Liquid rotary type continuous extraction process and device

An extraction and process technology, which is applied in the field of hydrocyclone continuous extraction processes and devices to achieve the effects of improving production efficiency, simplifying extraction equipment and reducing power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail in conjunction with process parameters below, but does not limit the present invention.

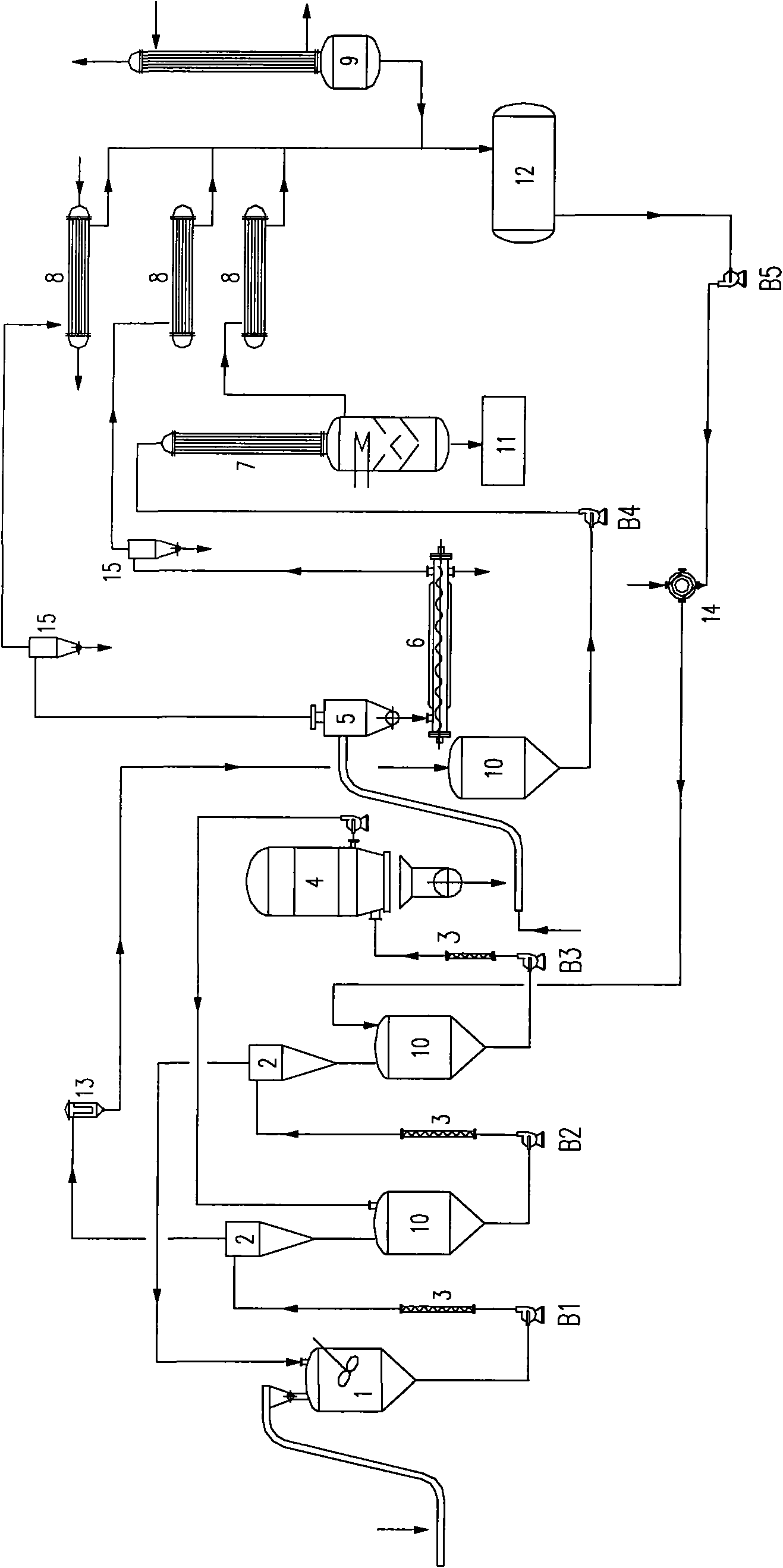

[0016] The cyclonic continuous extraction process of the present invention comprises the following steps successively:

[0017] a. Feeding and mixing: Continuously add the powdery material into the mixing tank 1 and fully stir and mix with the solvent. The cyclone-separated extract (solvent) was added while mixing.

[0018] b. Cyclone-liquid extraction: the mixed material is extracted through multiple sets of cyclone extractors 2 . In order to improve the extraction effect, the material will pass through the static mixer 3 during the conveying process. Make the material and the solvent fully contact with the dissolved extraction. The extraction time can be controlled within 10 to 30 minutes (the specific surface area of the powdery material is very large, and it is very easy to contact with the extraction solvent and be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com