Multi-radiation evaporation screen afterheat boiler

A waste heat boiler and evaporation screen technology, which is applied in the field of waste heat boilers, can solve the problems of high operating costs, large volume of heat pipe waste heat boilers, and easy condensation of dust removal bags, so as to achieve low maintenance costs and operating costs, improve flue gas dust removal efficiency, The effect of overcoming the problem of dust clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

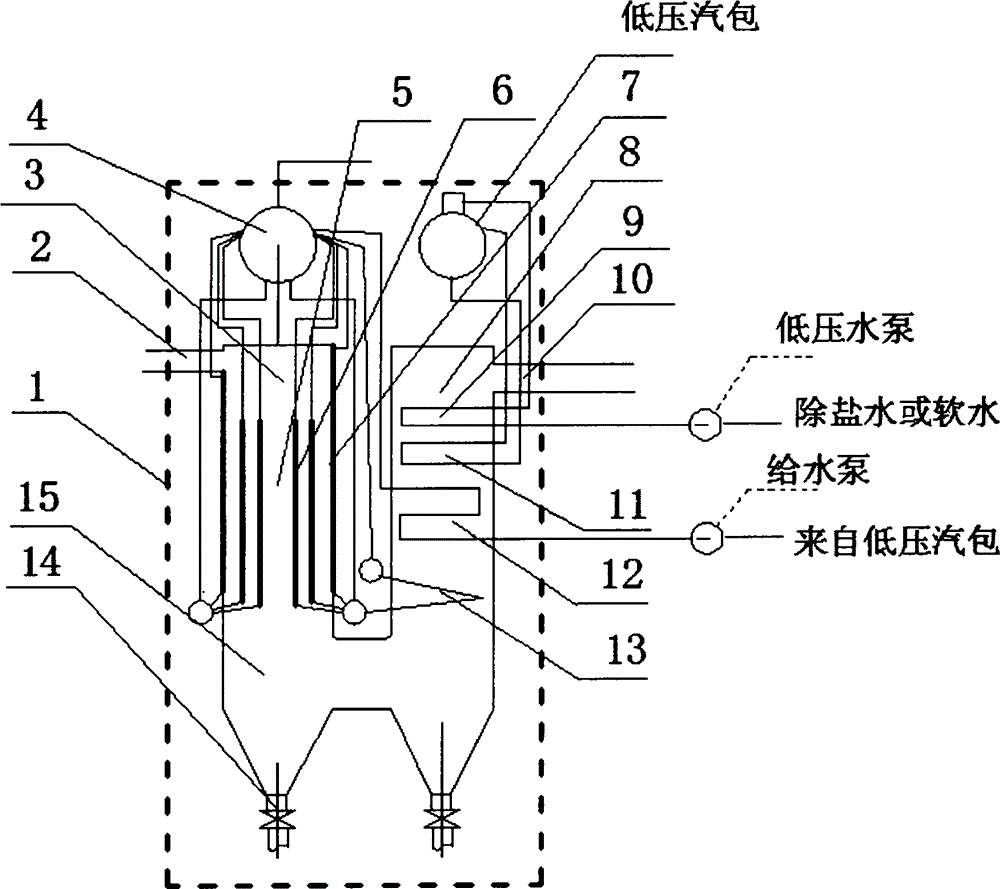

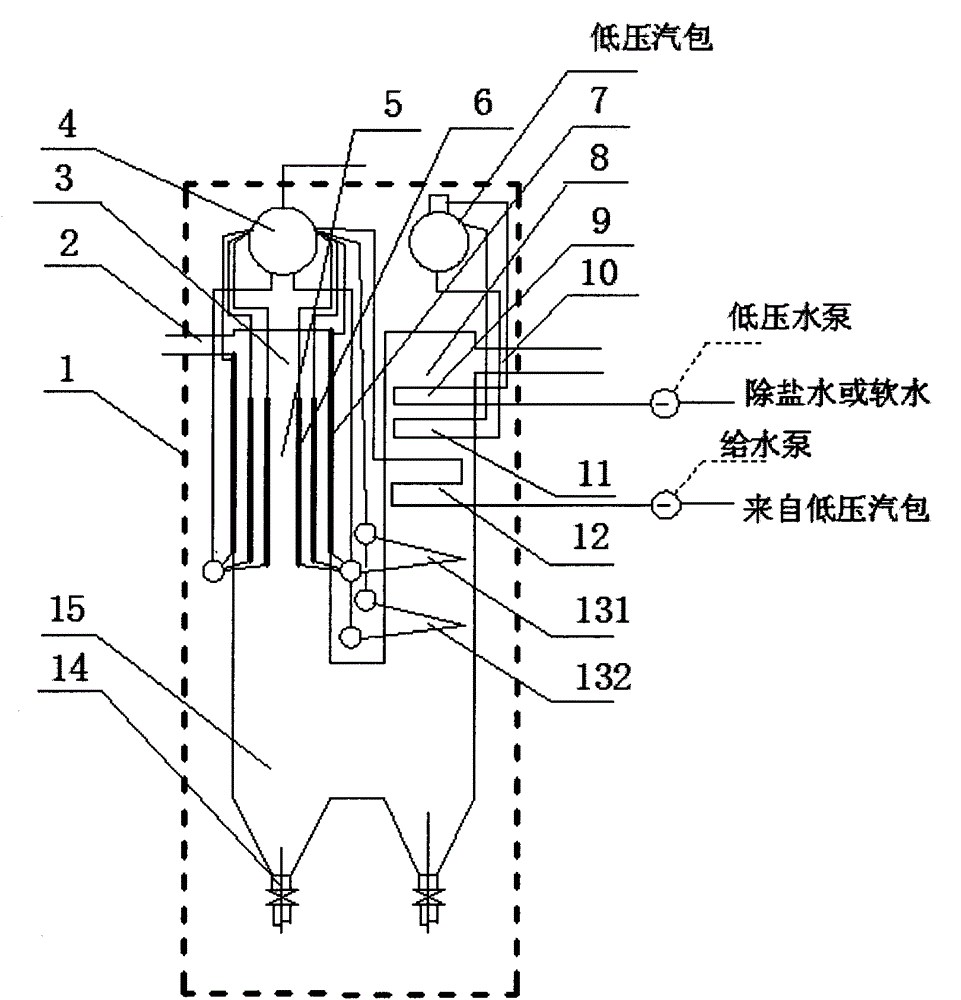

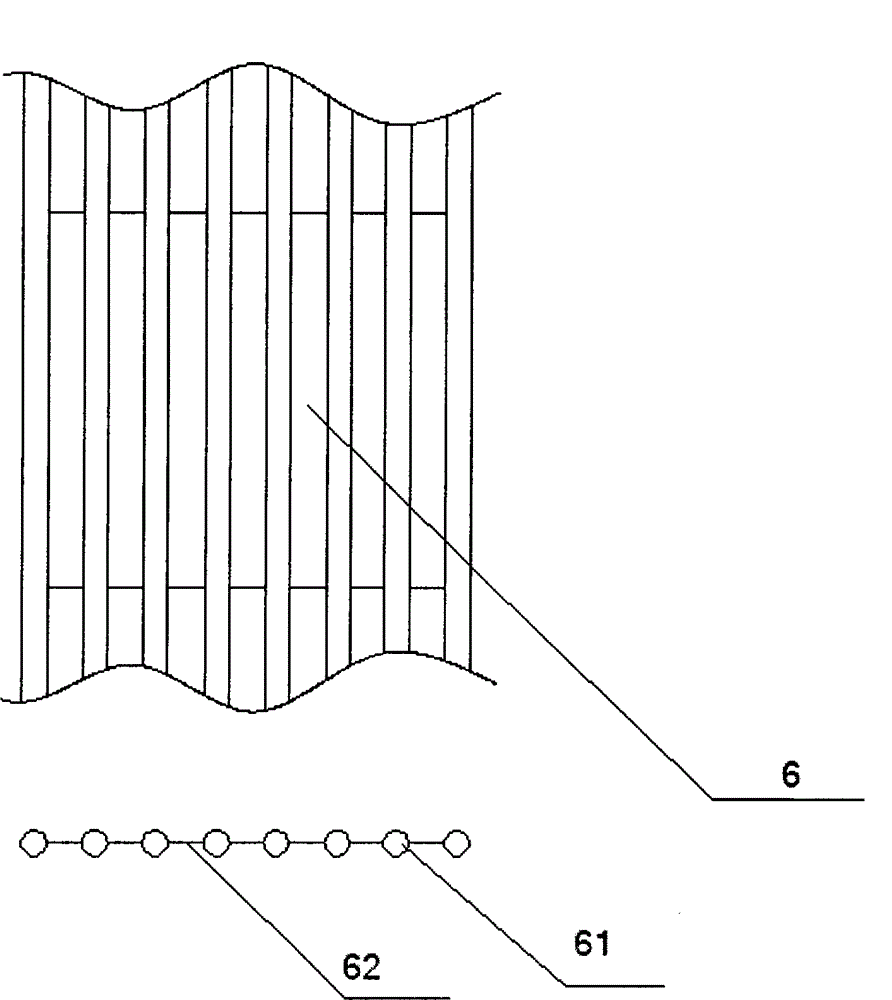

[0025] Such as figure 1 As shown: the multi-radiation panel waste heat boiler of the present invention has a U-shaped structure, including the flue gas inlet (2), flue gas equalization chamber (3), steam drum (4), Water-cooled radiation heat exchange chamber (5), intermediate settling chamber (15), convection heat exchange chamber (8), exhaust gas outlet (10); water-cooled radiation heat exchange chamber (5) is equipped with 8 radiation evaporation screens (6), water-cooled Membrane water-cooled walls (7) are installed around the heat exchange chamber of the radiation chamber, steam drum downcomers, membrane water-cooled wall inlet water headers are installed outside the radiation chamber, water inlet headers of radiation evaporation screens are installed, and piping is installed to connect the steam drum downcomers and Membrane water-cooled wall inlet header and membrane water-cooled wall are connected in series, install pipes to connect steam drum downcomer with radiant wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com