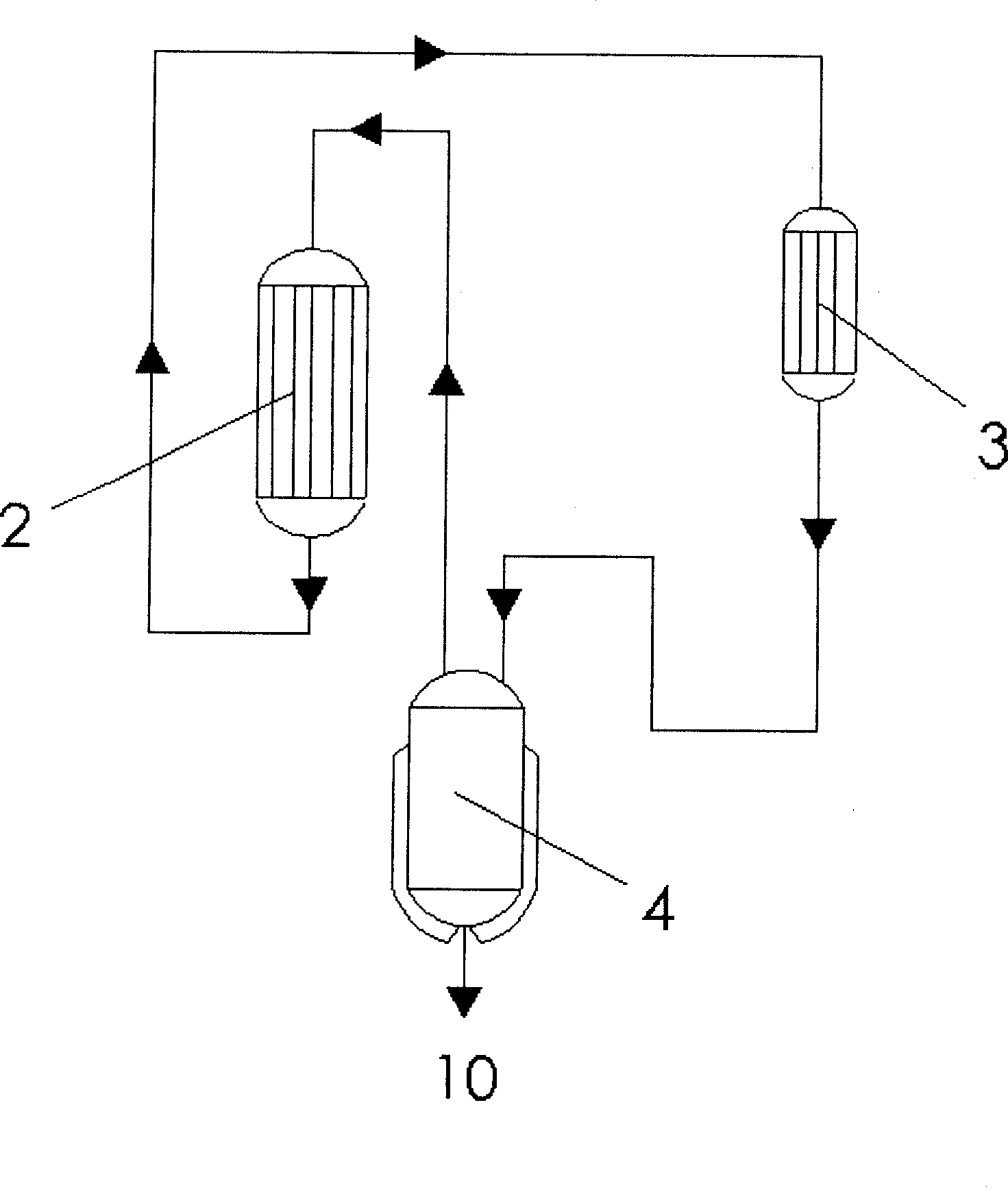

Gas phase circulation method in synthesis of thionyl chloride

ActiveCN101284653AEasy to scale up productionNo pollutionSulfur and halogen compoundsGas phaseDistillation

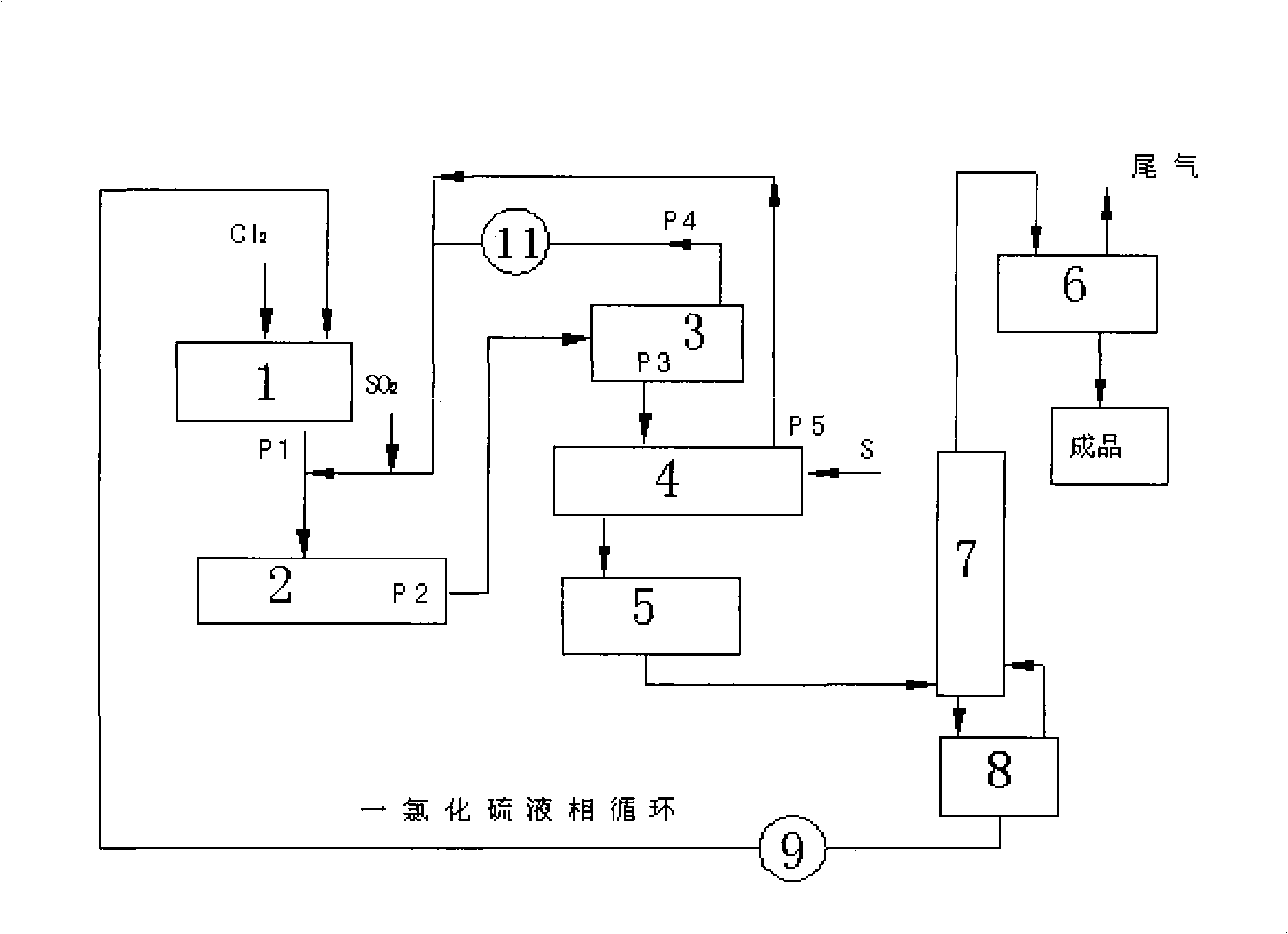

The invention relates to a method of gas phase in the synthesis of thionyl chloride, and particularly includes synthesizing sulfur dichloride by adding chlorine to sulfur monochloride, synthesizing crude thionyl chloride gas of light concentration by adding chlorine and sulfur dioxide, then subjecting the thionyl chloride gas to condensation, desaeration, purification, sulfuration and distillation to obtain the sulfur monochloride, and then rectifying the sulfur monochloride, thereby representing the method for all gases to enter the circulated use during the whole process.

