Slag adding method of slab crystallizer slag adding robot

A crystallizer and robot technology, which is applied in the field of steelmaking and continuous casting, can solve the problems of powder slag breaking, easy slag blocking, and heavier spiral slag feeding pipes, so as to achieve smooth slag feeding, maintain the original shape, and uniform slag feeding. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

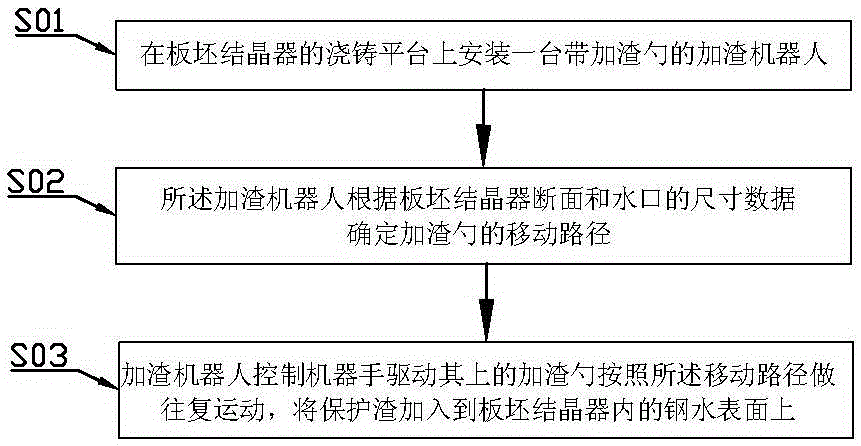

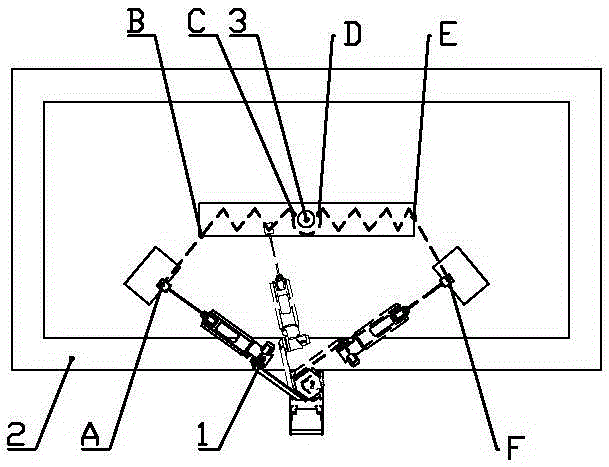

[0015] Such as Figure 1-2 As shown, the present invention provides a schematic diagram of the steps of an articulated robot automatic slagging method, which includes the following steps:

[0016] S01: Install a slag adding robot 1 with a slag adding spoon on the casting platform of the slab mold 2;

[0017] S02: The slag adding robot 1 determines the movement path of the slag adding spoon according to the size data of the slab mold section and the nozzle 3;

[0018] S03: The slag adding robot controls the robot to drive the slag adding spoon on it to reciprocate according to the moving path, and add the mold powder to the molten steel surface in the slab mold.

[0019] In the preferred embodiment of the present invention, the moving path of the slag adding robot 1 driving the slag adding spoon refers to the order from point A (the left slag basin where the mold powder is stored) → point B (the left end of the mold opening) → Point C (the left side of the nozzle) → Point D (the right...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com