Patents

Literature

103results about How to "Solve the clogging problem" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Complex heavy-metal waste water emergency quick treatment method

ActiveCN102603103AIncrease contact areaQuick responseMultistage water/sewage treatmentChemical oxygen demandSludge

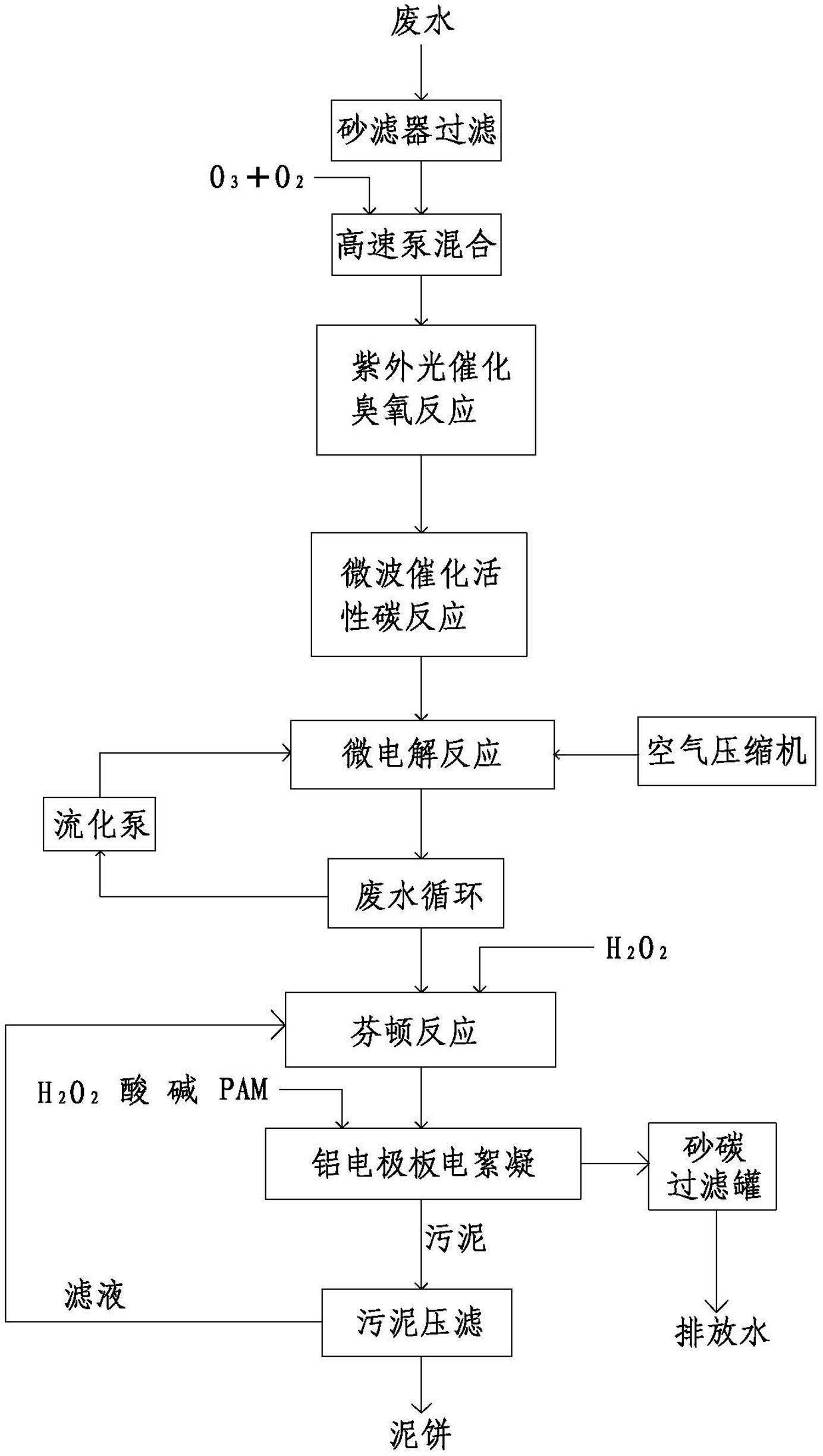

The invention relates to a complex heavy-metal waste water emergency quick treatment method, comprising the following steps of: filtering by a sand filter; mixing by a high-speed pump; carrying out an ultraviolet catalyzing ozone reaction; carrying a microwave catalyzing active carbon reaction; carrying micro-electrolytic reaction; circulating waste water; carrying out a Fenton reaction; carryingout electric flocculation on an aluminum electrode plate; and pressing and filtering sludge. Waster water in a circulating slot is pumped into an iron carbon fluidized bed by a fluidizing pump to be circularly treated; an air compressor is connected with the iron carbon fluidized bed and prevents a filler in the iron carbon fluidized bed from blocking; and the microwave active carbon reactor is an active carbon filling tower, and a microwave emitter is arranged outside the body of the active carbon filling tower. The complex heavy-metal waste water emergency quick treatment method disclosed by the invention is used for treating the complex heavy-metal waste water, associated devices are simple, easy, quick, can meet an emergency, and can update and convert, no various chemical raw materials are fed, and various complex heavy-metal waste water with unknown elements can be quickly treated as long as the current magnitude is regulated, and thus the heavy metal in the waste water and chemical oxygen demand can immediately reach the standard and are discharged.

Owner:东莞市珠江海咸水淡化研究所有限公司

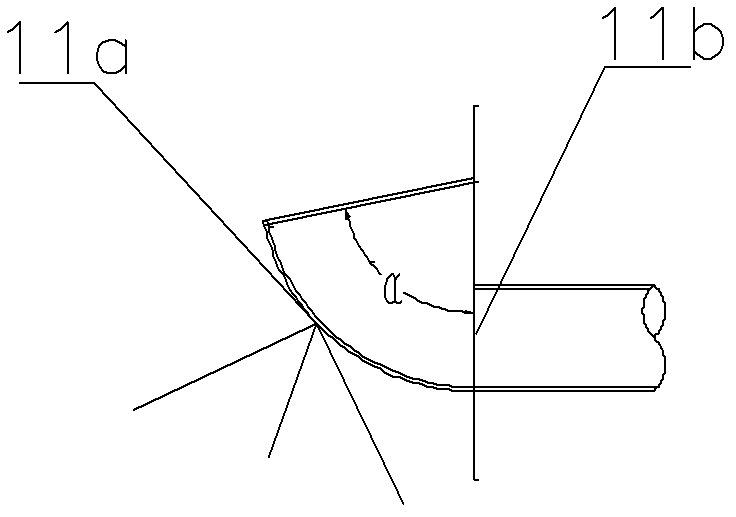

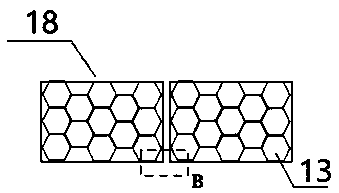

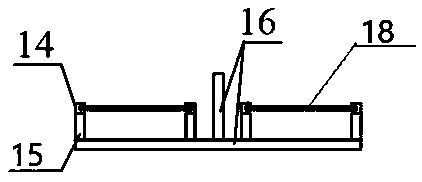

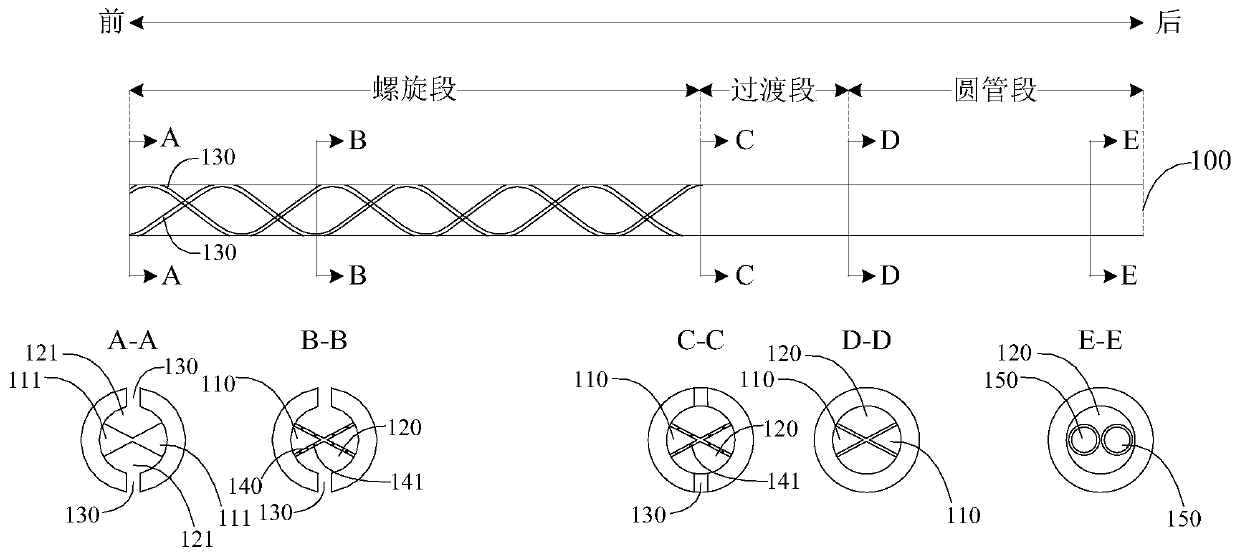

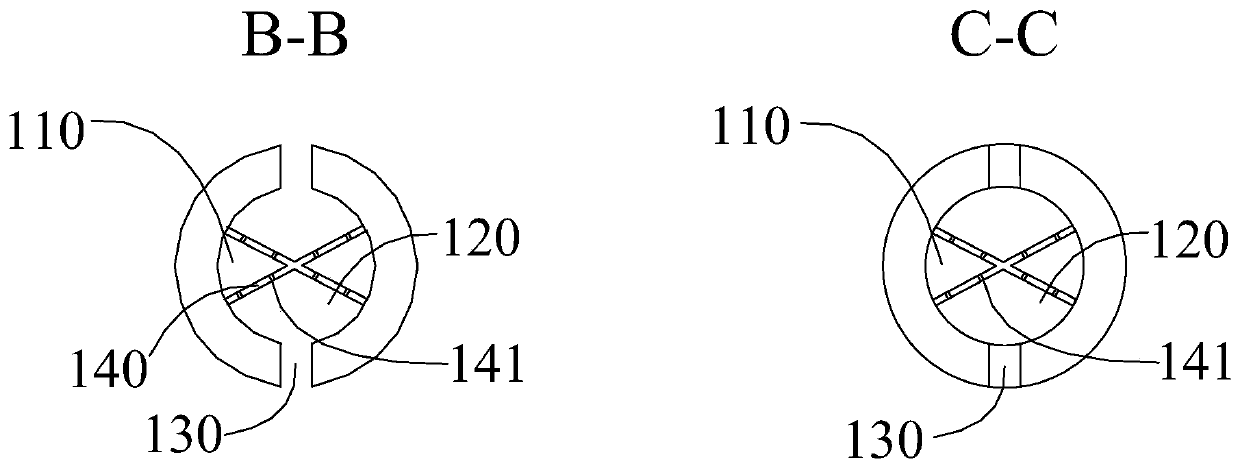

Heat shaped machine exhaust heat air purification heat energy utilized heat pipe exchanger

InactiveCN101113877AAvoid oil plugging sceneGuaranteed recyclingElectrostatic separationSteam/vapor condensersThermal energyEngineering

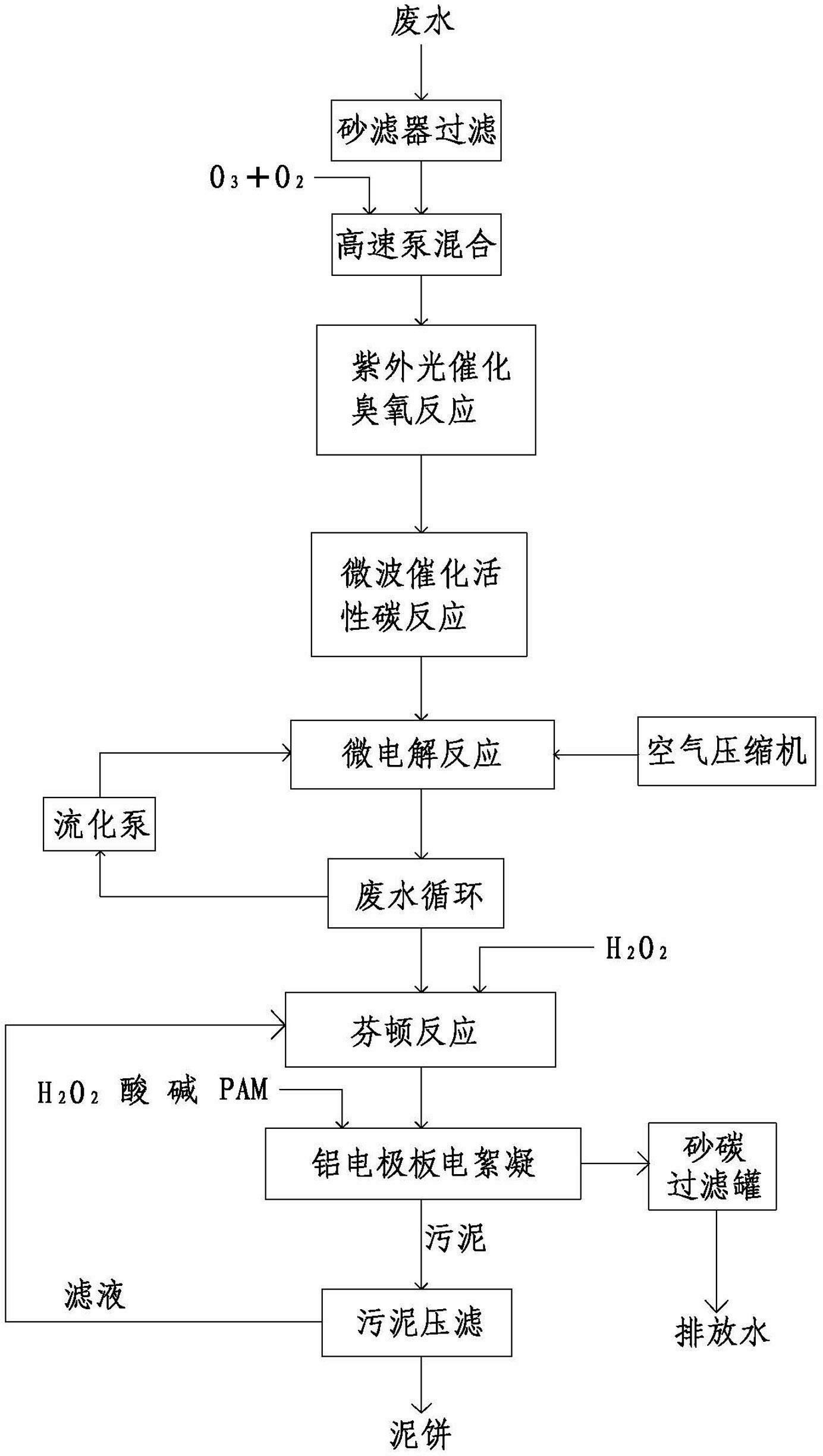

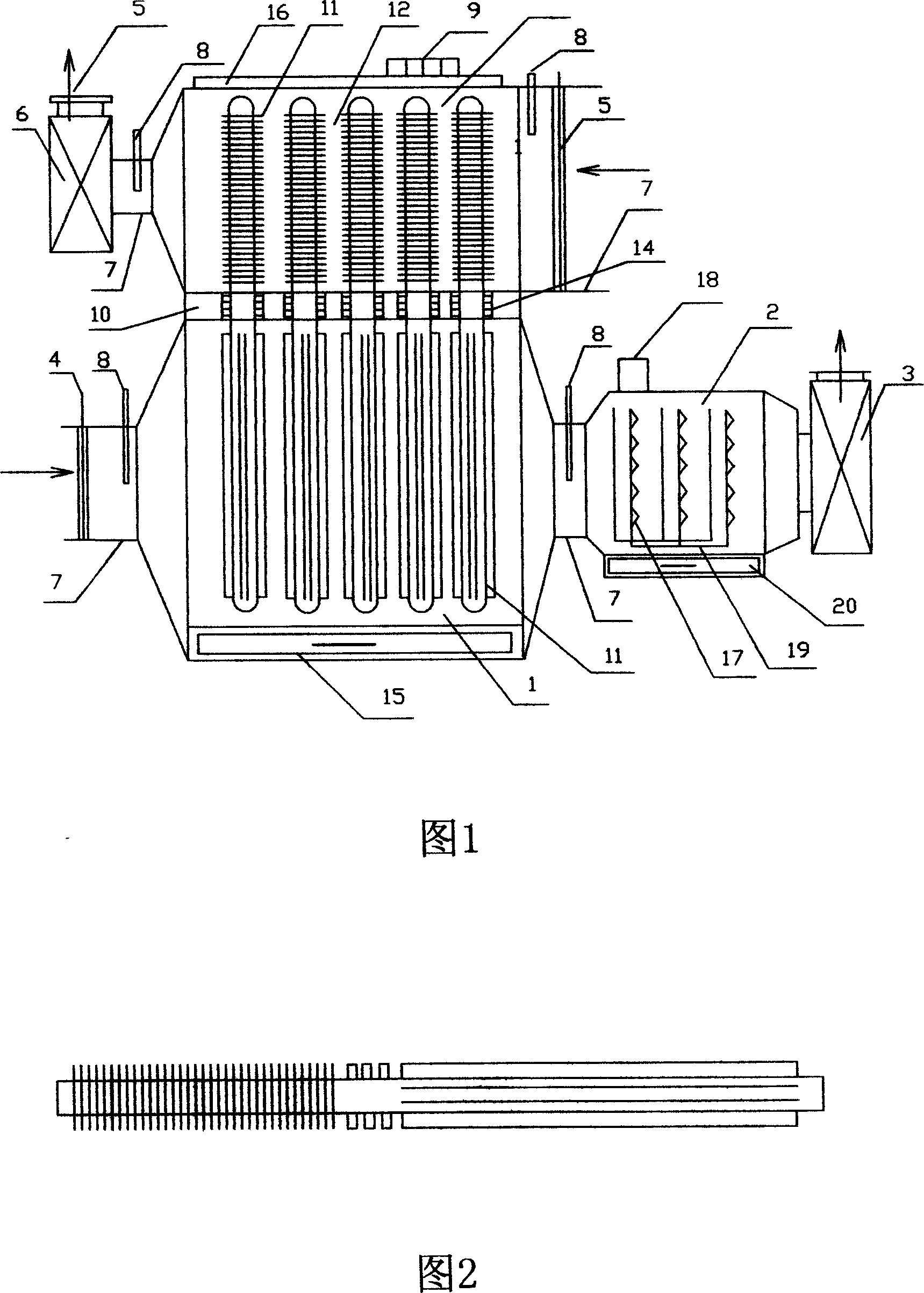

A heat pipe heat exchanger for waste heat air purifying and heat energy utilization of heat setting equipment is a heat pipe heat exchanger that is provided with heat pipes of different working mediums. An exothermic section of an air side heat pipe is of a spiral fin structure, and an endothermic section of a waste heat air side heat pipe is of a longitudinal fin structure. 50 percent of heat energy is recycled when the temperature of the waste heat air falls from 180 DEG C to 70-80 DEG C. At the same time, a waste heat air inlet tube and a heated air inlet tube are provided with a slot with a detachable and replaceable yarn dust filtering netting; the steamed and liquidized air that is condensed and discharged from the waste heat air with the heat absorbed by the heat pipe of longitudinal fin structure flows into an oil sump tank along the longitudinal fin, enters a low temperature electrostatic pulse oil fume staticizer, and the oil molecular is ionized in the high pressure pulse positive-negative electrode electric field. The waste heat air discharged from the heat setting equipment fundamentally reaches the requirements of environment protective of low temperature, dust free and oil free.

Owner:吴江市普天热管技术推广应用研究所

Soft soil foundation treatment method

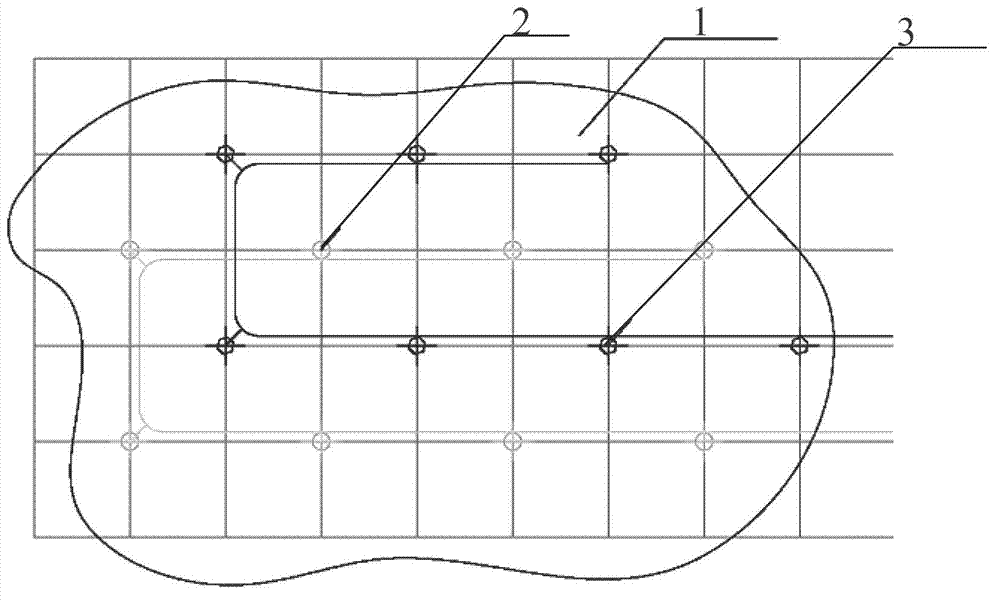

InactiveCN102953369AFlow fastDischarge as soon as possibleSoil preservationDynamic compactionAfter treatment

The invention provides a soft soil foundation treatment method. The soft soil foundation treatment method comprises the following steps of: leveling the ground; arranging a vacuum pipe and a ram pipe according to the designed interval and the designed pipe insertion depth after hole formation by a high-pressure water jetting method, and filling sand for preventing clogging while inserting the vacuum pipe; connecting and sealing the vacuum pipe and the ram pipe with a horizontal pipe of a vacuumizing system horizontally laid and a horizontal pipe of a pressurization system respectively; hermetically connecting the horizontal pipe of each system with a vacuum pipe and a booster pump respectively; starting the vacuum pump and the booster pump to start vacuuming and pressurization, thereby performing forced drainage on the soft soil foundation; in 3-5 days after drainage, removing all materials used by the vacuumizing system and the pressurization system, and performing dynamic compaction on the ground according to the requirements of the designed scheme. According to the method, the construction cost is low, the construction period is short, and the bearing capability is high after treatment.