Owner:JIANGXI SELON INDAL

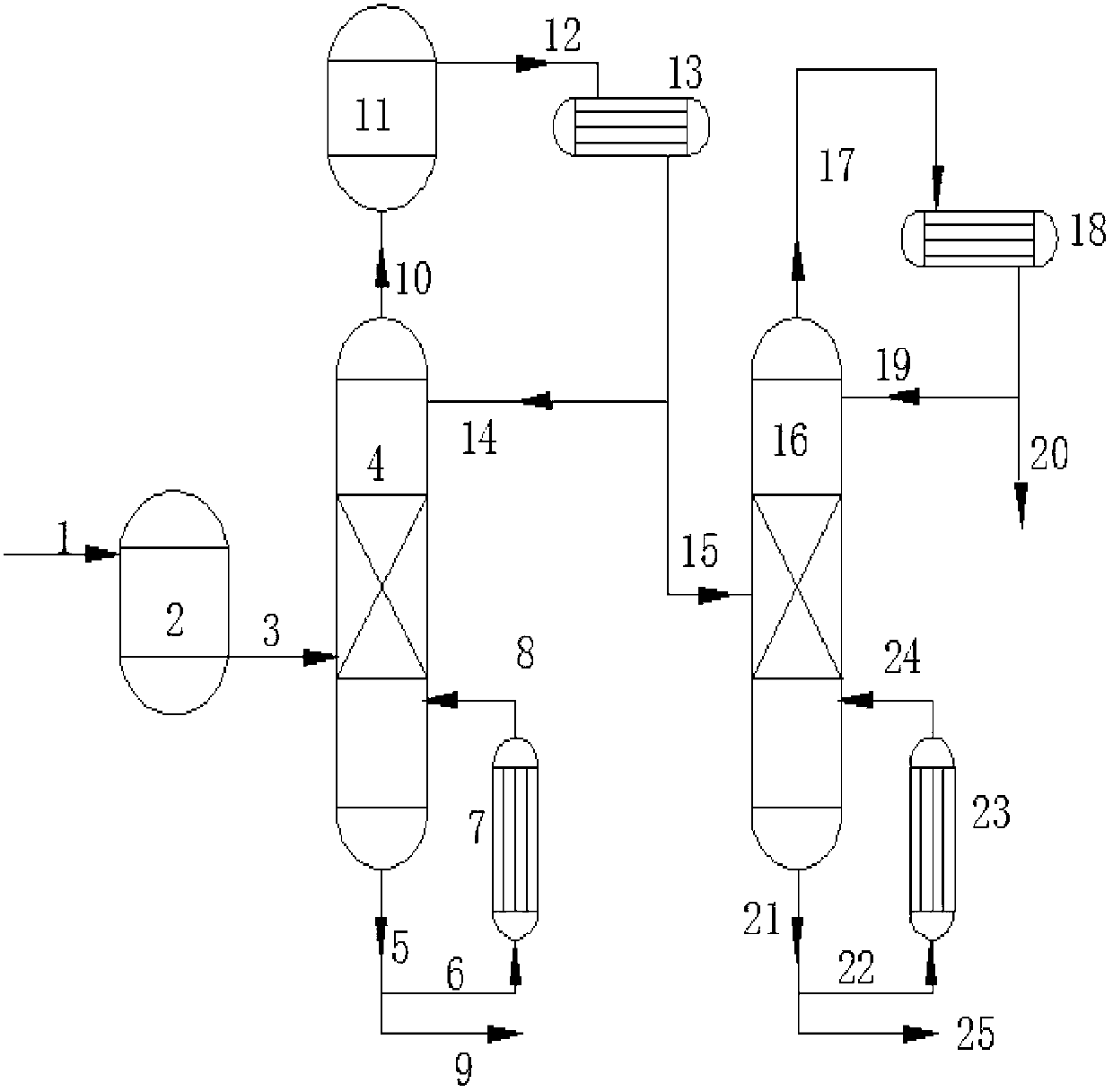

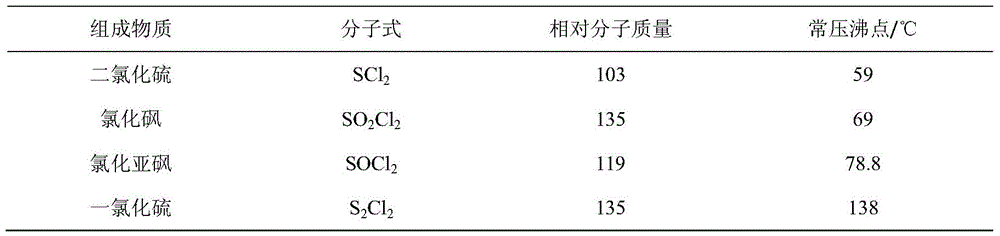

Continuous-pressure-changing rectification method and device for preparing medicine-level sulfoxide chloride

ActiveCN103130197AImprove continuityGuaranteed puritySulfur and halogen compoundsReaction rateDissolution

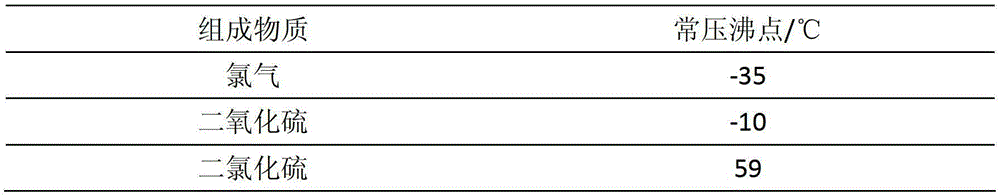

The invention relates to a continuous-pressure-changing rectification method and a device for preparing medicine-level sulfoxide chloride. With the adoption of the pressure-changing rectification method, an indirect sequence of carrying out heavy component removal and then carrying out light component removal is adopted as a rectification sequence, so that the decomposition of sulfoxide chloride at high temperature is reduced; sulfur is coarsely mixed with raw materials, sulfur is mixed with tower top gas of a heavy component removal tower, and a low-boiling-point substance, namely sulfur dichloride which is hard to remove, is fundamentally converted into a high-boiling-point substance, namely sulfur monochloride which is easy to remove, due to multistep sulfur adding; and a catalyst is added, so that the dissolution rate and reaction rate of the sulfur are accelerated. The heavy component removal tower is subjected to normal-pressure operation; and a light component removal tower is subjected to depressurized operation. The energy consumption of operation is reduced, and the decomposition reaction of the sulfoxide chloride hardly carries out under depressurized conditions, so that the probability that the color and luster of products are polluted by sulfur dichloride is greatly reduced, high-purity and colorless sulfoxide chloride products are produced from tower bottoms, and the content is over 99.9%.

Owner:TIANJIN UNIV

Method for synthesizing thionyl chloride with crude product thionyl chloride as raw material

ActiveCN101412503AEasy to scale up productionReduce manufacturing costSulfur and halogen compoundsCyclic processSulfur monochloride

The invention relates to a method for synthesizing thionyl chloride which takes a crude thionyl chloride product as an initial point. The method is a totally closed circulating process comprising the following steps: other materials in the synthesized crude thionyl chloride product is used to react with sulfur so as to mainly produce a sulfur monochloride product; the other materials comprises sulfur monochloride, sulfur dichloride, thionyl chloride, a small amount of chlorine and sulfur dioxide; and then the sulfur monochloride product is used to synthesize thionyl chloride together with chlorine, sulfur dichloride, and a gas product from the condenser after thionyl chloride synthesis and the crude product purification process.

Owner:JIANGXI SELON INDAL

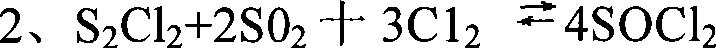

Medical corrosion-resistance high-toughness 3D printing material

The invention discloses a medical corrosion-resistance high-toughness 3D printing material which is prepared from the raw materials of ABS resin, SAN resin, butadiene rubber, chloroprene rubber, epoxy acrylic resin, polymethyl methacrylate, polycarbonate, polyolefin elastomer, sulphur, sulfur dichloride, chlorinated paraffin, dimethicone, zinc borate, isocyanate, nano graphite, carbon black, barite powder, nano aluminum hydroxide, polyphosphoric acid, nano silicon dioxide, mica powder, talcum powder, a silane coupling agent KH-560, sodium metaborate, pentaerythritol, polylactic acid, polycaprolactone, sodium stearate, sodium dodecyl benzene sulfonate, an antioxidant, a degassing agent, dimethicone, an anticorrosion additive, a modified filler and a toughening and modifying agent. The 3D printing material disclosed by the invention has excellent corrosion resistance and toughness.

Owner:HEFEI SKE INTELLIGENT TECH

Method for preparing thionyl chloride

InactiveCN106315519ASimple processReduce energy consumptionThionyl chlorideChemical synthesisGas phase

The invention belongs to the technical field of chemical synthesis, and particularly relates to a method for preparing thionyl chloride. Raw material mixed gas composed of sulfur dioxide, chlorine and sulfur dichloride enters a reactor from the upper portion, a crude product thionyl chloride gas phase directly enters a rectifying tower from the lower portion of the reactor, the gas phase on the top of the rectifying tower is recycled back to the reactor, a product is produced in the middle of the rectifying tower and enters a blowdown tank so that light components in the product can be blown away by nitrogen, and a qualified product is obtained. The pressure of the reactor and the pressure of the rectifying tower are normal pressure. The process for preparing thionyl chloride through a sulfur dioxide method is simplified, normal-pressure reaction is conducted, the process is simple, energy consumption is low, system safety is high, and the product yield is improved and reaches 99.95% or above.

