Groove drainage tube capable of flushing

A drainage pipe and groove technology is applied in the field of flushable groove drainage pipes, which can solve the problems of inability to realize water injection and small diameter of water passing through, and achieve the effects of improving drainage effect, solving clogging problem, and stable and feasible structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

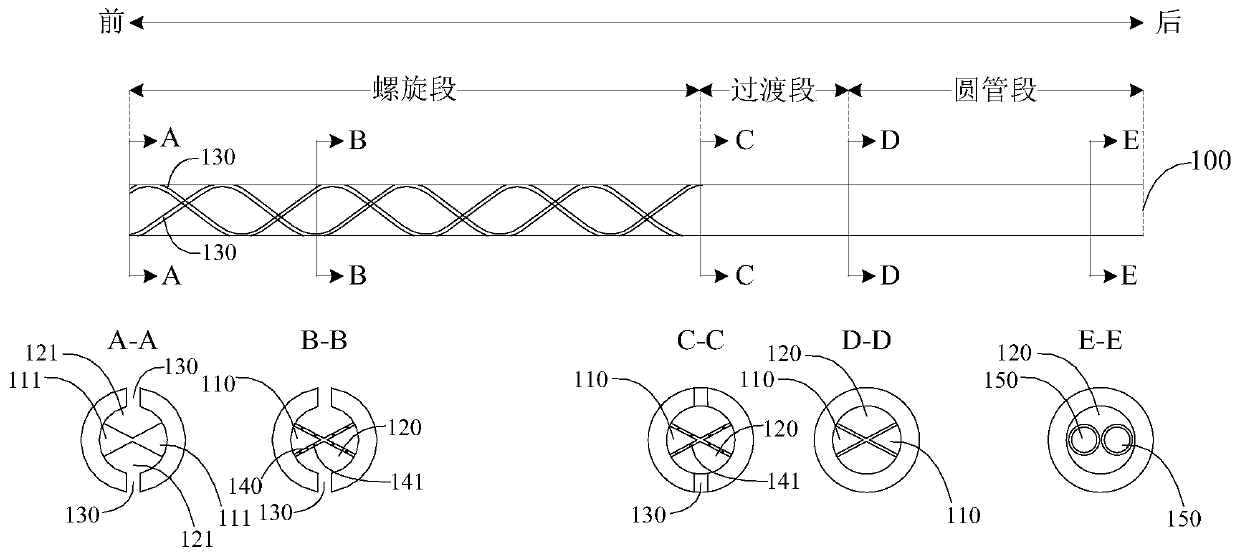

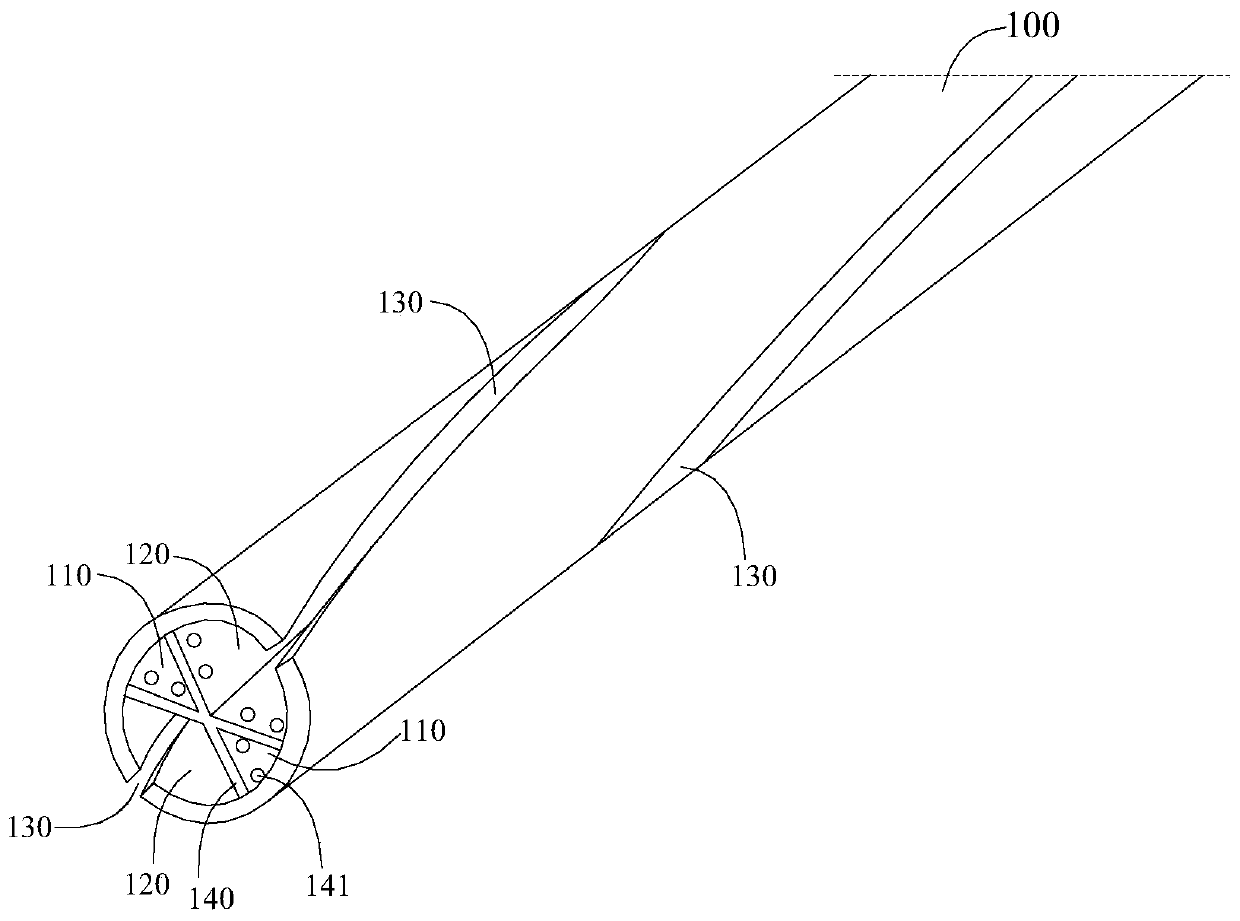

[0038] Example 1, please refer to Figure 1-3 , four lumens are opened in the drainage tube body 100 .

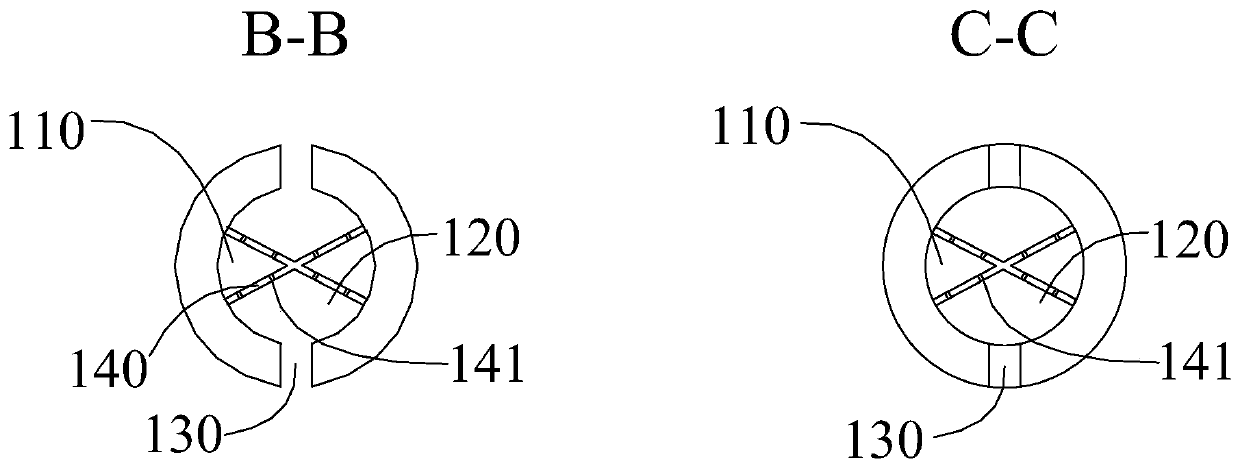

[0039] Specifically, as shown in the sectional views "B-B", "C-C", and "D-D", the cross section of the cavity wall 140 is X-shaped, two of which are used as the water injection cavity 110, and the other two are used as the drainage cavity 120, the water injection chamber 110 and the drainage chamber 120 are spaced apart from each other.

[0040] Optionally, the cross-sectional area of the water injection chamber 110 is smaller than the cross-sectional area of the drainage chamber 120, in order to reduce the occupation of the space of the drainage chamber 120 and facilitate the suction of human tissue fluid.

[0041] In this embodiment, as shown in the sectional view "A-A", the front end 111 of the water injection chamber is closed, and the front end 121 of the drainage chamber is open. Wherein, the front end 111 of the water injection chamber is closed, so that the wa...

Embodiment 2

[0045] Example 2, please refer to Figure 4 , 5 , three lumens are opened in the drainage tube body 100 .

[0046] Specifically, as shown in the sectional views "B-B", "C-C", and "D-D", the cross section of the chamber wall 140 is Y-shaped, one of which is used as the water injection chamber 110, and the other two chambers are used as the drainage chamber 120 , the water injection chamber 110 and the drainage chamber 120 are spaced apart from each other.

[0047] Compared with Embodiment 1, since there is only one water injection chamber 110 and two drainage chambers 120, the area of the water injection chamber 110 in this embodiment will be smaller than the area of the drainage chamber 120, greatly reducing the occupation of the space of the drainage chamber 120, It is more conducive to the suction of human tissue fluid.

[0048] In this embodiment, as shown in the sectional view "A-A", the front end 111 of the water injection chamber is closed, and the front end 121 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com