Owner:谷孝建

Acid liquid fertilizer for drip irrigation and its prepn

The present invention relates to one kind of acid liquid fertilizer for drip irrigation and including nitrogen fertilizer, phosphate fertilizer, potash fertilizer, rooting promoter, dissolution promoter, trace elements and sulfuric acid. It is prepared through the steps of: dissolving phosphate fertilizer, potash fertilizer, trace elements and dissolution promoter in water through stirring, dissolving nitrogen fertilizer, adding sulfuric acid and adding rooting promoter. Its preparation process is scientific, low in power consumption and low in cost and uses simple apparatus. Its dissolution promoter can raise the dissolution degree of routine phosphate fertilizer and its rooting promoter can promote the growth of plant root system and the plant absorption capacity to nutrients. Its acidity can prevent jamming of drip holes.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

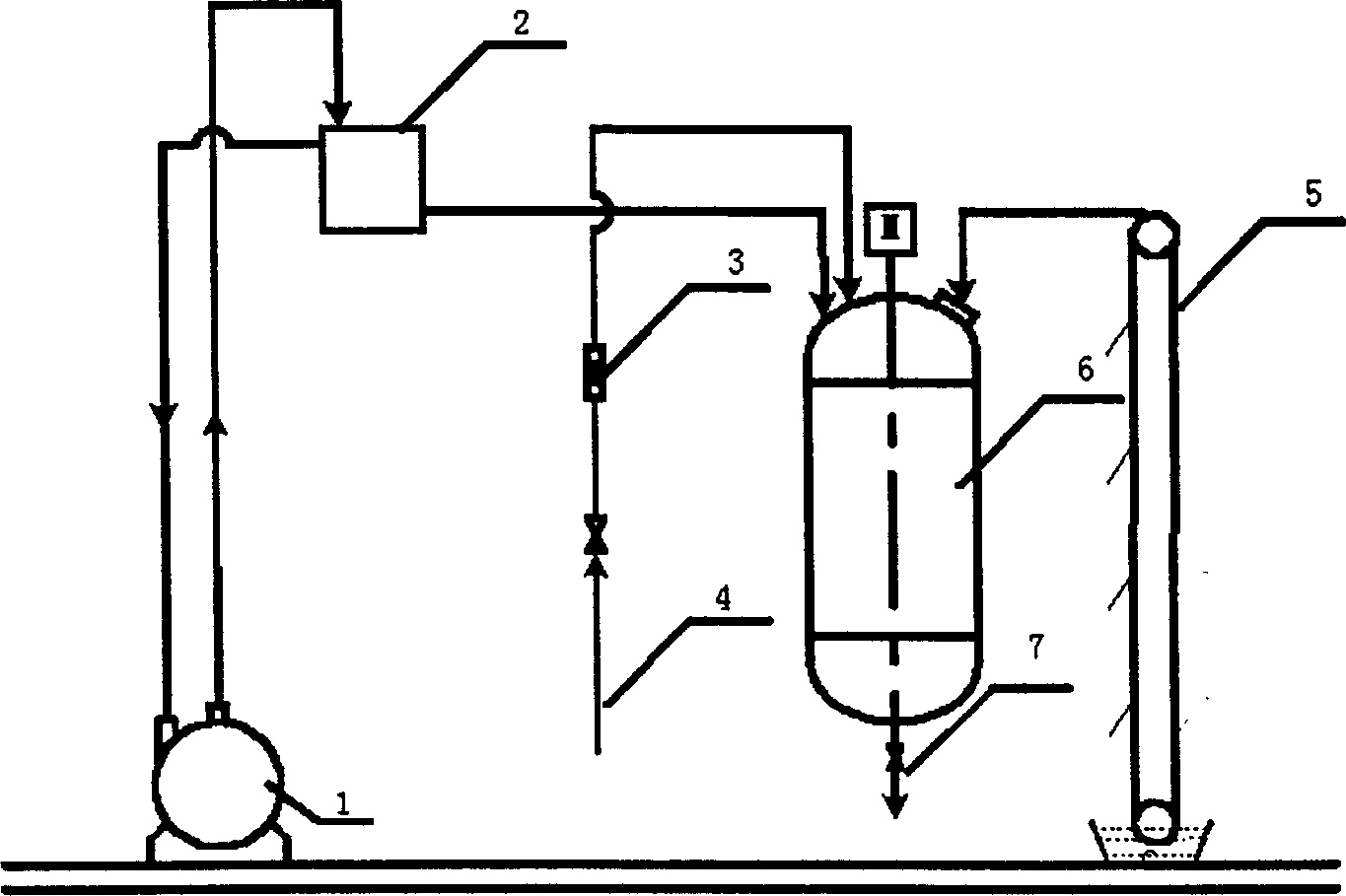

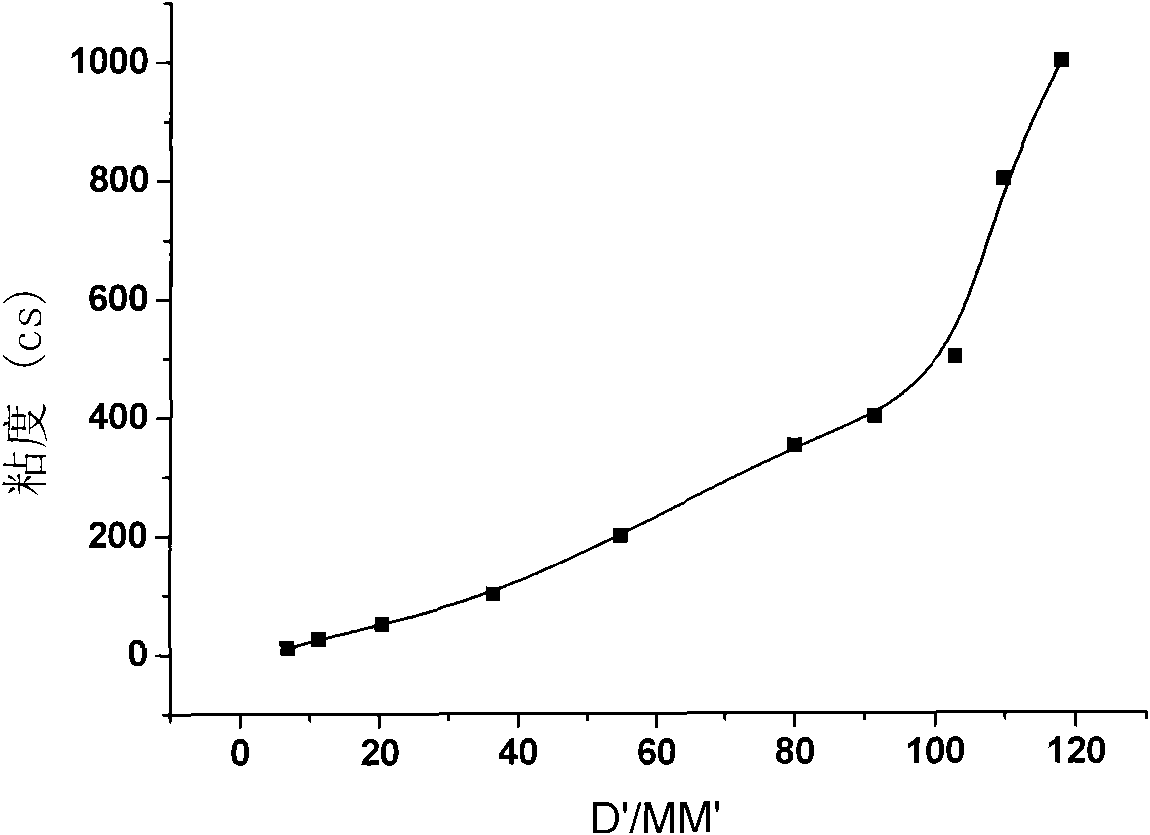

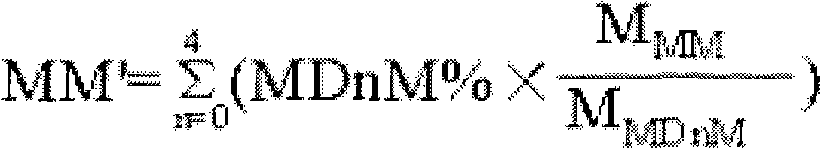

Method for preparation of silicon oil by silicon oil byproduct

The invention relates to a method for the preparation of silicon oil by silicon oil byproduct, in which dimethyl silicon oil byproduct in acid method production is used as raw material to prepare low-viscosity dimethyl silicone coil under the catalysis of solid acid catalyst. The method comprises the steps: calculating the constitution of raw materials in the silicon oil byproduct and drawing a proportion-viscosity relationship curve of the raw materials to set a feeding ratio, controlling reaction temperature between 50 and 110 DEG C under the catalyst of 3%-15% of solid catalyst, and implementing telomerization for 2 to 6 hours. By reutilizing the silicon oil byproduct, the method solves the problem of warehouse occupation of the silicon oil byproduct and lowers production cost. Using the solid acid catalyst can directly prepare neutral equilibration reaction product without neutralization and water washing procedures, the reaction process is simple, the viscosity of the product is easy to control and the regenerated byproduct can still be used repeatedly.

Owner:SHANDONG DONGYUE ORGANIC SILICON MATERIAL

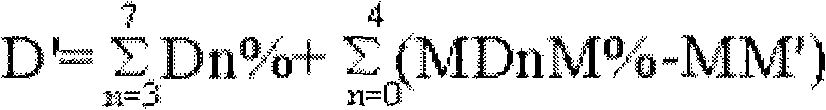

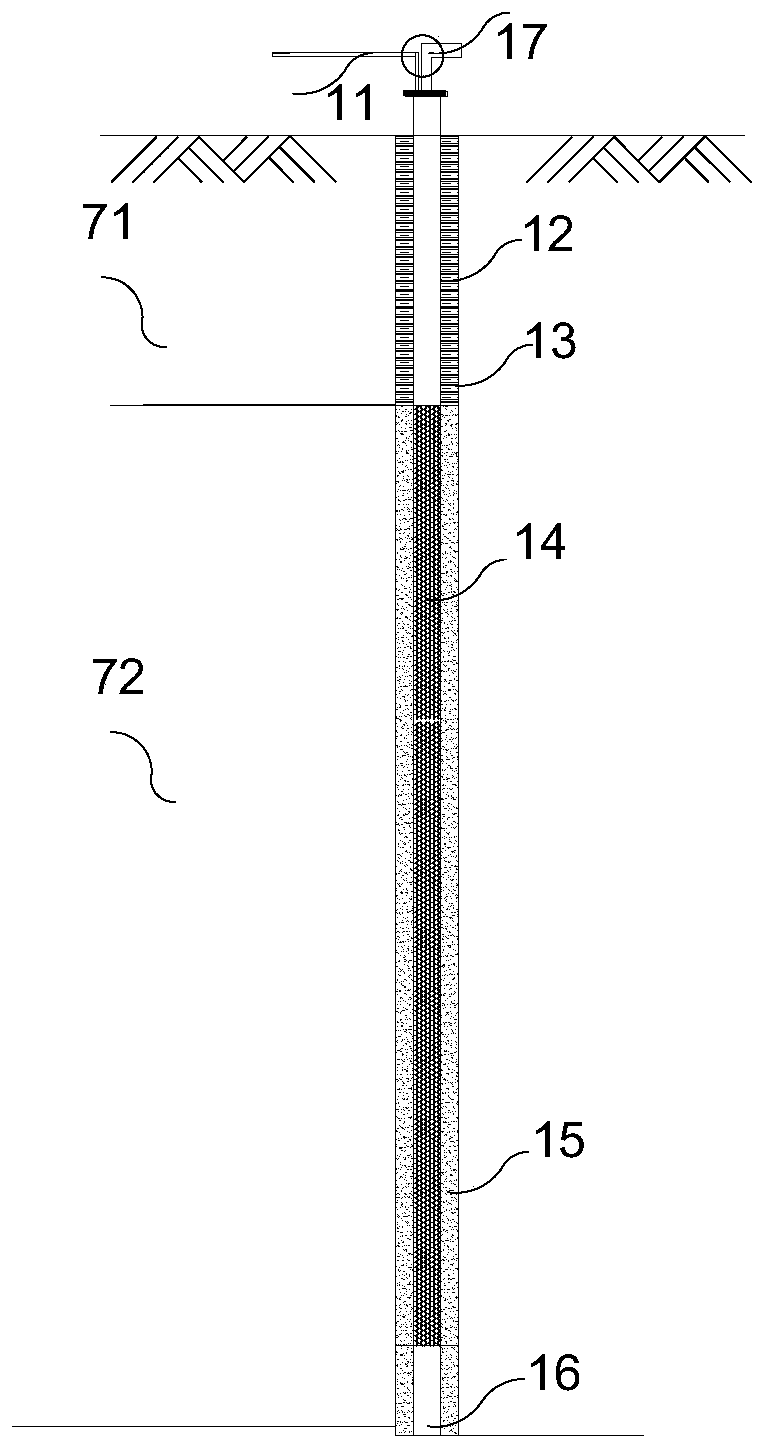

Salt cavern building method based on opposite-well mining type old wells and application thereof

InactiveCN107035343AEfficient water solution miningSolve the clogging problemFluid removalFresh waterSalt mine

The invention relates to a salt cavern building method based on opposite-well mining type old wells and an application thereof, and belongs to the technical field of salt mining. The salt cavern building method comprises the following steps that (1) detection and checking are conducted on the opposite-well mining type old wells; (2) a well is drilled between the two old wells and extends to a rock salt layer; (3) pipes are downwards put, specifically, a casing pipe and a center pipe are downwards put into the drilled well, and the center pipe is sleeved with the casing pipe; (4) oil is injected between the casing pipe and the center pipe; (5) fresh water is injected from the center pipe and reaches the old wells on the two sides through old well horizontal sections to dissolve rock salt into bittern, and the bittern is discharged from the old wells on the two sides; and (6) when a cavern reaches the set volume, injection of the fresh water is stopped, and building is finished. The salt cavern building method based on the opposite-well mining type old wells achieves the comprehensive targets of horizontal section plug removal, salt mining and oil and gas storage and is suitable for being widely applied and popularized.

Owner:CHONGQING UNIV

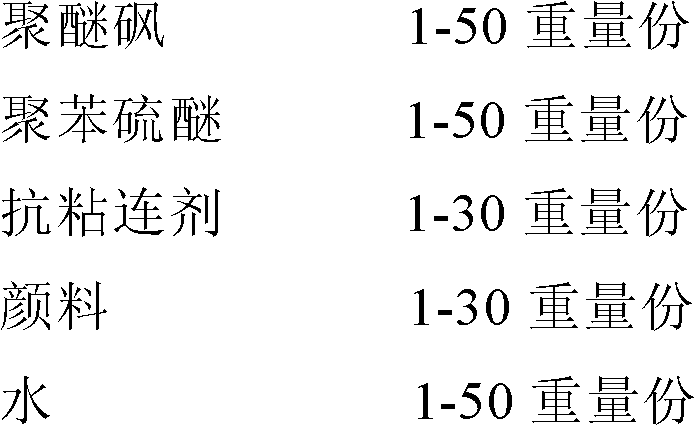

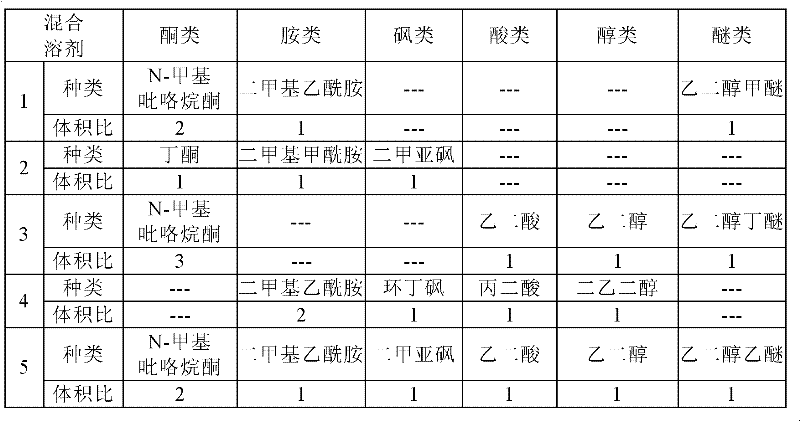

Anti-adhesion paint

InactiveCN102373009ASolve the clogging problemQuick releaseAnti-corrosive paintsAnti-Adhesion AgentHardness

The invention relates to an anti-adhesion paint which comprises polyether sulfone (PES), polyphenylene sulfide (PPS), anti-adhesion agent, pigment, water and solvent. Compared with the traditional waterborne PES paint, the coating formed by adopting the anti-adhesion paint has better performances such as corrosion resistance, wear resistance, hardness, adhesive force and non-viscosity. The paint can not only be singly coated to form the finished product, but also be used as any layer of the multilayer nonstick paint.

Owner:曾志玲

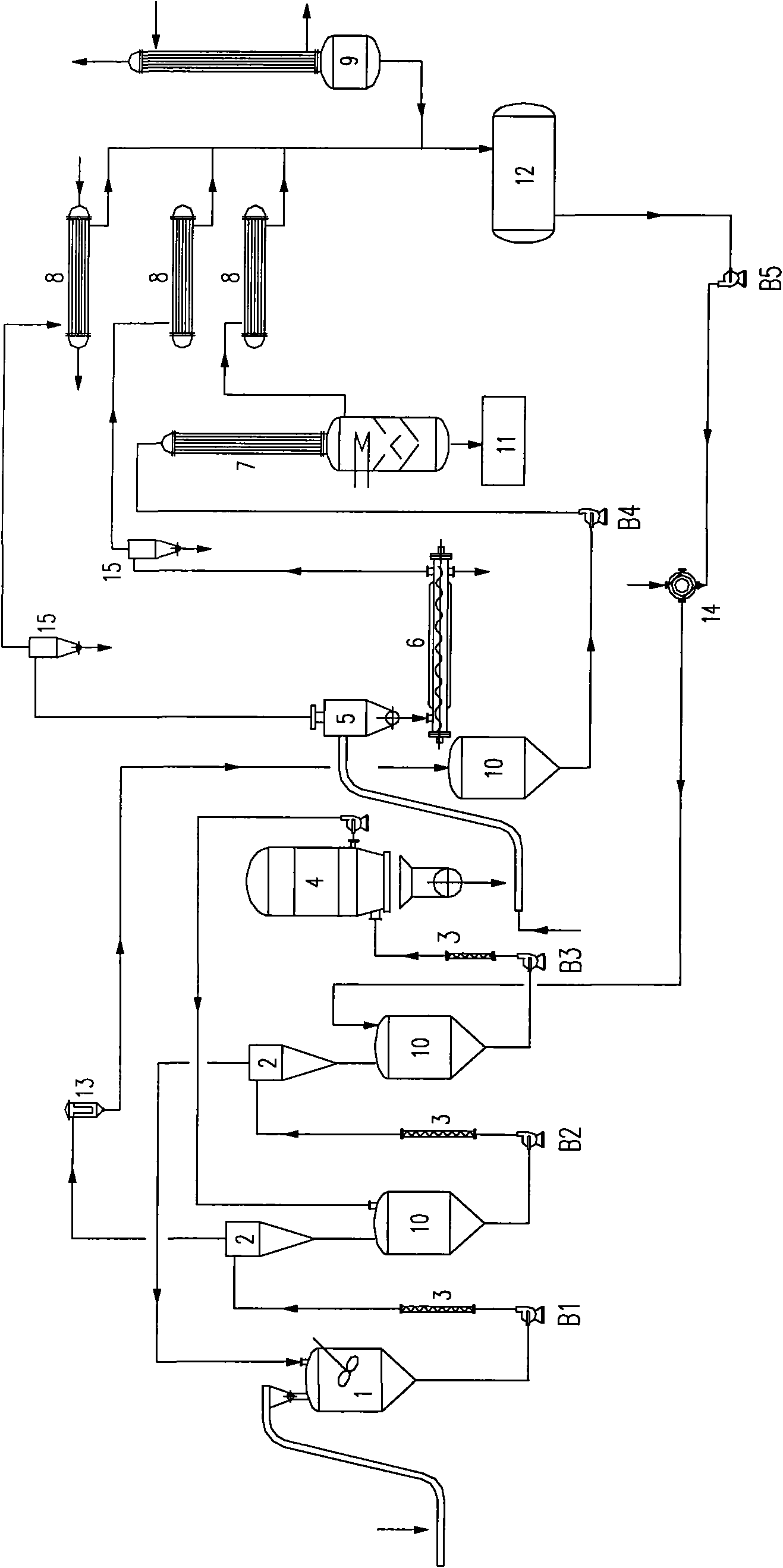

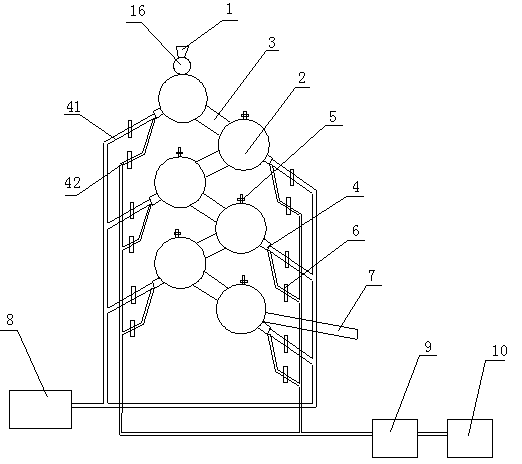

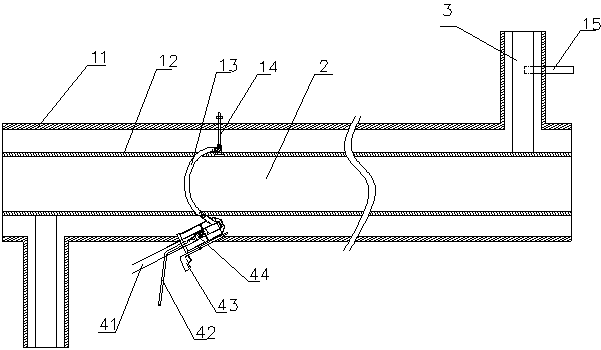

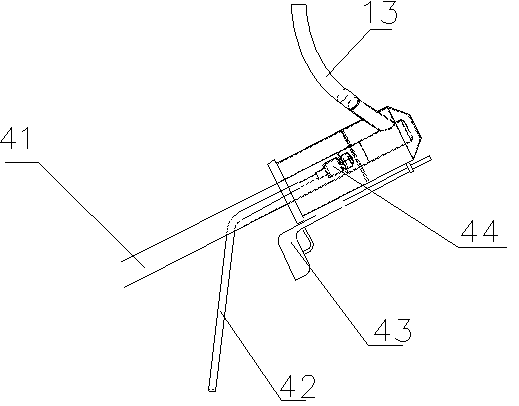

Liquid rotary type continuous extraction process and device

InactiveCN101596373ASolve the clogging problemSimplify extraction equipmentSolid solvent extractionSolventSolvent evaporation

The invention discloses a liquid rotary type continuous extraction process comprising the following steps: a. adding and mixing materials: powder materials are continuously added into a mixing tank to be fully stirred and mixed with extract liquor separated from a cyclone; b. rotary liquid extraction: the mixed materials pass through a static mixer and enter multiple groups of cyclone extractors for extraction; the extraction time can be controlled between 10min and 30min; the solvent ratio (weight ratio of the materials to a solvent) is 1:2-5; the solvent is hexane, ethanol or acetone; c. solvent evaporation: extracted mixed liquor passes through a combined evaporator formed by a falling film parallel tube evaporator and a stripping tower to obtain an extract; d. solvent recovery: the evaporated solvent is cooled and recovered in a condenser; e. material desolvation, drying and recovery: the extracted materials are first filtered by a leaf filter, then dried twice by a steam pneumatic drier and a steam jacketed type helical drier respectively and further desorbed to recover the solvent therein. The process solves the difficult problem of blockage of powder materials generally in the extractors.