Owner:SHANDONG KAISHENG NEW MATERIALS

Method for recovery and purification of sulfoxide chloride in acyl chloride production

InactiveCN102992276AEfficient recyclingHigh recovery rateSulfur and halogen compoundsActivated carbonThree level

The invention relates to a method for recovery and purification of sulfoxide chloride in acyl chloride production, which comprises the following steps of: implementing primary purification by a distilling way; converting sulfur dichloride which is difficult to separate into sulfur chloride which is easy to remove by sulfur powder; and adsorbing other colored components by active carbon; and obtaining pure sulfoxide chloride which reaches three-level color degree. The method disclosed by the invention can effectively recover the sulfoxide chloride, and is high in recovery rate, good in quality, safe in process and easy in control; the purified sulfoxide chloride can reach 98.5% in purity and three-level color degree in color.

Owner:YANTAI TAYHO ADVANCED MATERIALS CO LTD +1

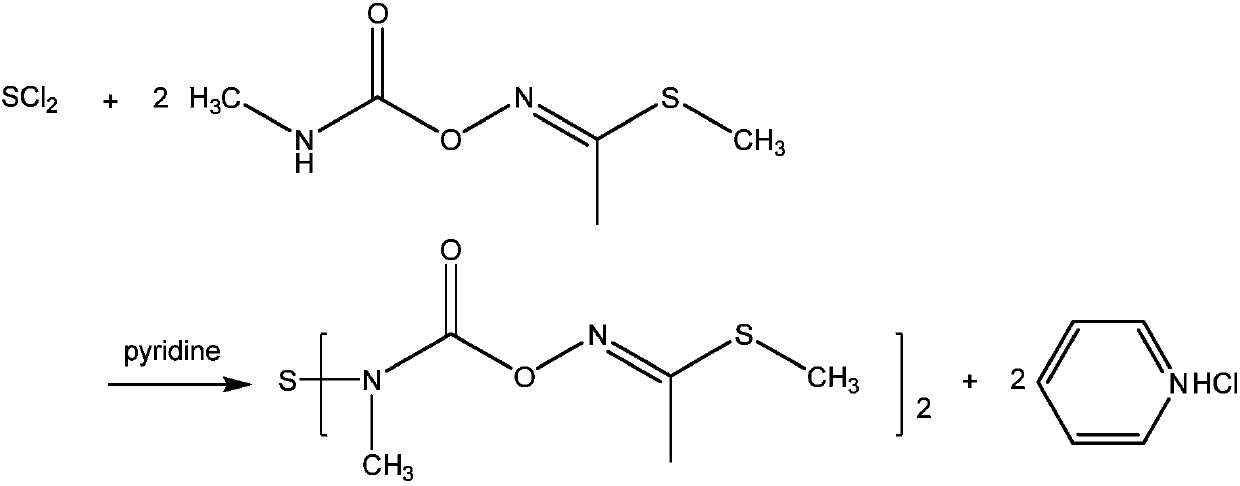

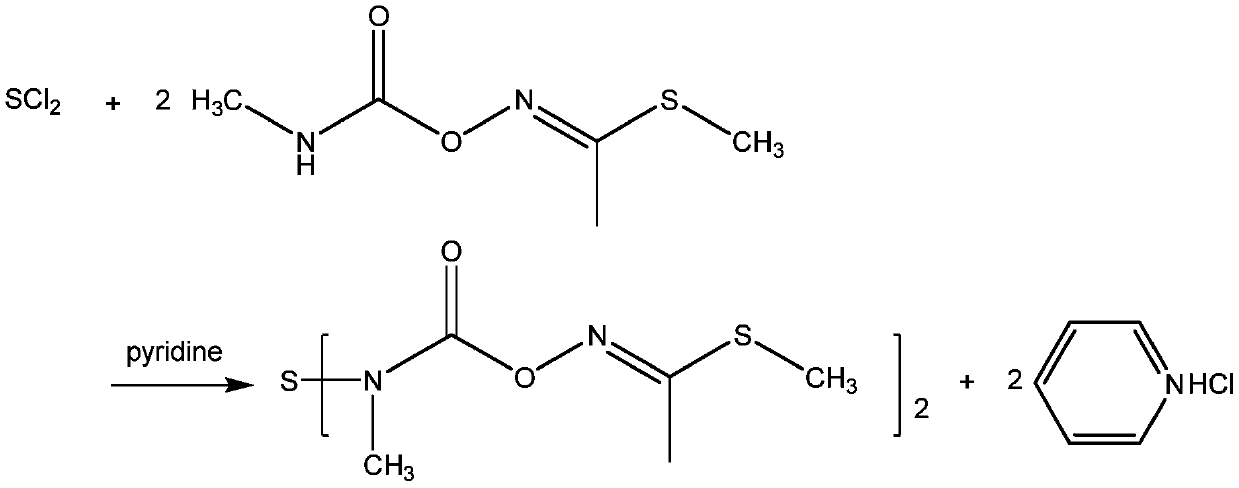

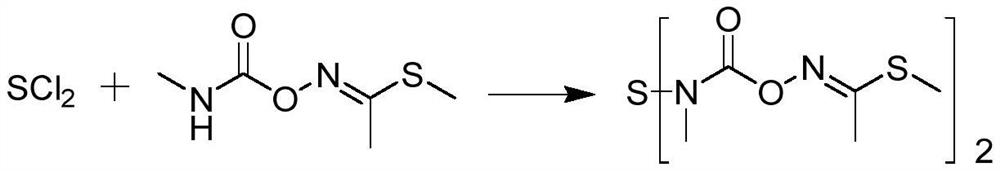

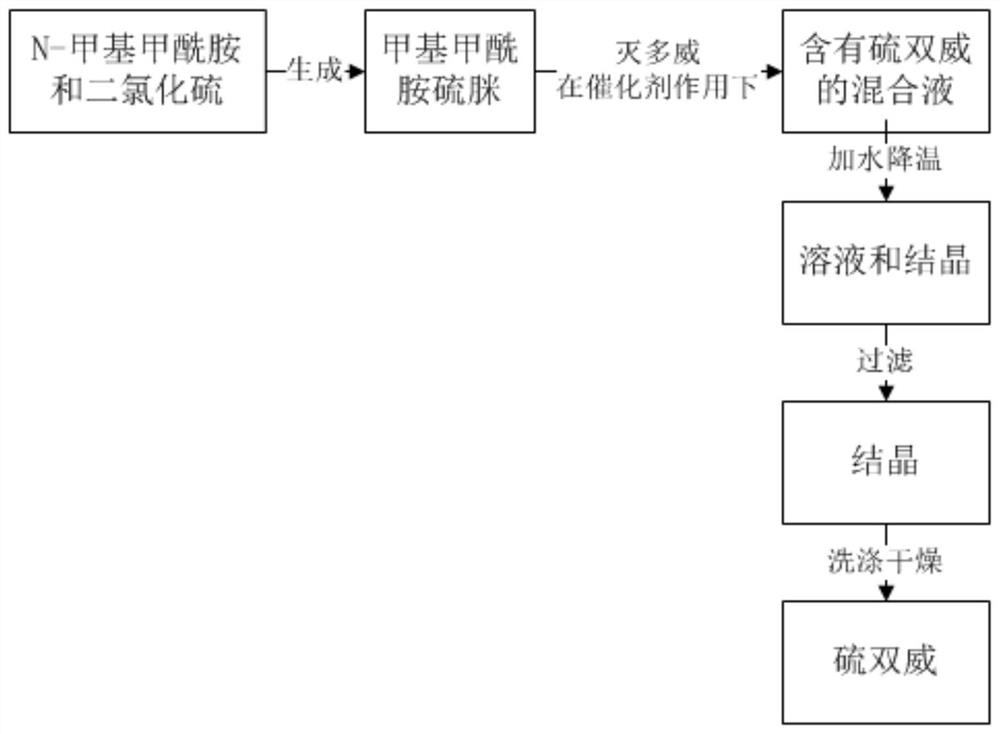

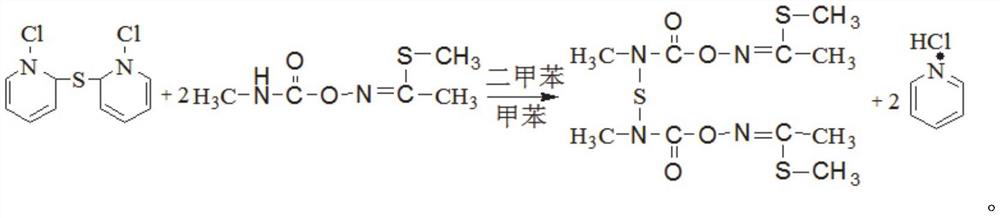

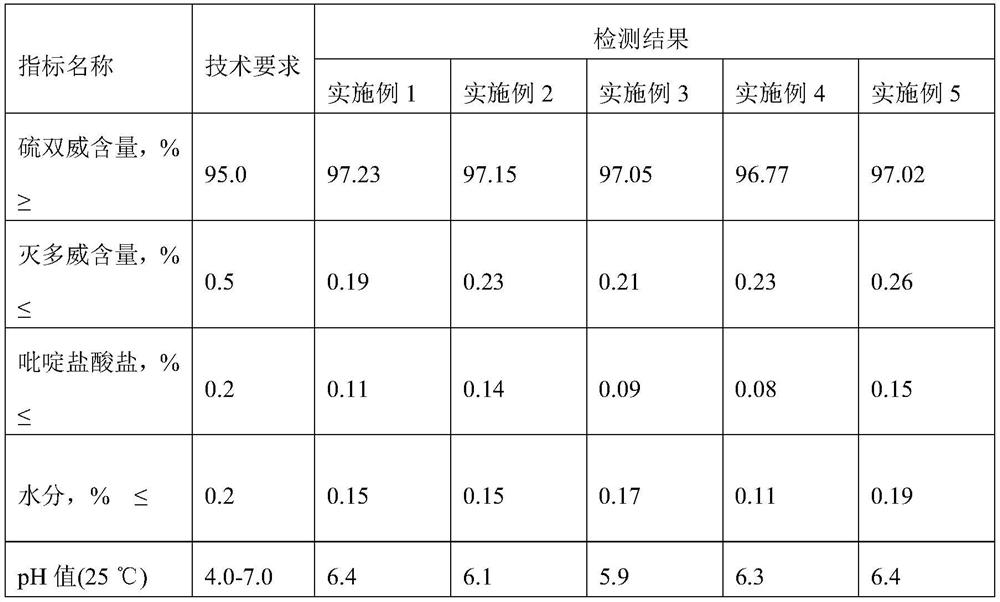

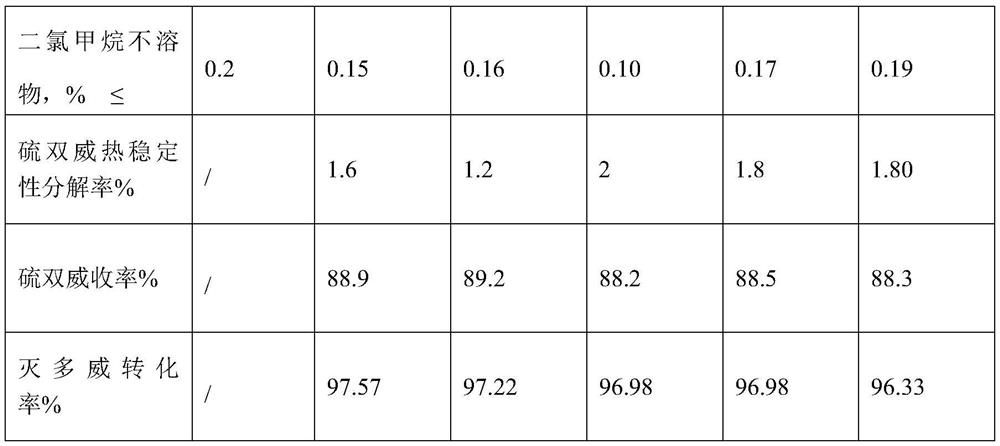

Preparation method of thiodicarb

The invention discloses a preparation method of thiodicarb. The preparation method comprises the following steps: (1) dividing a solvent into two portions, dissolving methomyl in one of the two portions to obtain a methomyl solution, and dissolving 4-dimethylaminopyridine in the other portion to obtain a solvent which contains a catalyst; and (2) dividing sulfur dichloride into two portions, dropwise adding one portion of the sulfur dichloride in the solvent which contains the catalyst