A door type packing machine

A door-type and pressure cylinder technology, applied in the field of door-type balers, can solve the problems of insufficient folding effect, average packing effect, and low production efficiency, and achieve the effects of large packing range, labor cost saving, and production efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing:

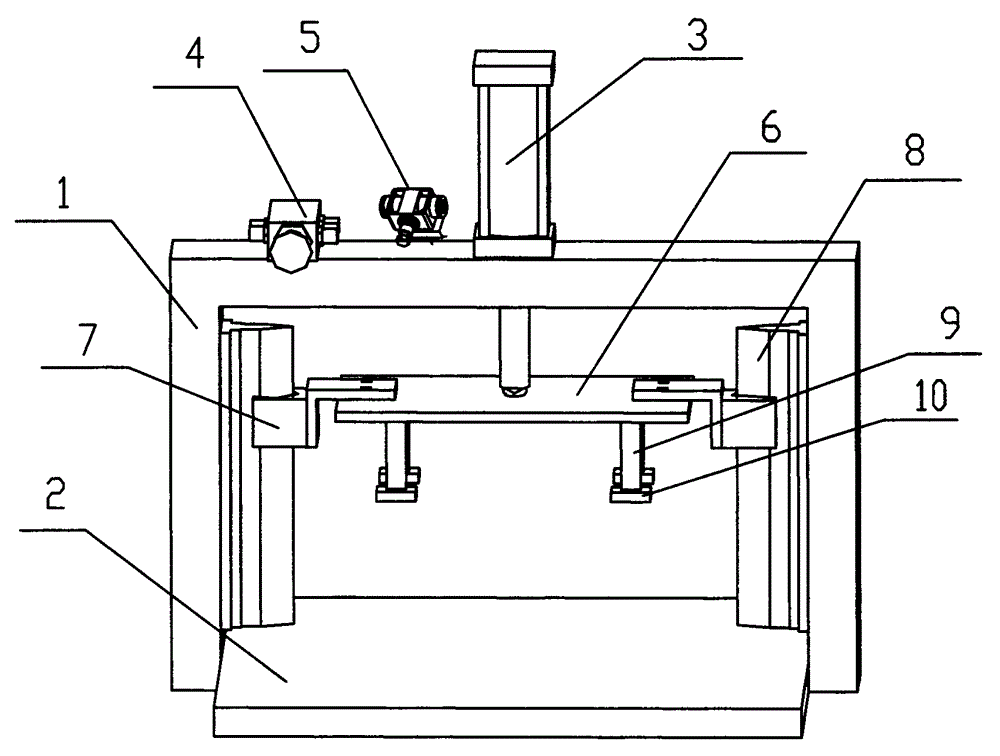

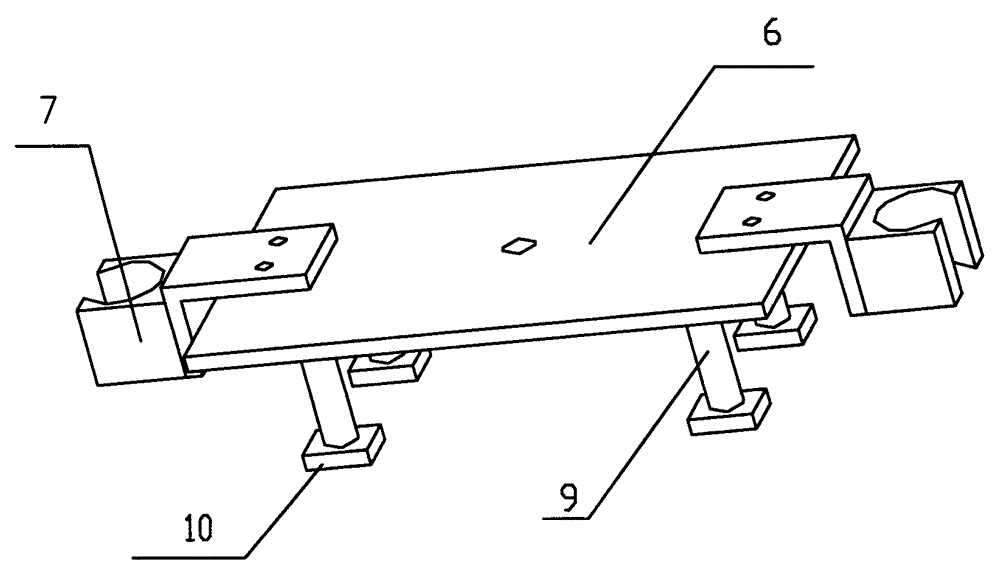

[0015] Such as figure 1 , figure 2 A portal baler shown includes a gantry bridge 1, a worktable 2 in contact with the gantry bridge 1, a transmission pressure cylinder 3 arranged on the gantry bridge 1, and a packaging assembly connected to the transmission pressure cylinder 3. A transmission pressure cylinder 3 is arranged in the middle of the beam of the gantry bridge 1, and a piston is set inside the transmission pressure cylinder 3. The piston passes through the beam of the gantry bridge 1 and is fixedly connected with the packaging assembly. The transmission pressure cylinder 3 is also fixed. Connected with a pressure working switch 4 and a slow pressure fine-tuning switch 5, the pressure can be adjusted. The packing assembly includes an active pressure plate 6, and the center of the active pressure plate 6 is provided with a threaded hole matching the piston and is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com