Owner:河南金龙工程技术有限公司

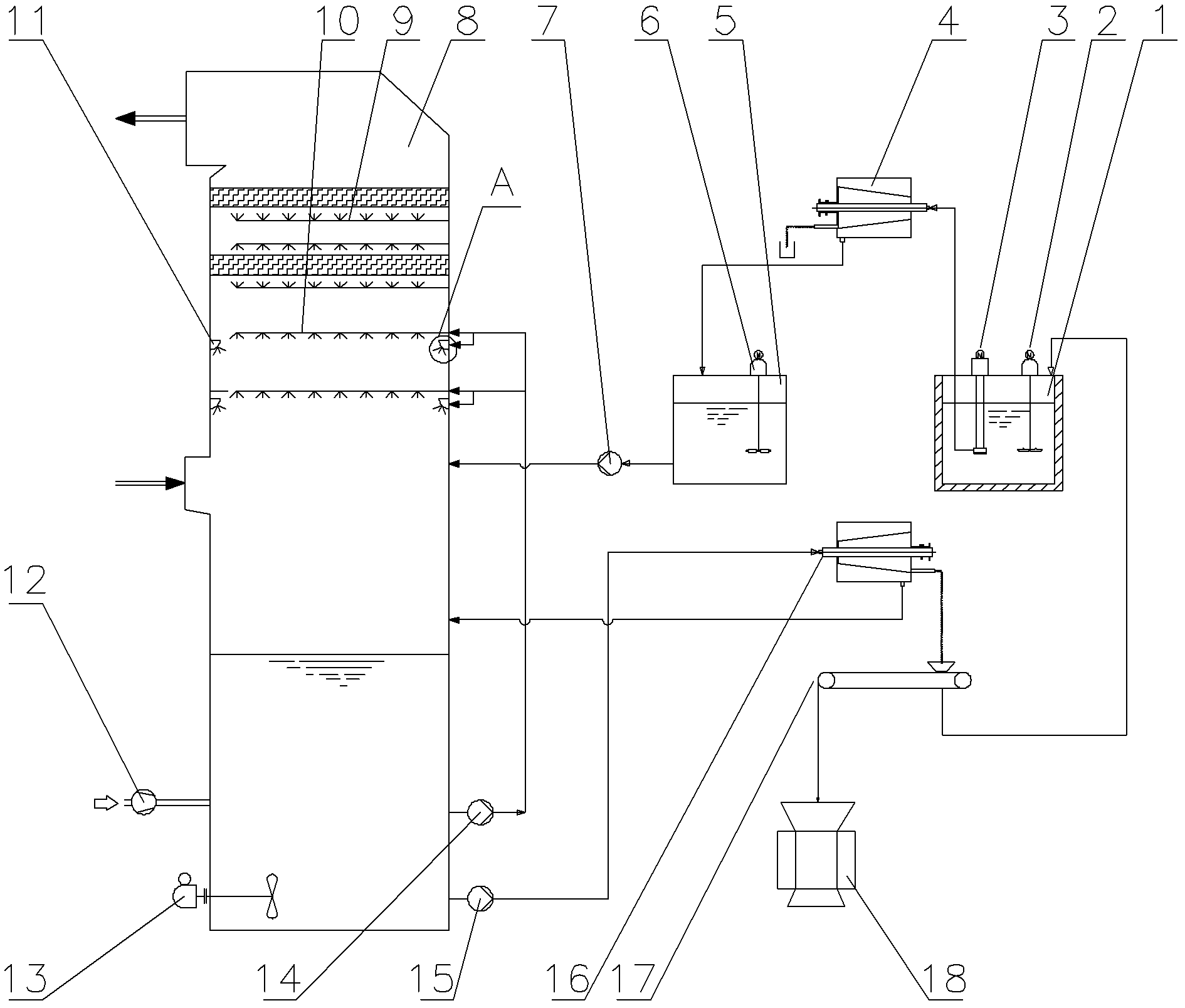

Equipment for performing wet-method flue gas desulfurization and producing gypsum by discarded carbide slag

ActiveCN102500223ASolve the problem of "short circuit"Easy to combSolid waste disposalDispersed particle separationCycloneSlag

The invention discloses equipment for performing wet-method flue gas desulfurization and producing gypsum by discarded carbide slag. The equipment mainly comprises a wet-method flue gas desulfurization part, a carbide slag pretreatment part and a gypsum slurry retreatment part, wherein a hollow annular boss with a slurry spray nozzle is arranged below a slurry spray layer and on the inner wall of a spray tower cylinder body of the wet-method flue gas desulfurization part, so that the problem of flue gas 'short circuit' in the spray tower cylinder body is solved; according to the carbide slag pretreatment part, the problem of the stoppage of a filter layer in the process of separating the carbide slag slurry is solved by the design of a first rotation separator with a cleaning function; and according to the gypsum slurry retreatment part, an expensive cyclone separator in the conventional gypsum separation equipment is replaced effectively by the design of a second rotation separator with the cleaning function. According to the equipment, the flue gas desulfurization of fire coal, the comprehensive utilization of the discarded carbide slag and the processing of the gypsum serving as a desulfurization byproduct are integrated organically, and the equipment has a simple structure, is stable in running and high in desulfurization efficiency, treats wastes with the wastes and meets the requirement of current environment friendliness.

Owner:WUHAN YONGQING ENVIRONMENTAL PROTECTION TECH ENG

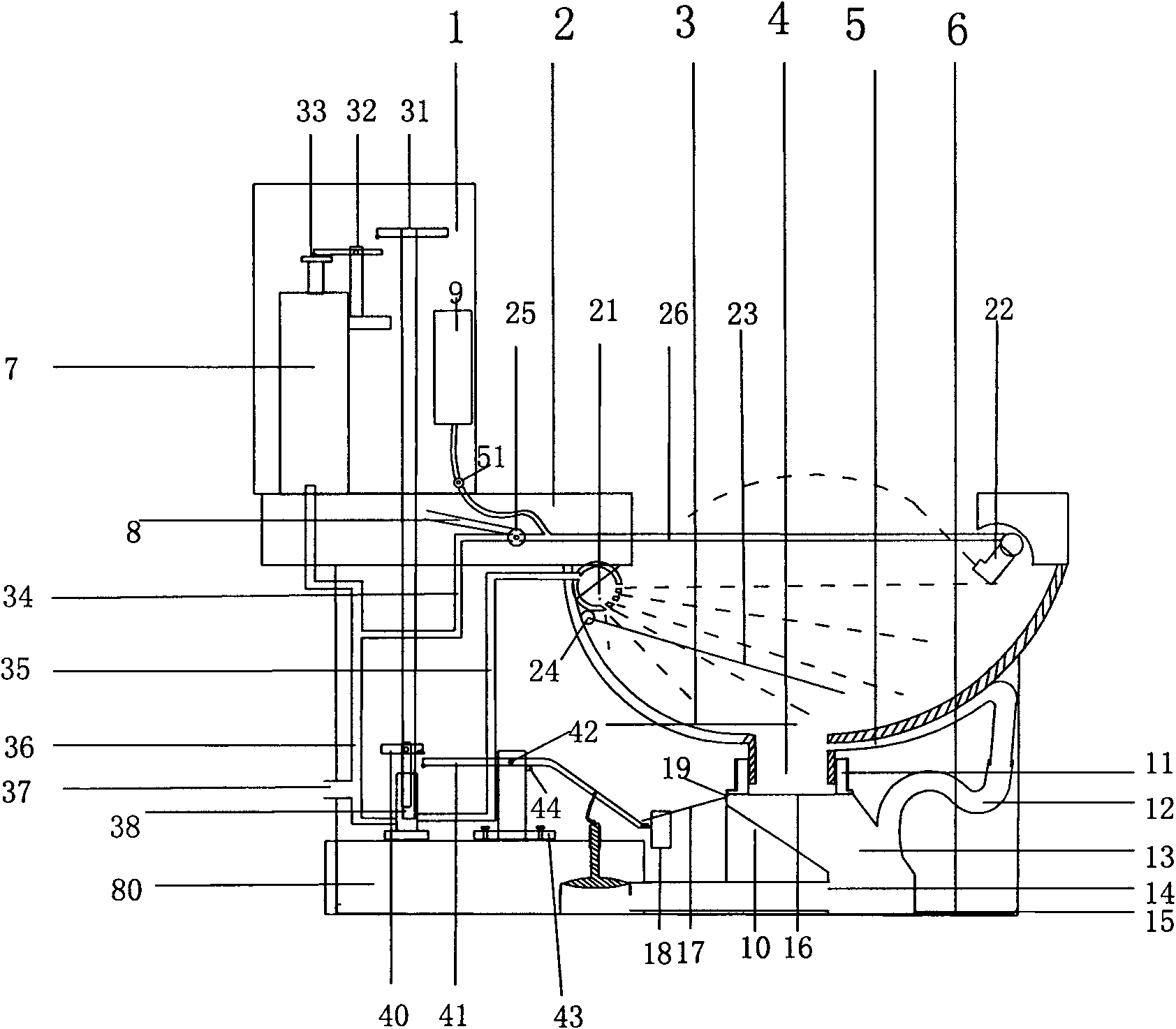

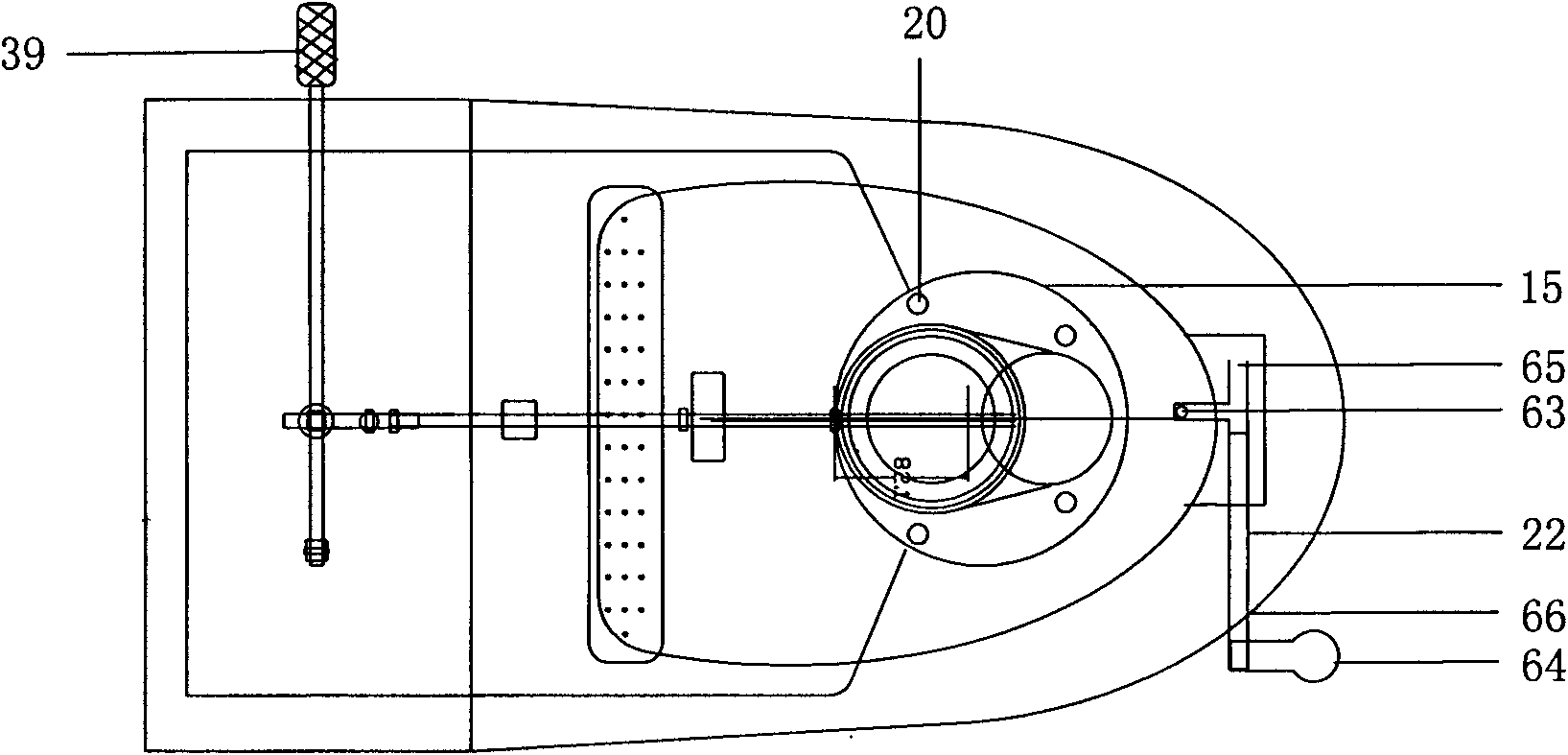

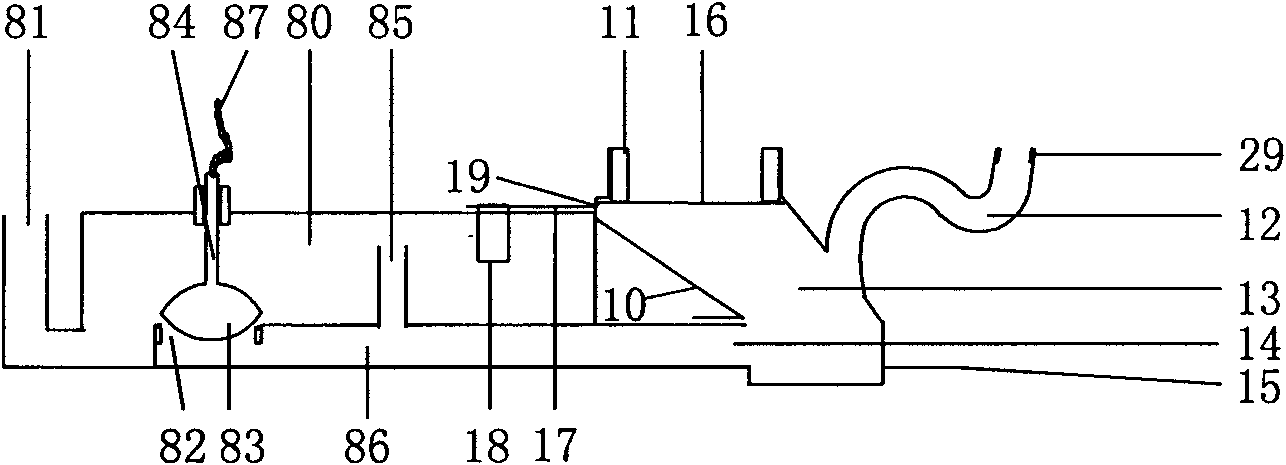

Water-saving splashproof woman washing integrating pedestal pan

InactiveCN101684668AImprove practicalityTake advantage ofWater closetsFlushing devicesWater savingDisease

The invention provides a water-saving splashproof woman washing integrating pedestal pan, which is characterized in that: the cleaning force is large enough to wash away gum adhered on the wall of the pan as a method of improving the pressure of running water is used to arrange a spray nozzle (21) to clean the inner wall (3) of the pan; a water supplement rod (32) and other parts are used to control the water supplement of a water part (7) and the water supplement amount can be selected randomly within a range from 0.7 to 2.4 liters; a waste water recycling tank (80) is used to store waste water from clothes washing and bathing so as to flush a sewage drainage pipe at the lower part of the pan, so the cleanness and the excrement conveying capacity of the sewage drainage pipe are improved greatly, the building sewage drainage pipe is more clean and running water is saved by 50 to 80 percent; a splashproof grid (23) is arranged to solve the problem of human body disease infection caused by sewage splashed by falling excrement; and a body washing nozzle (22), a hot water pipe (8) and a liquid medicament container (9) are arranged to provide the pedestal pan with a function of body washing with self-prepared cold and hot water and a function of treatment and health care with the liquid medicament. The pedestal pan is simple in operation, low in cost and free from fault, improves the health and quality of people and has remarkable therapeutic and health-care effect on gynecopathy and haemorrhoids.

Owner:王心弟

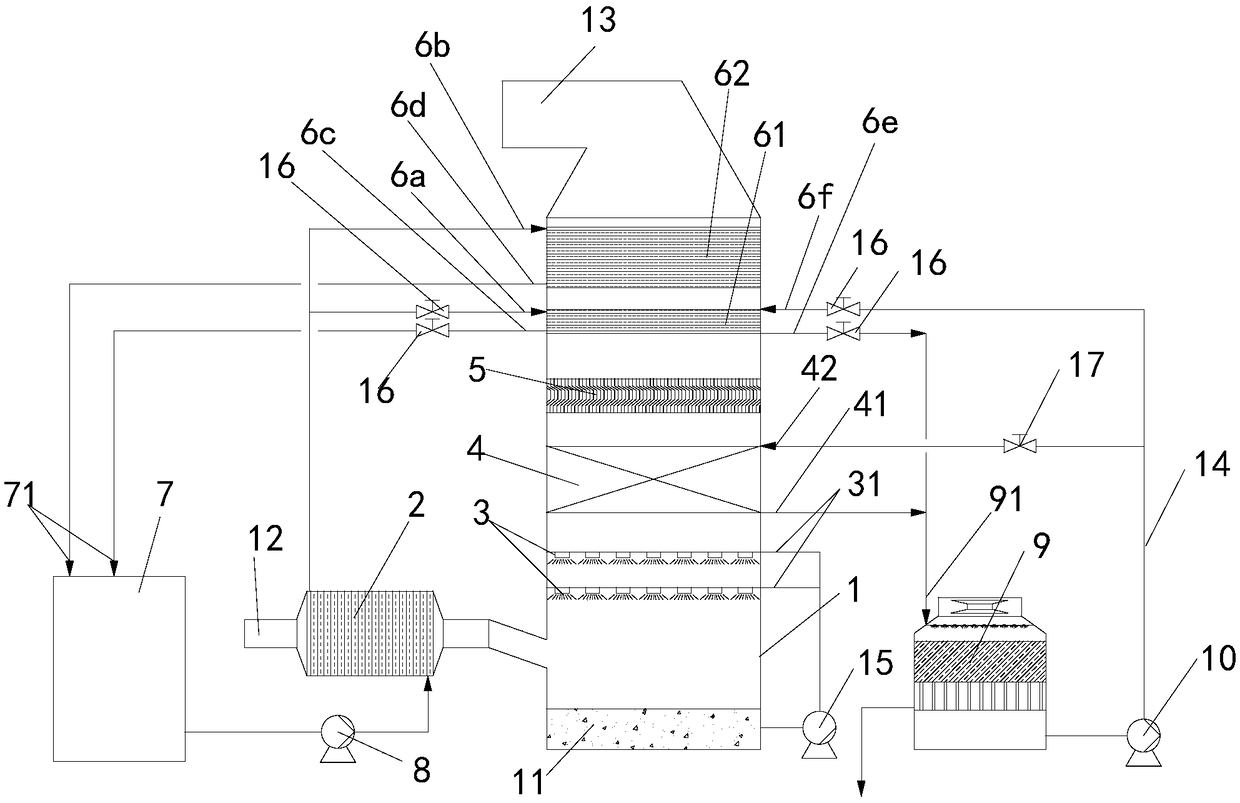

Low-cost deep flue gas purification device and purifying, dewatering and white-smoke-eliminating process thereof

PendingCN108970370ASave energyCut costsGas treatmentLighting and heating apparatusCooling towerRecuperator

The invention relates to a low-cost deep flue gas purification device and a purifying, dewatering and white-smoke-eliminating process thereof. The purification device comprises a desulfurization tower, and the desulfurization tower is sequentially provided with a desulfurizing and spraying unit, a cooling condenser, a defogging and dehydrating layer, a first outlet heat exchanger and a second outlet heat exchanger; an inlet flue heat exchanger is connected to an inlet flue channel, and a heat-exchange-liquid buffer tank, a heat-exchange-liquid circulation pump, a circulating-liquid cooling tower and a coolant circulation pump are arranged outside the desulfurization tower. The low-cost deep flue gas purification device and the purifying, dewatering and white-smoke-eliminating process thereof have the advantages that through cooling, condensation and coagulation of flue gases, deep purification of multiple pollutants is realized while moisture in the flue gases is recovered; after moisture recovery of the flue gases, the specific heat of the flue gases decreases, heat exchange energy consumption required for white smoke elimination of the outlet flue gases is reduced, and heat exchange energy consumption and costs for white smoke elimination of the outlet flue gases are reduced; inlet flue channel condensation and cooling are adopted, the volume of the flue gases is reduced, thestaying time of the flue gases in the tower is prolonged, the efficiency of the desulfurization tower is improved, and operation energy consumption is reduced; through heat exchange of the outlet flue gases and the self-cleaning process of the heat exchangers, the problems of scaling and blocking of the heat exchangers are solved.

Owner:杭州蕴泽环境科技有限公司

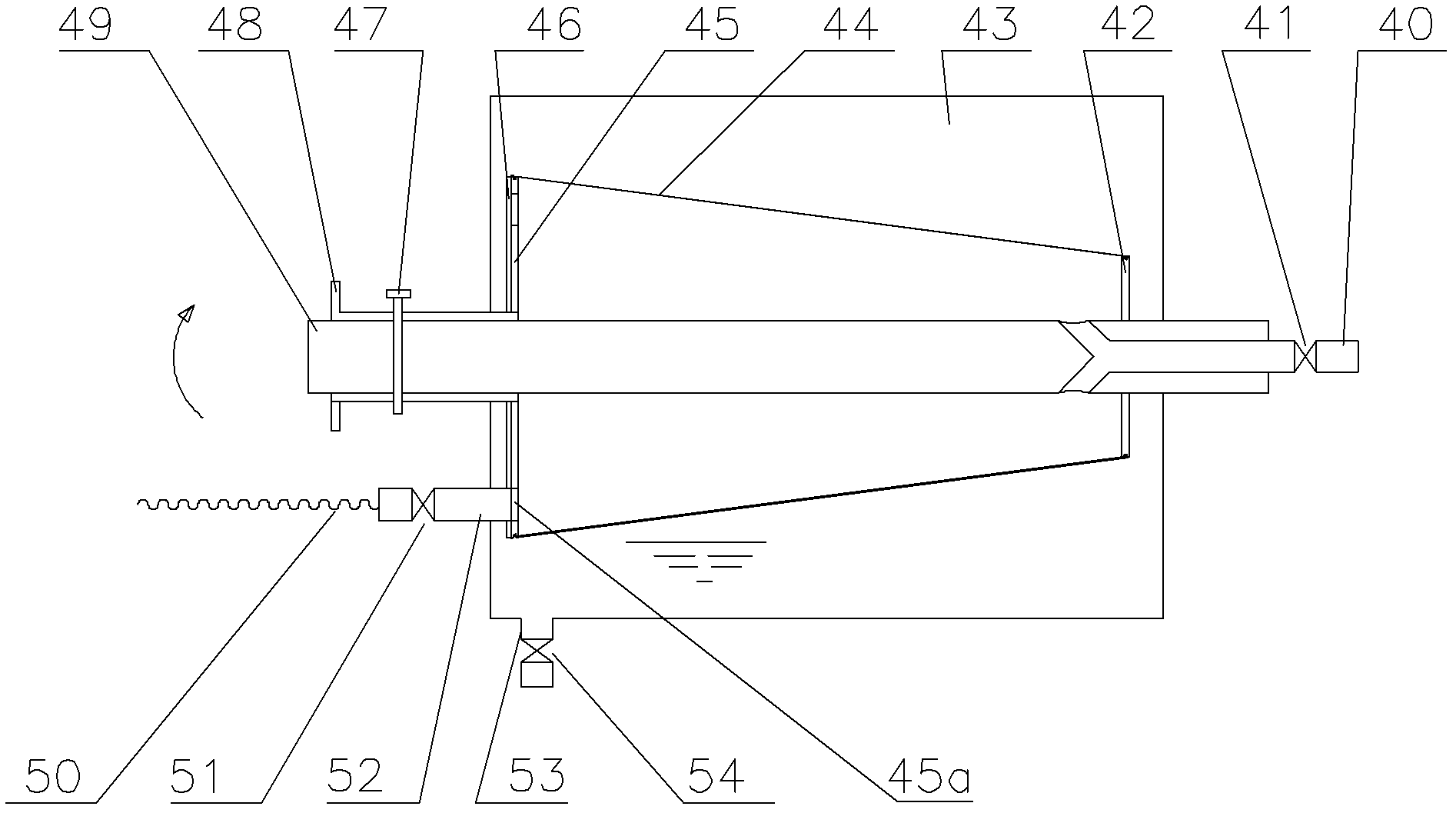

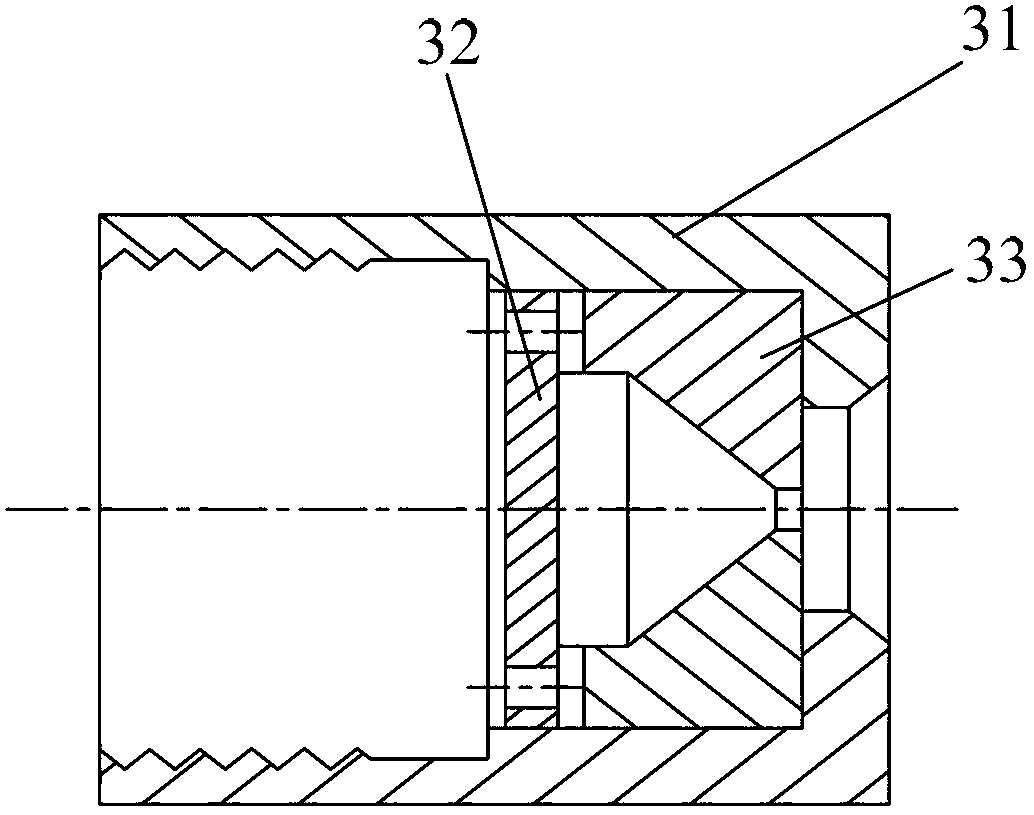

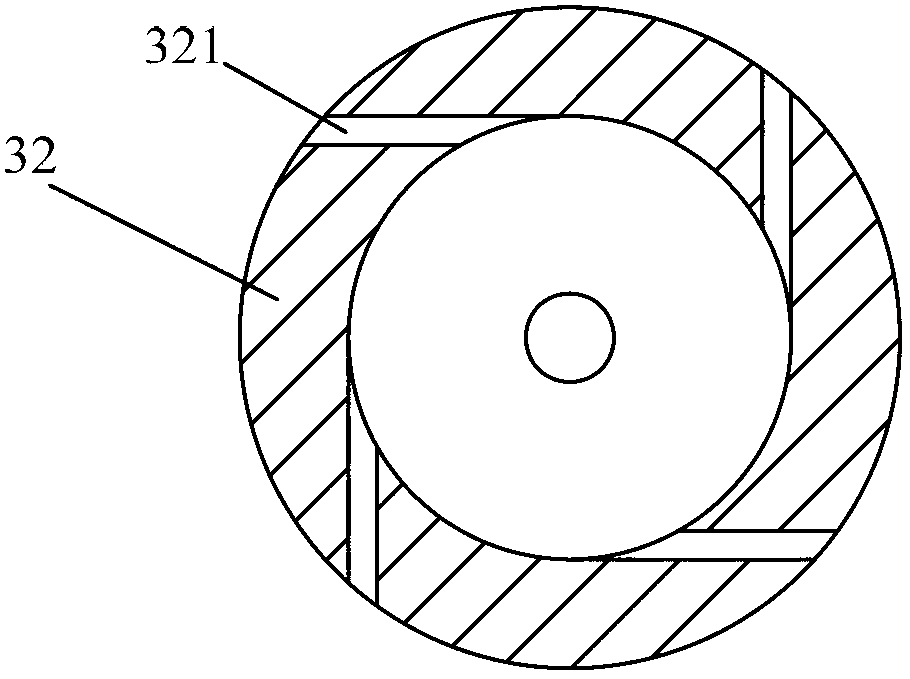

High-temperature gas washing and cooling device

ActiveCN103232863AImprove the delivery effectImprove anti-blocking performanceTrickle coolersCombined combustion mitigationWater sourceSlag