under a closed condition, meanwhile, dropwise adding the other portion of sulfur dichloride and carrying outdropwise adding reaction on the other portion of sulfur dichloride and the methomyl solution obtained in step (1), and carrying out insulating reaction after dropwise adding is finished to obtain thethiodicarb. The preparation method of the thiodicarb has the advantages that the reaction selectivity is high, the purity of the obtained product is high, the content of thiodicarb isomer is smaller than 0.4%, the yield is high and the like.

Owner:湖南海利常德农药化工有限公司

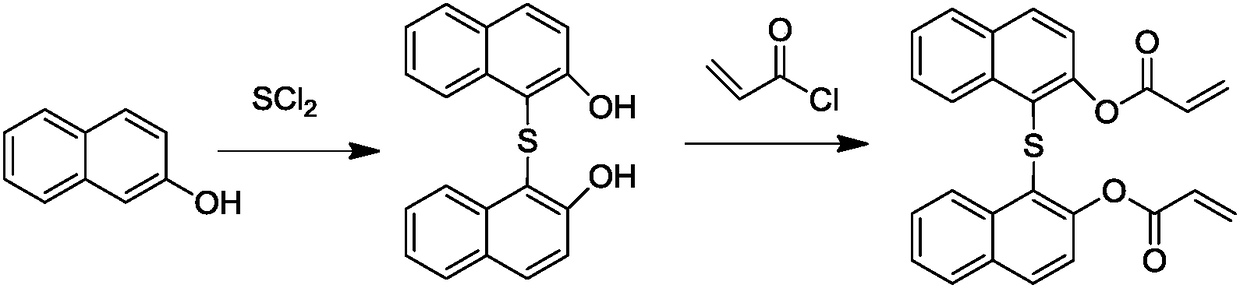

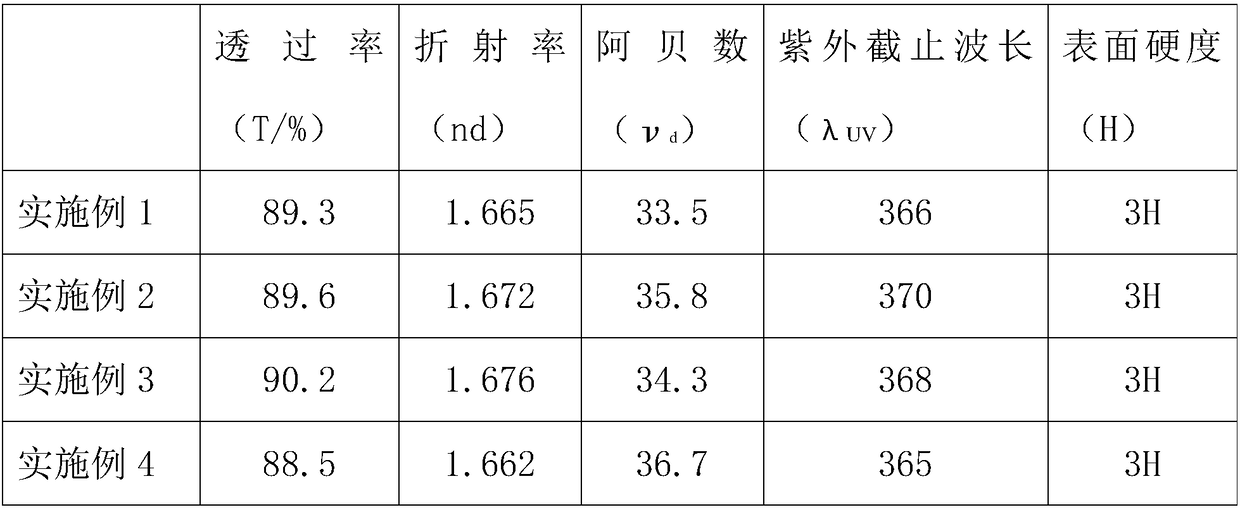

Preparation method of high refractive index sulfur-containing optical copolymerized resin

The invention discloses a preparation method of high refractive index sulfur-containing optical copolymerized resin. The preparation method comprises the following steps: stirring 2-naphthol and sulfur dichloride to react to obtain 1,1'-sulfobis(2-naphthol); adding the 1,1'-sulfobis(2-naphthol) into excessive triethylamine for quaternization, then dropwise adding acryloyl chloride, and stirring and reacting to obtain 2,2'-bis(2-acroloyloxyl)-1,1'-sulfobinaphthyl; and copolymerizing the 2,2'-bis(2-acroloyloxyl)-1,1'-sulfobinaphthyl, methyl methacrylate and styrene in a condition that azodiisobutyronitrile serves as an initiator, and heating and curing the mixture to obtain the high refractive index sulfur-containing optical copolymerized resin. By introducing a sulfur-containing monomer rich in electronic conjugated structural units with great molar refrangibility into a synthesized monomer of the optical copolymerized resin, the refractive index of the copolymerized resin is improved and the monomer is copolymerized with methyl methacrylate and styrene to prepare transparent resin.

