Method and device for removing impurity-sulfur dichloride in thionyl chloride

A technology of thionyl chloride and sulfur dichloride, which is applied in the direction of sulfur and halogen compounds, can solve problems such as pipeline blockage, inability to realize continuous production, and no specific conditions given, and achieve the effect of convenient supplementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

[0031] Present embodiment 1-3 all adopts following device:

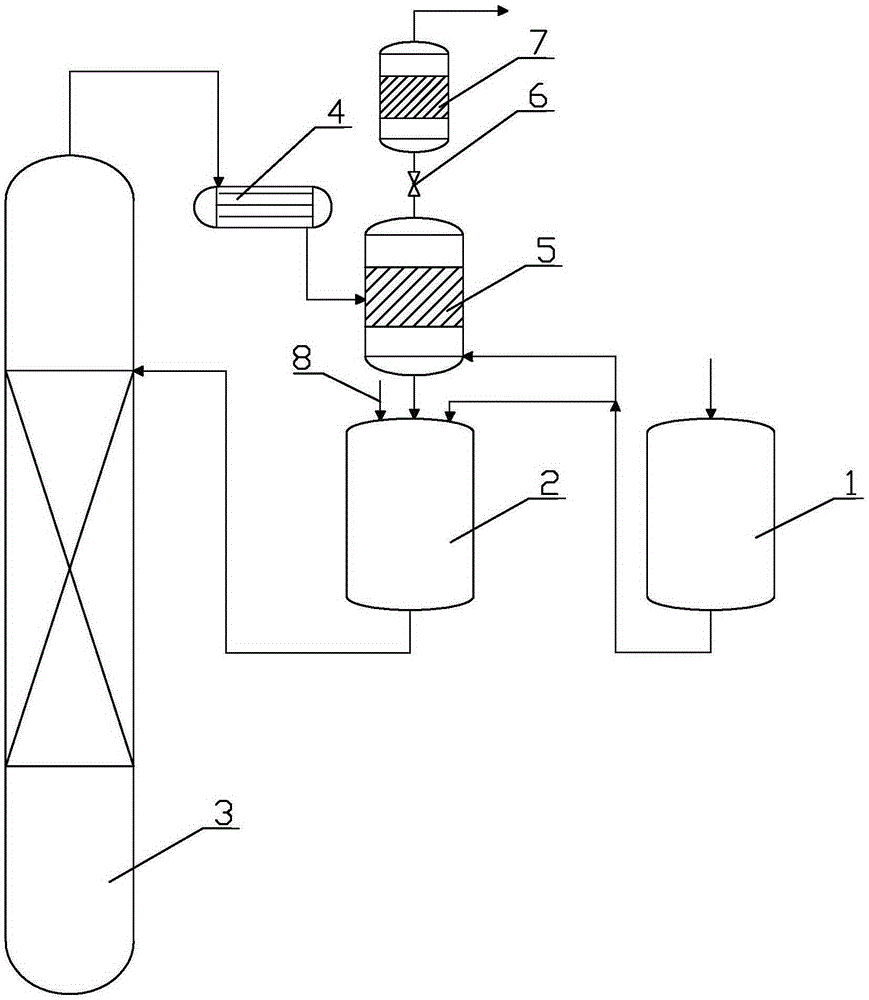

[0032] Such as figure 1 As shown, the described device for removing impurity sulfur dichloride in thionyl chloride comprises a crude product receiving tank 1, and the crude product receiving tank 1 passes through a pipeline and a sulfur distribution tank 2, a rectifying tower 3, a heater 4, an oversulfur The tanks 5 are connected successively, and the liquid sulfur line 8 is arranged on the top of the sulfur distribution tank 2 .

[0033] The top of the oversulfur tank 5 is connected with a sulfur feeding tank 7 through a pipeline, and a spherical valve 6 is arranged on the pipeline between the oversulfur tank 5 and the sulfur feeding tank 7 .

[0034] The bottom of the oversulfur tank 5 is connected to the crude product receiving tank 1 and the sulfur distribution tank 2 respectively.

Embodiment 1

[0036] The crude thionyl chloride is pumped into the sulfur distribution tank 2 from the crude product receiving tank 1, and then liquid sulfur is added to the sulfur distribution tank 2 through the liquid sulfur line 8, so that sulfur dichloride and sulfur react to convert sulfur monochloride into sulfur monochloride. Containing sulfur dichloride in the crude product sulfur oxychloride behind the sulfur records and is 2.3%, pushes into rectifying tower 3 and is carried out rectifying separation under the condition of 4kPa at tower top pressure, the sulfur oxychloride that tower top separates and Sulfur dichloride enters the heater 4, and the temperature rises to 85°C. It enters from the bottom of the oversulfur tank 5, and after passing through the 700mm high sulfur bed, the sulfur dichloride in the product sulfur oxychloride at the top of the oversulfur tank 5 is measured. The content of 0.003% has reached the requirement of 1# color of superior products in the industry stand...

Embodiment 2

[0039] The crude thionyl chloride is pumped into the sulfur distribution tank 2 from the crude product receiving tank 1, and then liquid sulfur is added to the sulfur distribution tank 2 through the liquid sulfur line 8, so that sulfur dichloride and sulfur react to convert sulfur monochloride into sulfur monochloride. Containing sulfur dichloride in the crude product thionyl chloride after the sulfur is measured as 2.0%, enters rectifying tower 3 and is carried out rectifying separation under the condition of 7kPa at tower top pressure, the thionyl chloride that tower top separates and Sulfur dichloride enters the heater 4, and the temperature rises to 88°C. It enters from the bottom of the oversulfur tank 5, and after passing through the 790mm high sulfur bed, the sulfur dichloride in the product sulfur oxychloride at the top of the oversulfur tank 5 is measured. The content of sulfur dioxide is 0.0025%, and after running continuously for 2 hours, the height of the sulfur bed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com