The invention discloses a high-temperature gas washing and cooling device. The high-temperature gas washing and cooling device comprises a housing. The top of the housing is provided with an opening for receiving gas needing to be washed and cooled. The middle of the housing is provided with a gas-guide tube. An inlet of the gas-guide tube is in a butt joint relationship with the opening. A washing and cooling water distribution ring is arranged at the butt joint position. A lower part of the housing is provided with a static slag breaking device. Multiple pressure atomizers for spraying water mist into the housing to reduce a temperature of the gas needing to be washed and cooled are arranged on the periphery of the housing. Each one of the pressure atomizers comprises a main body, the main body is provided with a port communicated with a washing and cooling water source, an annular flow deflector is arranged in the main body, a front end of the annular flow deflector is provided with a nozzle, and the nozzle points to an outlet of the gas-guide tube. Through combination of vertical falling film spray flowing and pressure atomization, the high-temperature gas washing and cooling device effectively improves heat and mass transmission effects, reduces slag-caused blocking possibility and improves a cooling chamber blocking resistance capability.

Owner:EAST CHINA UNIV OF SCI & TECH +1

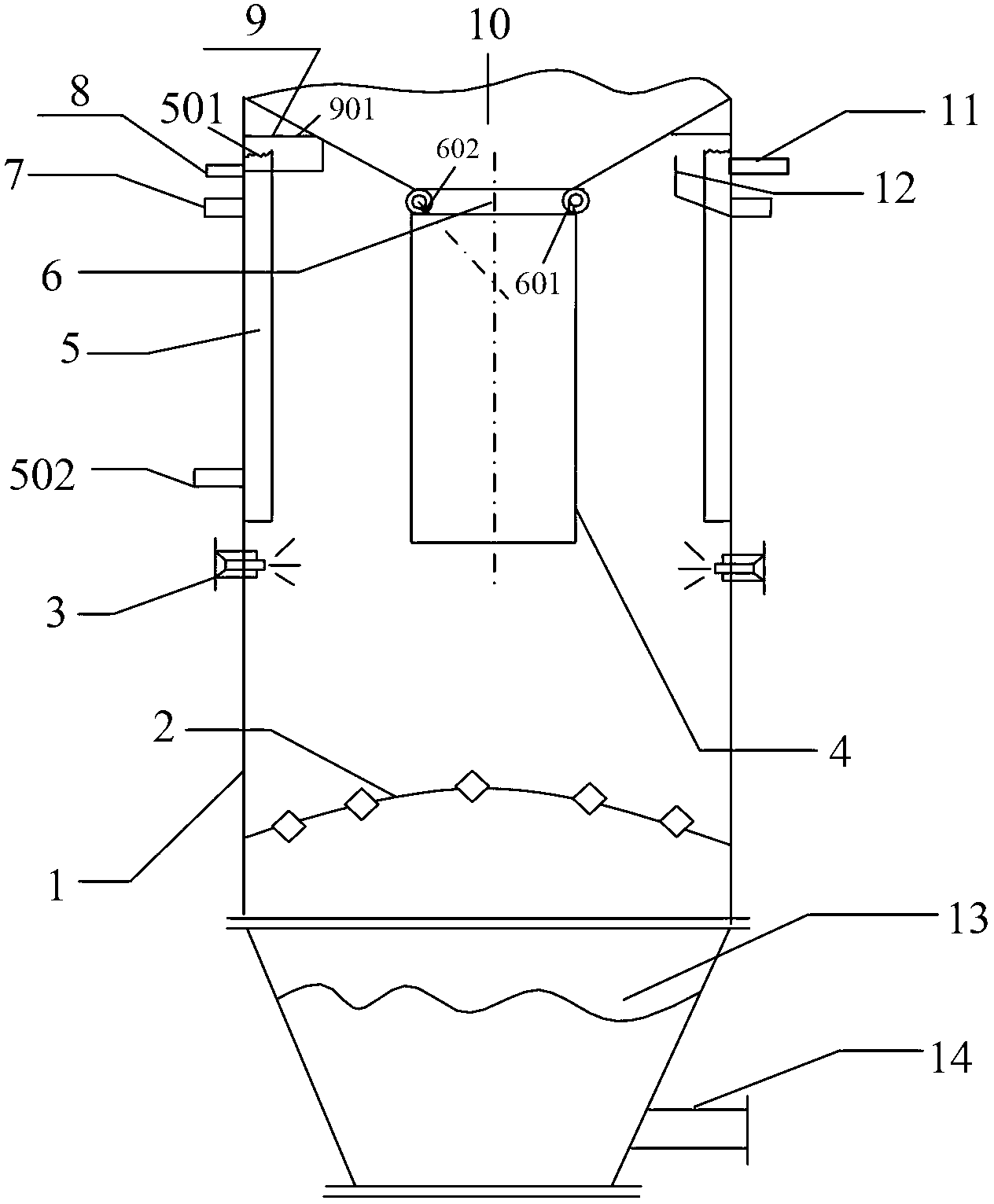

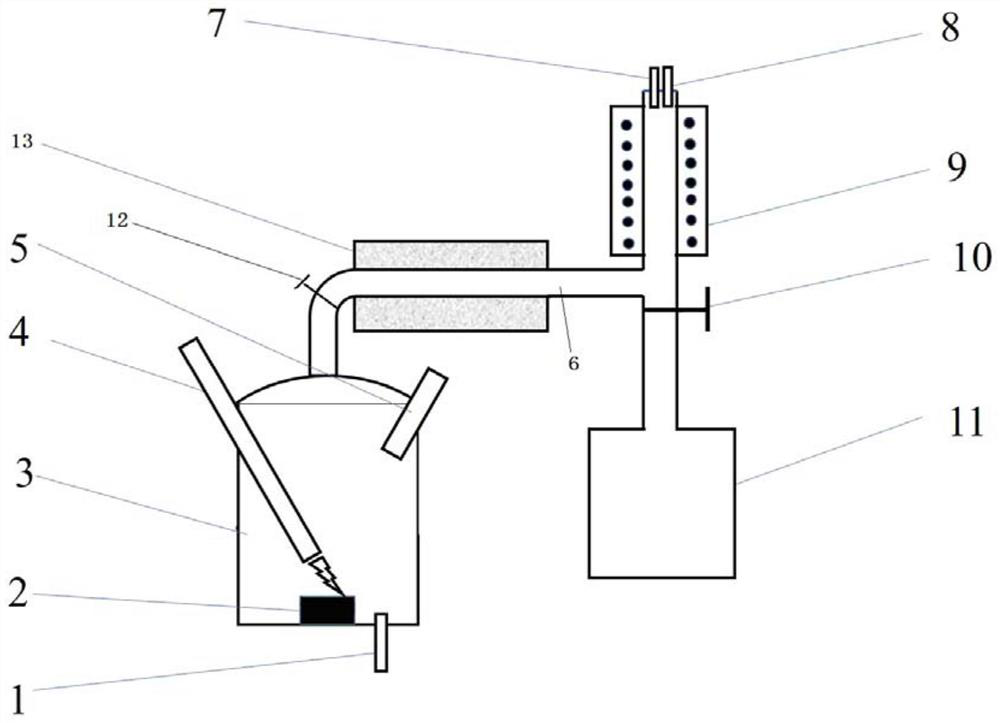

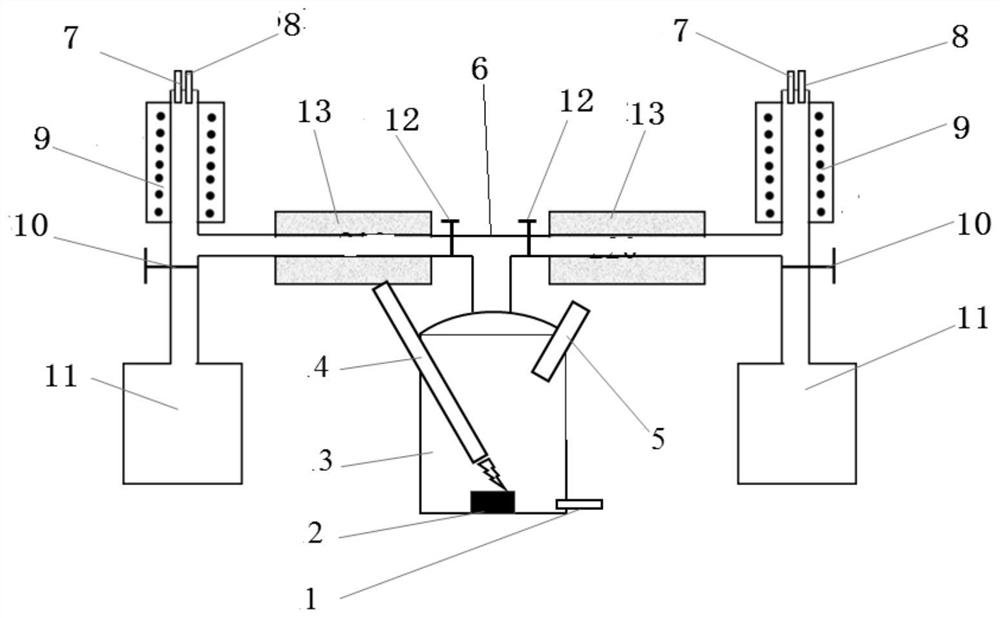

Continuous preparation system and preparation method of single-walled carbon nanotube

The invention belongs to the technical field of new materials, and relates to a single-walled carbon nanotube continuous preparation system and a process method, the device is formed by connecting a high temperature reaction chamber and a cooling unit in series, and vacuum, gas circuit, control, cooling and feeding systems and the like are used for assistance. According to the preparation method,a metal catalyst serving as a counter electrode is evaporated to form tiny catalyst particles by utilizing high temperature generated by direct-current arc flame, the tiny catalyst particles are rapidly combined with a high-temperature cracked organic carbon source to catalyze to generate single-walled carbon nanotubes, the single-walled carbon nanotubes are cooled and then enter a gas-solid separator, the obtained single-walled carbon nanotubes are enriched and separated by utilizing a magnetic field, and finally, the gas-solid separator is subjected to back-blowing by adopting inert gas to obtain a final product. According to the method, the catalyst can exist in the form of ultrafine particles in a high-temperature growth state, strict regulation and control on the purity, the pipe diameter structure and the like of the single-walled carbon nanotube are truly realized, and the high-quality single-walled carbon nanotube is continuously prepared. The device and the process are high inproduction efficiency and have important industrialization value.

Owner:JIANGXI COPPER TECHNOLOGY RESEARCH INSTITUTE CO LTD

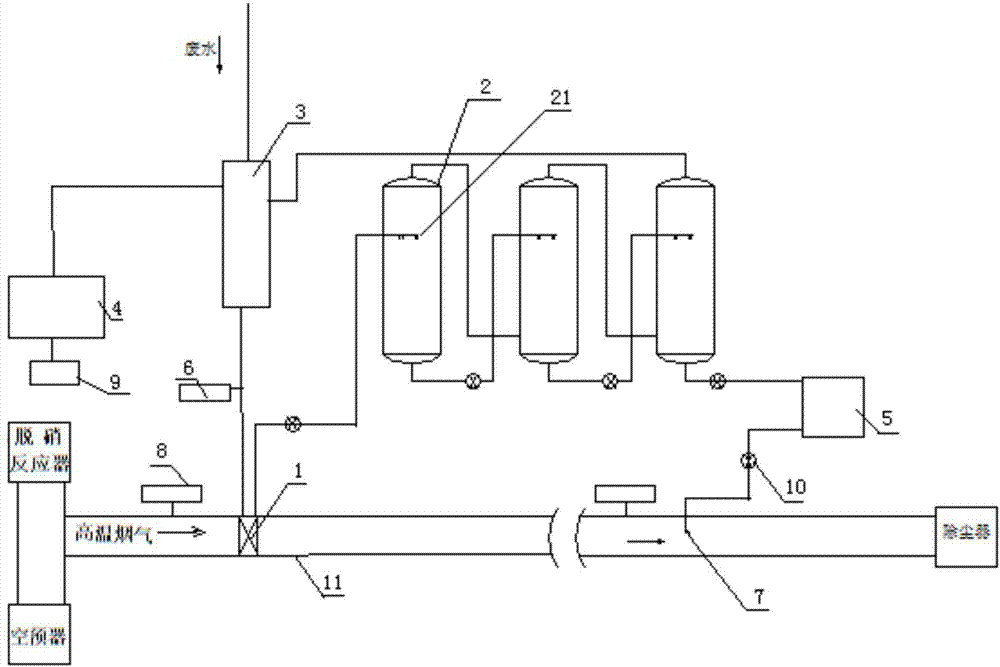

Coal-fired power plant ammonia spraying control method based on big data analysis, and denitrating system

ActiveCN109453664AAvoid wear and tearGuaranteed filtering interception effectNitrous oxide captureDispersed particle separationAir preheaterCombustion system

Owner:GUODIAN SCI & TECH RES INST +1

Method for treating silt

InactiveCN101851052ASolve the clogging problemSolve problemsSludge treatment by de-watering/drying/thickeningSolid waste managementBrickEnvironmental engineering

The invention provides a method for treating silt. Through the method, the river pollution is relieved in one aspect, and the new pollution can not be caused in the other aspect. In addition, waste materials can be changed into useful materials, ground resources can be saved, and a higher added value can be brought. The invention is realized through the technical scheme that the silt carries out separation treatment to be divided into a brick, tile and shell type and a plastic rubbish type, the two types are separated, the separated silt carries out heating treatment until the moisture content is within 35 percent, the treated silt is made into brick blanks to be baked and sintered, the separated brick, tile and shell type materials are crushed by a roll machine, the crushed materials are mixed with the separated free sand, and then, the mixture is made into brick blanks to be processed into bricks.

Owner:江苏润宏江河工程项目管理有限公司

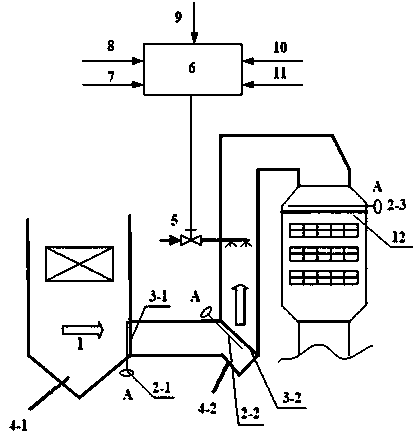

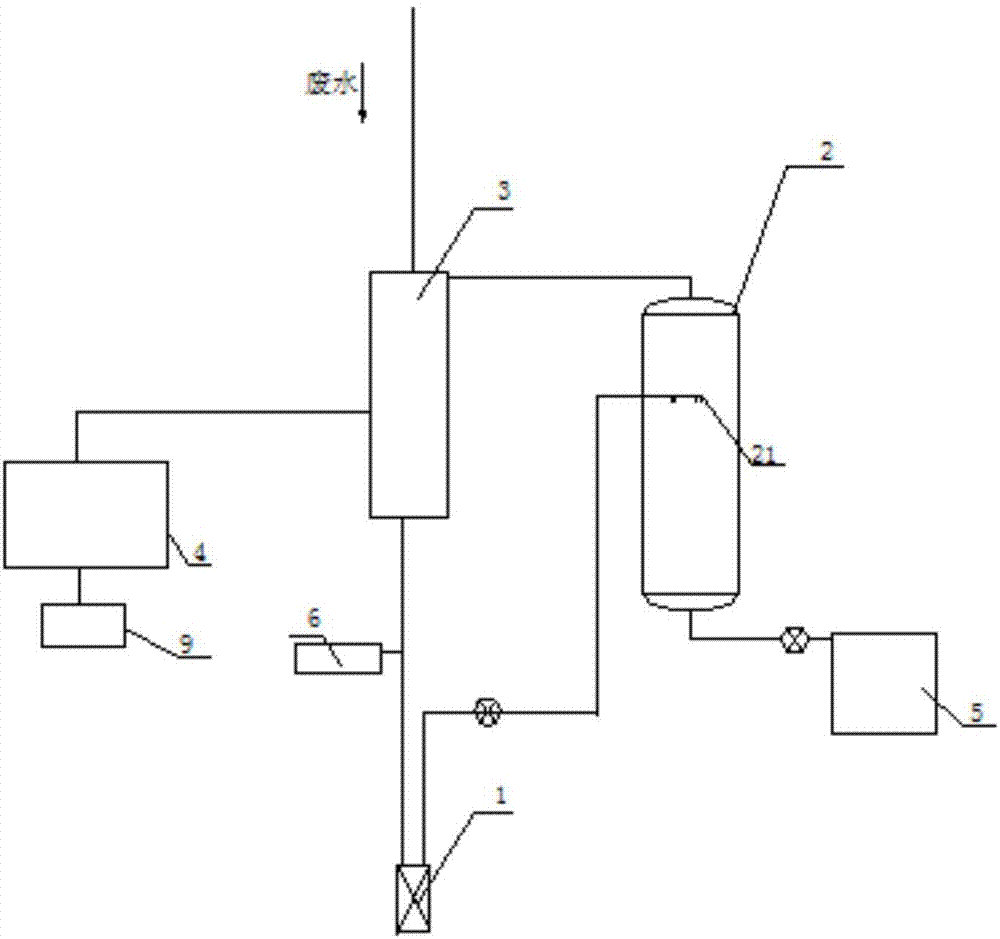

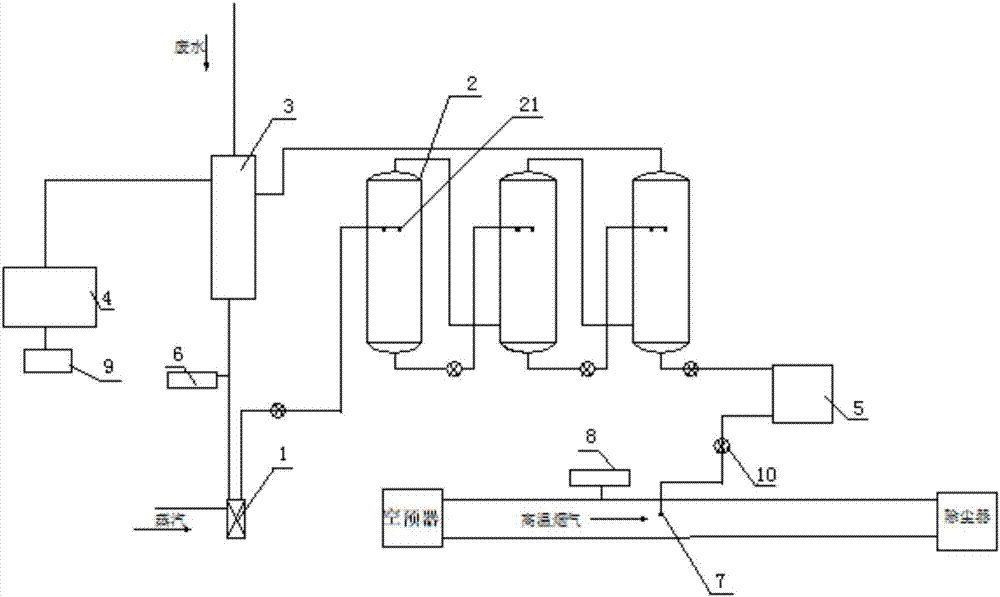

Method and device for realizing wastewater zero discharging based on multiple-effect sound wave action

PendingCN107324430ASolve fouling and cloggingMaximize reuseWaste water treatment from gaseous effluentsWater/sewage treatment by heatingTreatment pondSound wave

The invention discloses a method and a device for realizing wastewater zero discharging based on a multiple-effect sound wave action. The method comprises the steps that low-pressure evaporation is performed on desulfurization wastewater in a form of atomization, vapour generated after the low-pressure evaporation is subjected to heat exchange by wastewater and is condensated and recycled, and the unevaporated wastewater is subjected to secondary evaporation; the device comprises a wastewater pre-heater, a wastewater heater, a low-pressure evaporator, a condensate water recoverer, a concentrated water treating pond, an underwater acoustic transducer and a pneumatic generator used for removing dust and scale in a flue, wherein the wastewater heater is connected with the low-pressure evaporator through a pipeline, a vapour outlet of the low-pressure evaporator is connected with the condensate water recoverer through the wastewater pre-heater, a wastewater outlet of the low-pressure evaporator is connected with the concentrated water treating pond, and the underwater acoustic transducer is connected with the wastewater pre-heater, the wastewater heater and the low-pressure evaporator. The method and the device provided by the invention have the advantage that evaporated gas and the wastewater subjected to the evaporation in a wastewater treating process are effectively treated and used, so that the purpose of wastewater zero discharging is realized.