Owner:望江县天长光学科技有限公司

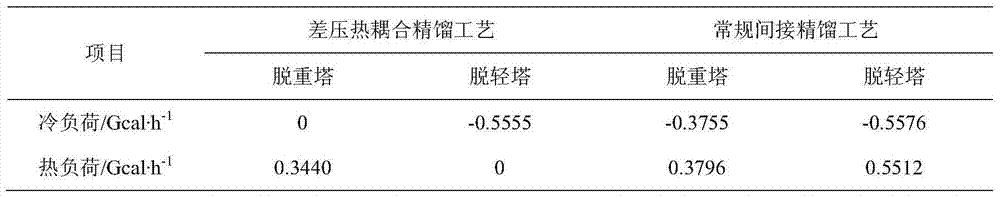

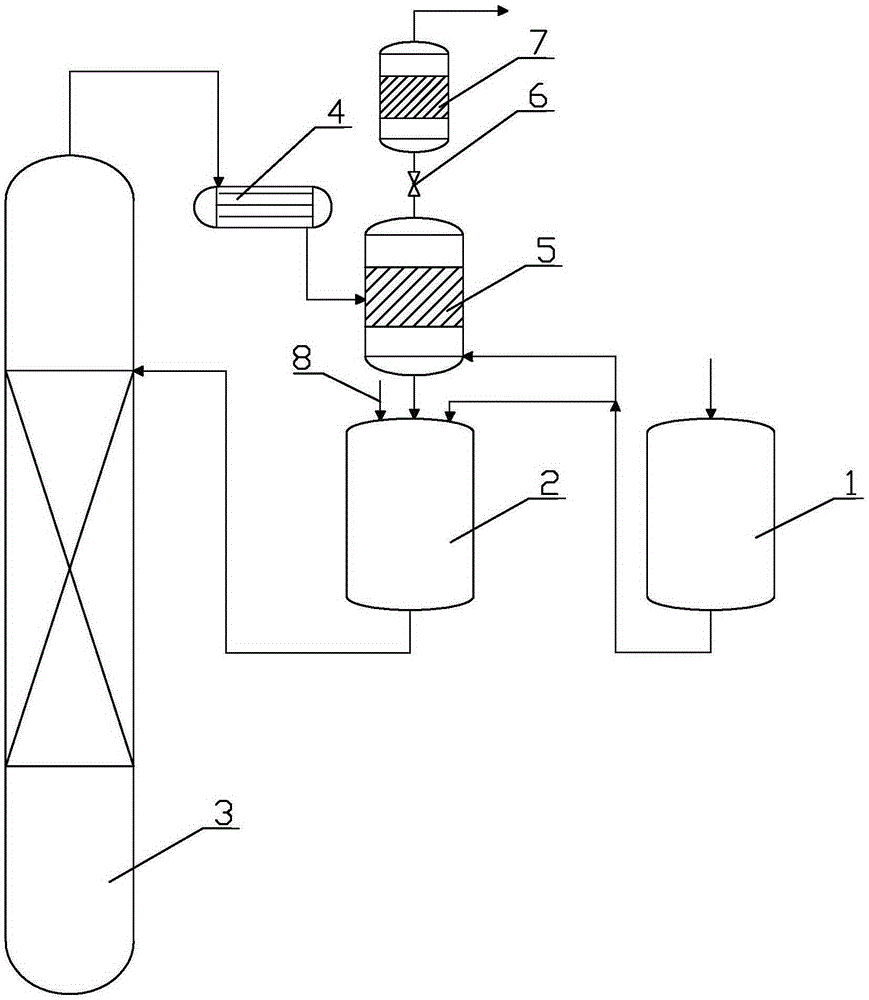

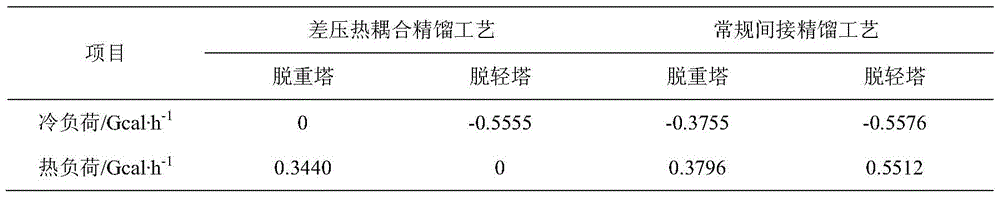

Differential pressure thermal coupling rectification method and equipment for sulfoxide chloride

ActiveCN103933751AReduce energy consumptionSolve problems affecting production scheduleChemical industrySulfur and halogen compoundsReboilerDifferential pressure

The invention relates to a differential pressure thermal coupling rectification method and equipment for sulfoxide chloride. According to the equipment, a heavy component removing tower of a re-boiler is arranged at the bottom of a tower and a light component removing tower of a condenser is arranged at the top of the tower; a condensation re-boiler, an auxiliary condenser and a conversion reactor are arranged between the heavy component removing tower and the light component removing tower. An extract of a vapor-phase material at the top of the heavy component removing tower is divided into two parts, wherein one part is connected with a heating medium inlet of the condensation re-boiler, a heating medium outlet is connected with the auxiliary condenser and then returns back to the top of the heavy component removing tower, a liquid-phase material outlet at the bottom of the light component removing tower is connected with a heated medium inlet of the condensation re-boiler, and then a heated medium outlet returns back to the bottom of the light component removing tower; the other part is connected with the conversion reactor to carry out a reaction of converting sulfur dichloride to sulfur chloride, and a reacted material vapor phase enters the light component removing tower. The differential pressure thermal coupling is used for coupling heat at the top of the heavy component removing tower and heat at the bottom of the light component removing tower and the energy consumption is saved. The difficulty of blocking a pipeline by sulfur is overcome. A practical example shows that a differential pressure thermal coupling rectification process can save energy by more than 50% compared with a conventional process.

Owner:SHANDONG KAISHENG NEW MATERIALS

Method and device for removing impurity-sulfur dichloride in thionyl chloride

ActiveCN105347312AMeet the requirements of 1# colorSolve the clogging problemSulfur and halogen compoundsVulcanizationImpurity

The invention belongs to the technical field of chemical production, and specifically relates to a method and a device for removing the impurity-sulfur dichloride in thionyl chloride. The method comprises the step of enabling thionyl chloride gas which is evaporated from the top part of a rectifying tower and contains 1 to 3 percent of sulfur dichloride to be subjected to temperature rising and to enter an over-vulcanization tank for reaction. The device comprises a crude product receiving tank, wherein the crude product receiving tank is sequentially connected with a sulfur preparing tank, the rectifying tower, a heater and the overvulcanization tank through pipelines; the top part of the sulfur preparing tank is provided with a hydraulic sulfur line. According to the method and the device, disclosed by the invention, 1 to 3 percent of sulfur dichloride which is contained in the thionyl chloride can be reduced to be below 0.004 percent; the requirement on color I of excellent products in industry standard is achieved; the problem that a pipeline arranged at the bottom part of the sulfur preparing tank is blocked can be solved, and continuous production is realized.

Owner:SHANDONG KAISHENG NEW MATERIALS

High-toughness corrosion-resistant rubber sealing element and preparation method thereof

InactiveCN106700367AImprove bindingImprove anti-corrosion performanceLow-density polyethylenePolymer science

The invention discloses a high-toughness corrosion-resistant rubber sealing element. The rubber sealing element comprises the following raw materials: silicone rubber, cis-1,4-polybutadiene rubber, chloroprene rubber, epoxy acrylic resin, modified high chlorinated polyethylene resin, coumarone resin, low-density polyethylene, ethylene propylene diene monomer rubber, sulfur, sulfur dichloride, chlorinated paraffin wax, styrene, dimethyl silicon oil, zinc borate, isocyanate, nano graphite, carbon black, barite powder, nano aluminum hydroxide, aluminum polyphosphate, nano silicon dioxide, mica powder, talcum powder, a silane coupling agent KH-570, sodium metaborate, pentaerythritol, ammonium polyphosphate, polysiloxane, sodium stearate, sodium dodecyl benzene sulfonate and an antioxidant. The invention also discloses a preparation method of the high-toughness corrosion-resistant rubber sealing element. The rubber sealing element has excellent toughness and favorable corrosion resistance.

Owner:安徽亚兰密封件股份有限公司

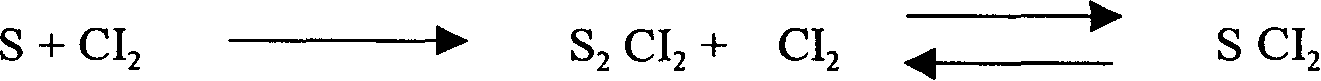

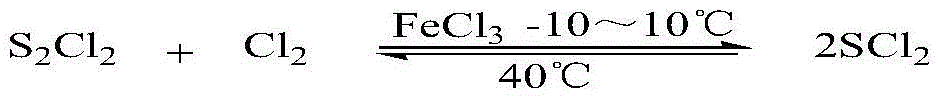

Method for preparing sulfur dichloride

InactiveCN1473758ANo wasteNo pollution in the processPhysical/chemical process catalystsSulfur and halogen compoundsChemical synthesisDisulfur dichloride

The present invention relates to chemical synthesis technology. Sulfur dichloride is prepared through gas-solid reaction between chlorine and sulfur and subsequent cooling. During the reaction between chlorine and sulfur, disulfur dichloride is first produced; after the temperature is lowered and more chloride is introduced, sulfur dichloride is then produced; and after the reaction is finished, stabilizer is added to obtain the product. The said process has high sulfur dichloride yield, has stability, high purity over 98 %, low cost, no environment and is suitable for industrial production.

Owner:淄博市新材料研究所

The preparation method of thiodicarb

ActiveCN108047106BHigh selectivityReduce self-decompositionOrganic chemistryPtru catalystCombinatorial chemistry

The invention discloses a preparation method of thiodicarb. The preparation method comprises the following steps: (1) dividing a solvent into two portions, dissolving methomyl in one of the two portions to obtain a methomyl solution, and dissolving 4-dimethylaminopyridine in the other portion to obtain a solvent which contains a catalyst; and (2) dividing sulfur dichloride into two portions, dropwise adding one portion of the sulfur dichloride in the solvent which contains the catalyst under a closed condition, meanwhile, dropwise adding the other portion of sulfur dichloride and carrying outdropwise adding reaction on the other portion of sulfur dichloride and the methomyl solution obtained in step (1), and carrying out insulating reaction after dropwise adding is finished to obtain thethiodicarb. The preparation method of the thiodicarb has the advantages that the reaction selectivity is high, the purity of the obtained product is high, the content of thiodicarb isomer is smaller than 0.4%, the yield is high and the like.

