Electric arc furnace smoke radiation type waste heat boiler recovery system

A waste heat boiler and recovery system technology, applied in furnaces, waste heat treatment, furnace components, etc., can solve problems such as high operating costs, clogging of evaporators, economizers, waste of heat, etc., and achieve low maintenance costs and operating costs , Overcoming the problem of dust clogging and improving the efficiency of dust removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

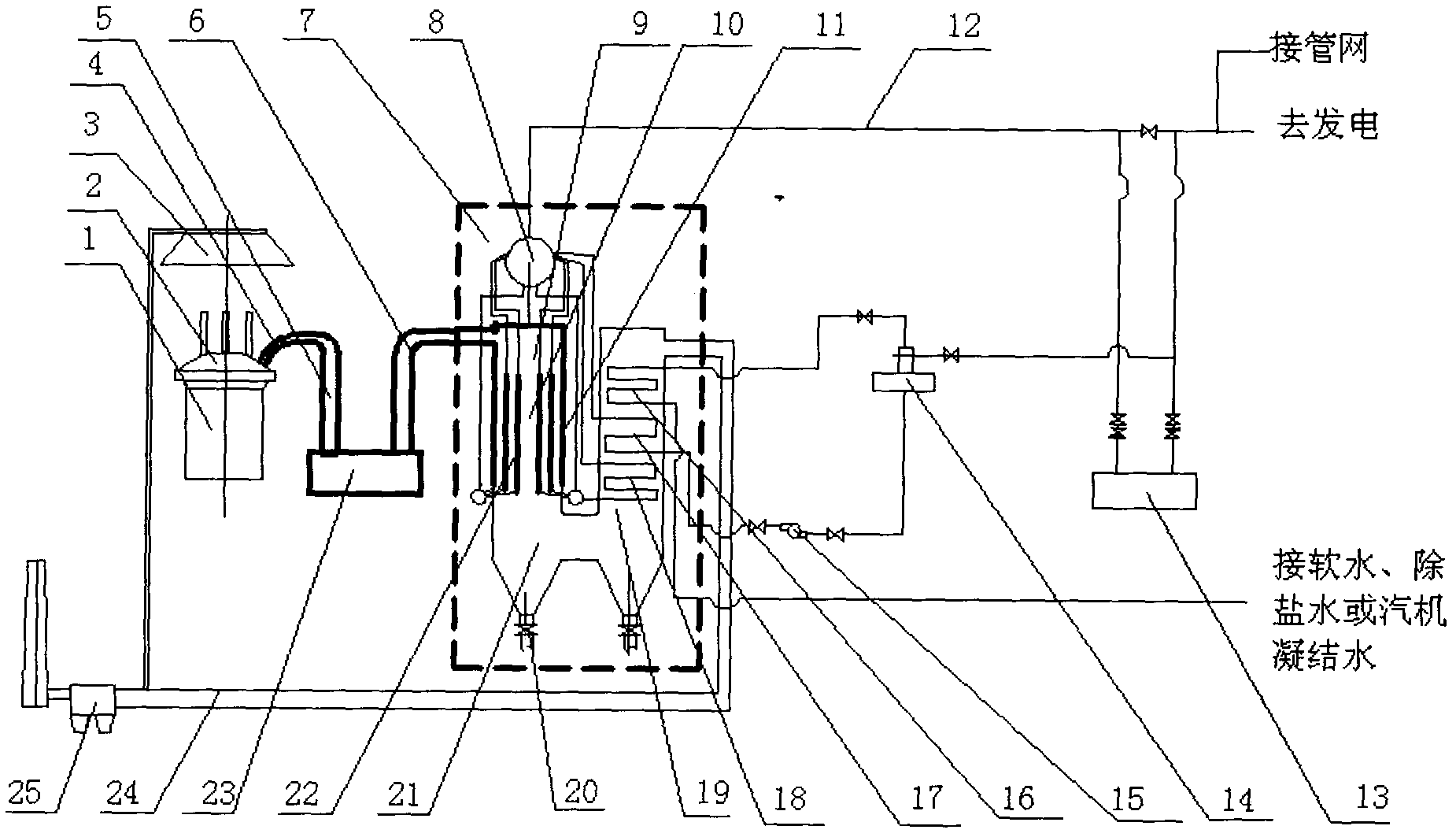

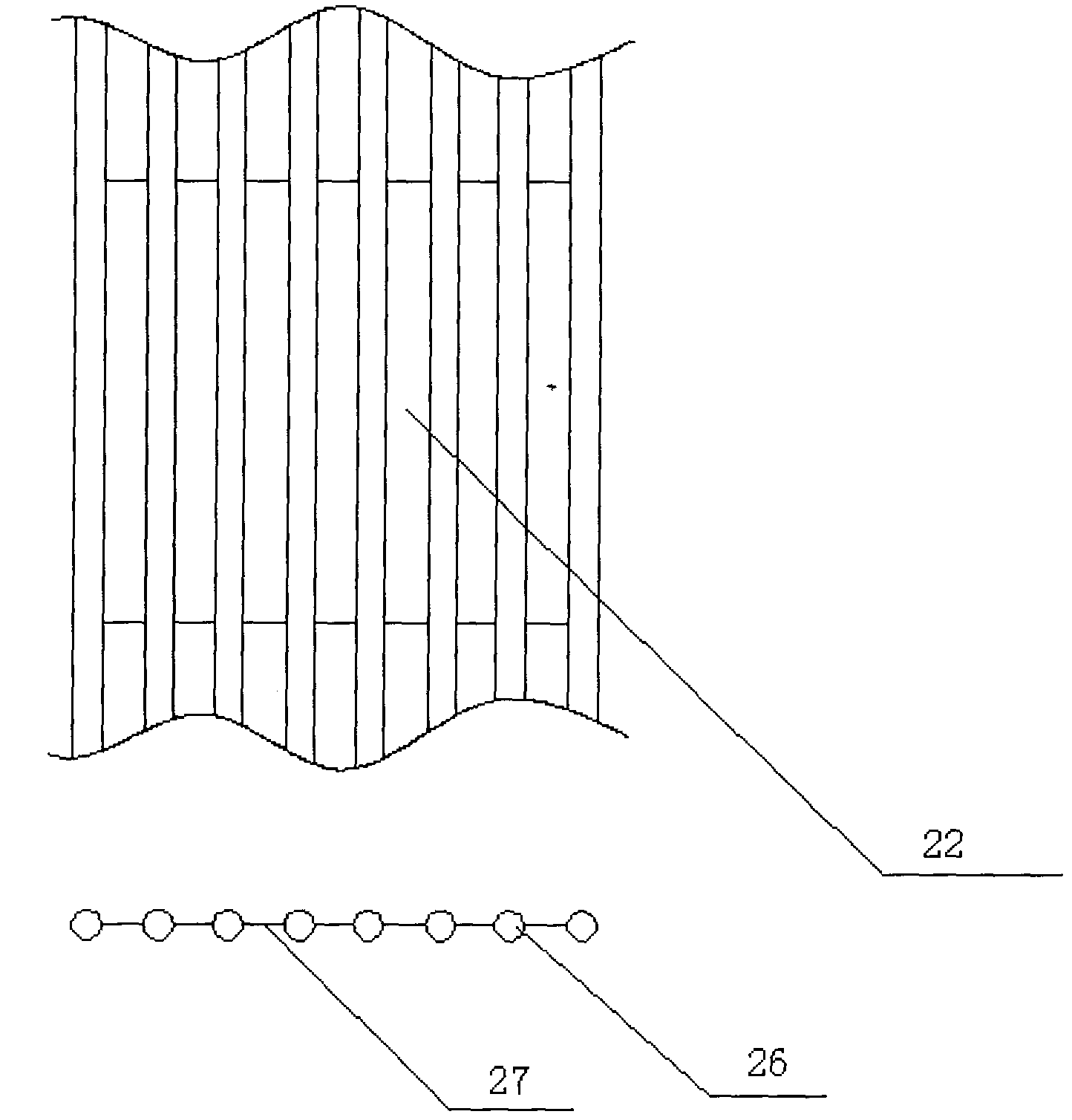

[0021] Such as figure 1 Shown: the electric arc furnace flue gas radiant waste heat boiler recovery system of the present invention includes the movable flue (4) of the electric arc furnace (1), the fixed flue (5) of the electric arc furnace, the boiler high temperature flue (6), and the radiant waste heat Boiler (7), heat accumulator (13), deaerator (14), radiant waste heat boiler with steam drum (8), flue gas equalization chamber (9), water-cooled radiant heat exchange chamber (10), membrane type Water wall (11), convection heat exchange chamber (19), ash discharge device (20), middle settling chamber of boiler (21); movable flue (4) of electric arc furnace (1) and fixed flue of electric arc furnace (5) The fixed flue of the electric arc furnace is connected with the settling chamber (23), the settling chamber (23) is connected with the boiler high-temperature flue (6), and the boiler high-temperature flue (6) is connected with the flue gas of the radiant waste heat boiler (...