Owner:NANJING CHANGRONG ACOUSTIC INC +2

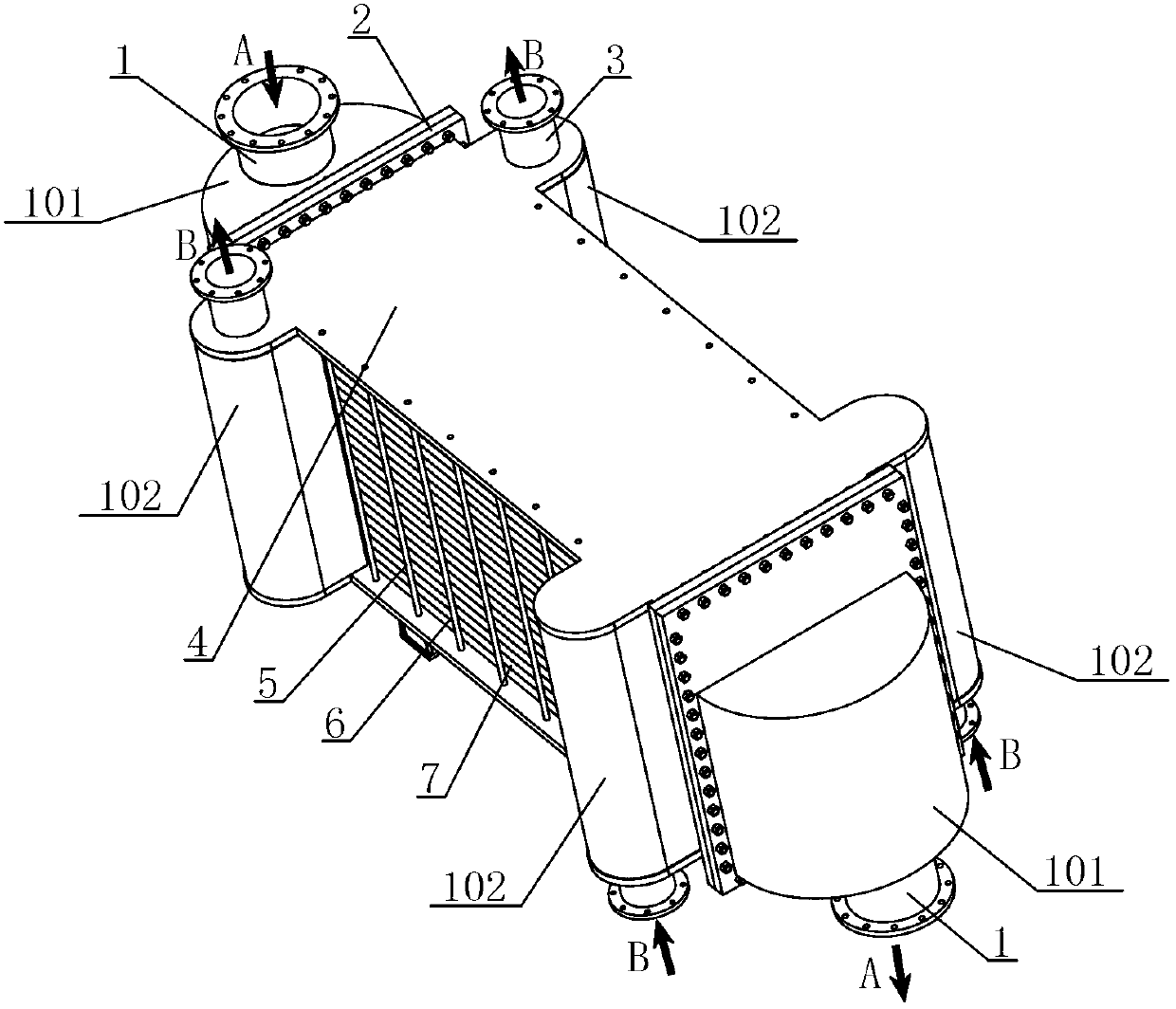

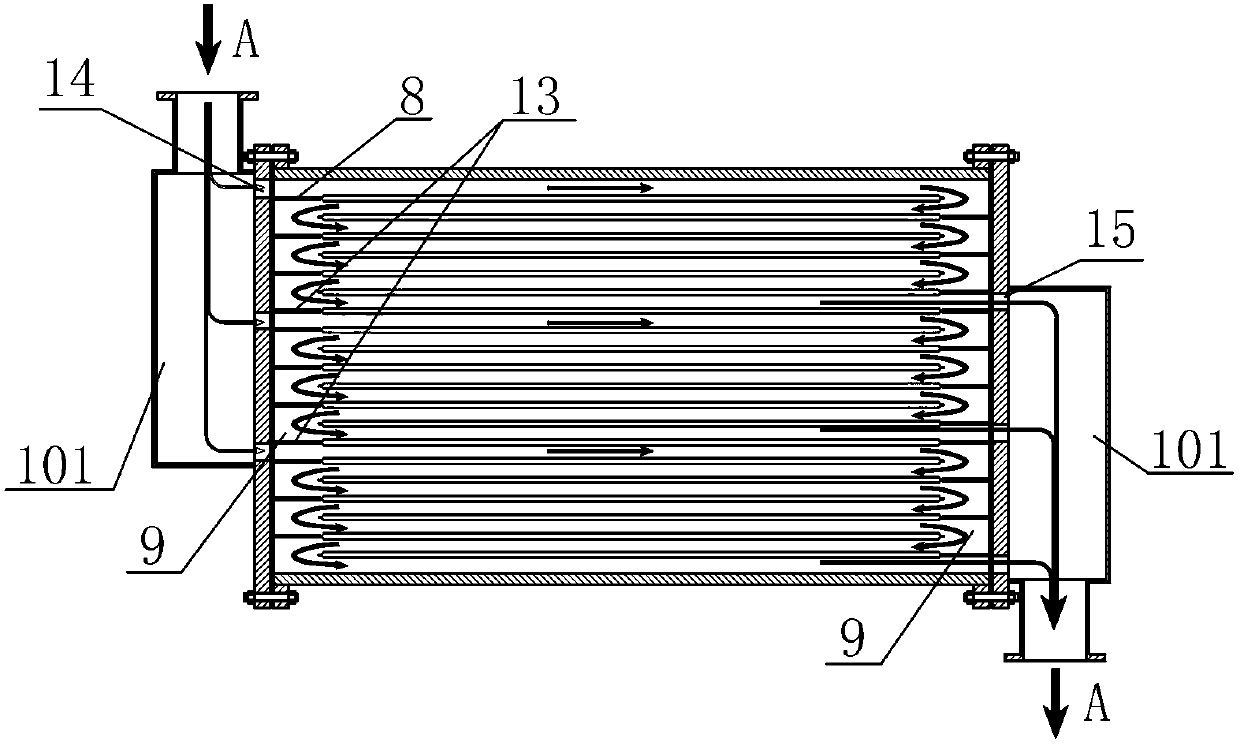

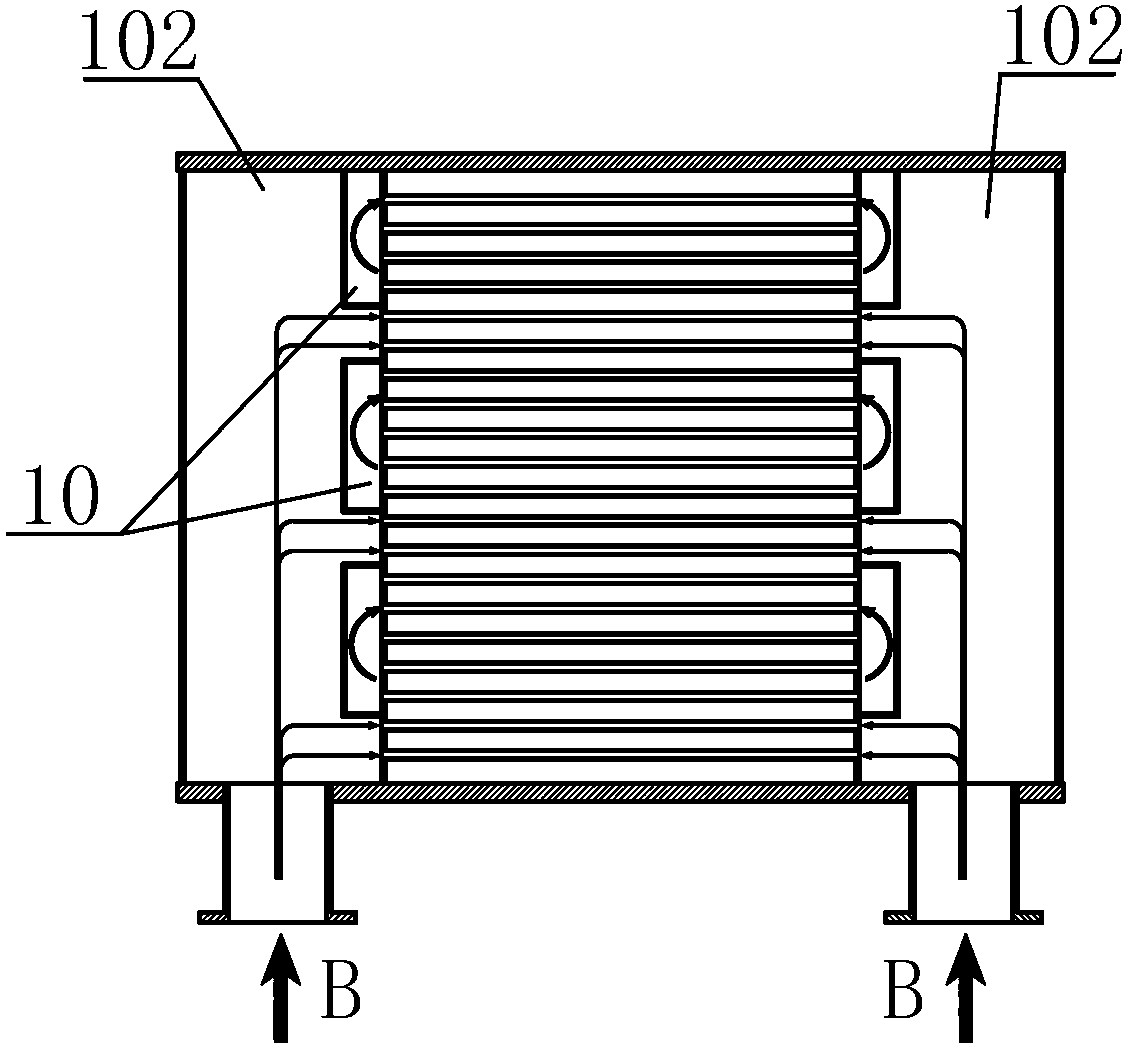

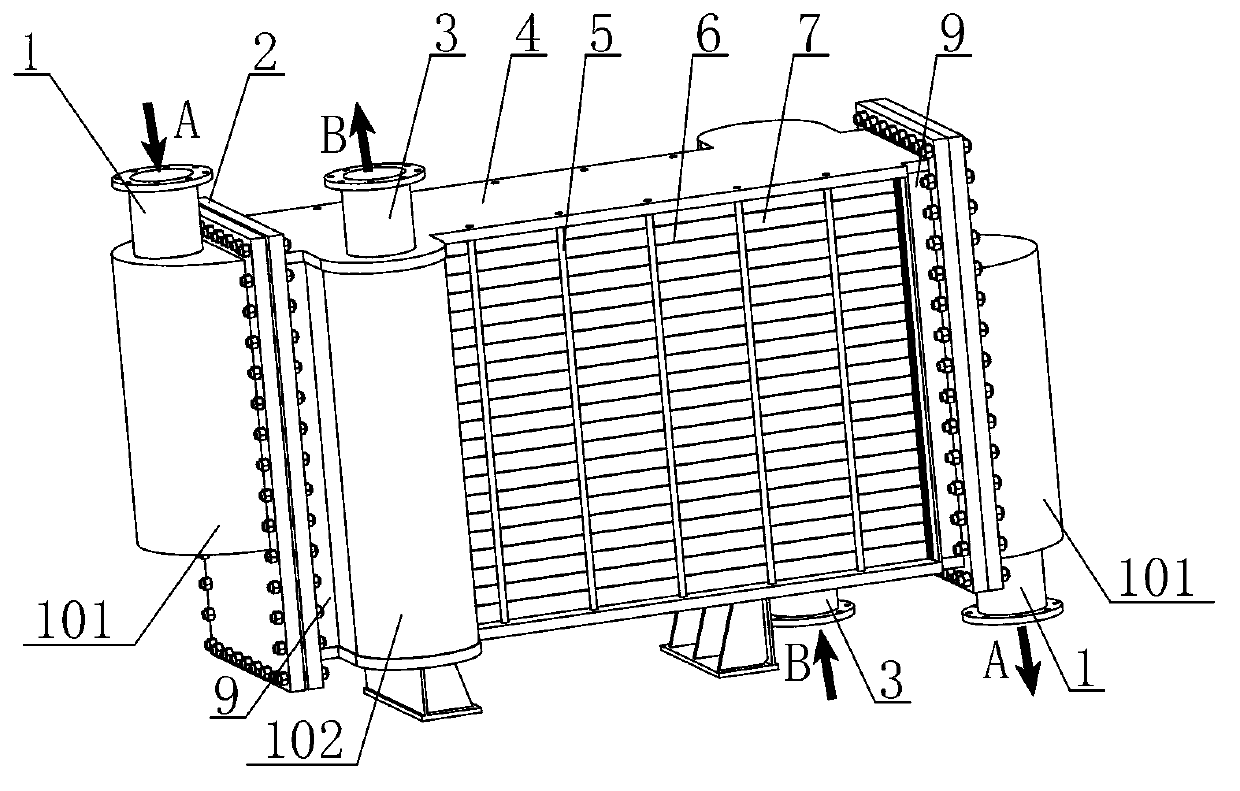

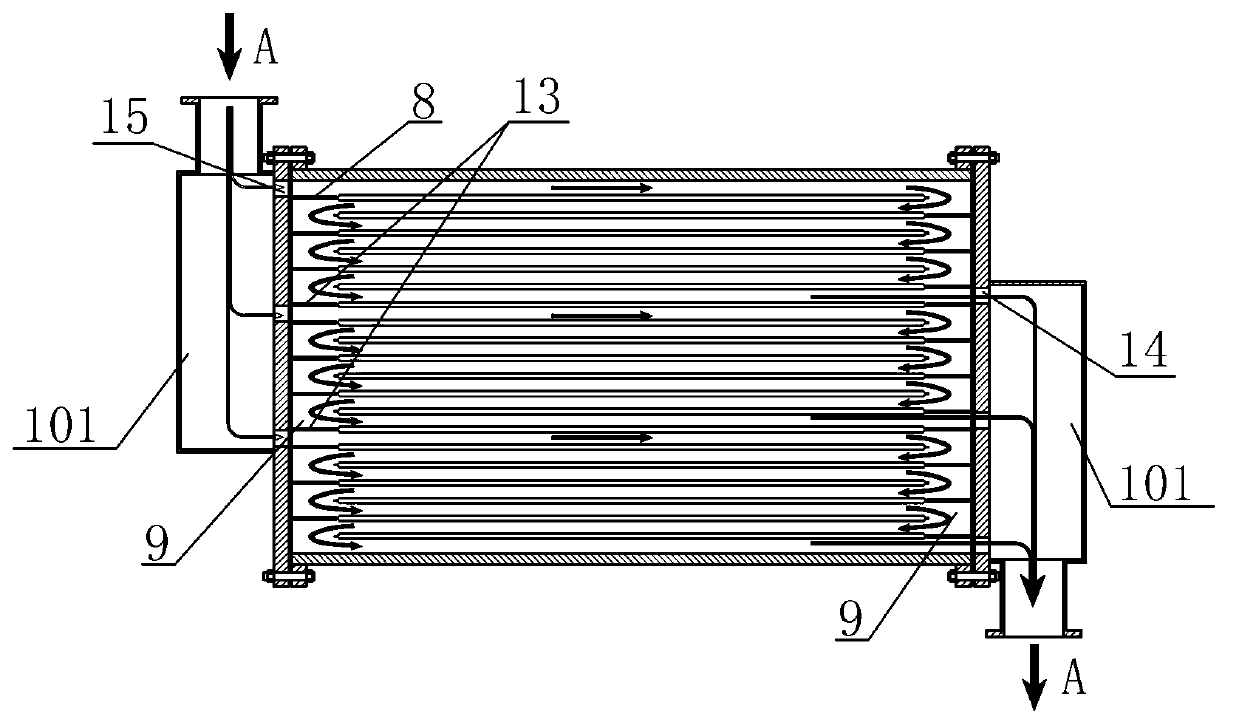

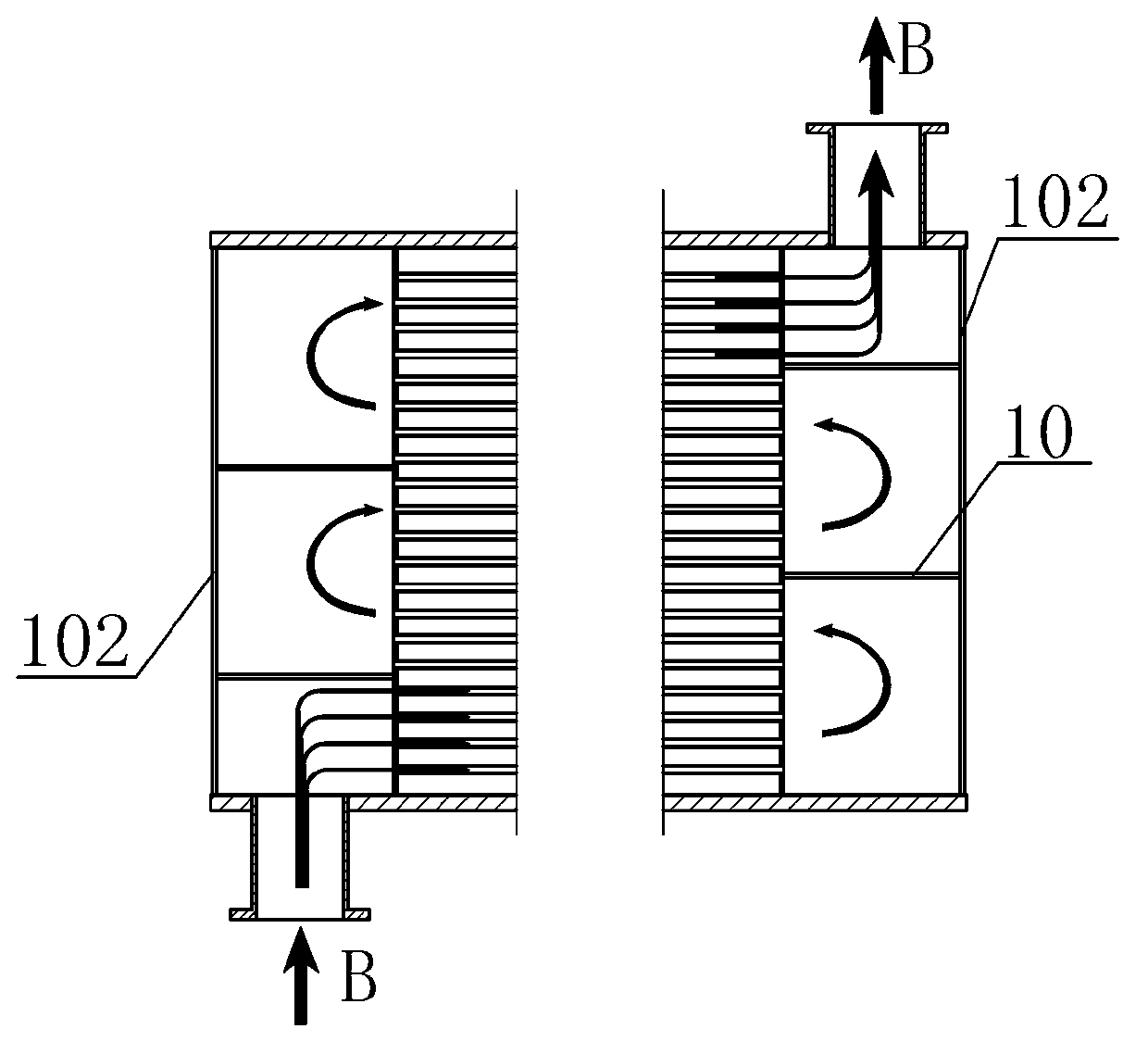

Multi-path heat exchanger for blast furnace slag flushing water

The invention relates to a multi-path heat exchanger for blast furnace slag flushing water, and the multi-path heat exchanger is of a welding plate structure. Multiple heat exchange units are assembled and stacked into a heat exchange plate bundle, each heat exchange unit comprises multiple horizontally-placed heat transfer plates, one side of the heat transfer plate is provided with a slag flushing water channel, the other side of the heat transfer plate is provided with a secondary water channel, one side of the slag flushing water channel is contactless, each slag flushing water channel is folded through slag flushing water pipe boxes connected to the two ends of the heat exchange plate bundle so as to form a contactless single-channel slag flushing water heat exchange flow path, and the heat exchange plate bundle assembled and stacked by multiple heat exchange units forms multiple contactless single-channel slag flushing water heat exchange flow paths which are connected in parallel; the outer side of a flat cover of each slag flushing water pipe box is provided with a slag flushing water diversion box, and the slag flushing water diversion box realizes the functions of flow diversion, flow collection, adapter tube importing and exporting, disassembling and flushing through an inlet and an outlet of a slag flushing water channel on the flat cover of the pipe box; and two pairs of secondary water pipe boxes are arranged on both sides of the heat exchange plate bundle. The structure of the heat exchanger can be used for solving the blocking problem caused by slag flushing water; and the heat exchanger is long in operation cycle, convenient to flush, compact in structure and high in heat transfer efficiency.