Owner:湖南海利常德农药化工有限公司

Synthesis method of thiodicarb

ActiveCN112778179AHigh selectivityImprove qualityOrganic chemistryBiochemical engineeringCombinatorial chemistry

The invention discloses a synthesis method of thiodicarb, which comprises the following steps: (1) dividing a solvent into two parts, dissolving methomyl in one of the two parts to obtain a methomyl solution, and dissolving 18-crown ether-6 in the other part of the mixture to obtain a solution of the 18-crown-6; and (2) under a closed condition, dropwise adding a part of sulfur dichloride into the 18-crown-6 solution, after dropwise adding is completed, dropwise adding the residual sulfur dichloride to react with the methomyl solution, and after dropwise adding is completed, continuing to carry out heat preservation reaction to obtain the thiodicarb. The method is high in reaction selectivity, by-products are reduced, the obtained product is high in purity and yield, and meanwhile, the problem that a pipeline is easily blocked in the production process can be effectively solved. The method is simple in process operation and suitable for large-scale industrial production.

Owner:湖南海利常德农药化工有限公司

Preparation method for synthetizing sulfur dichloride through gas phase catalysis

The invention discloses a preparation method for synthetizing sulfur dichloride through gas phase catalysis. Granular activated carbon supported by ferric chloride (FeCl3 / C) is taken as a catalyst, disulfur dichloride and chorine are taken as a reaction raw material and a carrier gas, a vaporized gas mixture of the disulfur dichloride and the chorine enters a fixed bed catalysis tubular reactor, the sulfur dichloride is prepared with a continuous gas phase catalysis method, the sulfur dichloride produced through the reaction is cooled by a condenser to be collected, and the excess chlorine is recycled. The sulfur dichloride product obtained with the method is free of catalyst residues, distillation is not required, and the content of sulfur dichloride in the product is higher than 90%. The excess chlorine is recycled. The preparation method is simple to operate, continuous, stable, high in conversion rate and free of waste gas and waste liquor emissions, so that the environmental pollution is reduced.

Owner:湖南海利常德农药化工有限公司

Method for scavenging mercury

Owner:RGT UNIV OF CALIFORNIA

Gas phase circulation method in synthesis of thionyl chloride

ActiveCN100480174CEasy to scale up productionNo pollutionSulfur and halogen compoundsGas phaseDistillation

The invention relates to a method of gas phase in the synthesis of thionyl chloride, and particularly includes synthesizing sulfur dichloride by adding chlorine to sulfur monochloride, synthesizing crude thionyl chloride gas of light concentration by adding chlorine and sulfur dioxide, then subjecting the thionyl chloride gas to condensation, desaeration, purification, sulfuration and distillation to obtain the sulfur monochloride, and then rectifying the sulfur monochloride, thereby representing the method for all gases to enter the circulated use during the whole process.

Owner:JIANGXI SELON INDAL

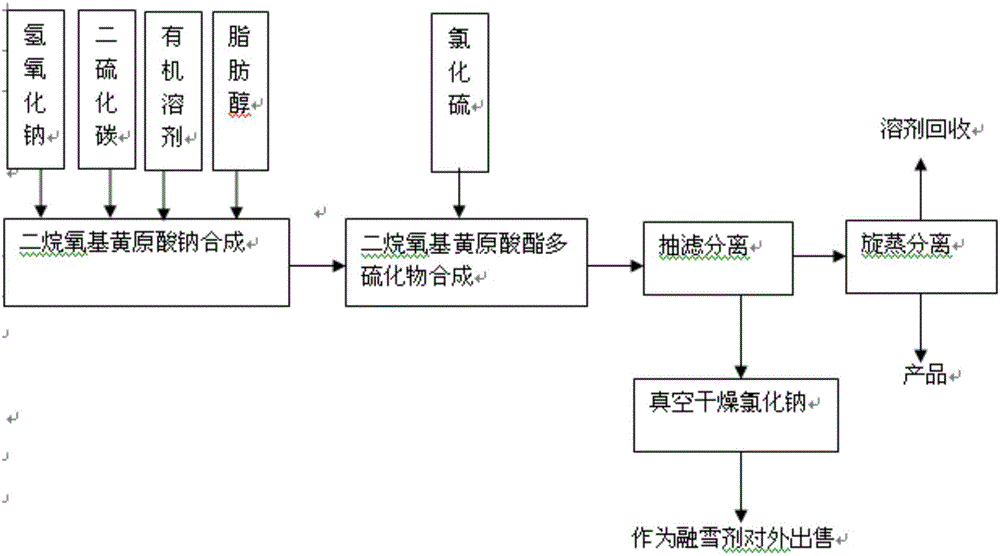

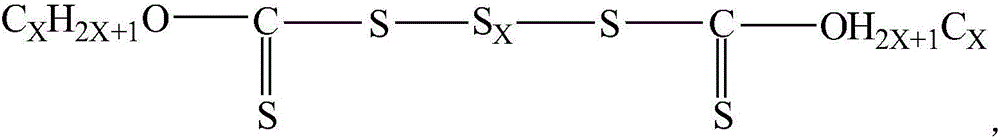

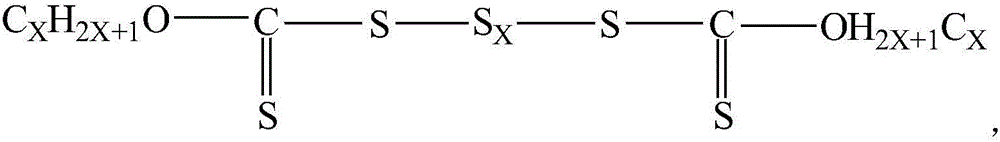

Preparation method of dialkoxyl xanthate polysulfide

Provided is a preparation method of dialkoxyl xanthate polysulfide. The preparation method comprises the steps that fatty alcohol, carbon disulfide and powdered sodium hydroxide synthesize sodium dimethyldithiocarbamate in an organic solvent, sulfur chloride (sulfur monochloride or sulfur dichloride) is dropwise added, and the dialkoxyl xanthate polysulfide is obtained through a reaction; after the reaction is completed, pumping filtration is conducted to separate out inorganic salt sodium chloride, inorganic salt sodium chloride is subjected to simple treatment to serve as a by-product for sale, liquid is subjected to rotary distillation separation to obtain the product, and the distilled organic solvent can be recycled. The preparation method is short in process, the product yield and quality are stable, and the production efficiency is high. The recovery technology of inorganic salt sodium chloride is simple, no other inorganic salt impurity is contained, the purity is high, and recycling is promoted.

