Blast furnace cinder flushing water multipath heat exchanger

A blast furnace slag flushing water and multi-process technology, which is applied to indirect heat exchangers, heat exchanger types, lighting and heating equipment, etc., to achieve the effects of increased processing capacity, high heat transfer efficiency, and long operating cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

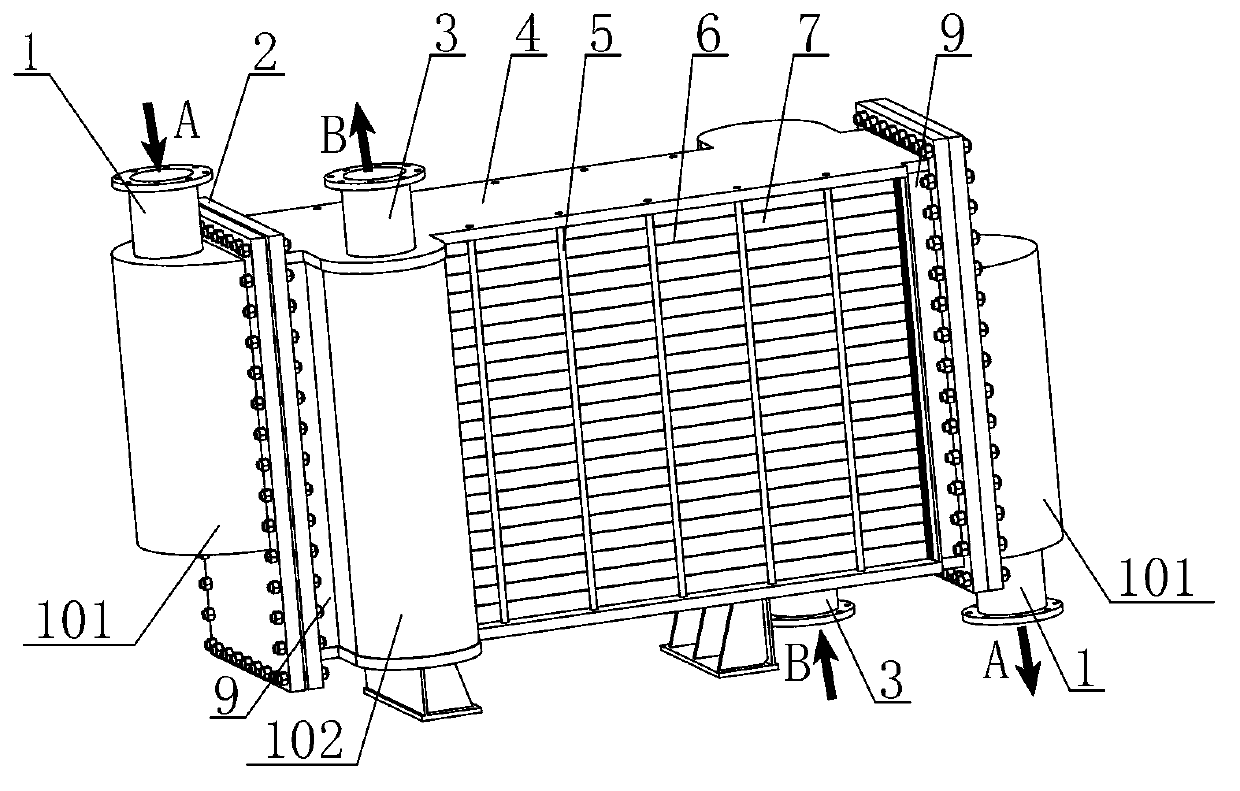

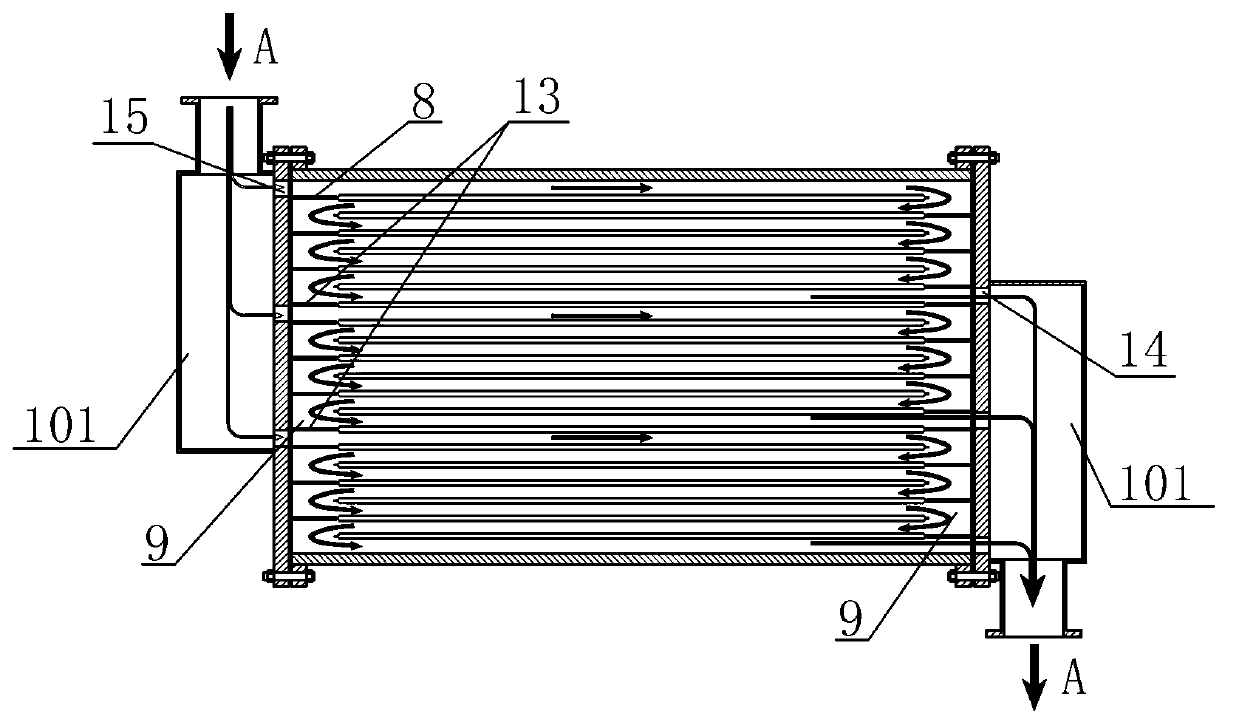

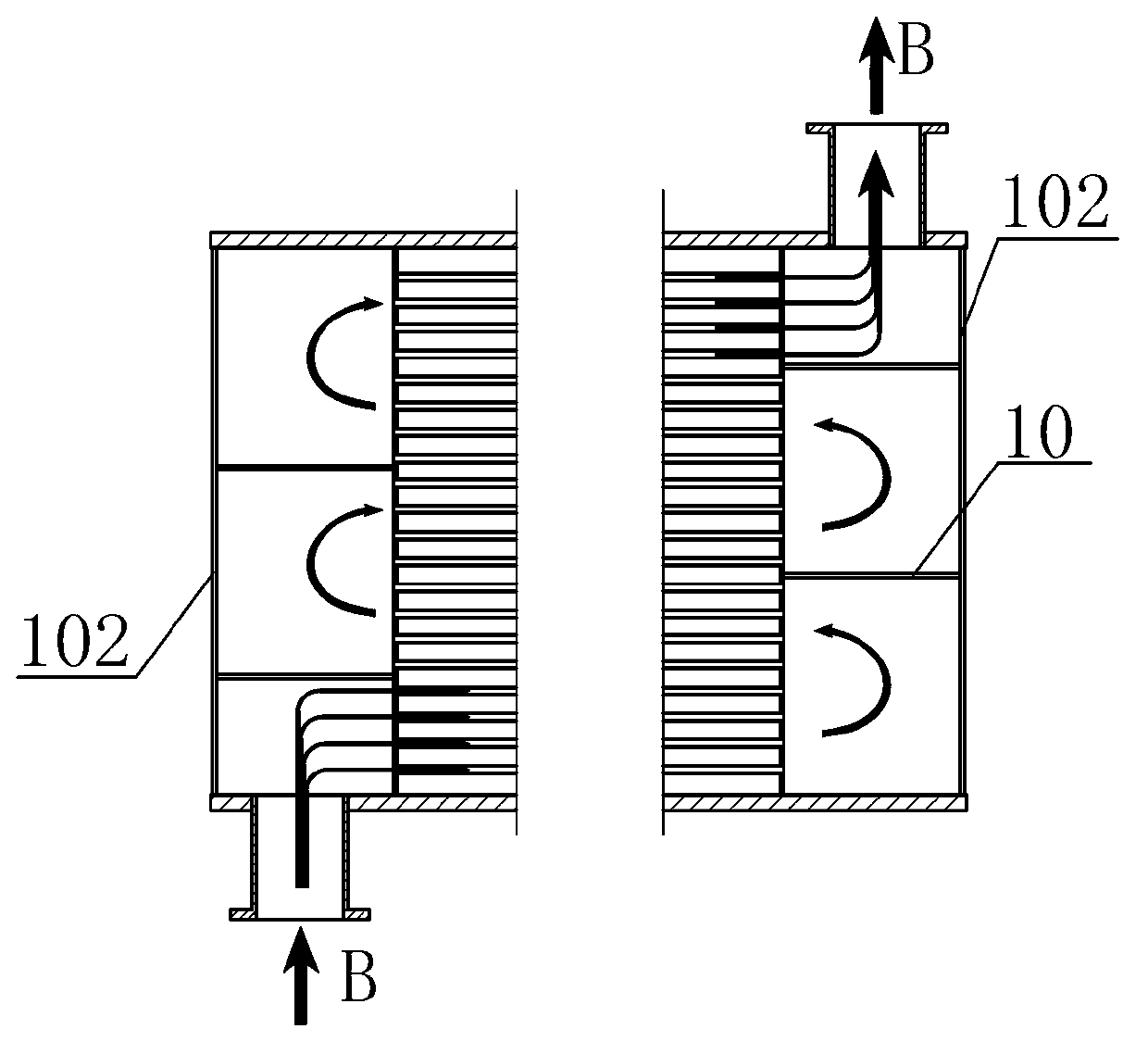

[0022] As shown in the figure, the present invention includes two pairs of slag flushing water connection pipes 1 and secondary water connection pipes 3 arranged at the upper and lower ends, two slag flushing water pipe boxes 9 arranged at both ends, and two slag flushing water pipe boxes 9 connected with the slag flushing water pipe box 9. The water pipe box flat cover 2 and its splitter box 101, two secondary water pipe boxes 102 arranged on both sides, the heat exchange plate bundle arranged between the slag flushing water pipe box and the secondary water pipe box and the pressure plate clamping the heat exchange plate bundle tight plate 4 and tie rod 5, the heat exchange plate bundle includes a plurality of heat excha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com