Owner:TIANJIN HUASAIER HEAT TRANSFER EQUIP

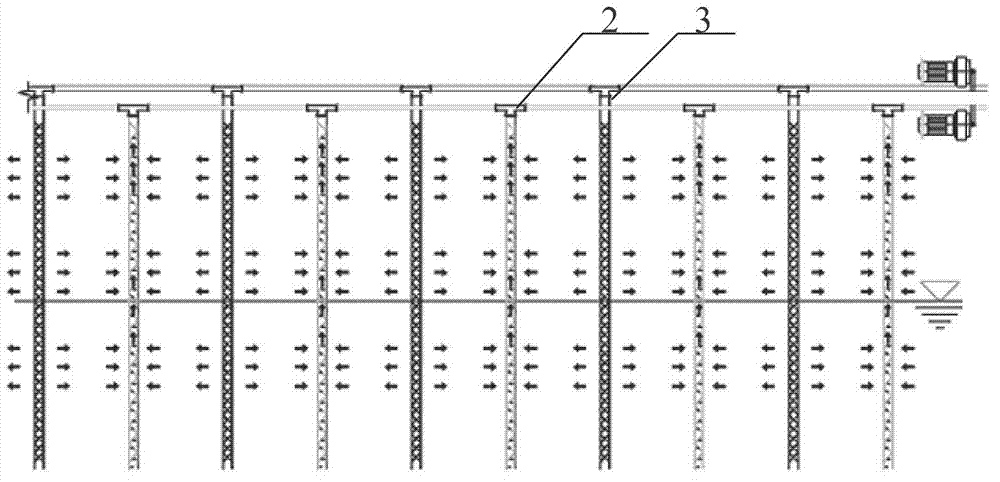

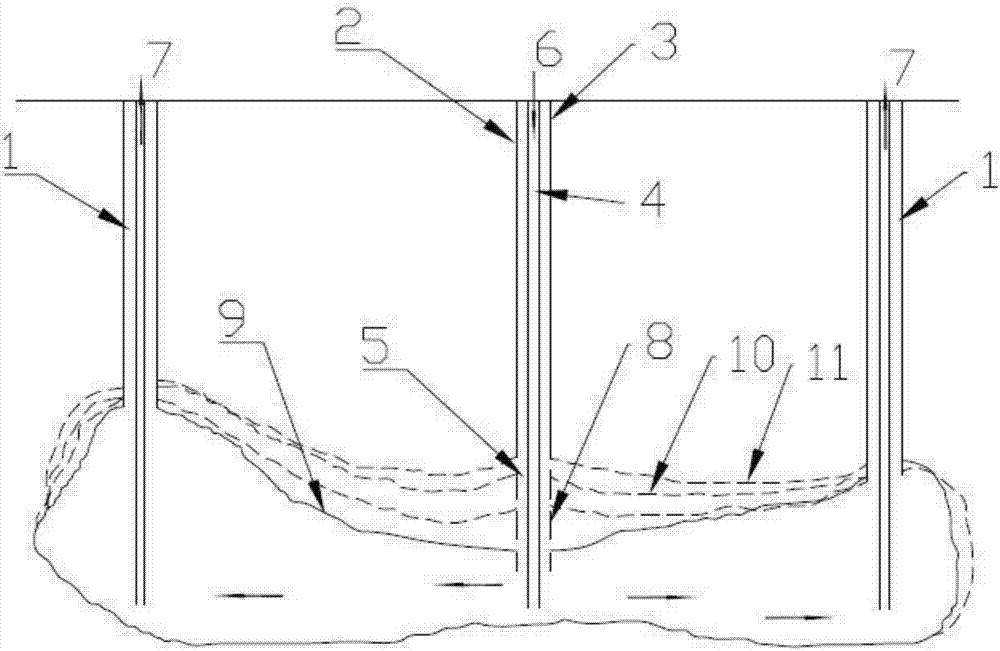

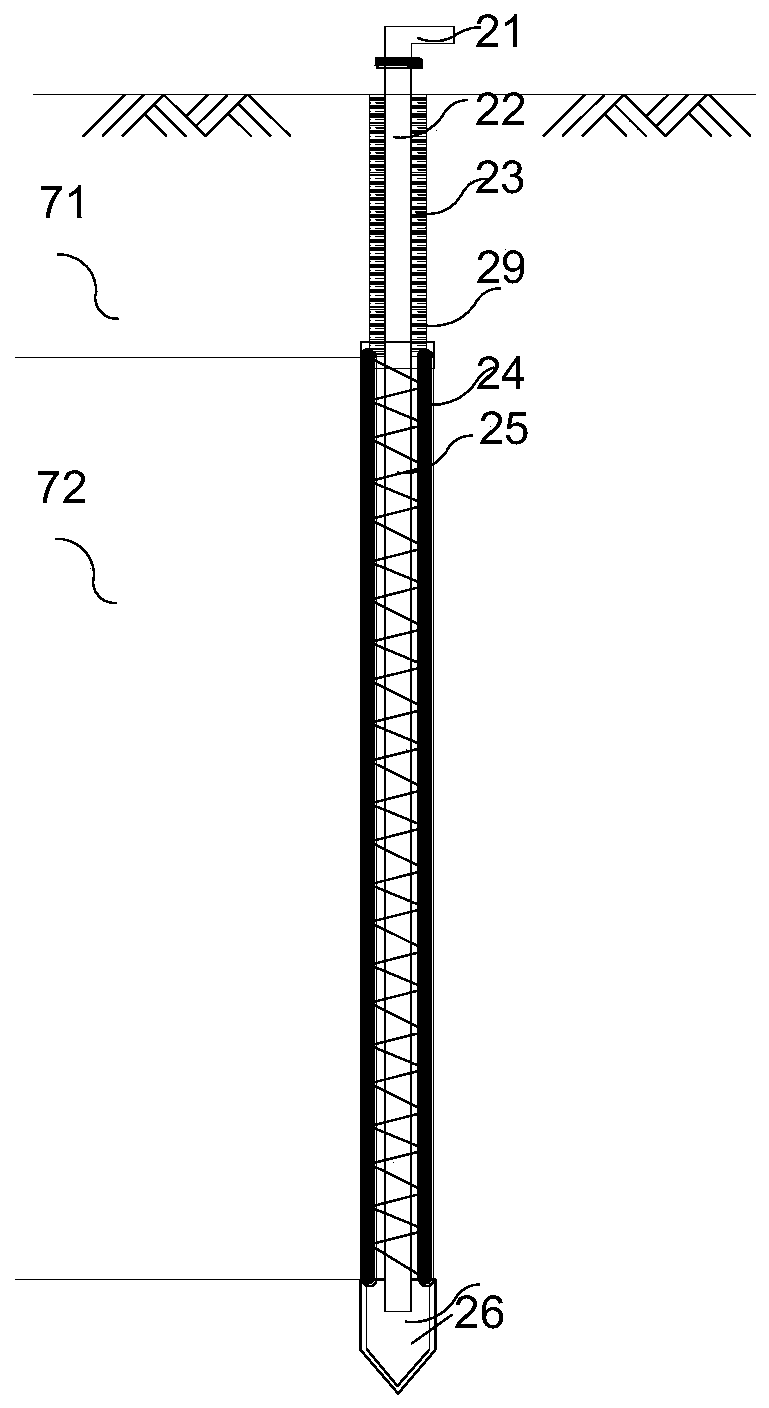

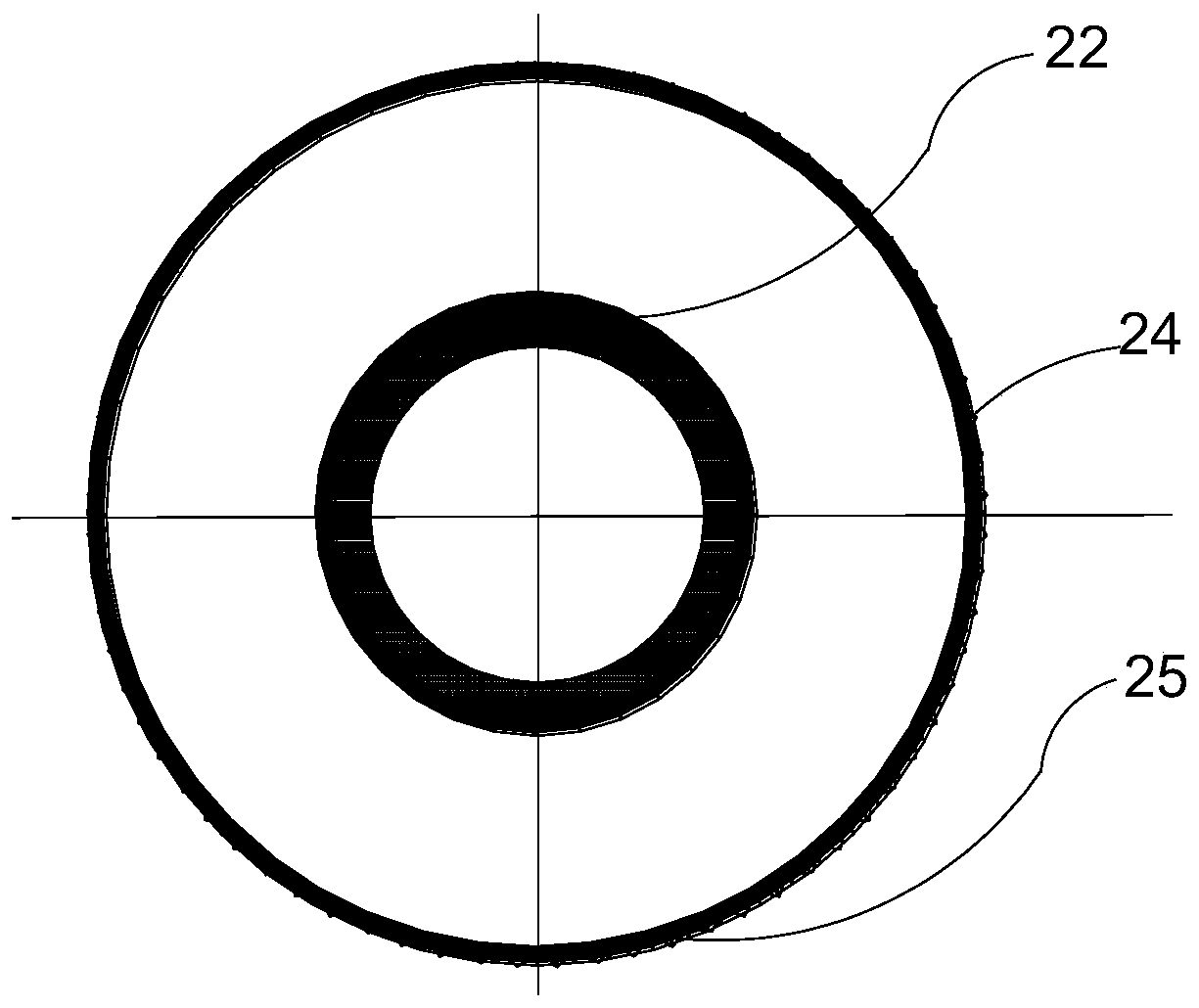

Pressurized vacuum flexible tubular well dewatering and drainage system and construction method thereof

The invention discloses a pressurized vacuum flexible tubular well dewatering and drainage system and a construction method thereof. The vacuum flexible tubular well comprises a tube shoe, a filteringtype flexible tube, a sealing tube, an air pumping and water draining tube and a connecting joint, wherein the tube shoe is positioned at the lower part of the vacuum flexible tubular well; the upperpart of the tube shoe is in shape of a hollow tube, and the lower part of the tube shoe is in shape of a tube cone; and the bottom part of the tube shoe is sealed; the filtering type flexible tube isa hollow circular tube; a tube body is prepared by coiling an elastic framework with porous filtering cloth; the sealing tube is a hollow hard tube and is positioned at the upper part of the filtering type flexible tube; and the air pumping and water draining tube is a hollow hard tube and is positioned in the filtering type flexible tube. The dewatering and drainage system comprises a pluralityof pressurized vacuum tubes, a tubular well connecting tube, an air and liquid separating tank, a one-way overflowing valve, a main water draining tube, a vacuum pump and an air compressor. The systemachieves the purpose of quickly dewatering and draining water.

Owner:王琪

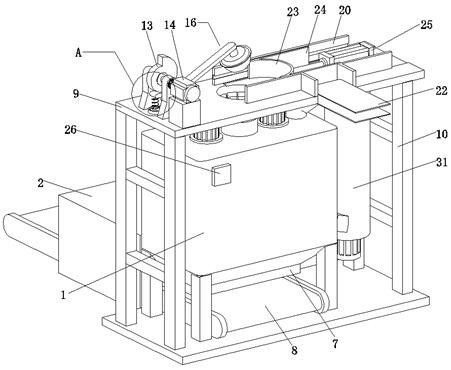

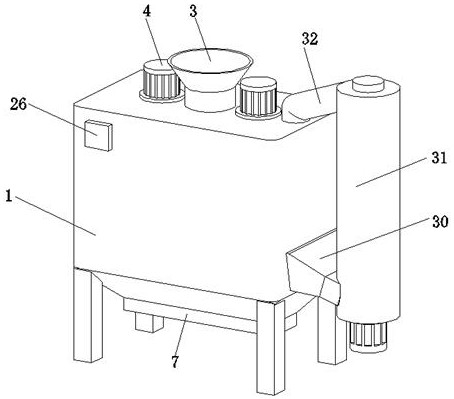

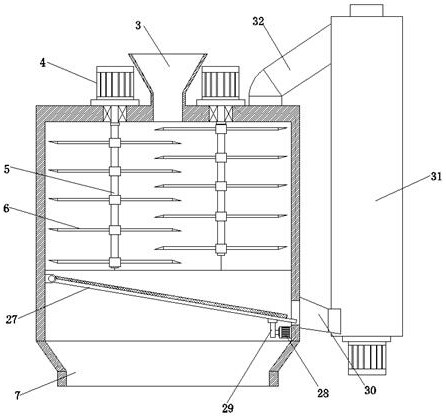

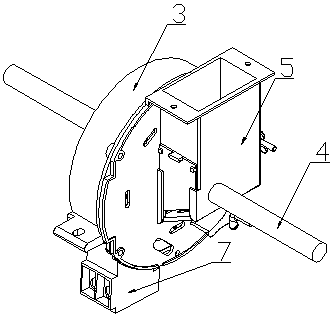

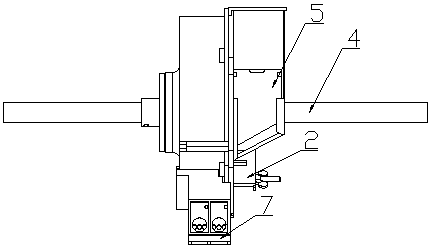

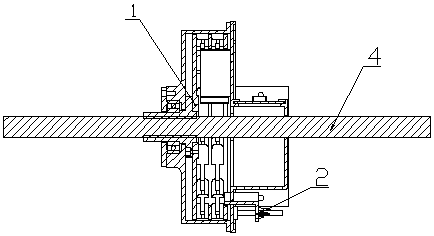

Secondary processing device for caked pig feed

ActiveCN111921590AImprove crushing effectSolve the problem of cloggingSievingFeeding-stuffAnimal scienceMedicine

The invention relates to the technical field of pig feed processing devices, and particularly discloses a secondary processing device for caked pig feed. The secondary processing device comprises a smashing box and a drying box, wherein the center of the upper surface of the smashing box is provided with a feeding hopper, the portions, on the left and right sides of the feeding hopper, of the upper surface of the smashing box are provided with smashing motors, the lower ends, extending into an inner cavity of the smashing box, of output shafts of the smashing motors are connected with smashingshafts, the two smashing shafts are each provided with a plurality of smashing blades arranged in a staggered manner, the lower end of the smashing box is provided with a discharging port, and a first conveyor belt is arranged in the drying box in a penetrating manner. The secondary processing device effectively solves the problem that at present, the feeding hopper is liable to be blocked when the caked pig feed is directly put into the smashing box from the feeding hopper, it is unnecessary to manually break the caked pig feed in advance, it is only required that an operator pours the cakedpig feed onto a second conveyor belt, and the labor intensity of the operator is effectively reduced; and besides, with the dual action of hammering breaking and blade smashing, the smashing effect on the caked pig feed is better.

Owner:申亚生物科技股份有限公司

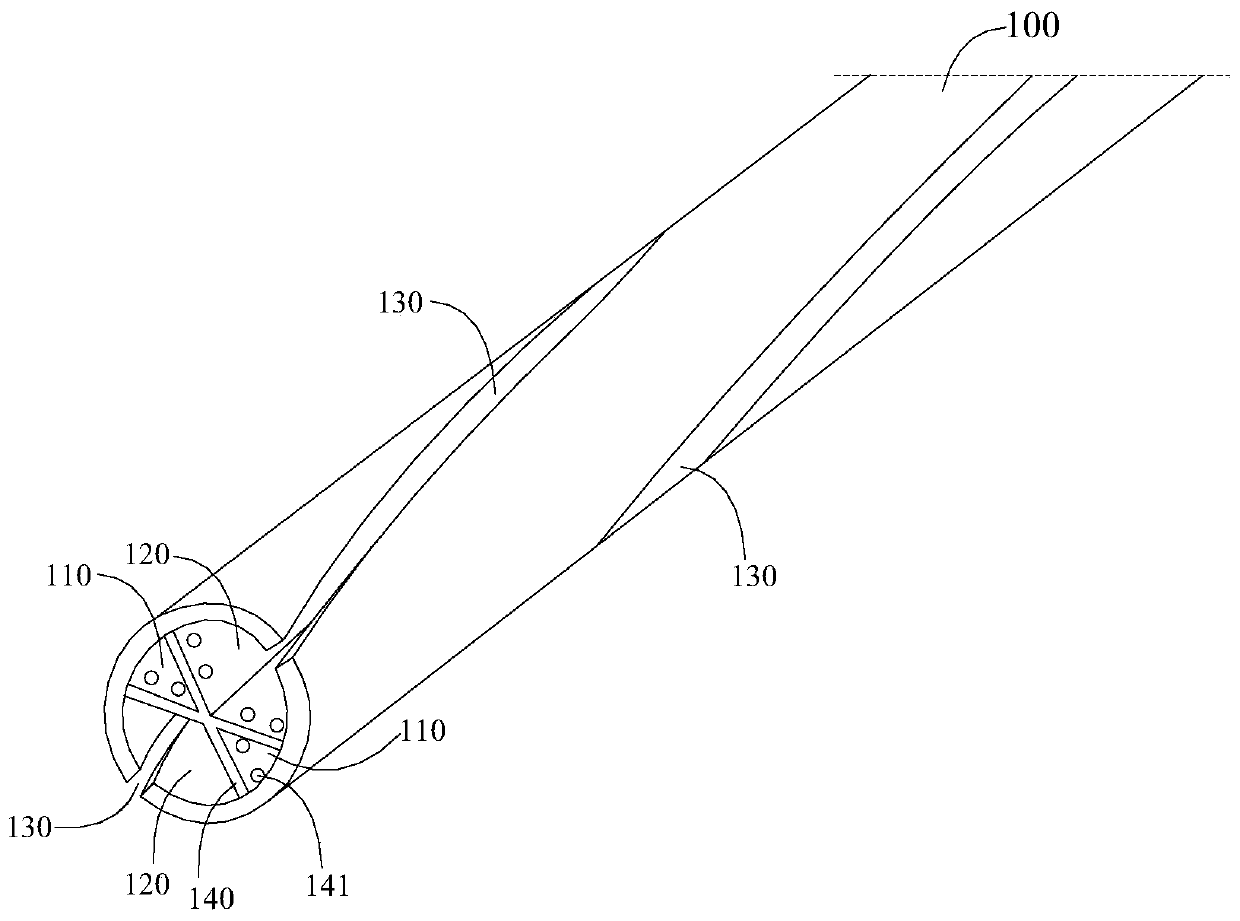

Peanut seeder

PendingCN108243682ASolve the clogging problemAvoid cloggingSeed depositing seeder partsRegular seed deposition machinesSeederEngineering

The invention belongs to the field of agricultural equipment, and specifically relates to a peanut seeder. The peanut seeder comprises a seeding sieve, the seeding sieve comprises a round plate, a circumference-shaped wall is arranged on the outer diameter edge of one side of the round plate close to a seed feeding box, two rows of obround particle through holes are uniformly arranged along the circumference direction of the wall; two annular slots are formed in the inner side of the wall along a circumference direction, the two annular slots respectively penetrate through central lines of thetwo rows of particle through holes; and an arc seed blocking plate for shielding the particle through holes is arranged below the inner side of the wall. A large number of peanut seeds enter an innercavity of a shell so as to enter the wall of the seeding sieve, the seeding sieve is rotated through the driving of a seeding shaft, thereby disturbing the seeds and reducing the seed blocking; the seeding sieve is composed of the wall, the round plate and the particle through holes, and the red skin damage of the seed is reduced in the rotation of the seeding sieve; the seed blocking plate is matched with the annular slots to realize the flux control of the peanut seed.

Owner:SHANDONG ACADEMY OF AGRICULTURAL MACHINERY SCIENCES

Anti-adhesion paint and product coated by the anti-adhesion paint

InactiveCN105482685ALower glass transition temperatureGood weather resistanceLayered productsAnti-corrosive paintsPoly ether ether ketoneAnti-Adhesion Agent

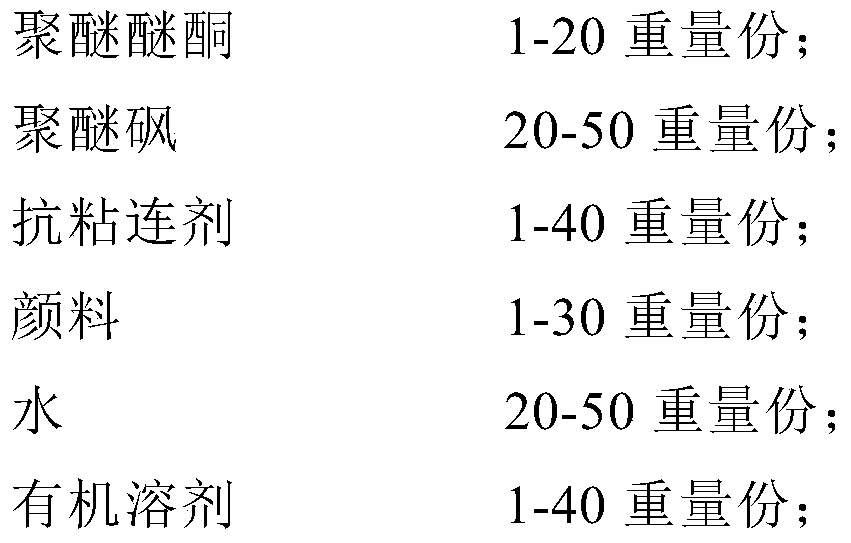

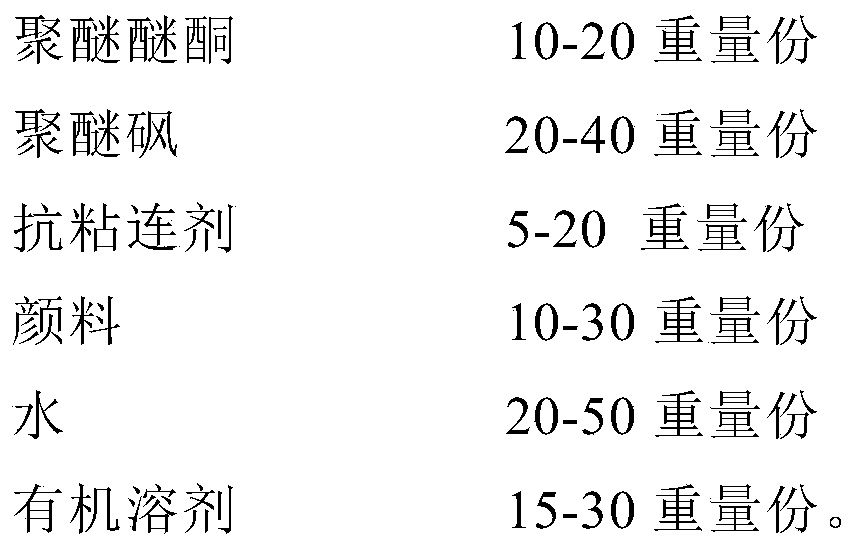

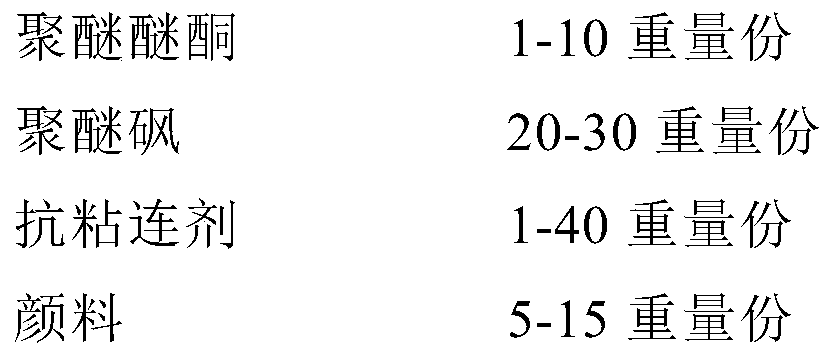

The invention relates to an anti-adhesion paint and a product coated by the anti-adhesion paint. The purpose of the anti-adhesion paint is to solve the problems of relatively bad leveling performance and bad post-film-formation flatness of poly-(ether-ether-ketone). According to the invention, polyether sulphone is added into the poly-(ether-ether-ketone) paint and the proportions of the ingredients are adjusted, so that an anti-adhesion paint of good leveling performance, excellent high-temperature resistance, excellent corrosion resistance and excellent weather resistance is obtained. The anti-adhesion paint disclosed by the invention comprises the following ingredients in parts by weight: 1-20 parts of poly-(ether-ether-ketone), 20-50 parts of polyether sulphone, 1-40 parts of anti-adhesion agent, 1-30 parts of pigment, 20-50 parts of water and 1-40 parts of organic solvent. The anti-adhesion paint disclosed by the invention can be used for products with anti-adhesion requirements and especially for outdoor products or kitchenware products with relatively high weather-resisting and scratch-resisting requirements.

Owner:曾志玲

Blast furnace cinder flushing water multipath heat exchanger

ActiveCN103134359AWon't clogSolve the clogging problemStationary plate conduit assembliesContact freeWater channel

The invention relates to a blast furnace cinder flushing water multipath heat exchanger of a welding plate type structure. The heat exchanger is characterized in that a heat exchanging plate beam is formed by stacking multiple heat exchanging units, each heat exchanging unit comprises multiple horizontal heat transmitting plate pieces, cinder flushing water channels are arranged on one sides of the heat transmitting plate pieces, and secondary water channels are arranged on the other sides of the heat transmitting plate pieces, no contact exists on one sides of the cinder flushing water channels, each cinder flushing water channel realizes process returning through cinder flushing water pipe boxes connected at two ends of the heat exchanging plate beam to form a single-channel cinder flushing water heat exchanging process, the heat exchanging plate beams formed by stacking the multiple heat exchanging units forms multiple parallel-connected contact-free single-channel cinder flushing water heat exchanging processes, cinder flushing water branching boxes are arranged on outer sides of flush covers of the cinder flushing water pipe boxes and realize functions of flow branching, flow collecting, connecting pipe guiding in and out and demounting flushing through in and out of cinder flushing water channel ports arranged on the pipe box flush covers, and the two secondary water pipe boxes are arranged on two sides of the heat exchanging plate beam. The heat exchanger of the structure solves the problem of blockage of cinder flushing water and is long in operating period, convenient to flush, compact in structure and high in heat transmitting efficiency.