Owner:SHANDONG YANGGU HUATAI CHEM

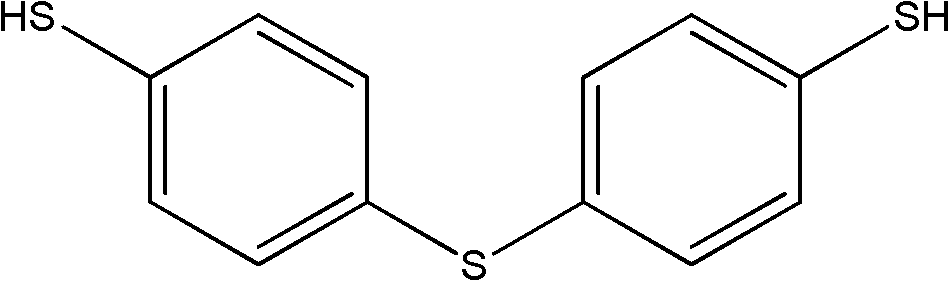

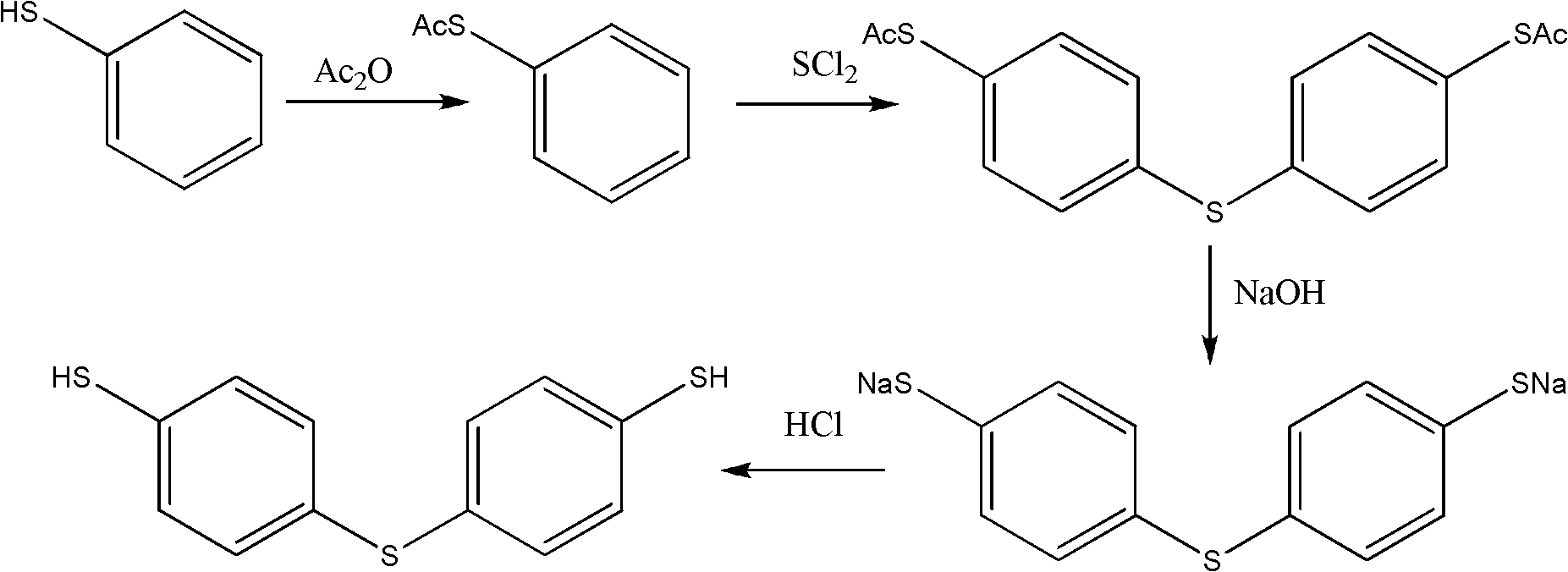

Synthesis method of 4,4'-thiobisbenzenethiol

The invention discloses a synthesis method of 4,4'-thiobisbenzenethiol. The method comprises the following steps of: 1) esterfying, namely adding acetic anhydride into phenthiol serving as an initiative raw material dropwise for reacting, and laminating; 2) etherifying, namely adding a solvent, iodine and sulfur dichloride into an organic layer I obtained in the step 1) for reacting, laminating, decompressing an organic layer II and removing the solvent to obtain a yellow solid; 3) hydrolyzing, namely adding sodium hydroxide and the yellow solid into water for a warming reflux reaction, adding hydrochloric acid solution dropwise, and filtering to obtain a white solid; and 4) recrystallizing, namely recrystallizing the white solid with a recrystallizing solvent to obtain white crystalline 4,4'-thiobisbenzenethiol. The 4,4'-thiobisbenzenethiol synthesized by the method has the characteristics of simple process and high yield.

Owner:江西扬帆新材料有限公司

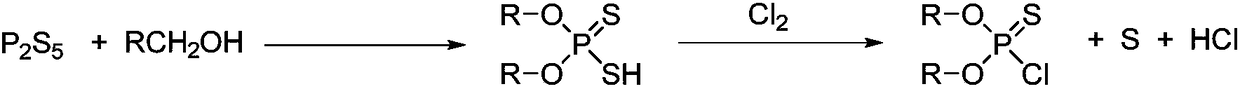

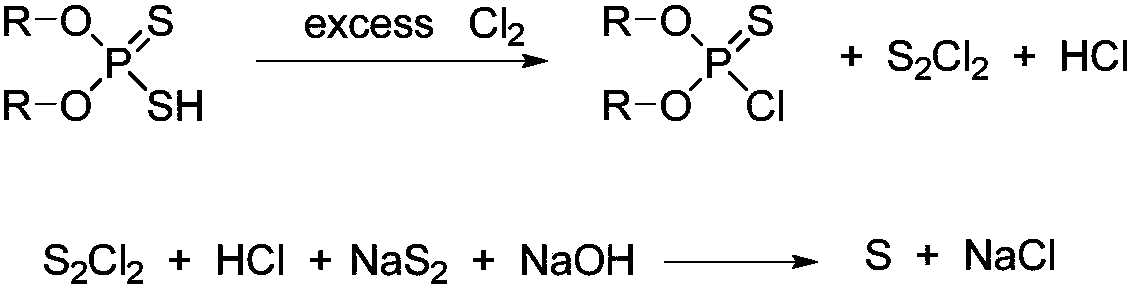

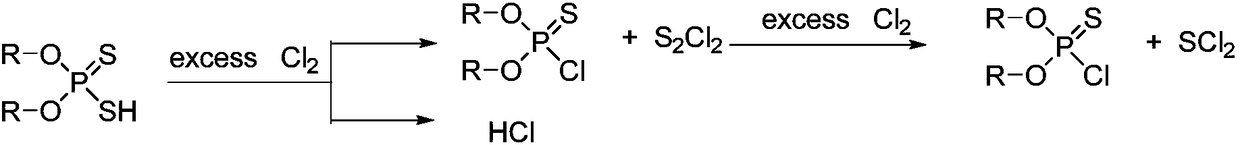

Synthesis method of O, O-dialkyl thiphosphoryl chloride

ActiveCN108329346ALow costAchieving Atomic EconomicsGroup 5/15 element organic compoundsSynthesis methodsDistillation

The invention discloses a synthesis method of O, O-diakyl thiphosphoryl chloride. In a reaction system where O, O-dialkyl S-hydro-phophorodithioate and chlorine are subjected to a chlorination reaction to prepare O, O-dialkyl thiphosphoryl chloride, an excess chlorine is introduced to make sulphur generated in the reaction be converted into disulfur dichloride, and disulfur dichloride is convertedinto sulfur dichloride afterwards; and by controlling the reaction temperature and arranging the reaction system to be in the negative pressure state, sulfur dichloride is moved out of the reaction system in the reaction process through distillation and condensing. The synthesis method substantially achieves the atomic economy based on a green chemistry concept; the overall cost of raw materialsis far lower than that in a traditional method, the amount of the three wastes is less, and the three wastes are easy to dispose; a traditional solid-liquid separation step is cancelled, automated production is facilitated, and meanwhile, improvement of the safety and environment production level of the device is facilitated; and O, O-dialkyl thiphosphoryl chloride is not in contact with water, disintegration of the product is avoided, the yield rate is as high as 93%, and the product content can reach 99%.

Owner:HUNAN CHEM RES INST

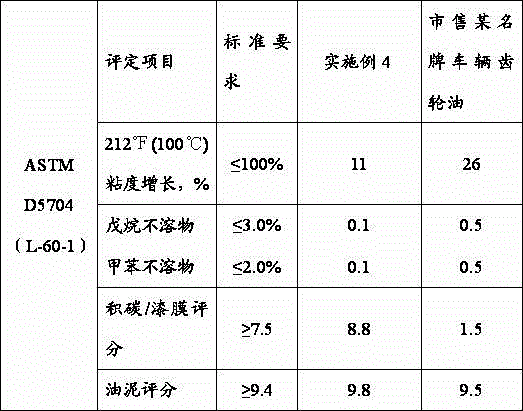

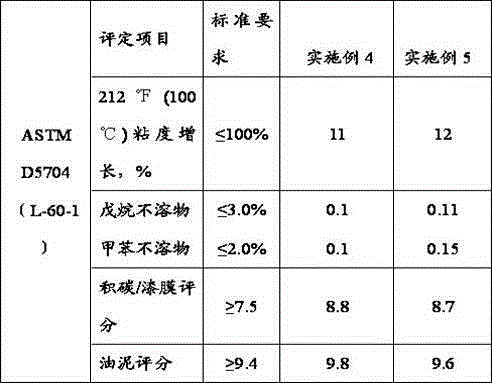

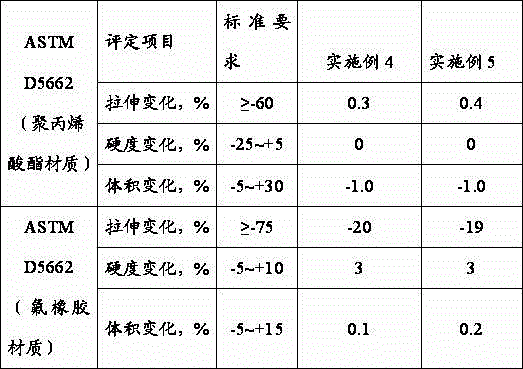

High-temperature antioxidant and preparation method thereof, and applications of high-temperature antioxidant in gear oil

ActiveCN104893788AImprove antioxidant capacityReduce carbon depositionAdditivesAntioxidantP-tert-octylphenol

The present invention belongs to the field of lubricating oils, and relates to antioxidants, particularly to a high-temperature antioxidant and a preparation method thereof, and applications of the high-temperature antioxidant in gear oil. The high-temperature antioxidant comprises p-tert-octylphenol, n-hexane, sulfur dichloride, alkenyl succinic acid phenol, benzene, thio bis-p-tert-octyl phenol benzene, and hydrated copper acetate. Compared with the high-temperature antioxidant, the preparation method and the applications thereof in the prior art, the high-temperature antioxidant, the preparation method and the applications thereof of the present invention have the following advantages and positive effects that the high-temperature antioxidant is provided and is added to the gear oil so as to improve excellent anti-oxidation capacity of the gear oil, effectively reduce the carbon deposition on the vehicle gear surface, reduce the oil seal wear, prolong the oil change period, and improve the economic benefits.

