Pressurized vacuum flexible tubular well dewatering and drainage system and construction method thereof

A vacuum flexible drainage system technology, which is applied in infrastructure engineering, soil protection, construction, etc., can solve the problems of drainage failure, long drainage path, and easy silting of the filter layer, so as to reduce the radius of precipitation and reduce the project cost. The effect of reducing the cost and shortening the precipitation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

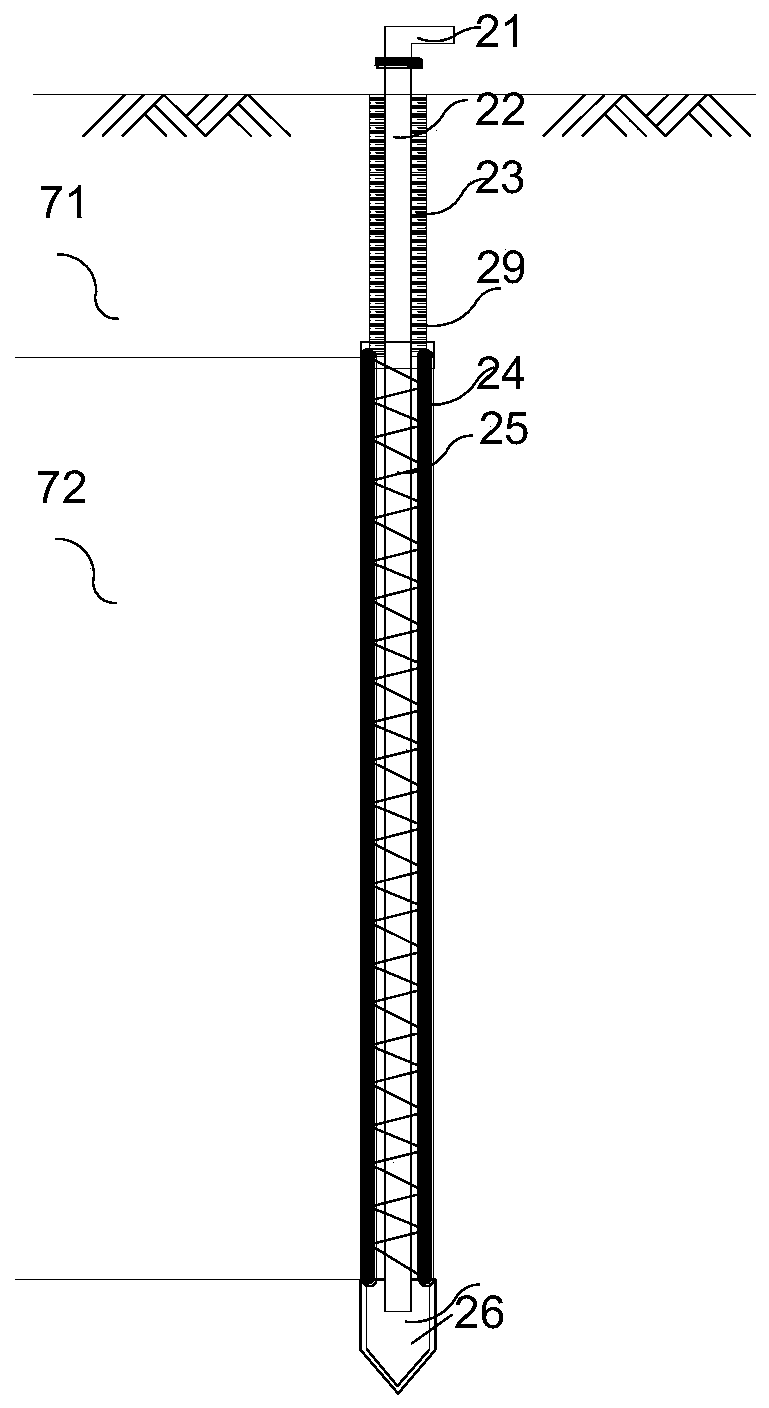

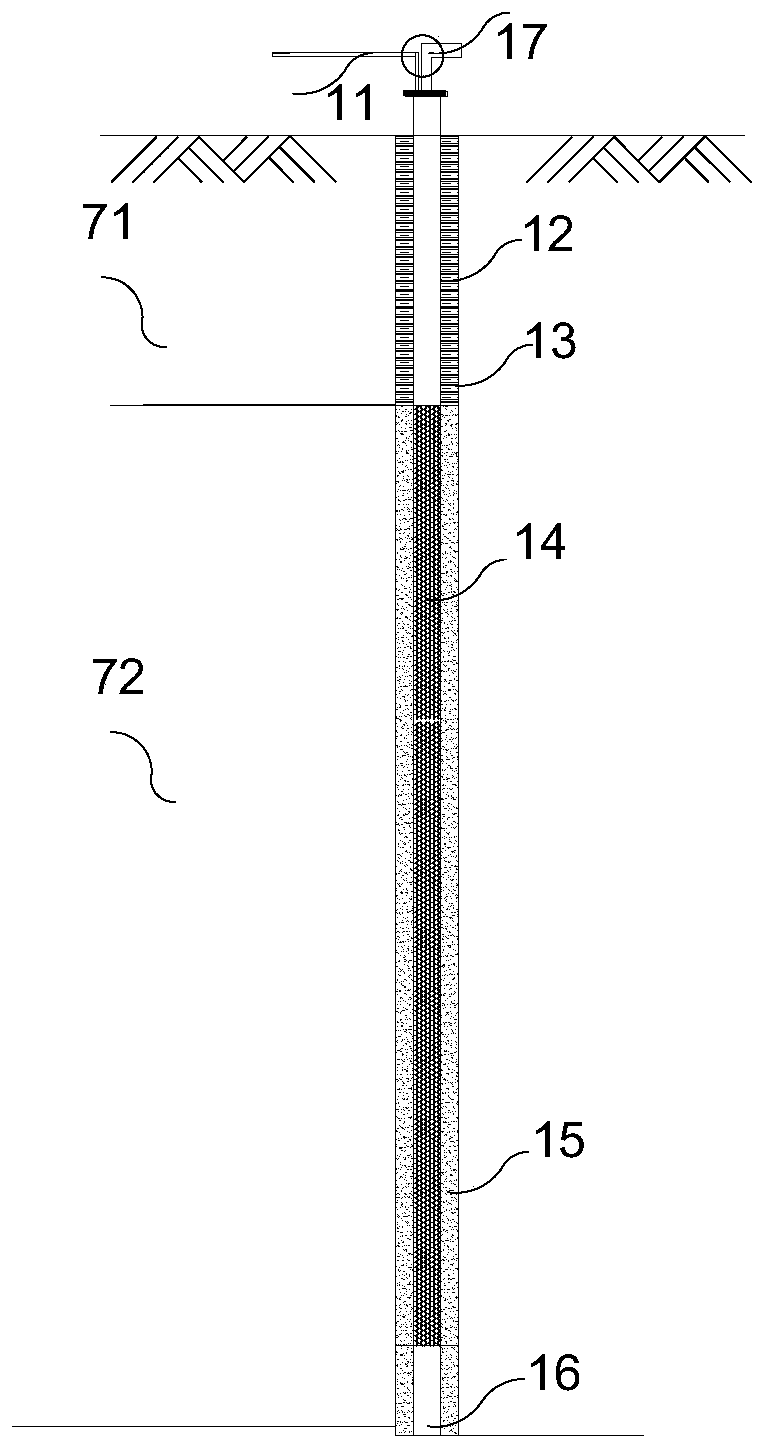

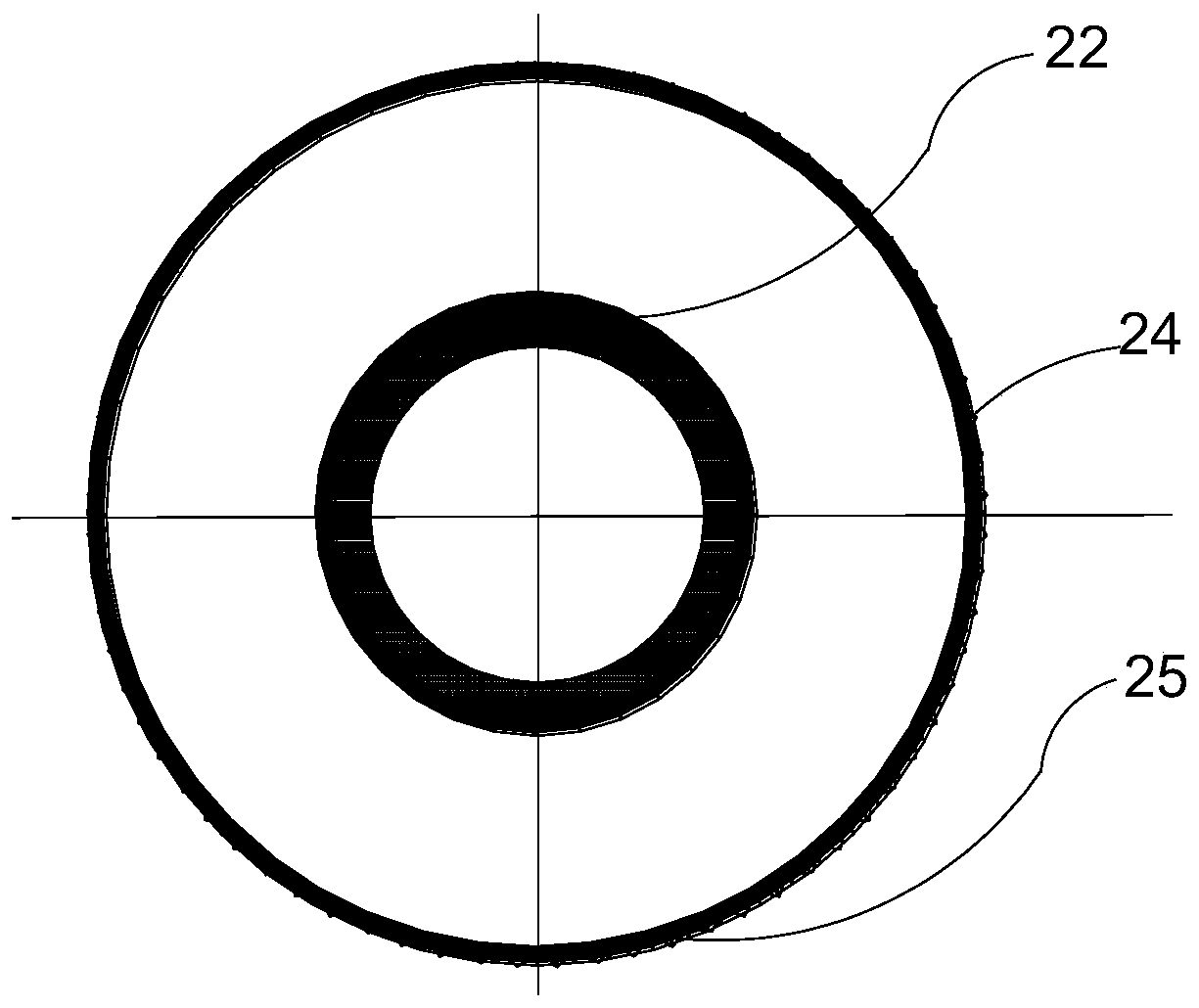

[0040] In order to fully illustrate the working principle of this new type of pressurized drainage system, we will make a structural section of a pressurized vacuum flexible tube well as shown in figure 1 Compared with the traditional vacuum tube well profile such as figure 2 List them together. from figure 2 It can be seen that the traditional vacuum tube well is composed of a steel pipe 12, a porous steel pipe wrapped around a filter pipe 14, a granular filter material 15 and a sealing clay sphere 13 at the drainage part, and a vacuum tube 11 and a drain pipe 17 are arranged in the well pipe. When it is a tube well with a larger diameter, a submersible pump is directly provided inside for drainage. The bottom of the tube well is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com