Owner:TIANJIN HUASAIER HEAT TRANSFER EQUIP

Groove drainage tube capable of flushing

PendingCN111450331ASolve the clogging problemThe structure is stable and feasibleMulti-lumen catheterIntravenous devicesCavity wallEngineering

Owner:CHONGQING UNIV CANCER HOSPITAL

Biomass carbonizing equipment

ActiveCN103923674AGuaranteed carbonization qualityIncrease working lengthBiofuelsWaste based fuelTemperature controlCarbonization

The invention discloses biomass carbonizing equipment, wherein conveyers are arranged in the vertical direction in a wrinkle manner, every two conveyers are connected through a corrugated pipe, each conveyer is covered with an electric heating device, insulating layers are arranged outside the conveyer and the corrugated pipe and completely cover the whole conveyer and the corrugated pipe, the gap between the electric heating device and the insulating layer is a heating space, the corrugated pipe is internally provided with a temperature probe which is connected with a temperature control system, the temperature control system is further connected with the electric heating device, each conveyer is provided with an oil / gas conveying pipe communicated with the inner cavity of the conveyer, the oil / gas conveying pipe on each conveyer is connected with an air injection combustion mechanism in the heating space, and a discharge opening is communicated with a cooling mechanism. The equipment disclosed by the invention solves the problem in the prior art that oil and gas block the pipeline, carbonization heating is non-uniform, and the carbonizing quality is low because of too small carbonizing temperature gradient or no gradient, has the characteristics of low energy consumption and no pollution, and can be applied to carbonization of various biomasses.

Owner:INST OF GEOCHEM CHINESE ACADEMY OF SCI

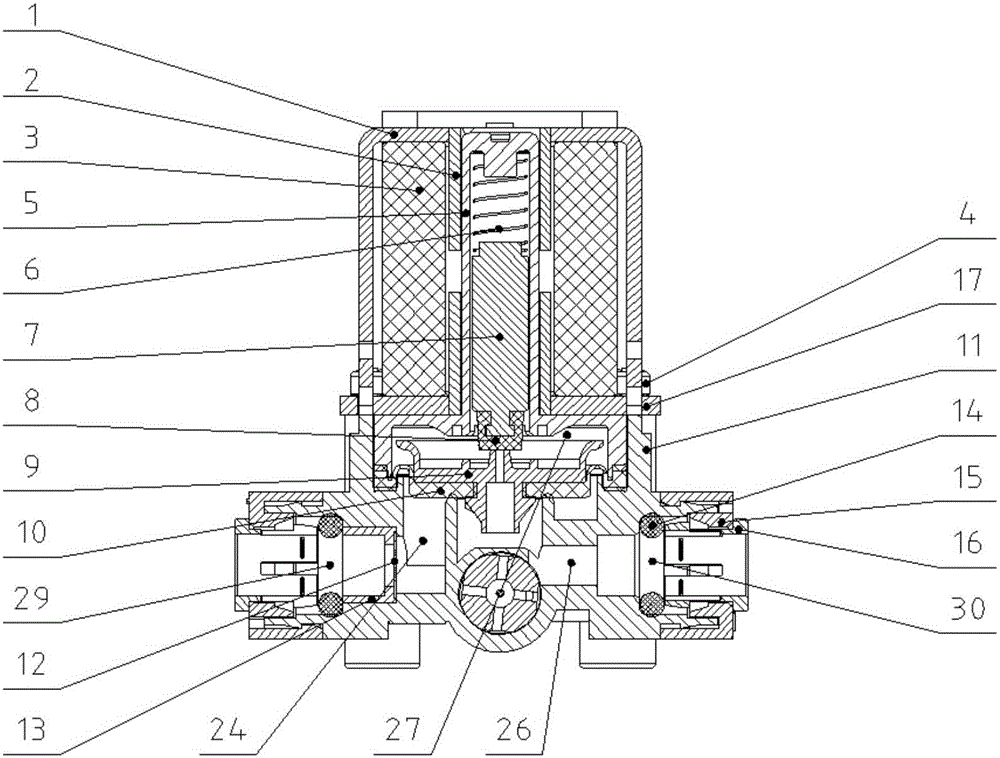

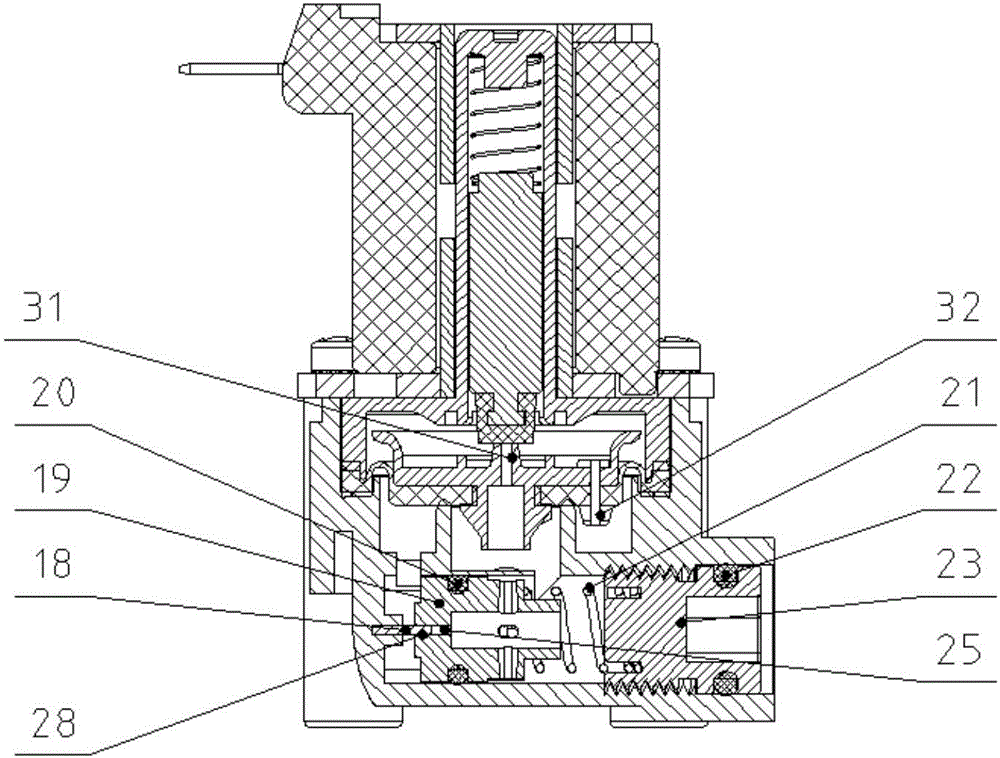

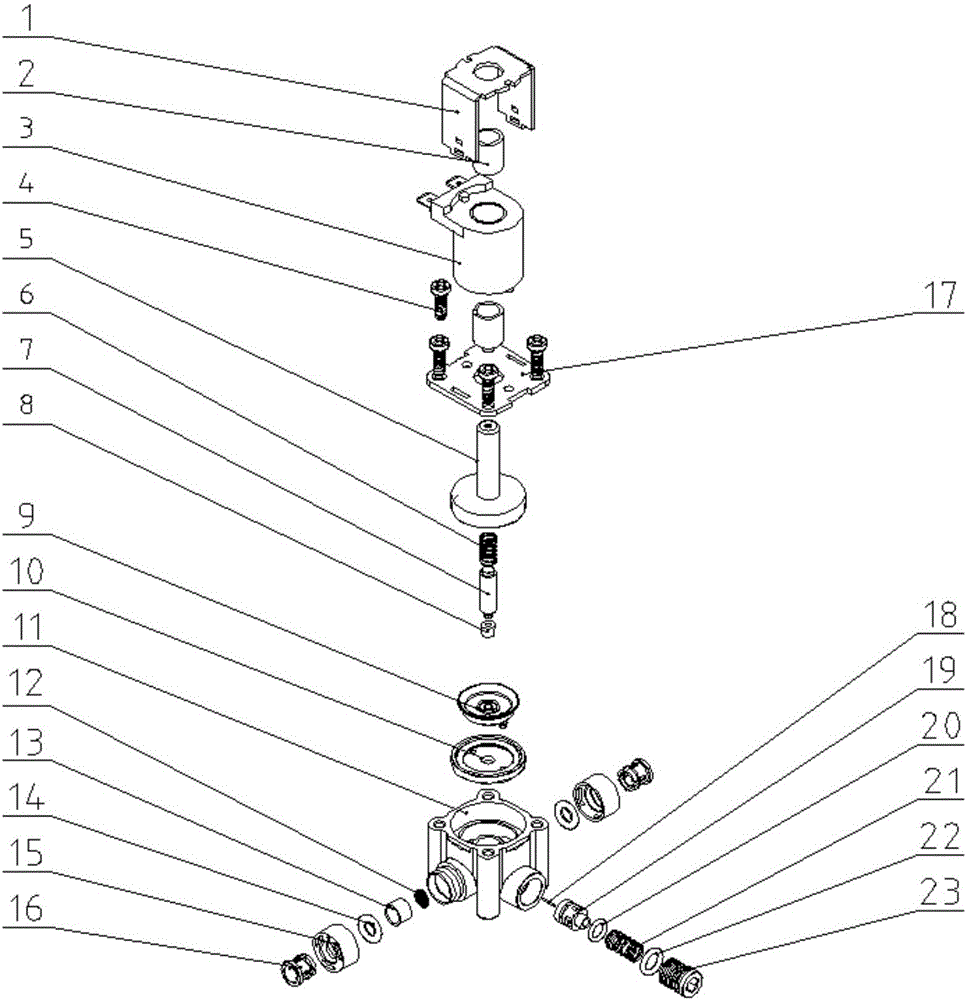

Anti-blocking and self-cleaning effluent proportional solenoid valve

InactiveCN106555900ASolve the clogging problemOperating means/releasing devices for valvesSolenoid valveWastewater

The invention provides an anti-blocking and self-cleaning effluent proportional solenoid valve comprising a valve body; valve diaphragms are arranged in the valve body; the inside of the valve body is defined into a water inlet chamber, a water outlet chamber and a water separation chamber by the valve diaphragms; the water inlet chamber is internally provided with a fixed anti-blocking needle, a movable anti-blocking sleeve and a fixed anti-blocking seat, wherein the fixed anti-blocking needle is fixedly arranged in the water inlet chamber, the fixed anti-blocking seat is fixedly arranged in the water outlet chamber, the movable anti-blocking sleeve is movably arranged between the fixed anti-blocking needle and the fixed anti-blocking seat, and the excircle of the movable anti-blocking sleeve is sealed together with the valve body to partition the water inlet chamber and the water outlet chamber; the movable anti-blocking sleeve is provided with an anti-blocking through hole corresponding to the fixed anti-blocking needle end; and an anti-blocking reset spring is arranged between the fixed anti-blocking seat end in the movable anti-blocking sleeve and the fixed anti-blocking seat. The anti-blocking and self-cleaning effluent proportional solenoid valve has the advantage that the problem of effluent hole blockage of the effluent proportional solenoid valve is solved.

Owner:ZHEJIANG DAWEI ELECTRONICS

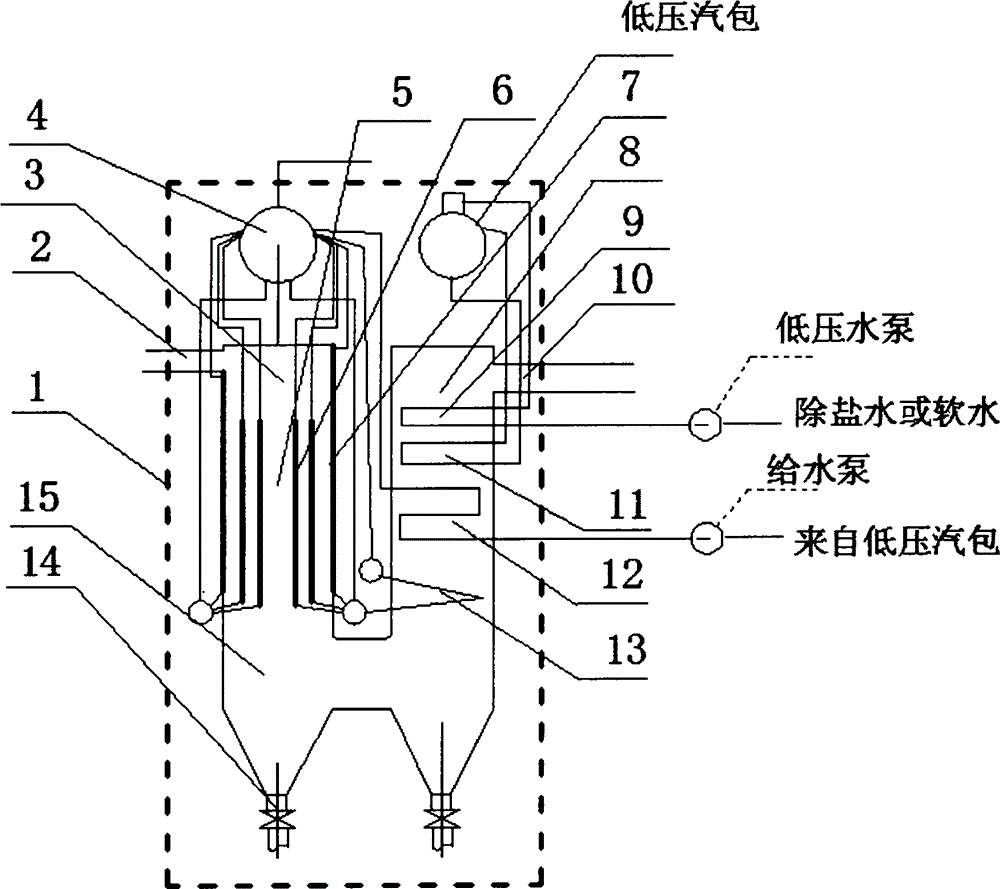

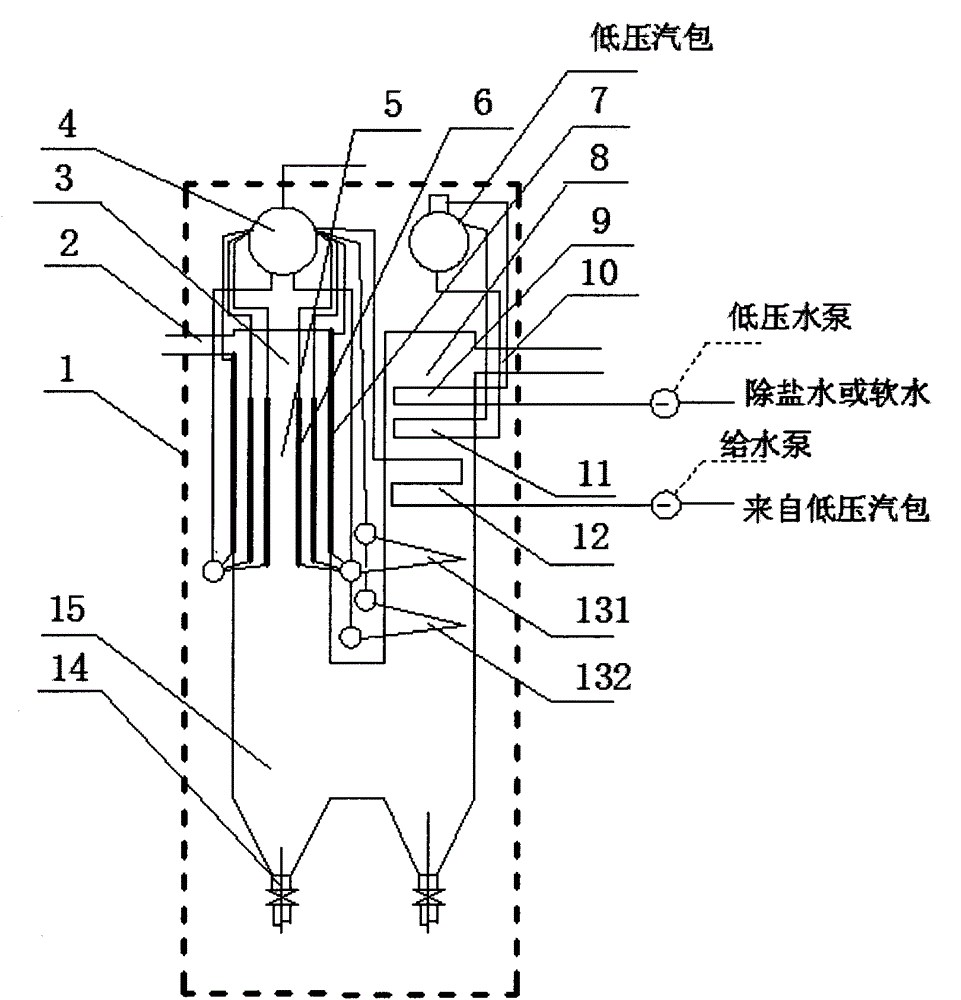

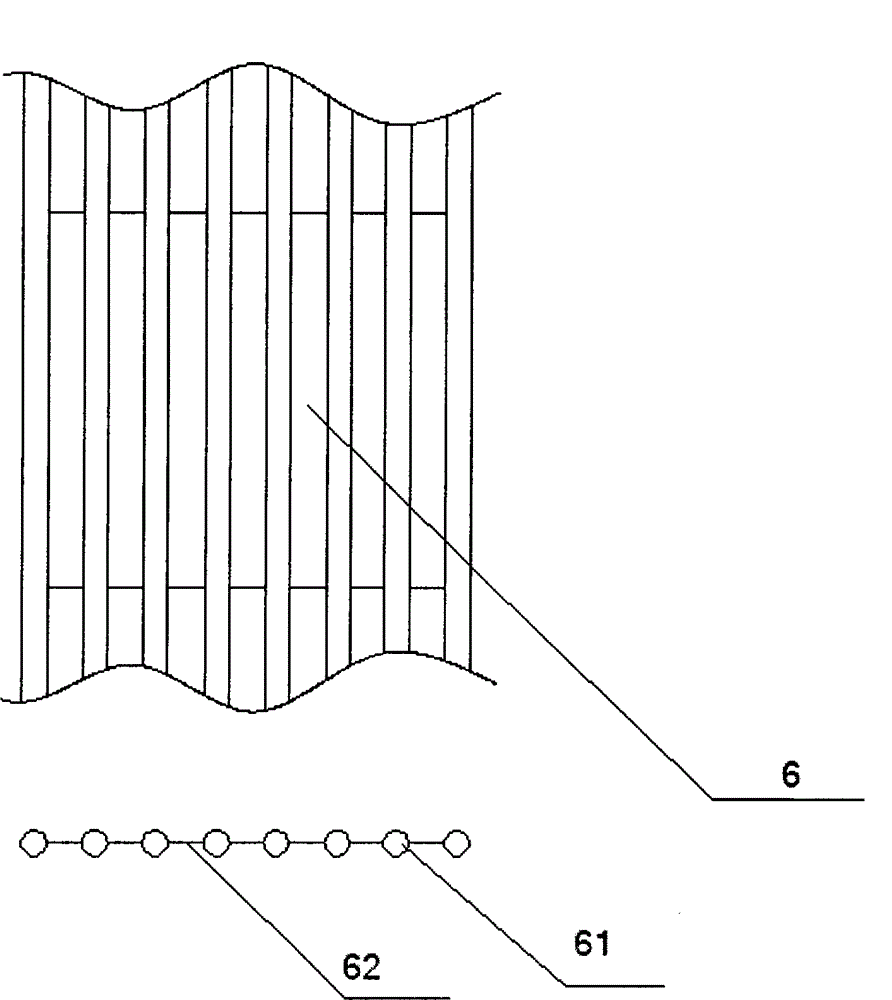

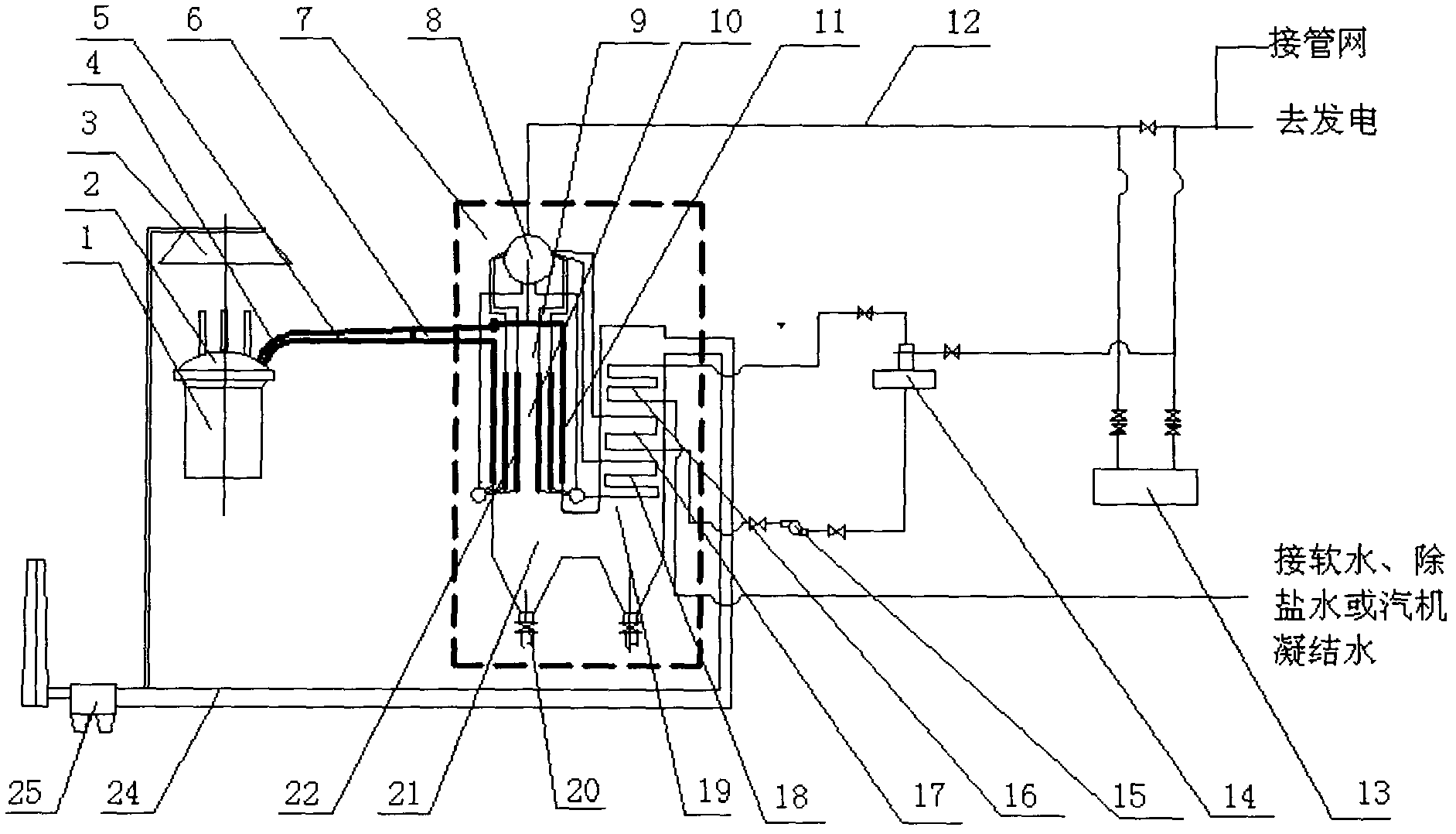

Multi-radiation evaporation screen afterheat boiler

InactiveCN103982884AImprove dust removal efficiencySolve the clogging problemIncreasing energy efficiencySteam generation using hot heat carriersElectricityFlue gas

The invention discloses a multi-radiation evaporation screen afterheat boiler. The multi-radiation evaporation screen afterheat boiler comprises a flue gas inlet, a flue gas flow equalizing chamber, a water-cooling radiation heat exchange chamber, a radiation evaporation screen, a film type water cooling wall, a convective heat exchange chamber, an evaporator, a coal saver, a steam pocket, a dust discharging device and the like. High-temperature flue gas enters the flue gas flow equalizing chamber from a flue gas inlet of the afterheat boiler, after being equalized, the flue gas enters the water-cooling radiation heat exchange chamber, after exchanging heat with the film type water cooling wall and the radiation evaporation screen, the flue gas enters the convective heat exchange chamber again, after the flue gas exchanges heat with the evaporator and the coal saver, the temperature of the flue gas is greatly reduced, the flue gas is exhausted from a boiler system, and after being de-dusted, the flue gas is exhausted; the afterheat boiler absorbs the heat of the high-temperature flue gas, and the generated steam is used for production or generating electricity. The afterheat boiler can fully reclaim the heat of the high-temperature and high-dust content flue gas of an arc furnace, convertor and the like, the temperature of the absorbed flue gas can be up to 1,600 DEG C, and the reclaimed heat can be up to over 70 percent of the heat of the exhausted flue gas; the equipment of the reclaiming system is stable and reliable in operation, and the maintenance cost and the operation cost are low.