Owner:SHANDONG YUANGEN PETROLEUM CHEM

Method for inhibiting generation of chlorosulfuric acid in thionyl chloride preparation process

InactiveCN104445091AQuality improvementSulfuryl chloride content decreasedSulfur-halogen-hydrogen-oxygen compoundsThionyl chlorideChlorosulfuric acidSulfur dichloride

The invention relates to a method for inhibiting generation of chlorosulfuric acid in a thionyl chloride preparation process. The method comprises the following steps: feeding a raw material gas mixture prepared from sulfur dioxide, sulfur dichloride and chlorine to a catalytic reactor after pre-heating, and reacting to obtain thionyl chloride; and preheating the gas mixture to 120-180 DEG C. Chlorosulfuric acid in a crude product thionyl chloride is inhibited within 1% from 2%, so that the quality of the crude product thionyl chloride is greatly improved; reduction of the content of chlorosulfuric acid in subsequent refined products is facilitated; and the generation condition through chlorosulfuric acid is avoided.

Owner:SHANDONG KAISHENG NEW MATERIALS

Continuous-pressure-changing rectification method and device for preparing medicine-level sulfoxide chloride

ActiveCN103130197BImprove continuityGuaranteed puritySulfur and halogen compoundsPtru catalystReaction rate

The invention relates to a continuous-pressure-changing rectification method and a device for preparing medicine-level sulfoxide chloride. With the adoption of the pressure-changing rectification method, an indirect sequence of carrying out heavy component removal and then carrying out light component removal is adopted as a rectification sequence, so that the decomposition of sulfoxide chloride at high temperature is reduced; sulfur is coarsely mixed with raw materials, sulfur is mixed with tower top gas of a heavy component removal tower, and a low-boiling-point substance, namely sulfur dichloride which is hard to remove, is fundamentally converted into a high-boiling-point substance, namely sulfur monochloride which is easy to remove, due to multistep sulfur adding; and a catalyst is added, so that the dissolution rate and reaction rate of the sulfur are accelerated. The heavy component removal tower is subjected to normal-pressure operation; and a light component removal tower is subjected to depressurized operation. The energy consumption of operation is reduced, and the decomposition reaction of the sulfoxide chloride hardly carries out under depressurized conditions, so that the probability that the color and luster of products are polluted by sulfur dichloride is greatly reduced, high-purity and colorless sulfoxide chloride products are produced from tower bottoms, and the content is over 99.9%.

Owner:TIANJIN UNIV

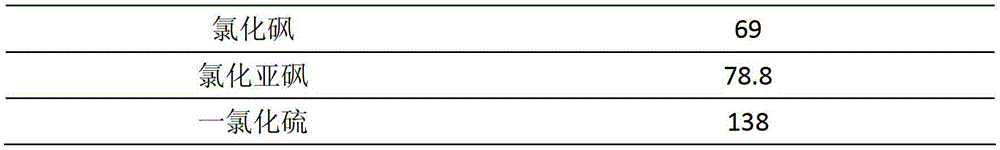

Synthesis method of 4,4'-thiobis(6-tert-butyl-3-methylphenol)

ActiveCN113200893AEasy to recycleEasy to reuseOrganic compound preparationSulfide preparationSilver iodideMethyl benzene

The invention relates to a synthesis method of 4,4'-thiobis(6-tert-butyl-3-methylphenol). According to the method, chlorine and sulfur dichloride which are necessary to use in a traditional process are avoided, and a large amount of hydrogen chloride tail gas is not generated; a byproduct silver iodide and acid liquor are easy to recover and reuse, the environmental protection property and safety of the reaction are greatly improved, and the problems of equipment corrosion and the like are avoided. Therefore, the method is suitable for industrially synthesizing the 4,4'-thiobis(6-tert-butyl-3-methylphenol).

Owner:JIANGSU JIYI NEW MATERIAL CO LTD

Thionyl chloride differential pressure thermal coupling rectification method and equipment

ActiveCN103933751BReduce energy consumptionSolve problems affecting production scheduleChemical industrySulfur and halogen compoundsReboilerDifferential pressure

The invention relates to a differential pressure thermal coupling rectification method and equipment for sulfoxide chloride. According to the equipment, a heavy component removing tower of a re-boiler is arranged at the bottom of a tower and a light component removing tower of a condenser is arranged at the top of the tower; a condensation re-boiler, an auxiliary condenser and a conversion reactor are arranged between the heavy component removing tower and the light component removing tower. An extract of a vapor-phase material at the top of the heavy component removing tower is divided into two parts, wherein one part is connected with a heating medium inlet of the condensation re-boiler, a heating medium outlet is connected with the auxiliary condenser and then returns back to the top of the heavy component removing tower, a liquid-phase material outlet at the bottom of the light component removing tower is connected with a heated medium inlet of the condensation re-boiler, and then a heated medium outlet returns back to the bottom of the light component removing tower; the other part is connected with the conversion reactor to carry out a reaction of converting sulfur dichloride to sulfur chloride, and a reacted material vapor phase enters the light component removing tower. The differential pressure thermal coupling is used for coupling heat at the top of the heavy component removing tower and heat at the bottom of the light component removing tower and the energy consumption is saved. The difficulty of blocking a pipeline by sulfur is overcome. A practical example shows that a differential pressure thermal coupling rectification process can save energy by more than 50% compared with a conventional process.

Owner:SHANDONG KAISHENG NEW MATERIALS

Preparation method of high-content thiodicarb

PendingCN114031533AIncreased toxicityReduce the risk of safety occupational health hazardsBiocideOrganic chemistryChemical synthesisPtru catalyst

The invention discloses a preparation method of high-content thiodicarb, and relates to the technical field of chemical synthesis. The method comprises the following steps: generating methylformamide thiamidine by taking N-methylformamide and sulfur dichloride as raw materials, carrying out condensation reaction on the methylformamide thiamidine and methomyl as raw materials under the action of a catalyst to generate a mixed solution containing thiodicarb, adding water into the mixed solution, conducting cooling to obtain a solution and crystals, filtering the solution and crystals, washing the filtered crystals, centrifugally filtering the crystal and a detergent, and drying the centrifugally filtered crystal to obtain thiodicarb with the content of greater than or equal to 98.0% and the total yield of greater than or equal to 95.0% in terms of methomyl. According to the method provided by the invention, the safety occupational health hazard risk is reduced, the process is safer, the operation is convenient, the use of pyridine is avoided, the foul odor on the production site is avoided, the environmental protection pressure is relieved, the production cost is reduced, the product quality and yield of thiodicarb are remarkably improved, and the thiodicarb reaches the export standard.

Owner:山东华阳农药化工集团有限公司

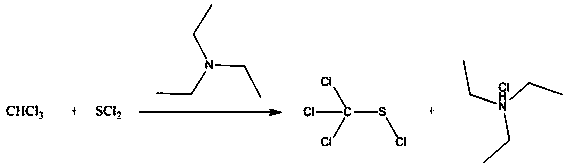

Synthetic method of perchloromethyl mercaptan

The invention discloses a synthetic method of perchloromethyl mercaptan. According to the synthetic method, trichloromethane and sulfur dichloride are used as reaction raw materials, and organic alkali is used as a catalyst and an acid-binding agent to prepare the perchloromethyl mercaptan. The method has the advantages of simple operation, strong operability, avoidance of the use of carbon disulfide and chlorine, effective solving of potential safety hazards caused by the use of carbon disulfide and chlorine and high safety; and the obtained perchloromethyl mercaptan appears to be yellow oilyliquid, has yield of 85% or above and density of 1.69 or above, meets use requirements, and presents industrial application value.

Owner:SHANDONG YANGGU HUATAI CHEM

Method for synthesizing thiodicarb with high methomyl conversion rate

The invention relates to a thiodicarb synthesis method with high methomyl conversion rate. The method comprises the following steps: adopting xylene and toluene as solvents; reaction: when the temperature in the synthesis kettle is reduced to be lower than 0 DEG C, starting to dropwise add SCl2, after the SCl2 is dropwise added, adding methomyl into the synthesis kettle, introducing nitrogen into the kettle, heating, and reacting; after the reaction is finished, centrifuging to obtain centrifugate and a centrifugal filter cake; primary water washing and filter pressing; carrying out secondary washing and centrifugation; washing with methanol, and centrifuging; and carrying out vacuum drying on a filter cake obtained by centrifuging the methanol washing material to obtain a thiodicarb finished product. According to the synthesis method provided by the invention, when the intermediate thiobipyridine hydrochloride is synthesized, a toluene and xylene double-component solvent is adopted, pyridine is used as a raw material and a solvent, and the reasonable material ratio avoids the influence on the reaction process of pyridine and sulfur dichloride due to overhigh solid material concentration in a reaction system; the yield of the thiobipyridine hydrochloride and the conversion rate of methomyl in the subsequent reaction between the thiobipyridine hydrochloride and methomyl are improved.

Owner:SHANDONG FIRST MEDICAL UNIV & SHANDONG ACADEMY OF MEDICAL SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com