Embodiment 1

[0036] The advantage of embodiment 1 is that dust removal is carried out in the settling chamber for the radiant waste heat boiler, which reduces the dust content of the flue gas and reduces the ash accumulation in the waste heat boiler; the disadvantage is that the flow of the flue gas increases and the floor area is large. Big investment.

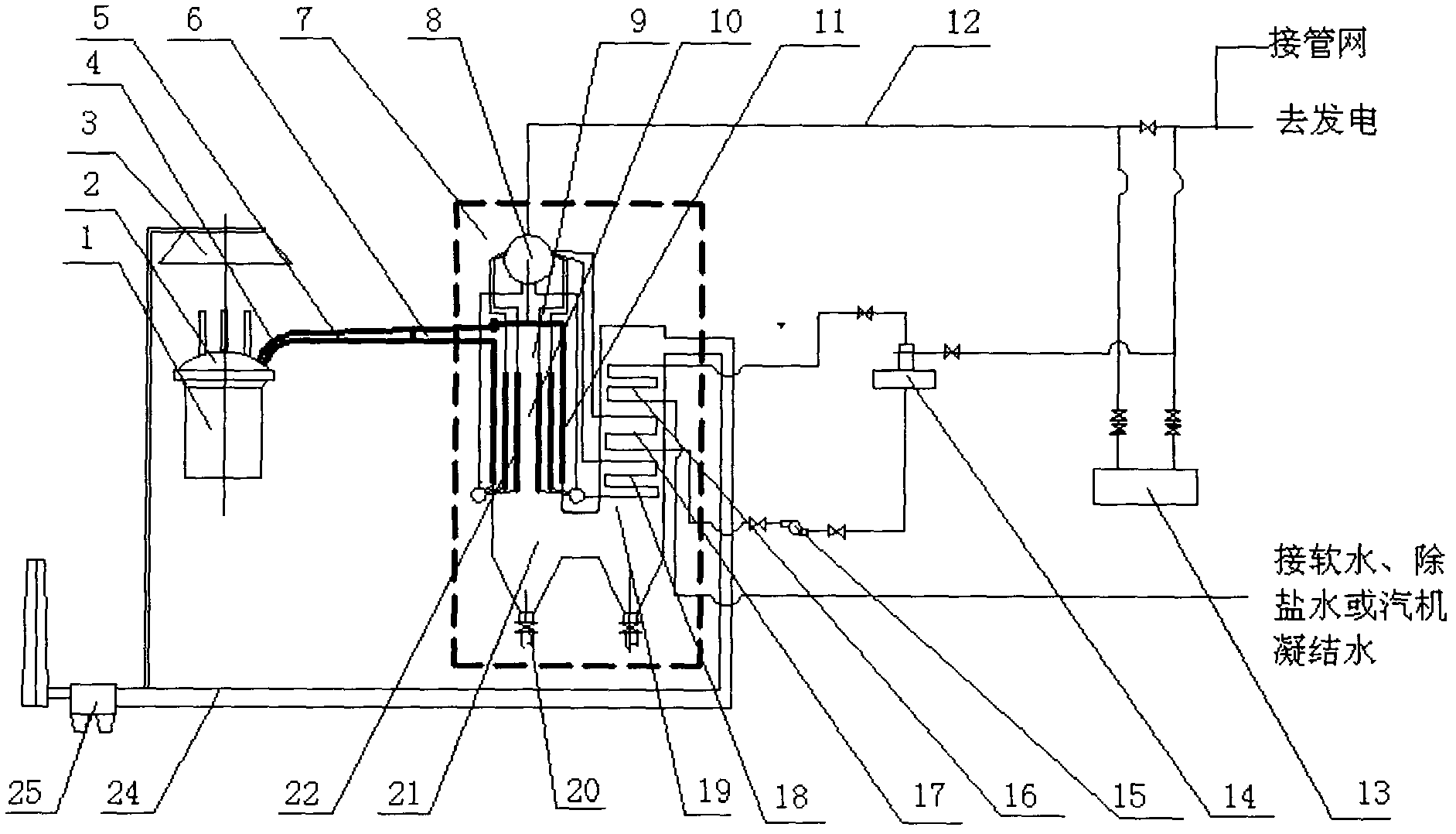

Embodiment 2

[0037] Embodiment 2 cancels the settling chamber, which has the advantages of short flue gas flow, simple structure, small floor space, and low investment; the disadvantage is that the dust content entering the radiant waste heat boiler is large, and the inner pipe of the equalization chamber is severely scoured and worn. The pipes in the equalizing chamber need anti-wear treatment, and the settling chamber in the middle of the boiler has a large amount of ash discharge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com