Biomass carbonizing equipment

A biomass and equipment technology, applied in the field of biomass carbonization equipment, can solve problems affecting the yield and quality of biomass carbonization, unreasonable equipment structure layout, blockage of oil and gas pipelines, etc., to save carbonized fuel, prevent and control air pollution, The effect of increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

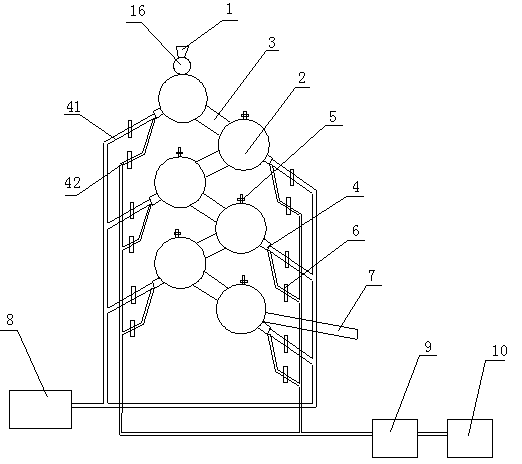

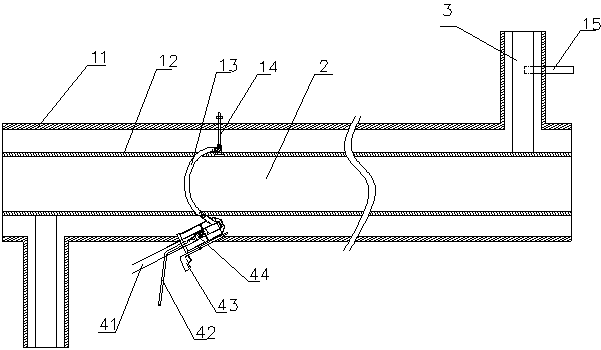

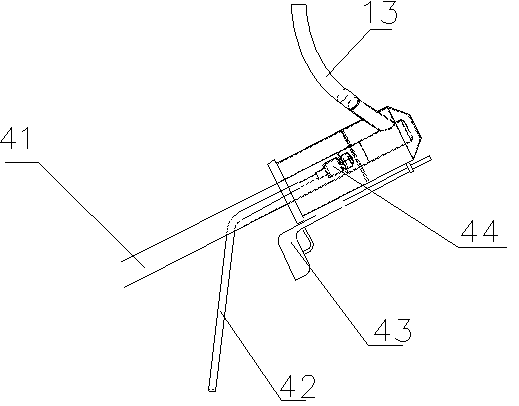

[0025] refer to Figure 1 to Figure 4 , the electric heating device 12, the motor, and the temperature control system (including PLC, etc.) involved in the present invention are all commercially available products. The electric heating device adopts a crawler heater, which has the characteristics of fast heating speed, high heat utilization rate, remarkable energy saving, low labor intensity, safe and reliable use, and convenient operation. The temperature control system has analog output / output modules, A / D conversion Modules, data processing modules, etc., among which PLC uses programmable memory for internal storage of programs and various calculations.

[0026] The biomass carbonization equipment of the present invention includes a feed hopper 1, a conveyor 2 and a discharge port, and a rigid feeder 16 is installed between the feed hopper 1 and the conveyor 2, which can not only fix the feeding speed, but also prevent The cracked oil and gas escape from the feeding hopper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com