Owner:孙慕文

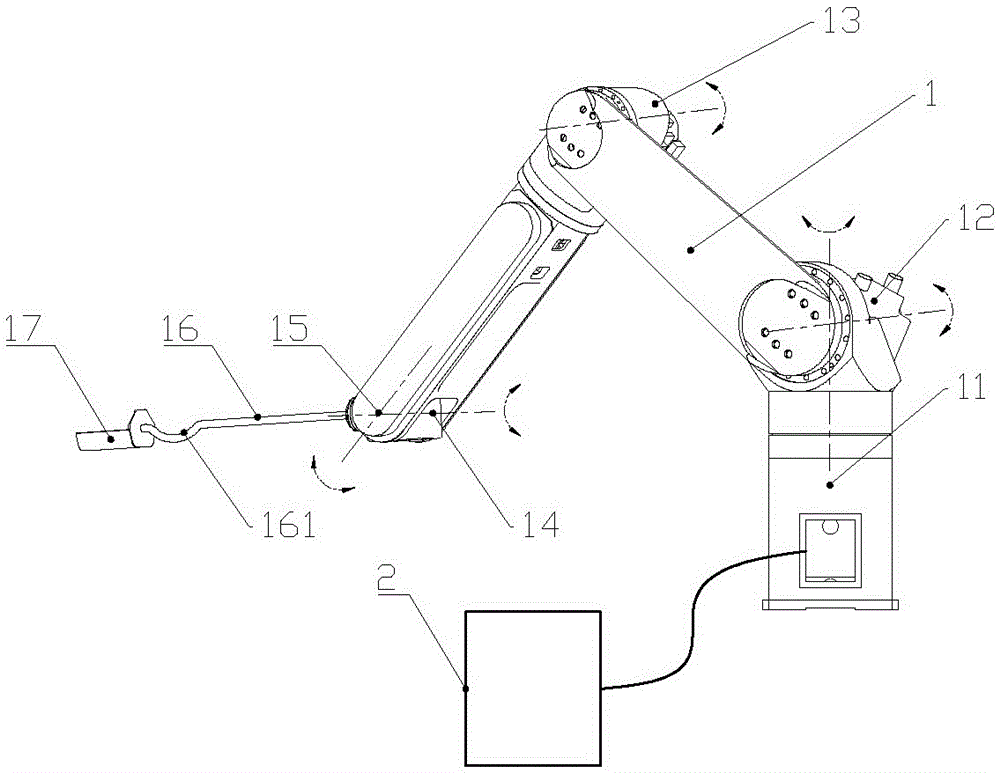

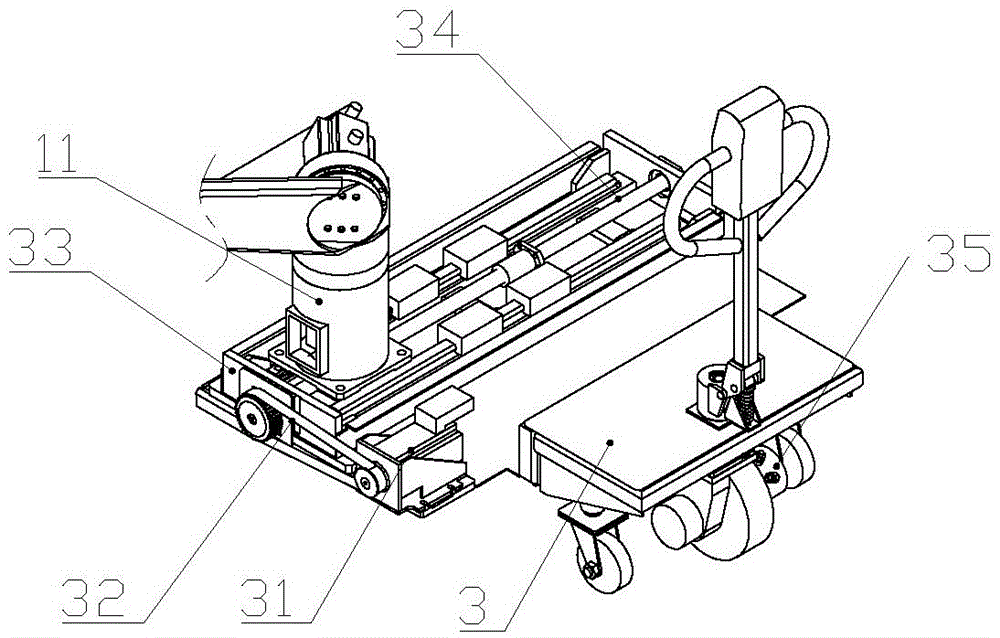

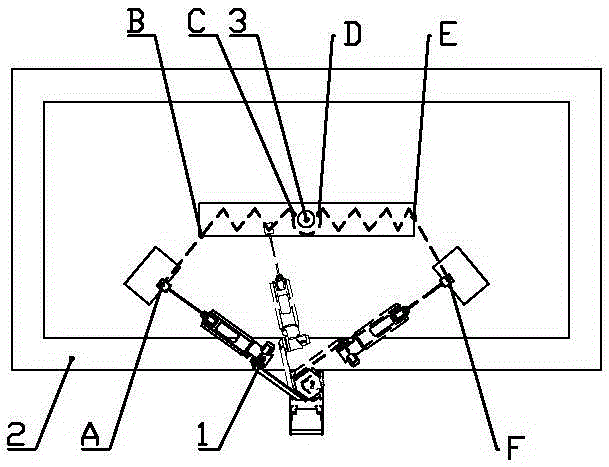

Automatic slag feeding robot

The invention provides an automatic slag feeding robot comprising a slag feeding spoon, a joint arm and a control system electrically connected with the joint robot arm. The slag feeding spoon is installed on the end of the joint robot. The beneficial effects are that the slag feeding robot has small size, low price and even and smooth slag feeding; protective slag original states can be maintained; and problems of large size, high price, slag block, uneven slag feeding, protective slag smashing and dust pollution of the present automatic slag feeding technology can be solved.

Owner:HENGYANG RAMON SCI & TECH CO LTD

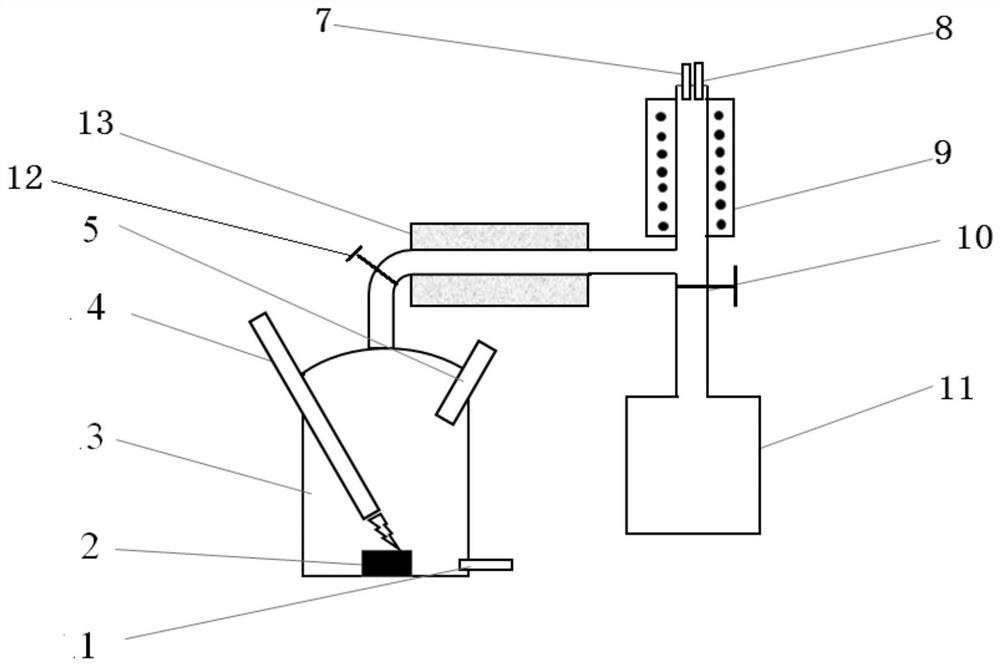

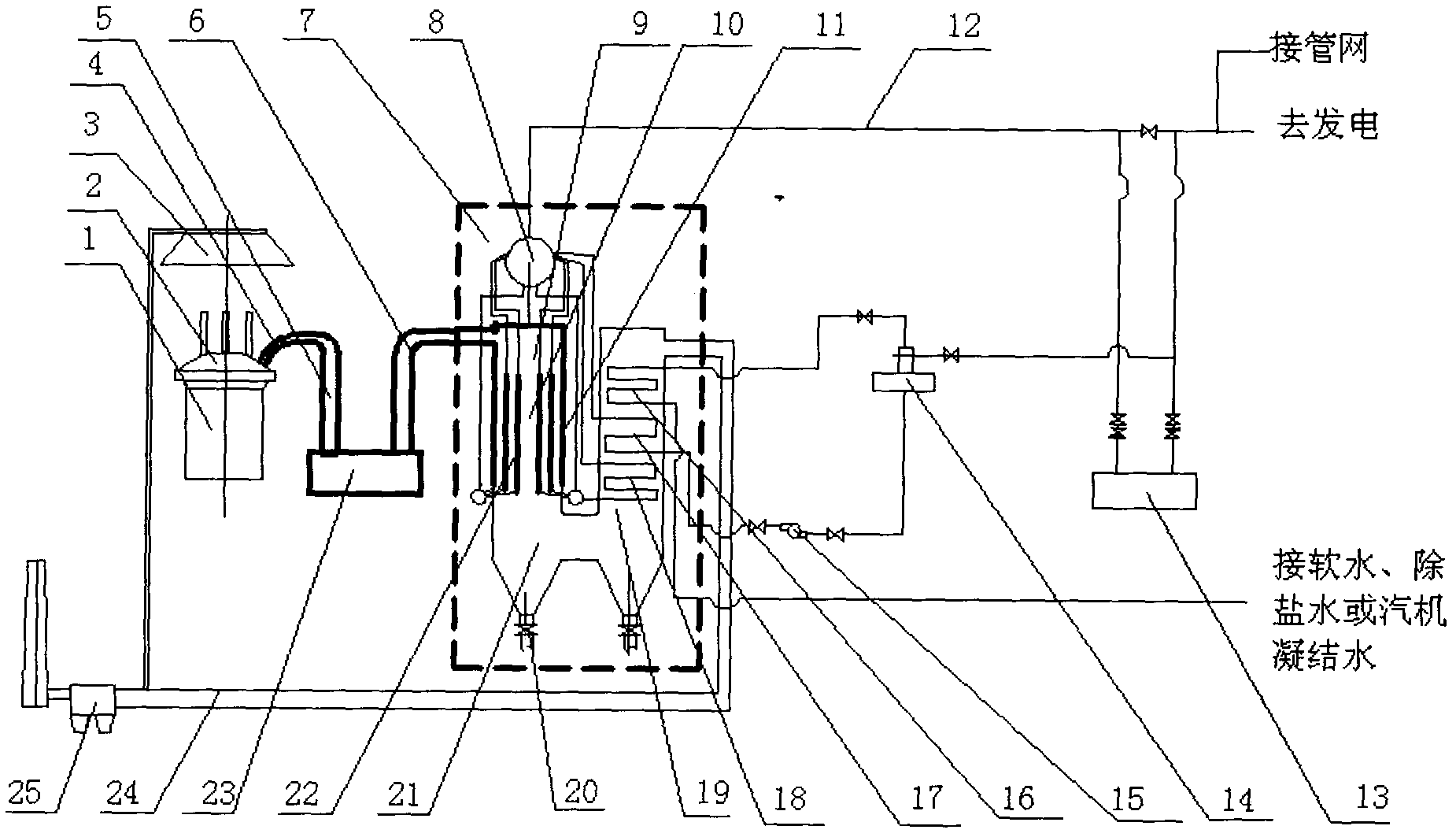

Electric arc furnace smoke radiation type waste heat boiler recovery system

InactiveCN102322746AImprove dust removal efficiencySolve the clogging problemEnergy industryIncreasing energy efficiencyElectric arc furnaceEngineering

The invention discloses an electric arc furnace smoke radiation type waste heat boiler recovery system, which comprises a radiation type waste heat boiler and a heat accumulator. The radiation type waste heat boiler is provided with a smoke homogeneous flow chamber, a water cooling radiation heat exchange chamber, a convection heat exchange chamber, a steam pocket, an ash discharging device and the like. After passing through a settling chamber, the smoke of an electric arc furnace enters the smoke homogeneous flow chamber; after being homogeneous, the smoke enters the water cooling radiation heat exchange chamber; after being exchanged with a water cooling wall and a radiation water cooling screen, the smoke enters the convection heat exchange chamber; after the smoke is exchanged with an evaporator and an economizer, the temperature of the smoke is greatly reduced; then, the smoke is discharged from the boiler system; after being dedusted, the smoke is discharged; and, after entering the heat accumulator to be stabilized, intermittent steam discharged by the steam pocket is changed into continuous steam provided for production or power generation. According to the electric arc furnace smoke radiation type waste heat boiler recovery system disclosed by the invention, the smoke heat of the electric arc furnace can be sufficiently recovered; the heat is up to 70% of the heat of the smoke discharged by the electric arc furnace; the system can be suitable for smoke temperatures of various electric arc furnaces; and equipment of the recovery system has the advantages of steady and reliable operation and low maintenance and operation cost.

Owner:孙慕文

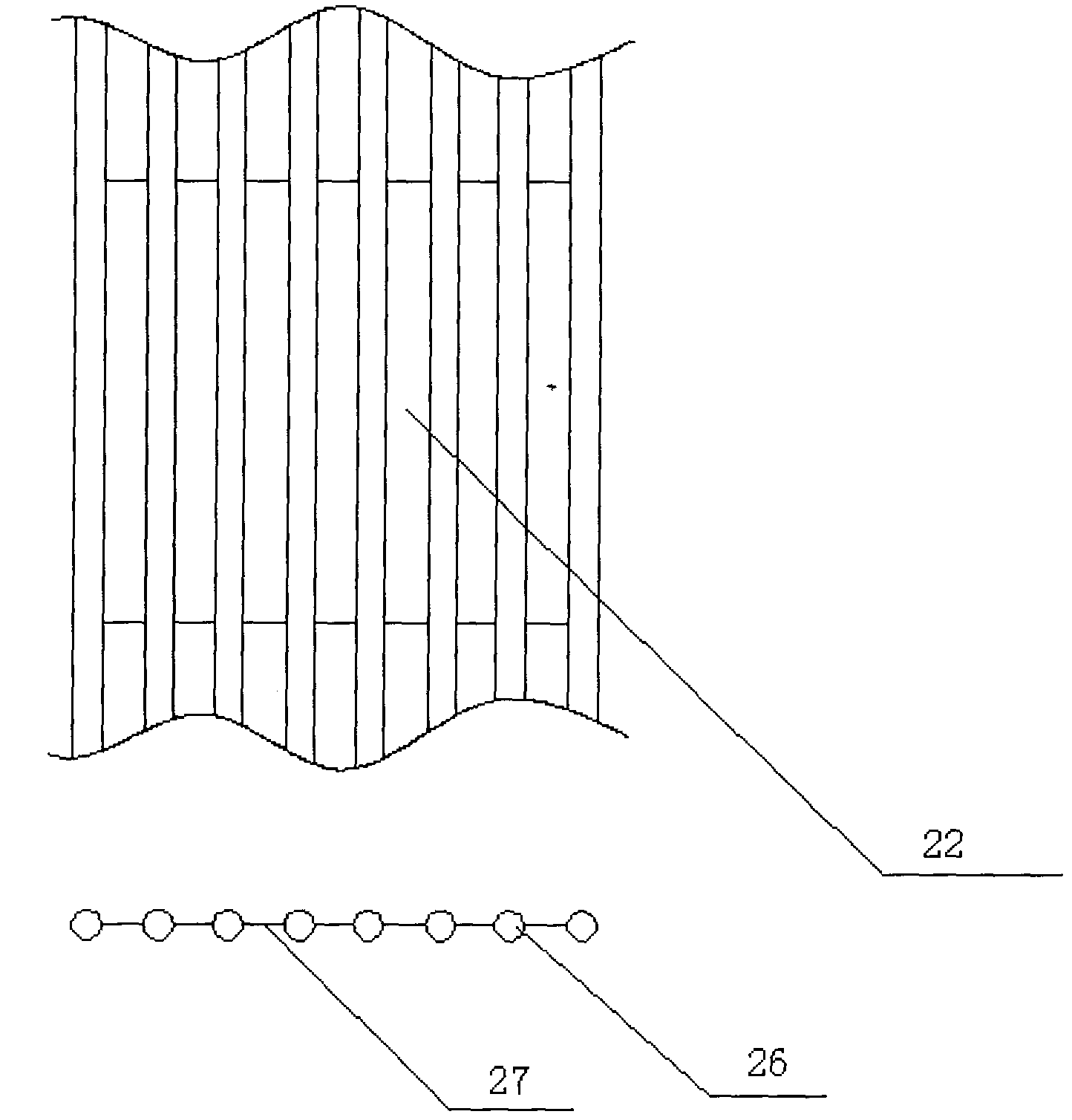

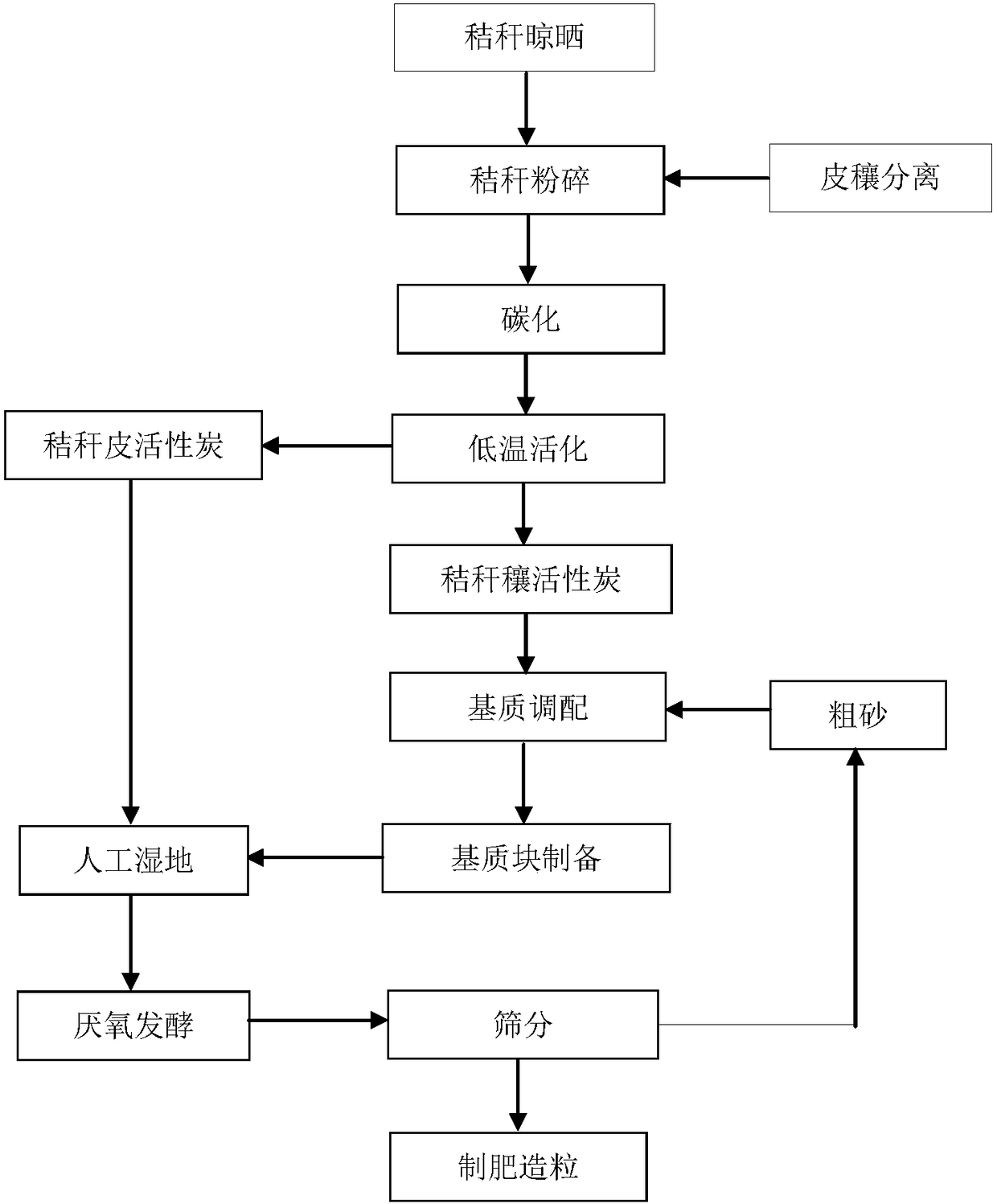

Method for preparing constructed wetland substrate from cornstalks

ActiveCN108569768AImprove purification effectReduce manufacturing costBiological water/sewage treatmentActivated carbonConstructed wetland

The invention discloses a method for preparing constructed wetland substrate from cornstalks. The method includes steps of airing, crushing, carbonizing, low-temperature activating, substrate mixing and substrate block preparation. Harvested cornstalks are defoliated and aired until the moisture content reaches 15%, skin and stalks are separated and crushed into different specifications prior to carbonizing, then soaking in water and low-temperature activation are performed, and coarse sand in particle size of 0.5-1mm is added into activated stalk based activated carbon to obtain substrate blocks. The substrate blocks are used for constructed wetland, and straw skin based activated carbon is placed at the top of the constructed wetland. The prepared constructed wetland substrate is renewable and effective in domestic sewage purification, and waste substrate can be used for organic fertilizer preparation after a use cycle ends, so that high recycling rate is realized.

Owner:NORTHEAST NORMAL UNIVERSITY

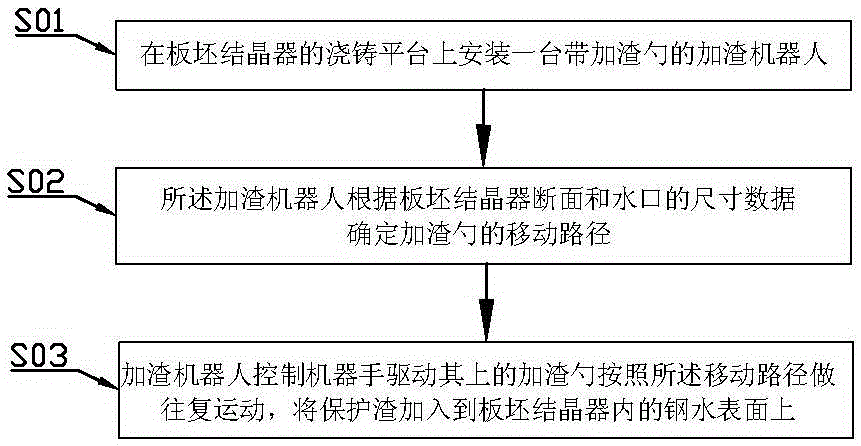

Slag adding method of slab crystallizer slag adding robot

The invention provides a slag adding method of a slab crystallizer slag adding robot. The slag adding method comprises the following steps: a slag adding robot with a slag adding spoon is mounted on a casting platform of a slab crystallizer; the slag adding robot determines a moving path of the slag adding spoon according to the size data of a section of the slab crystallizer and a water port; the slag adding robot controls a machine arm to drive the slag adding spoon thereon to perform a reciprocating motion according to the moving path; and protection slag is added on the surface of molten steel in the slab crystallizer. The slag adding method has such beneficial effects as smooth and uniform slag adding, keeping of initial shape of the protection slag and environmental protection, and solves such problems as slag blockage, nonuniform slag adding, crushing of the protection slag and easy generation of the dust pollution in traditional automatic slag adding.

Owner:HENGYANG RAMON SCI & TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com